Patents

Literature

204results about How to "Effective temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

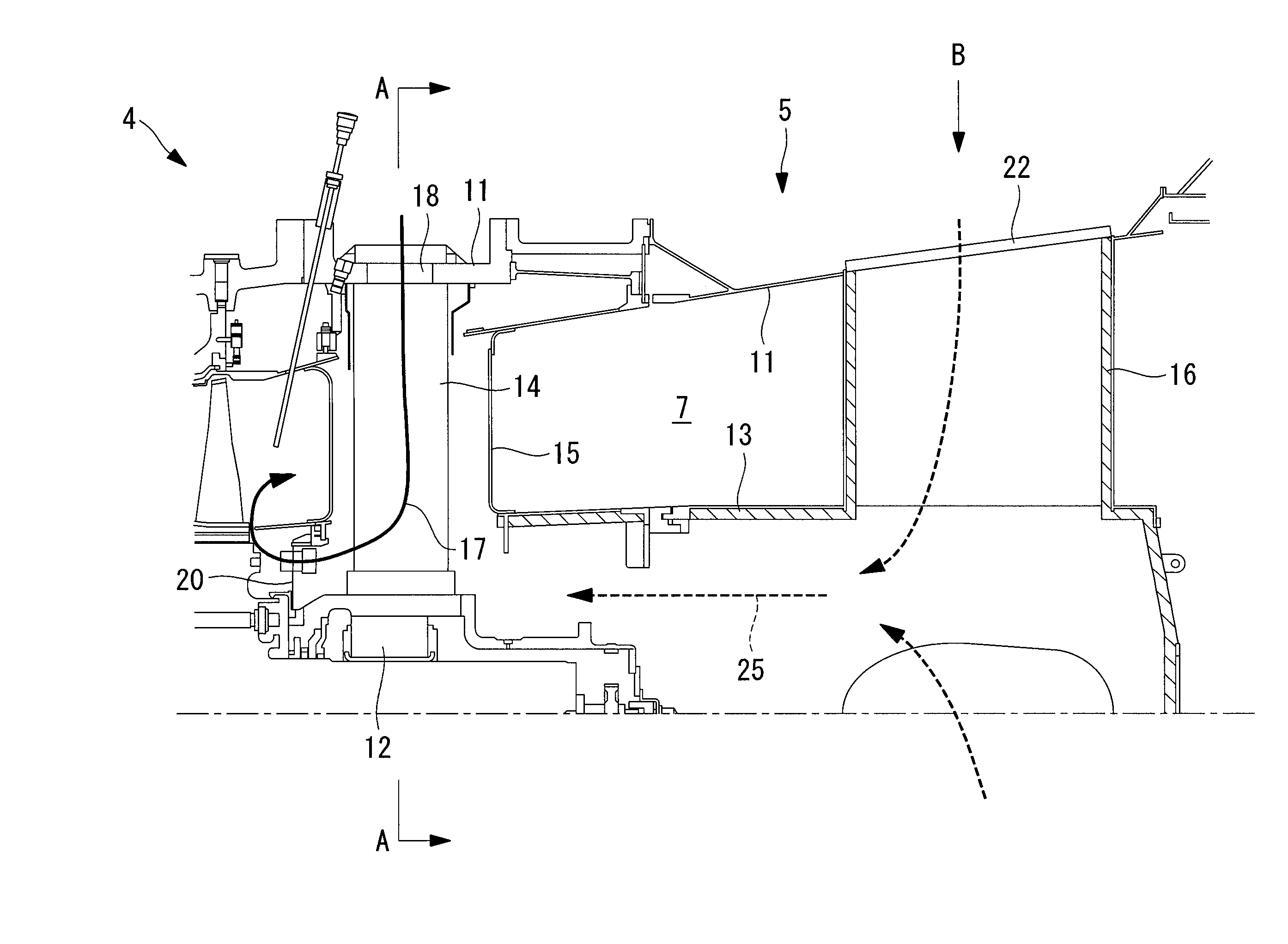

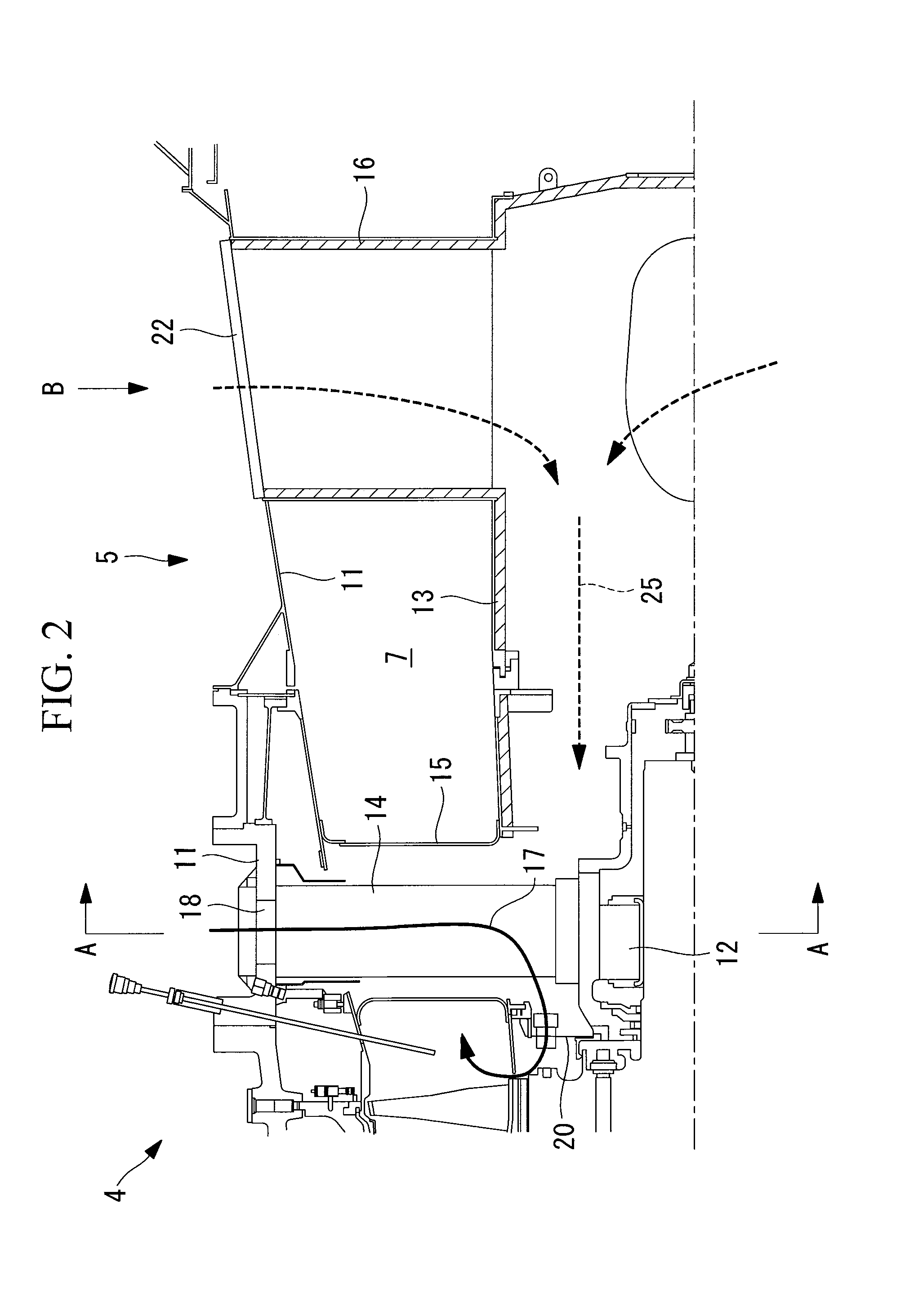

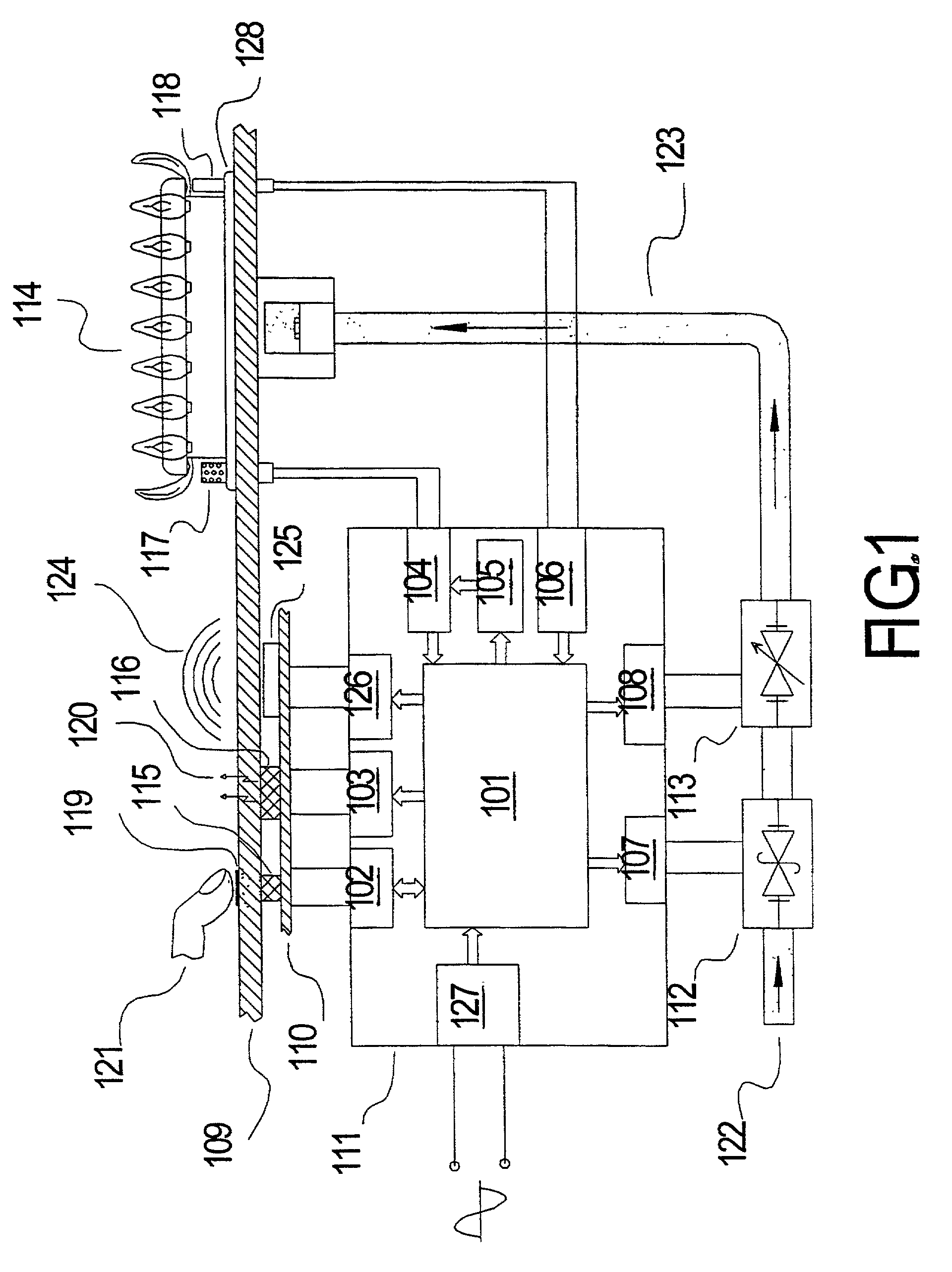

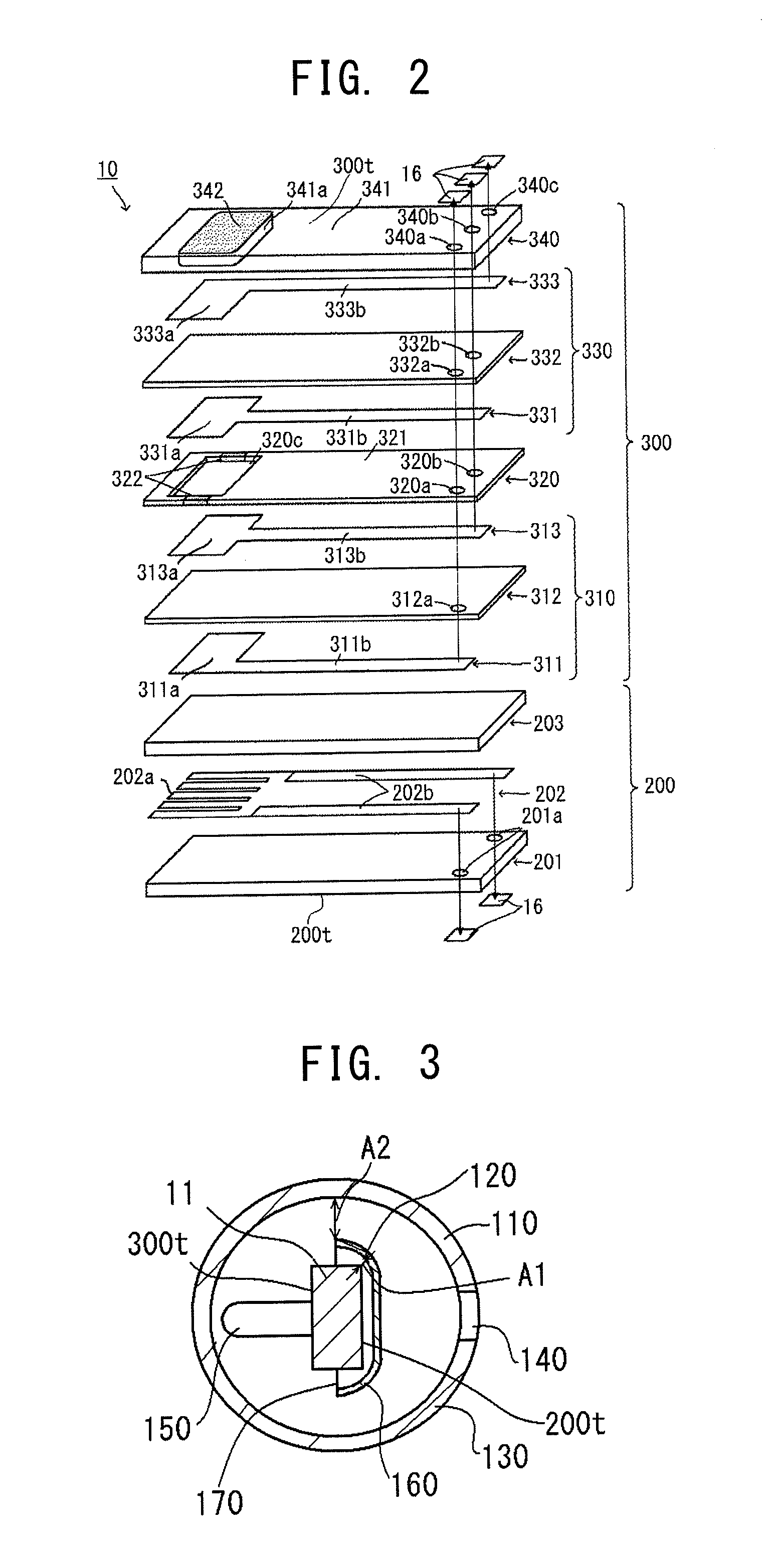

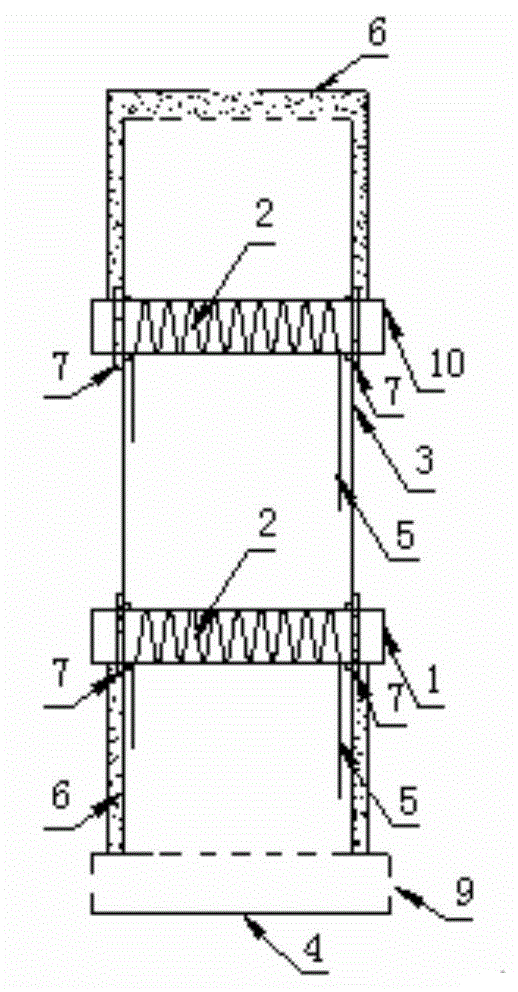

Structure of exhaust section of gas turbine and gas turbine

ActiveUS20100322759A1Low efficiencyEffective temperaturePump componentsTurbine/propulsion engine coolingTurbineGas turbines

There is provided an exhaust section of a gas turbine and a gas turbine that can cool a strut and the periphery of a bearing without decreasing the efficiency of the gas turbine. A structure of an exhaust section of a gas turbine has: a casing in which a gas path part is formed; a bearing part that rotatably supports moving blades of a turbine section; a strut that extends inwardly from the casing and supports the bearing part; an opening formed in the casing; and a cooling flow channel that extends from the opening toward the bearing part along the strut to guide air at a lower temperature than an exhaust gas flowing in the gas path part to the gas path part and opens into the gas path part at a position downstream of a last-stage moving blade of the turbine section.

