Preparation method for rare earth permanent magnet material

A rare earth permanent magnet and magnet technology, applied in magnetic materials, metal material coating process, inductance/transformer/magnet manufacturing, etc., can solve the problems of easy occurrence of melting pits, low utilization rate of heavy rare earth elements, and high processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

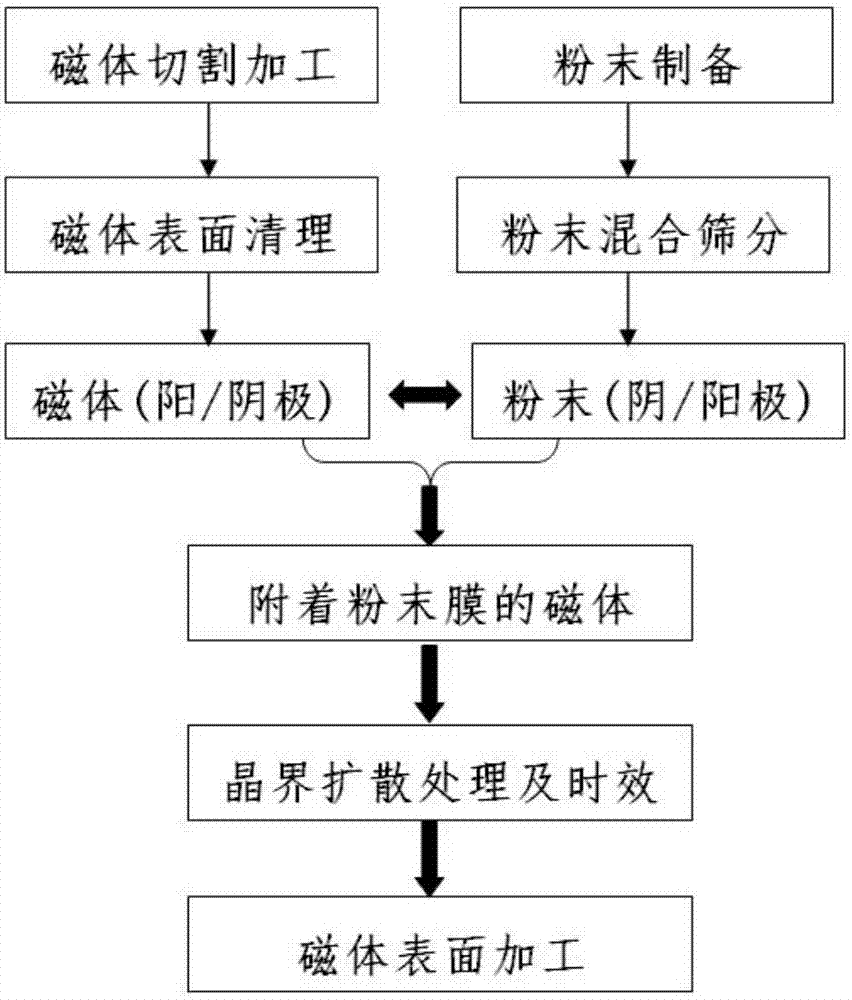

Method used

Image

Examples

Embodiment 1

[0042] (1) According to the powder ratio formula (TbF 3 ) 95 Nd 2 Al 3 Configure composite powder. Weigh TbF 3 Powder, -150 mesh; metal Nd powder, -150 mesh; metal Al powder, -150 mesh; mix the above powders evenly, and sieve through 150 mesh, and the powder mixing and sieving process is carried out under nitrogen environment.

[0043] (2) Firstly, the commercial 50H grade sintered NdFeB magnet is machined into the shape to be processed, and the orientation direction is 1.96mm thick; then enter the surface cleaning procedure, and the cleaning surface procedure is as follows: put the magnet in the degreasing tank and soak for 10 minutes to remove the surface of the magnet For oil stains, wash the surface with water and then use dilute HNO 3 (Concentration: 50wt%) pickling for 20s, and after washing with water and ultrasonic treatment for 20s, the surface of the magnet was quickly dried by strong wind; thus the NdFeB magnet to be treated was obtained.

[0044] (3) Under a ...

Embodiment 2

[0049] (1) According to the powder ratio formula (DyF 3 ) 95 Nd 1 Al 4 Configure composite powder. Weigh DyF3 Powder, -150 mesh; metal Nd powder, -150 mesh; metal Al powder, -150 mesh; mix the above powders evenly, and sieve through 150 mesh, and the powder mixing and sieving process is carried out under nitrogen environment.

[0050] (2) Firstly, the commercial 48H brand sintered NdFeB magnet is machined into the shape to be processed, and the orientation direction is 3 mm thick; then enter the cleaning surface procedure, the cleaning surface procedure is as follows: put the magnet in a degreasing tank and soak for 10 minutes to remove the surface of the magnet. For oil stains, wash the surface with clean water and then use dilute HNO 3 After pickling for 20s, washing with water and ultrasonic treatment for 20s, the surface of the magnet was quickly dried by strong wind; thus the NdFeB magnet to be treated was obtained.

[0051] (3) Under a nitrogen environment, the comp...

Embodiment 3

[0056] (1) According to the powder ratio formula (TbF 3 ) 95 Cu 5 Configure composite powder. Weigh TbF 3 Powder, -150 mesh; Metal Cu powder, -150 mesh; Mix the above powders evenly, and sieve through 150 mesh, and the powder mixing and sieving process is carried out under nitrogen environment.

[0057] (2) Firstly, the commercial 42M grade sintered NdFeB magnet is machined into the shape to be processed, wherein the orientation direction is 5mm thick; For oil stains, wash the surface with clean water and then use dilute HNO 3 After pickling for 35s, washing with water and ultrasonic treatment for 35s, the surface of the magnet was quickly dried by strong wind; thus the NdFeB magnet to be treated was obtained.

[0058] (3) Under a nitrogen environment, the composite powder prepared in step (1) is charged with positrons through the spray gun according to the process conditions of voltage 60kV, time 25s, spray gun moving speed 20cm / s, and spray distance 20cm, and accelerate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com