Owner:MITSUBISHI POWER LTD

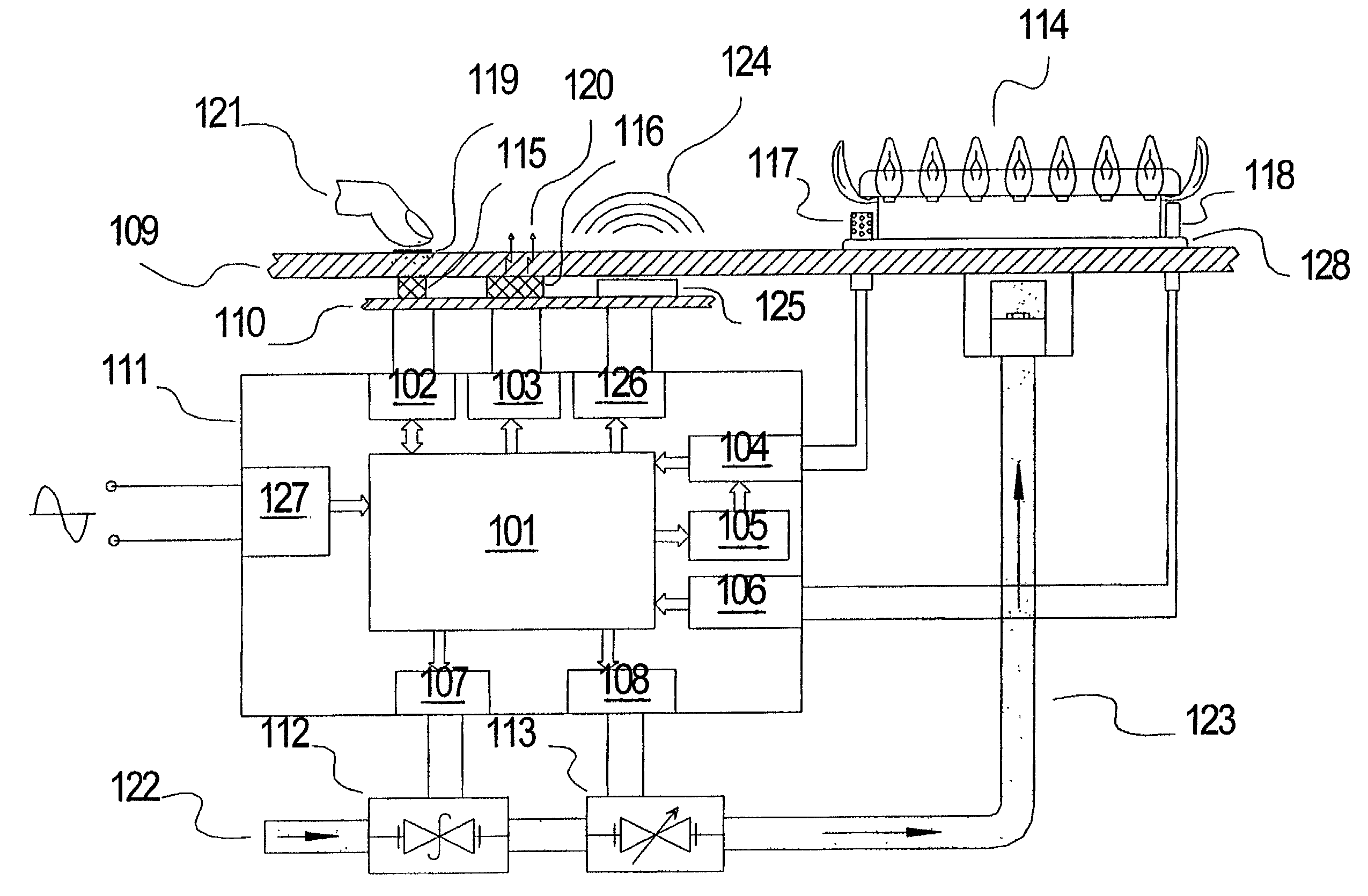

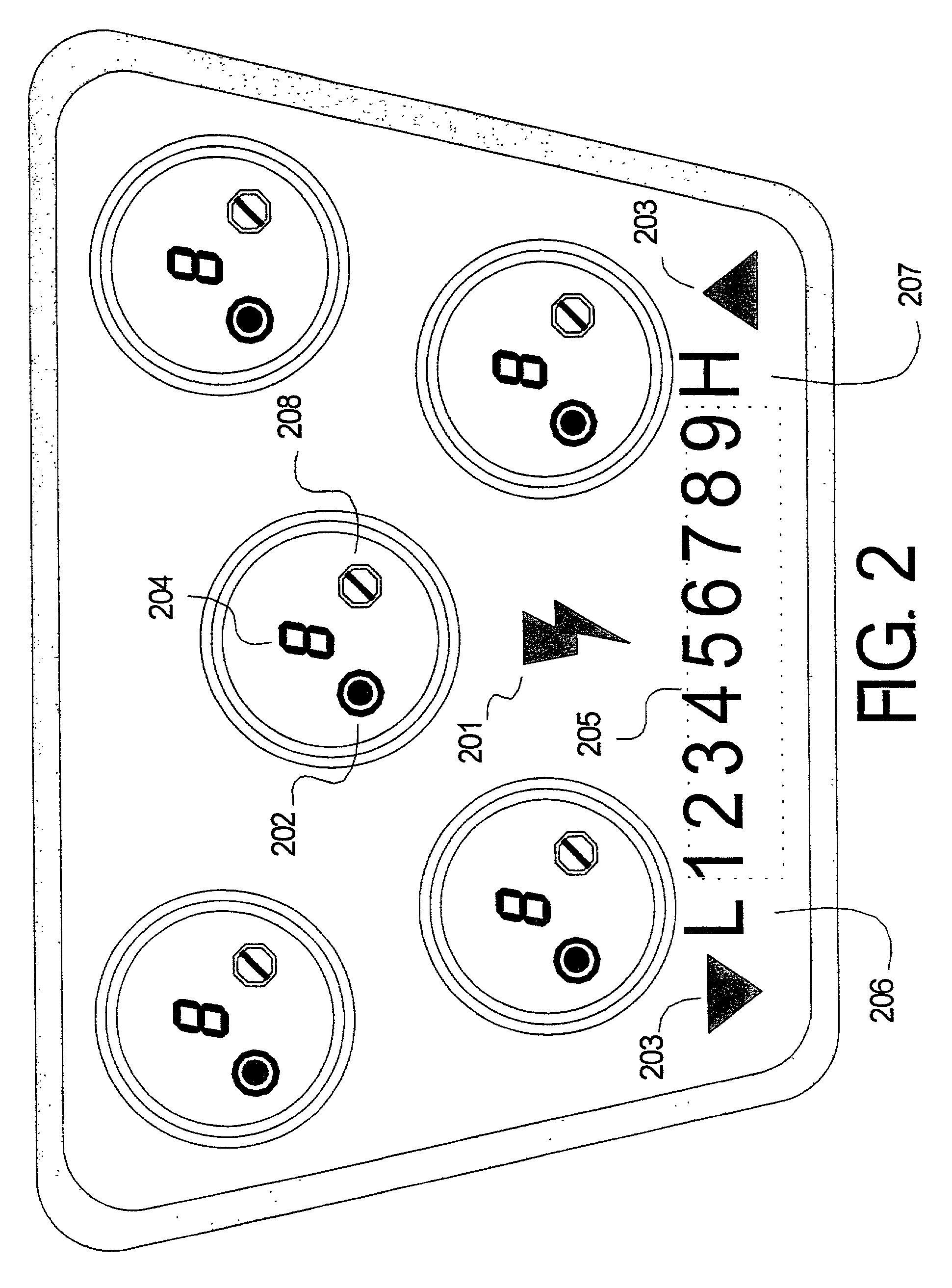

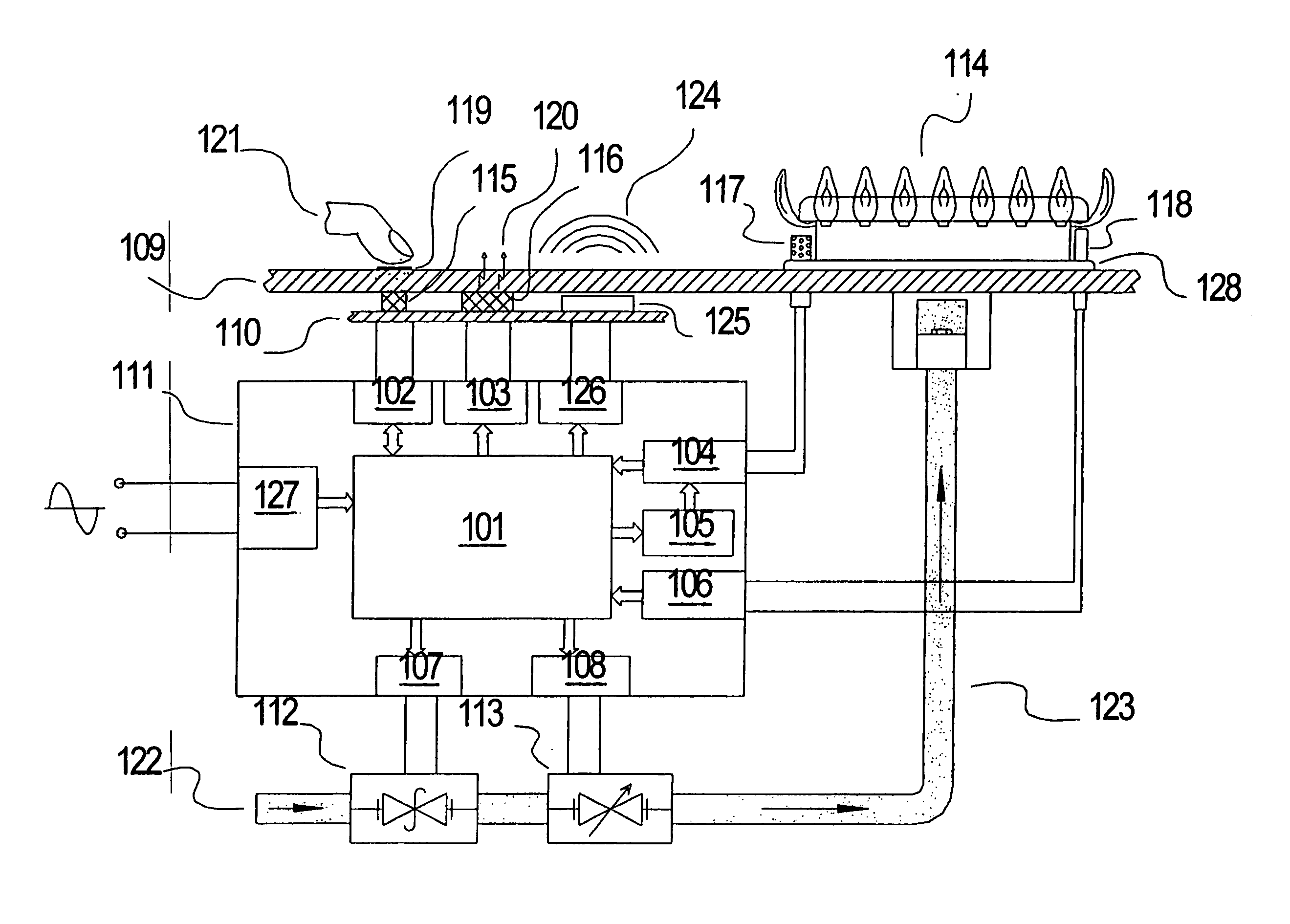

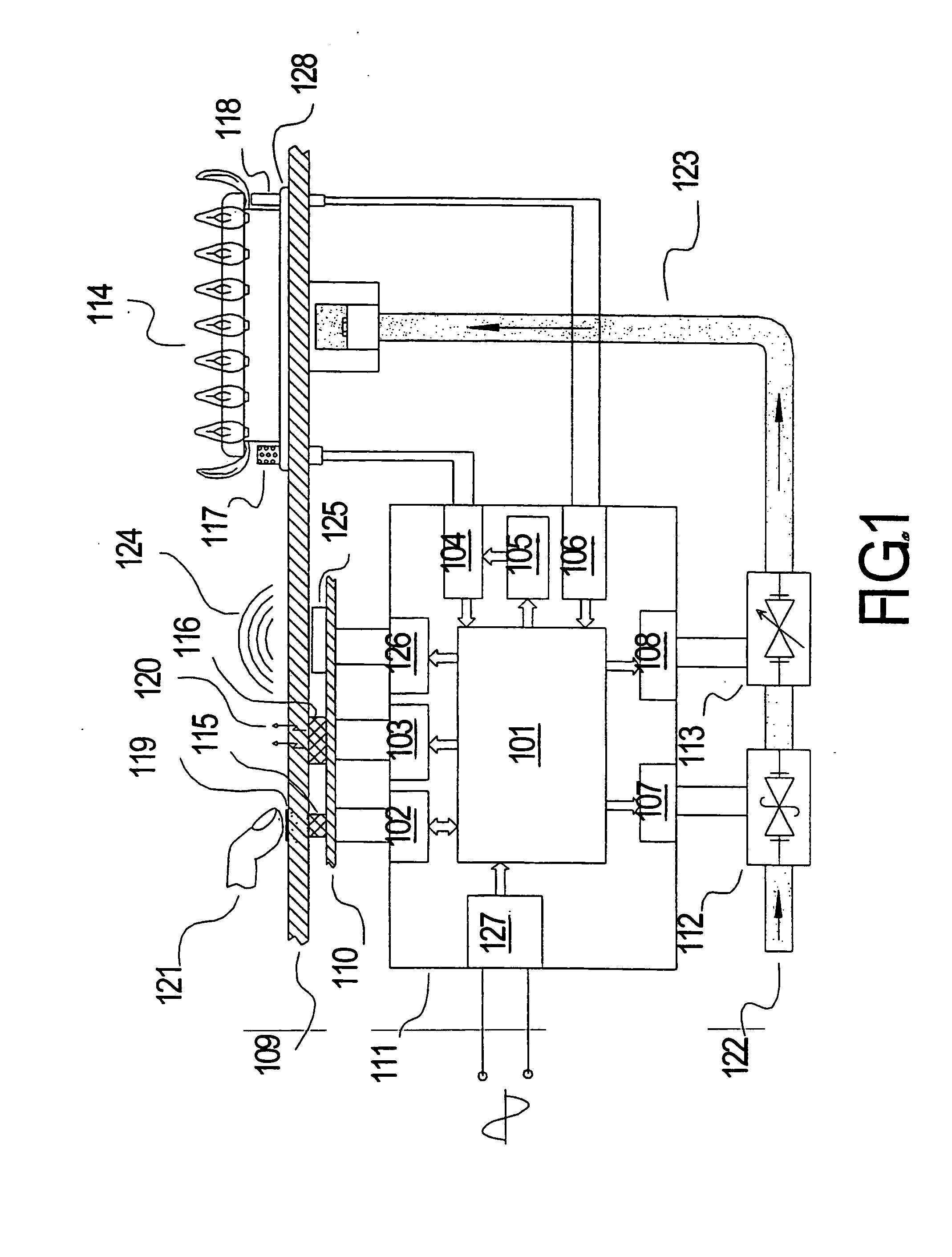

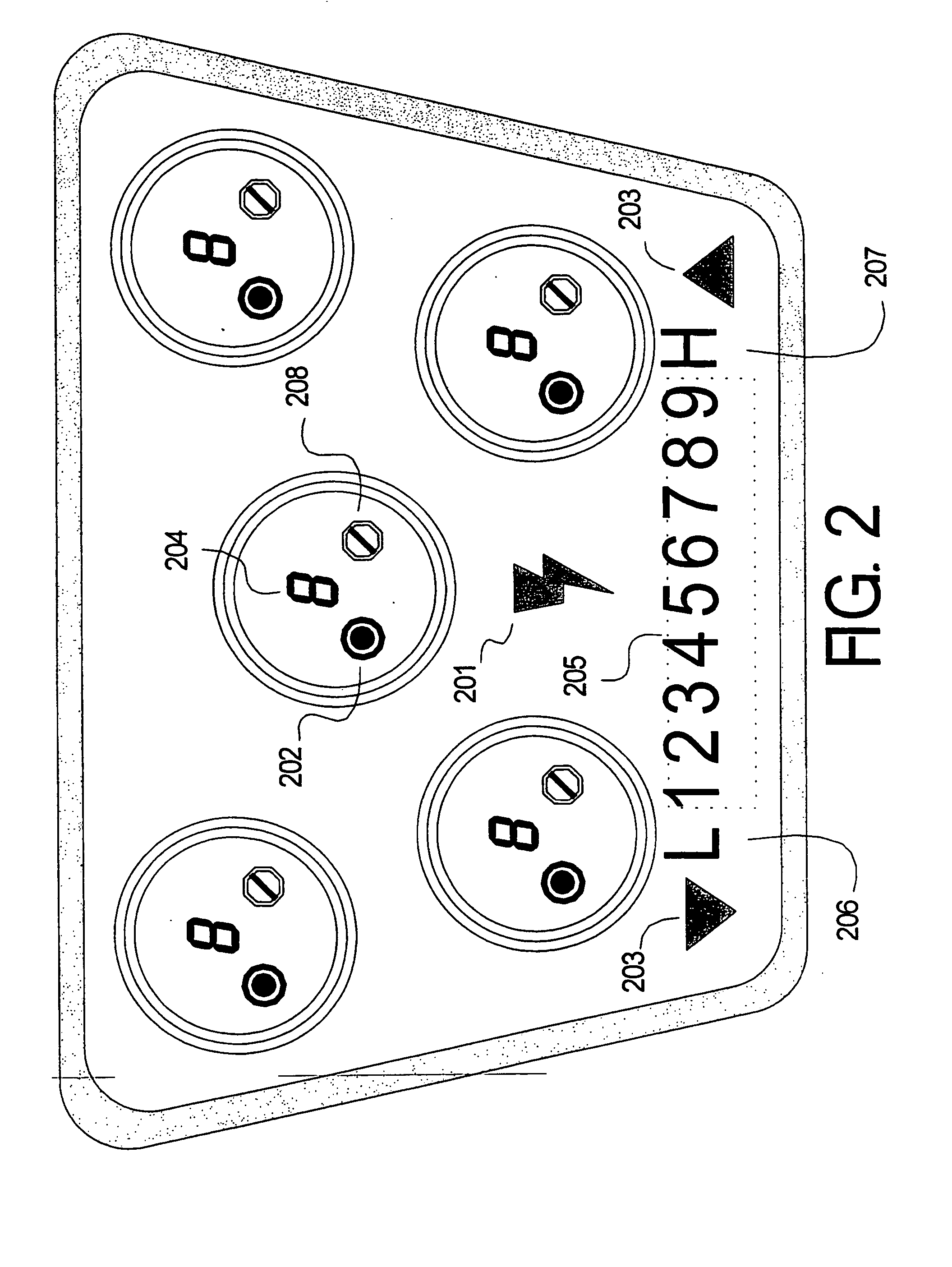

Electronic gas cooktop control with simmer system and method thereof

InactiveUS7255100B2Reduce heating powerHigh outputFuel supply regulationDomestic stoves or rangesControl systemElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

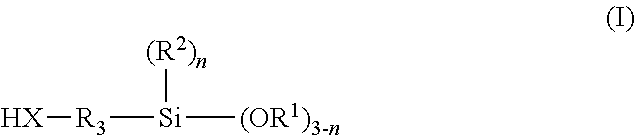

Complex oxynitride phosphor, light-emitting device using same, image display, illuminating device, phosphor-containing composition and complex oxynitride

InactiveUS20090033201A1Reduce emission efficiencyEfficient excitationDischarge tube luminescnet screensNitrogen compoundsFluorescencePhosphor

To provide a green phosphor with high conversion efficiency of blue of near-ultraviolet light and excellent color purity, a multinary oxynitride phosphor represented by the general formula [I] is proposed.M1xBayM2zLuOvNw [I]In the formula [I], M1 represents Cr, Mn, Fe, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm and Yb, M2 represents Sr, Ca, Mg and Zn, L represents metal elements belonging to the fourth group or the fourteenth group of the periodic table, and x, y, z, u, v and w are the numeric values in the following ranges:0.00001≦x≦30≦y≦2.999992.6≦x+y+z≦30<u≦116<v≦250<w≦17.

Owner:MITSUBISHI CHEM CORP

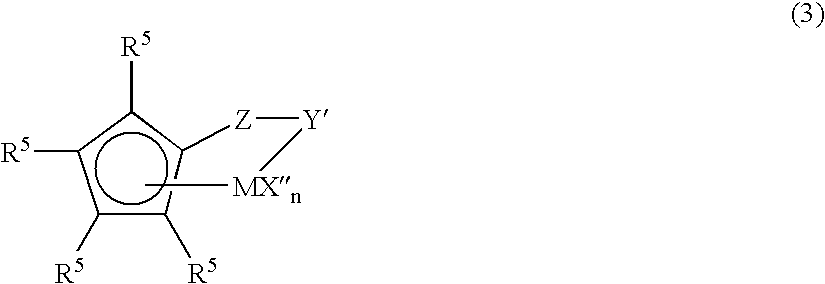

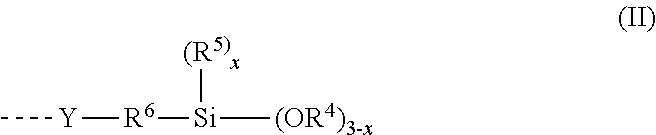

Multinary oxynitride phosphor, and light emitting device, image display, illuminating device and phosphor-containing composition using the same, and multinary oxynitride

InactiveUS20090166584A1Efficient excitationEffective temperatureSolid-state devicesLuminescent compositionsPhosphorNear ultraviolet

To provide a green phosphor with high conversion efficiency of blue of near-ultraviolet light and excellent color purity, a multinary oxynitride phosphor represented by the general formula [I] is proposed. <?in-line-formulae description="In-line Formulae" end="lead"?>M1xBayM2zLuOvNw [I]<?in-line-formulae description="In-line Formulae" end="tail"?> In the formula [I], M1 represents Cr, Mn, Fe, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm and Yb, M2 represents Sr, Ca, Mg and Zn, L represents metal elements belonging to the fourth group or the fourteenth group of the periodic table, and x, y, z, u, v and w are the numeric values in the following ranges: <?in-line-formulae description="In-line Formulae" end="lead"?>0.00001<=x<=3<?in-line-formulae description="In-line Formulae" end="tail"?> <?in-line-formulae description="In-line Formulae" end="lead"?>0<=y<=2.99999<?in-line-formulae description="In-line Formulae" end="tail"?> <?in-line-formulae description="In-line Formulae" end="lead"?>2.6<=x+y+z<=3<?in-line-formulae description="In-line Formulae" end="tail"?> <?in-line-formulae description="In-line Formulae" end="lead"?>0<u<=11<?in-line-formulae description="In-line Formulae" end="tail"?> <?in-line-formulae description="In-line Formulae" end="lead"?>6<v<=25<?in-line-formulae description="In-line Formulae" end="tail"?> <?in-line-formulae description="In-line Formulae" end="lead"?>0<w<=17.<?in-line-formulae description="In-line Formulae" end="tail"?>

Owner:MITSUBISHI CHEM CORP

Multinary oxynitride phosphor, and light emitting device, image display, illuminating device and phosphor-containing composition using the same, and multinary oxynitride

InactiveUS7833436B2Efficient excitationEffective temperatureSolid-state devicesLuminescent compositionsFluorescencePhosphor

To provide a green phosphor with high conversion efficiency of blue of near-ultraviolet light and excellent color purity, a multinary oxynitride phosphor represented by the general formula [I] is proposed. M1xBayM2zLuOvNw [I] In the formula [I], M1 represents Cr, Mn, Fe, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm and Yb, M2 represents Sr, Ca, Mg and Zn, L represents metal elements belonging to the fourth group or the fourteenth group of the periodic table, and x, y, z, u, v and w are the numeric values in the following ranges: 0.00001≦̸x≦̸3 0≦̸y≦̸2.99999 2.6≦̸x+y+z≦̸3 0<u≦̸11 6<v≦̸25 0<w≦̸17.

Owner:MITSUBISHI CHEM CORP

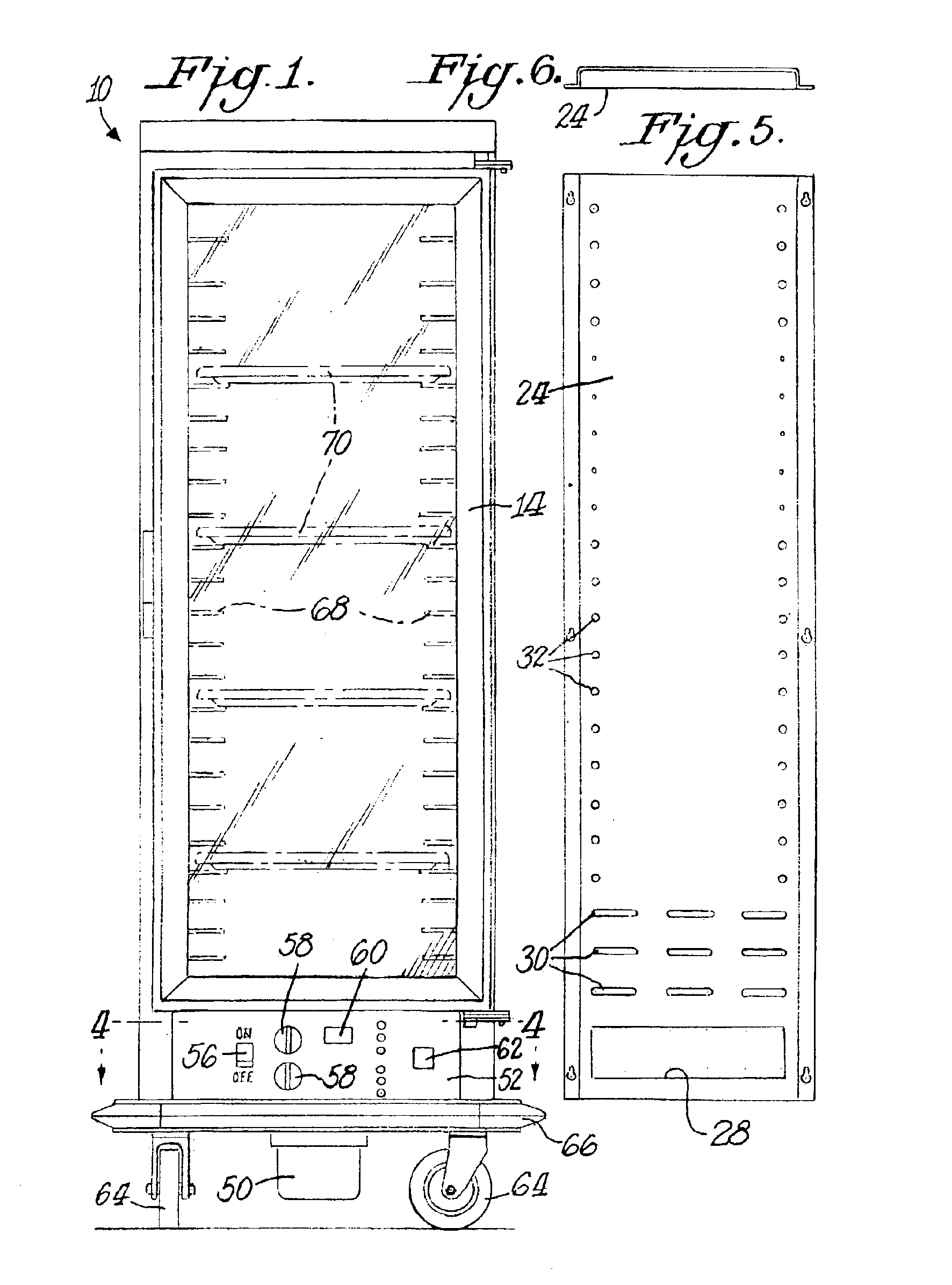

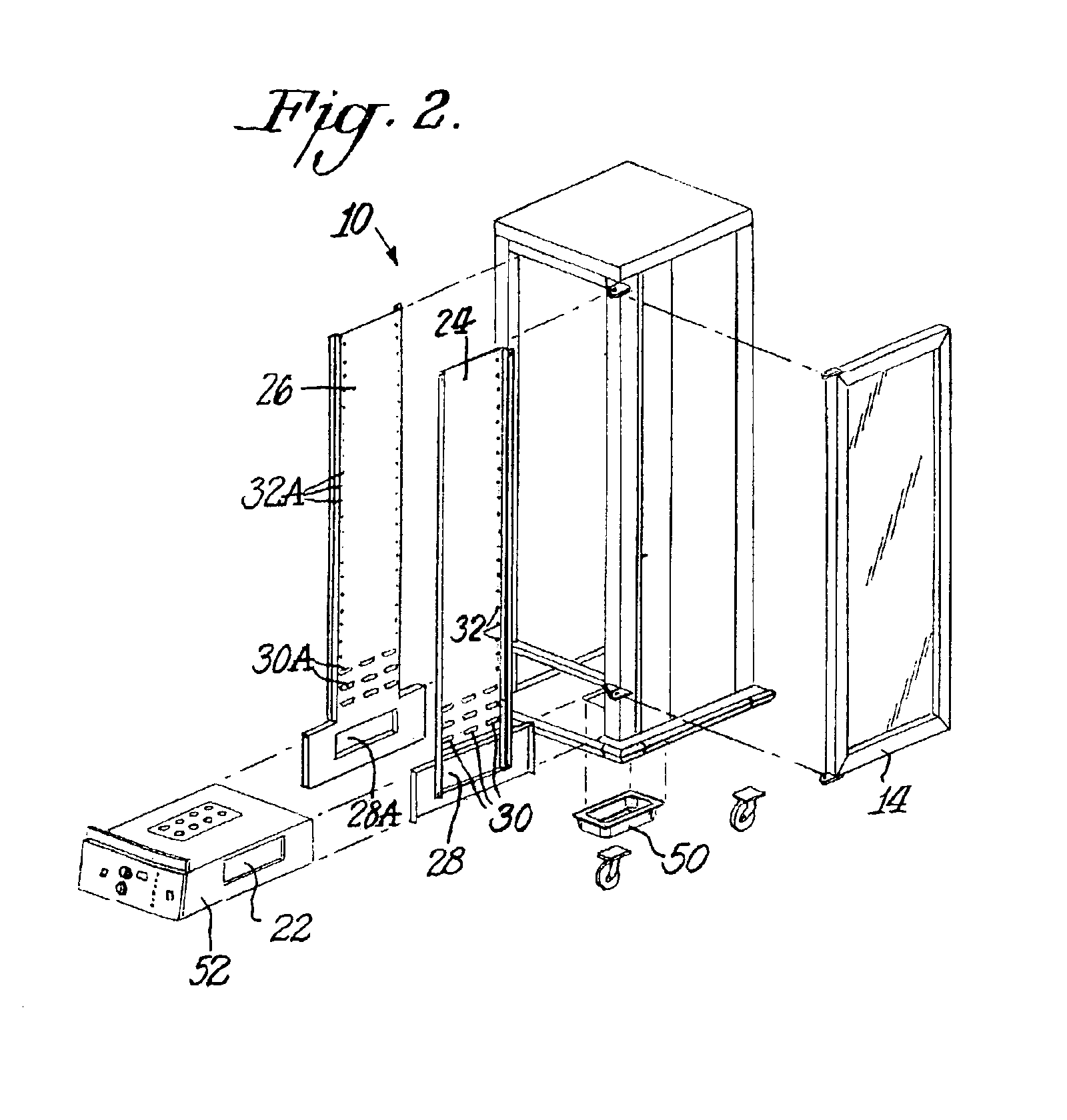

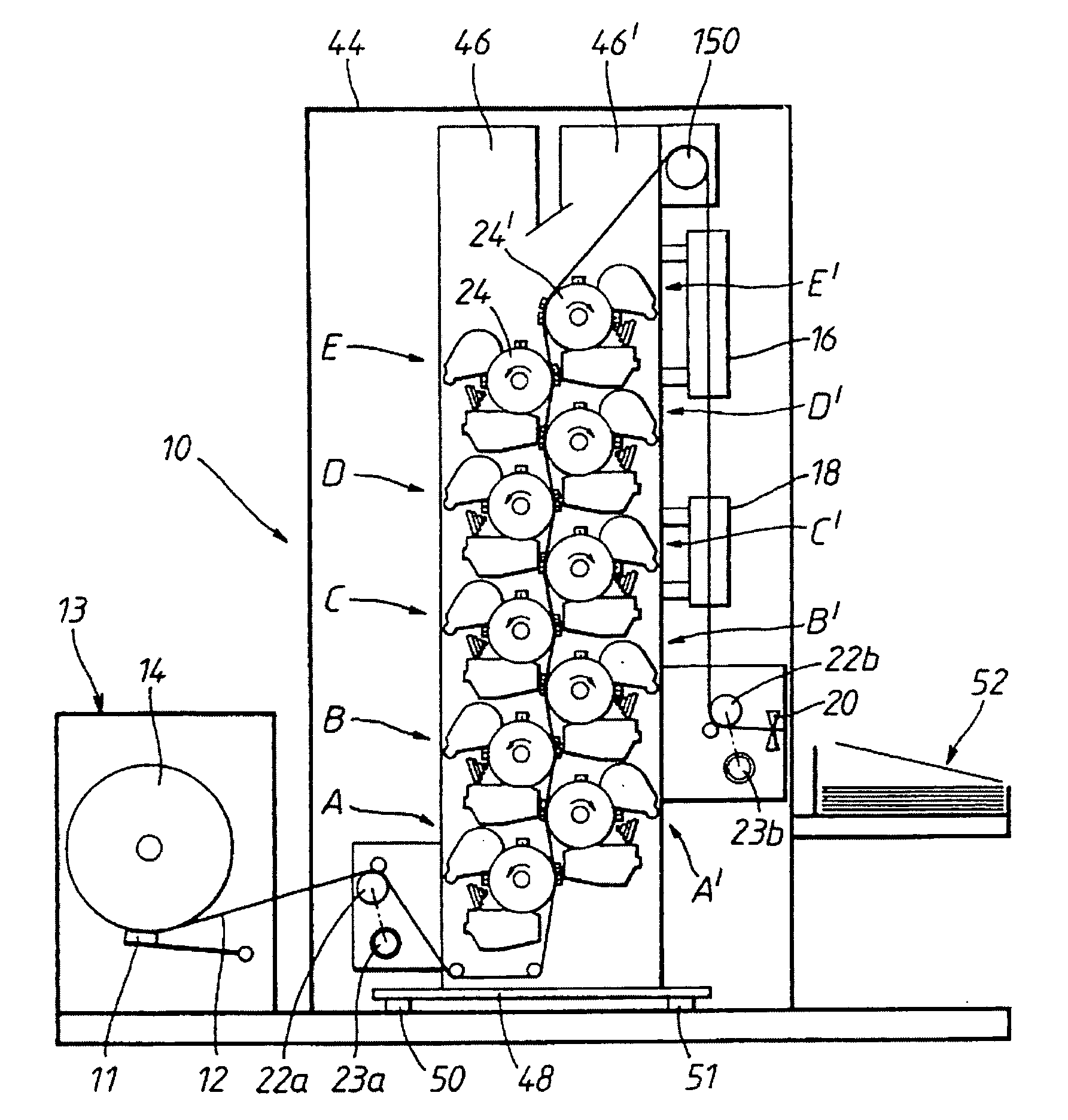

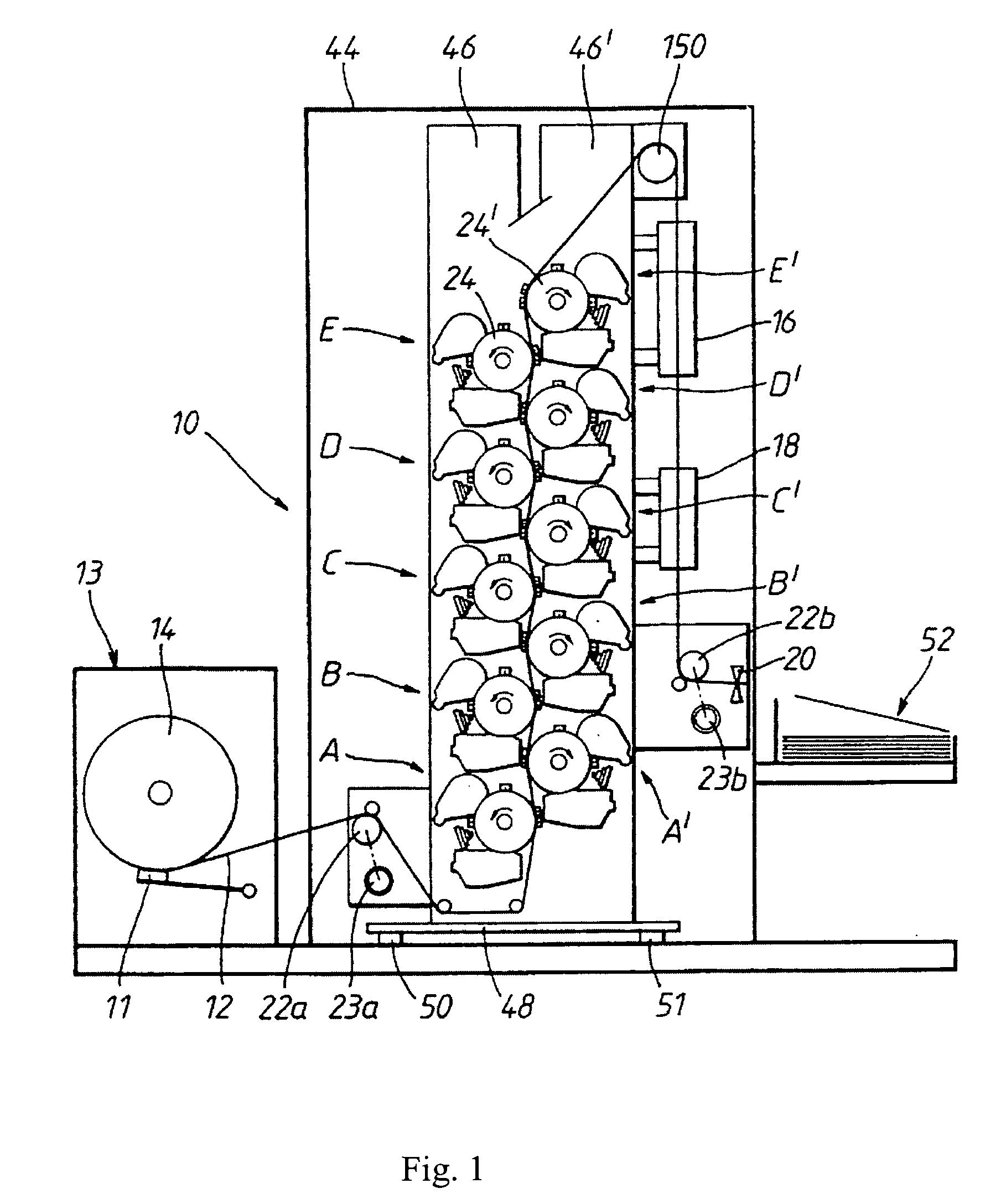

Heated proofing cabinet

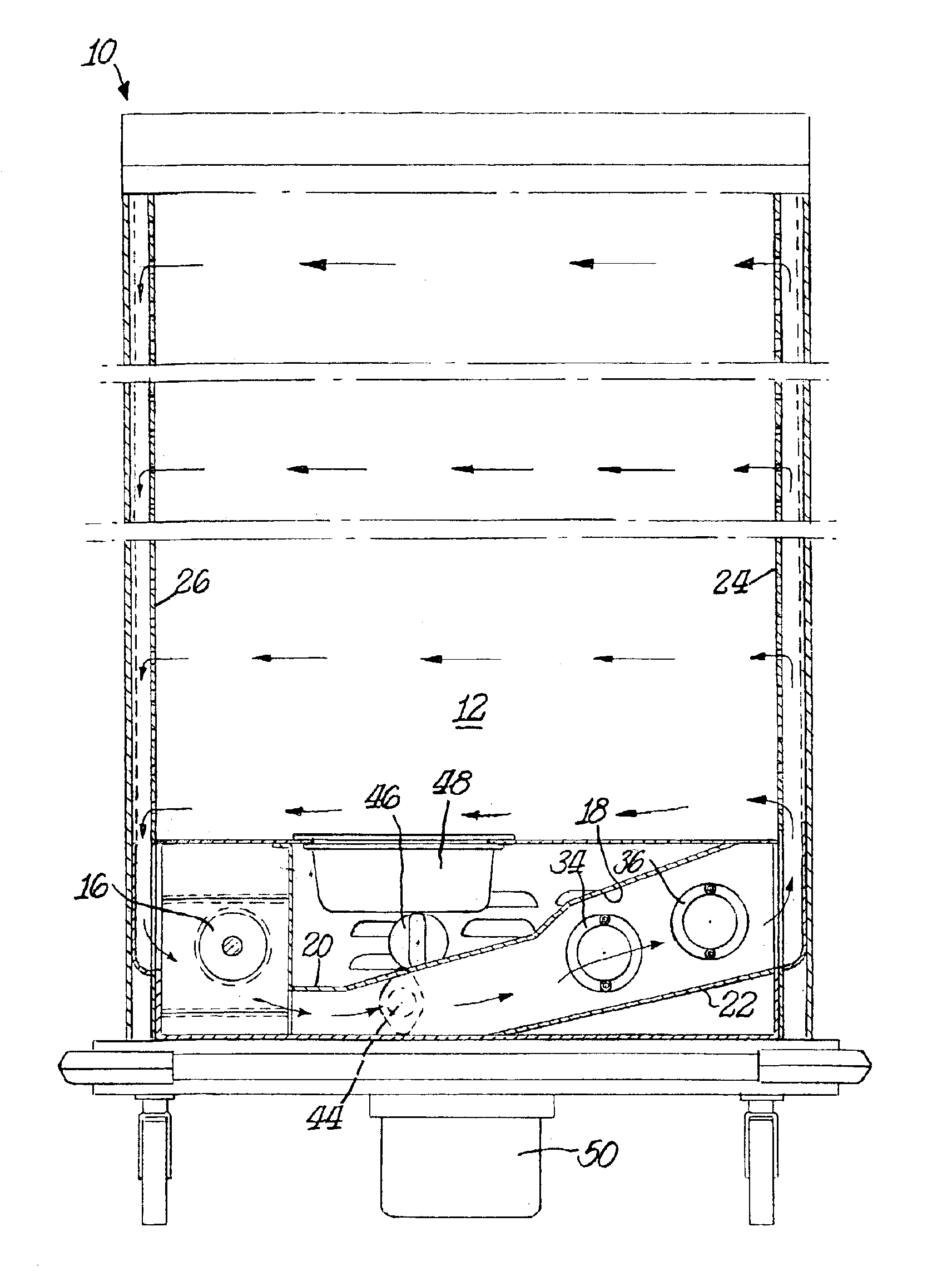

InactiveUS6847013B2Increase air circulationEffective regulationAir-treating devicesDomestic stoves or rangesInterior spaceForced-air

A heated proofing cabinet with improved air flow and minimal air leakage comprises an enclosure having an interior space and an access door. A blower is positioned to supply forced air into the interior space of the enclosure and at least one heater is positioned to heat the air. A venturi air flow chamber has an entrance end connected to receive forced air from the blower and an exit end connected to deliver air to the interior space of the enclosure. A first air duct receives air from the exit end of the venturi air flow chamber and distributes the air to the interior space of the enclosure, and a second air duct receives air from the interior space of the enclosure and directs the air to the blower. Temperature and humidity levels within the interior space of the enclosure are controlled.

Owner:METAL MASTERS FOOD SERVICE EQUIP

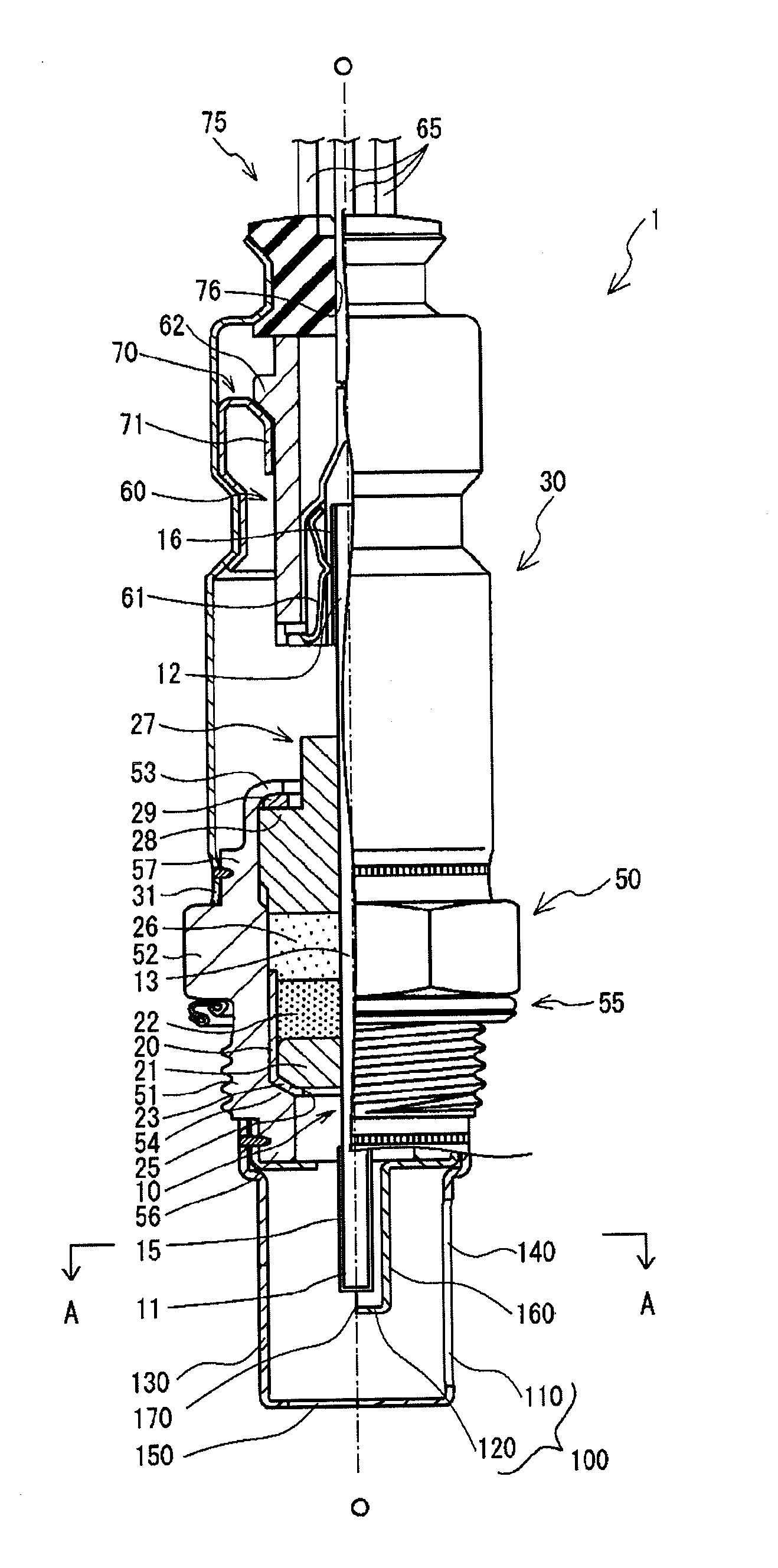

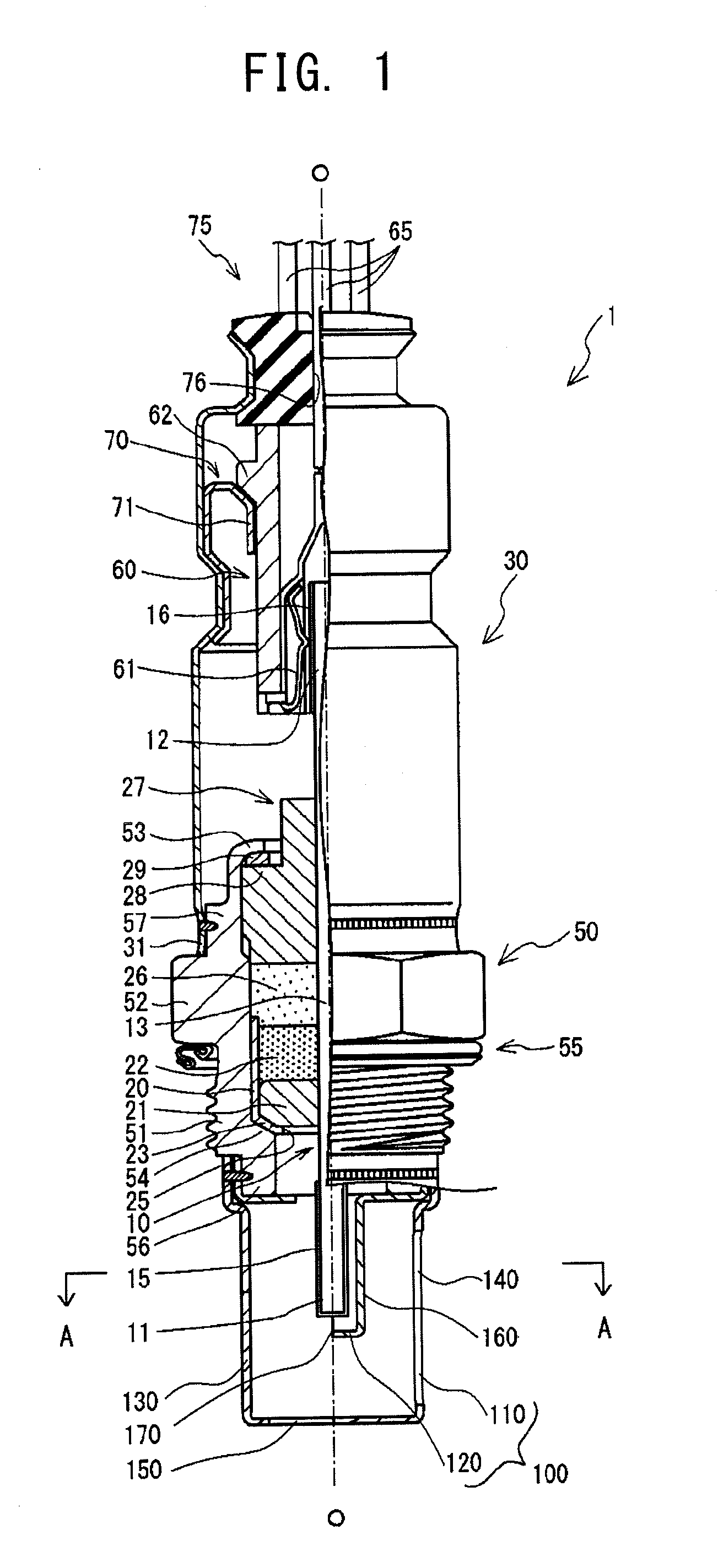

Gas sensor

InactiveUS20110209523A1Inhibit the generation of cracksDeterioration in detection can be restrainedInternal-combustion engine testingMaterial analysis by electric/magnetic meansEngineering

Owner:NGK SPARK PLUG CO LTD

Ultrahigh-molecular ethylene polymer

The present invention relates to an ultrahigh molecular weight ethylene polymer which is either an ethylene homopolymer (A) or an ethylene copolymer (B), the ethylene copolymer (B) being obtained by copolymerizing a) 99.9 to 75.0% by weight of ethylene and b) 0.1 to 25.0% by weight of a comonomer which is at least one olefin selected from the group consisting of α-olefins having 3 to 20 carbon atoms, cyclic olefins having 3 to 20 carbon atoms, compounds represented by the formula CH2═CHR (in which R is an aryl group having 6 to 20 carbon atoms) and linear, branched or cyclic dienes having 4 to 20 carbon atoms, the ethylene polymer having i) a viscosity average molecular weight of 1 million or more ii) a molecular weight distribution (Mw / Mn) of more than 3 and iii) a Ti content of not more than 3 ppm and a Cl content of 5 ppm in the polymer.

Owner:ASAHI KASEI CHEM CORP

Electronic gas cooktop control with simmer system and method thereof

InactiveUS20050089809A9Facilitate maintenanceEliminate needFuel supply regulationDomestic stoves or rangesProcess engineeringElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

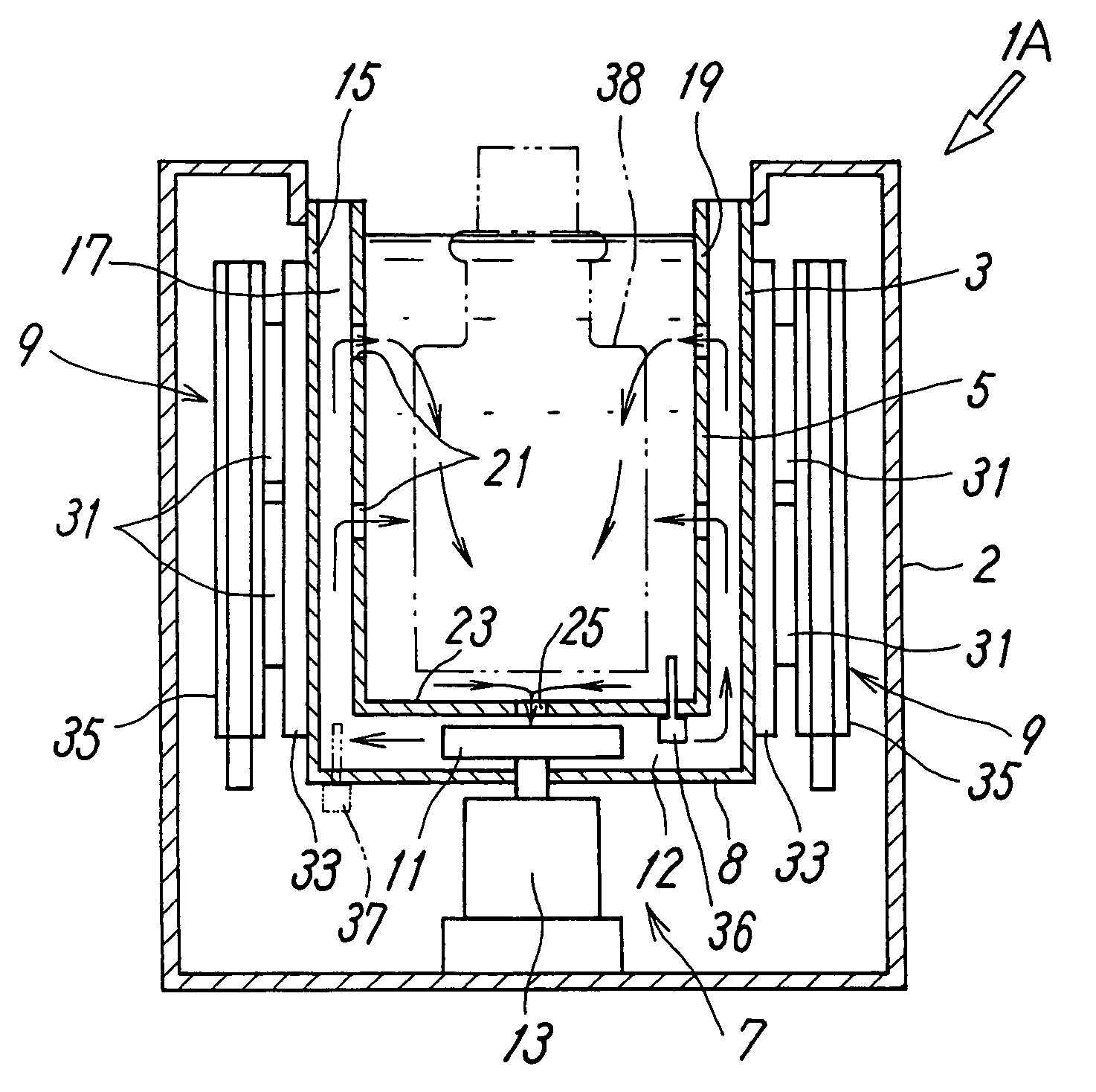

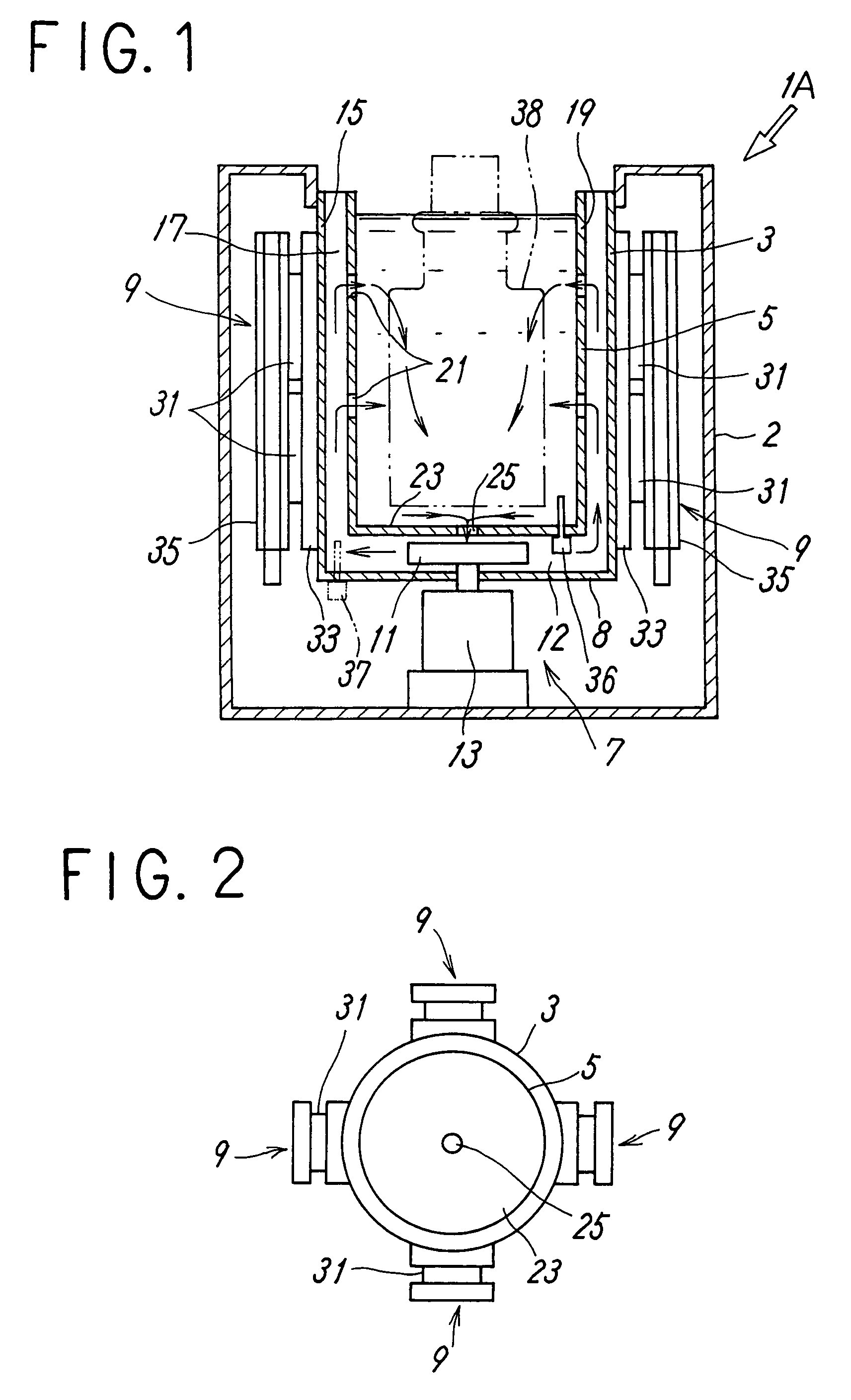

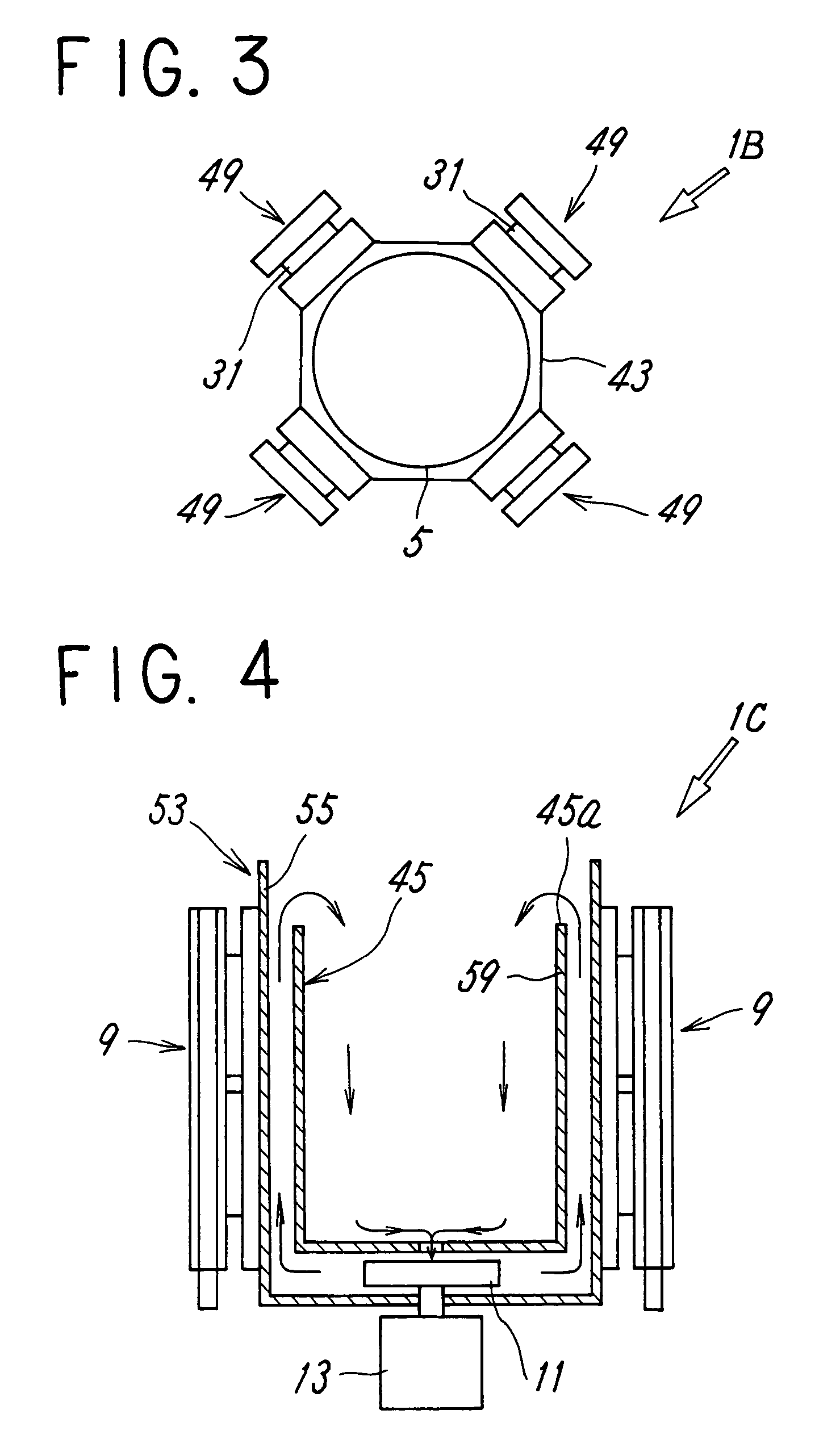

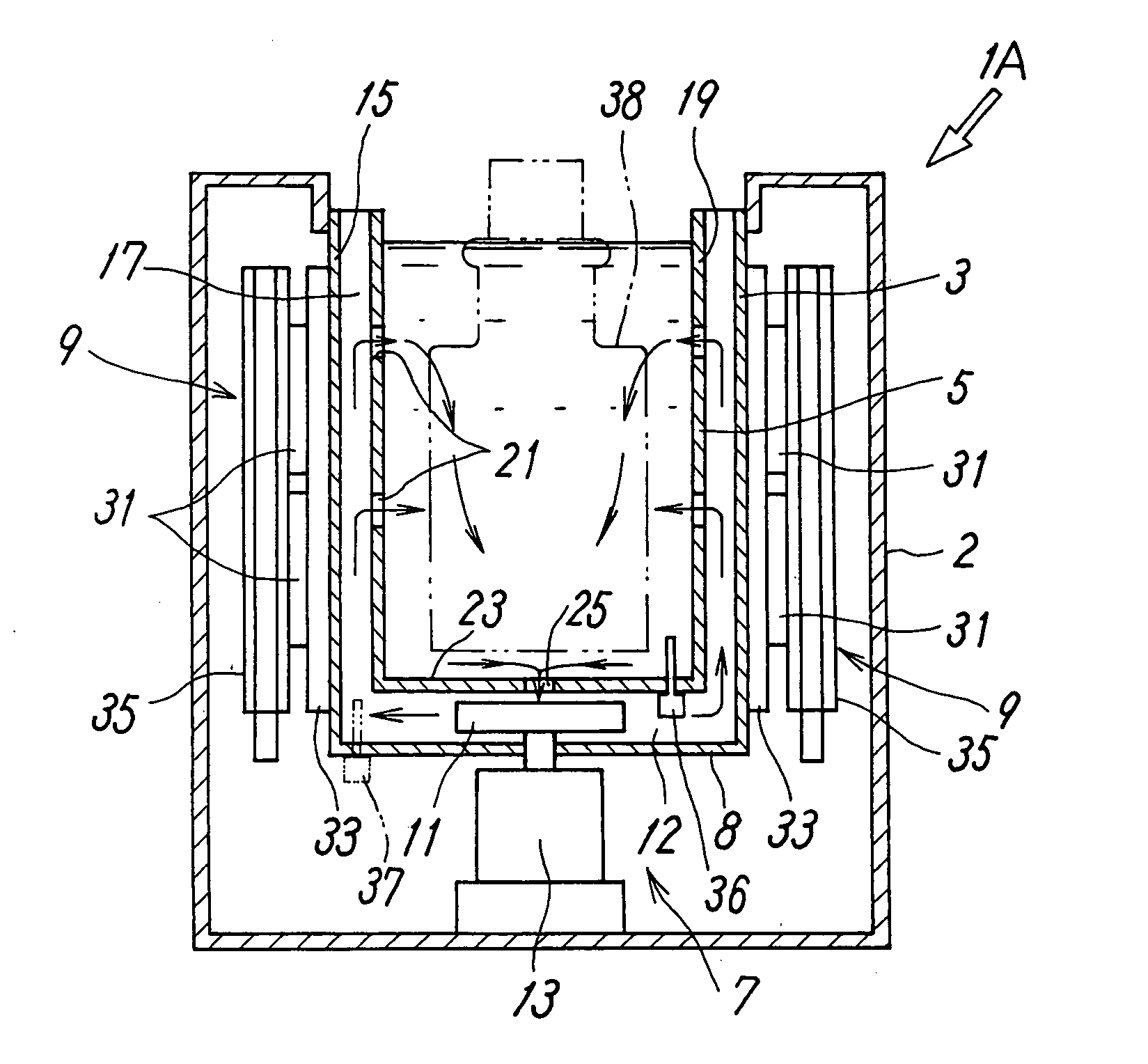

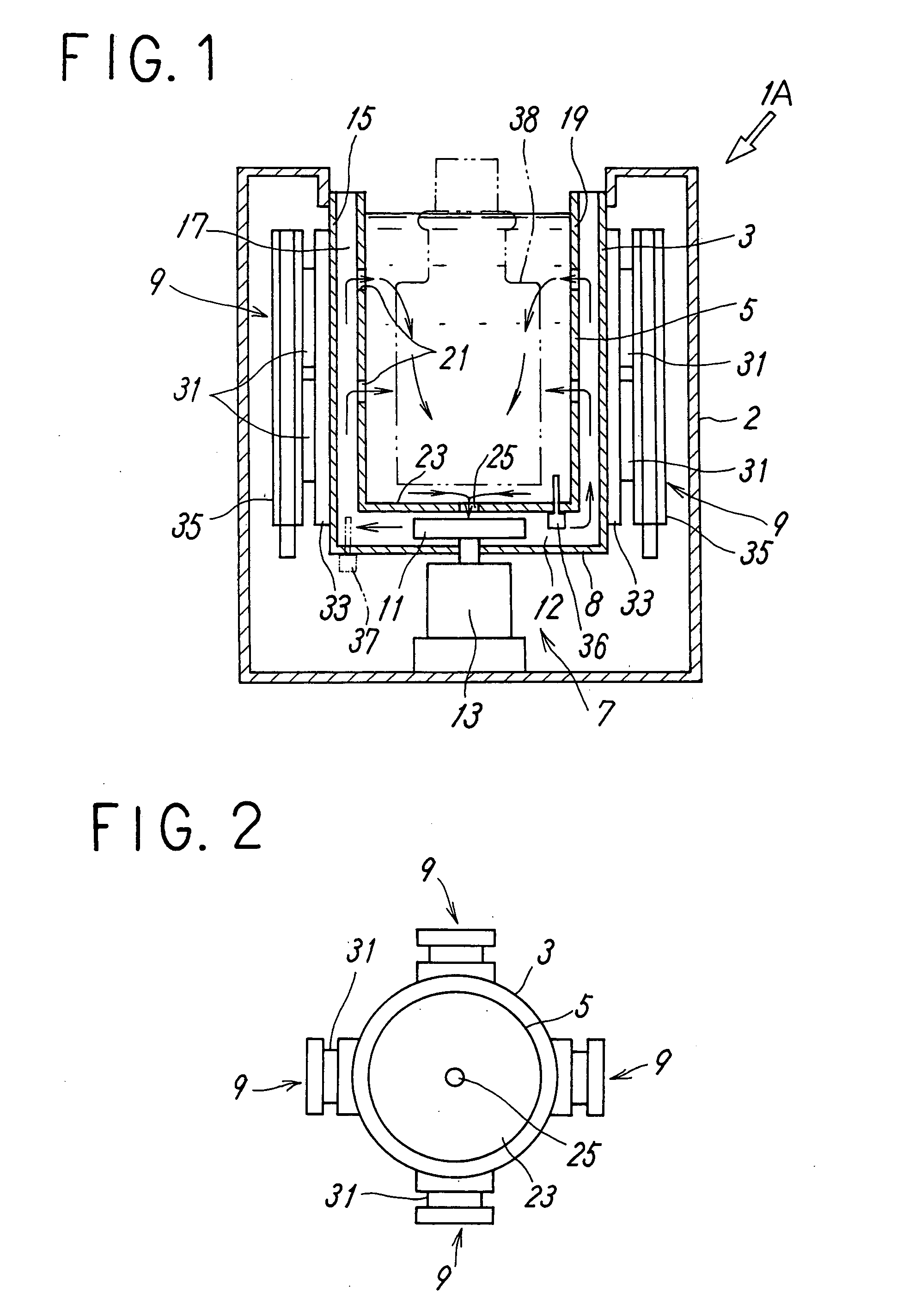

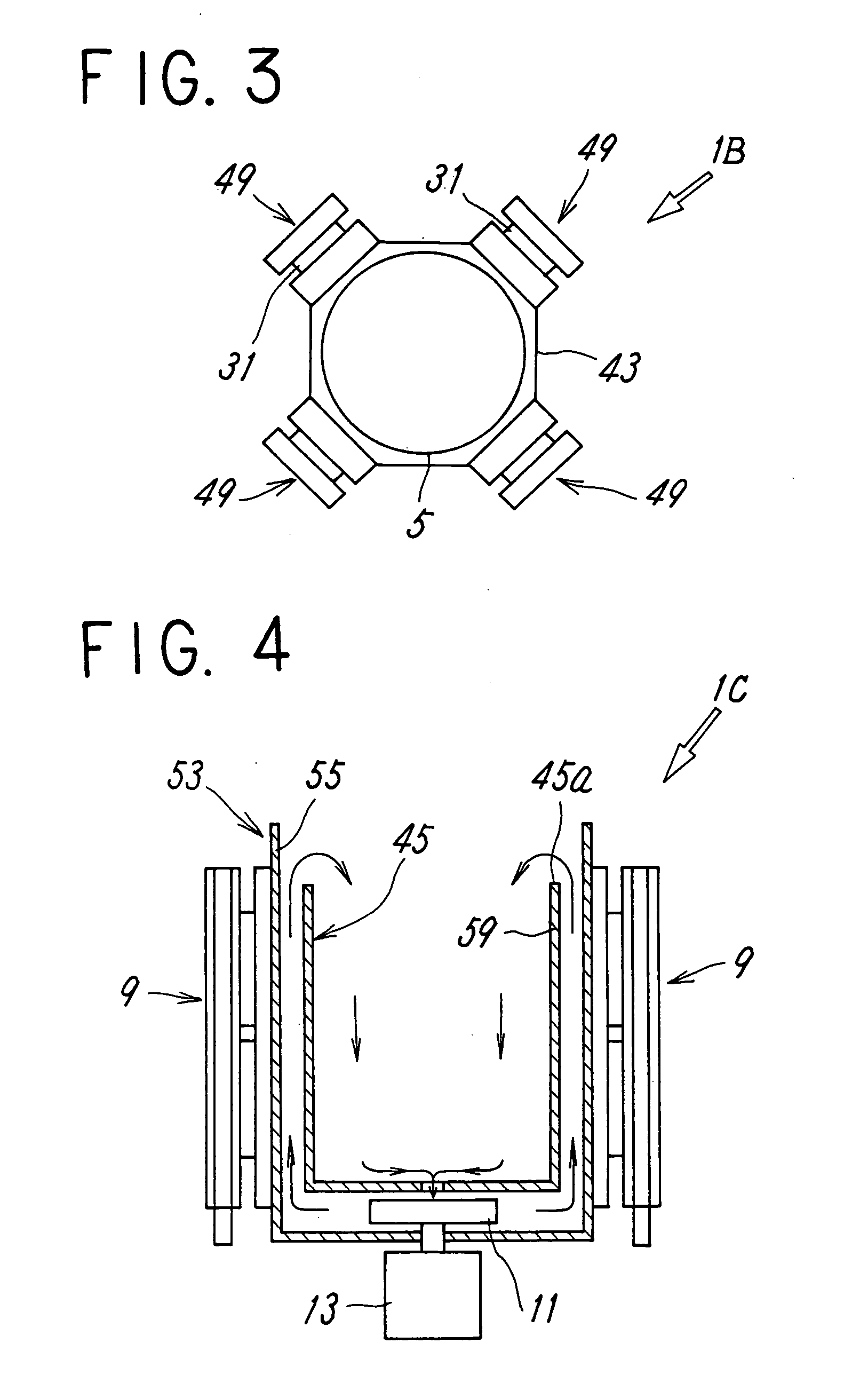

Constant temperature liquid bath

ActiveUS7748223B2Efficient heatingEasily and swiftly adjustContainer filling methodsDomestic refrigeratorsEngineering

A constant temperature liquid bath using a thermo-module in which even if an article whose temperature is to be controlled exists in the bath, the temperature of the liquid is efficiently adjusted to a constant value. The liquid bath includes an outer bath storing the liquid, an inner bath disposed in the outer bath through a gap, and including holes in its sidewall through which the liquid flows into the inner bath from the outer bath and an opening at a central portion of its bottom, and an agitator that causes the liquid to flow upward from the opening of the bottom of the inner bath between sidewalls of the inner and outer baths by a rotor blade disposed on a central portion of a bottom between the outer bath and the inner bath. The thermo-module is mounted on an outer surface of the sidewall of the outer bath.

Owner:SMC CORP

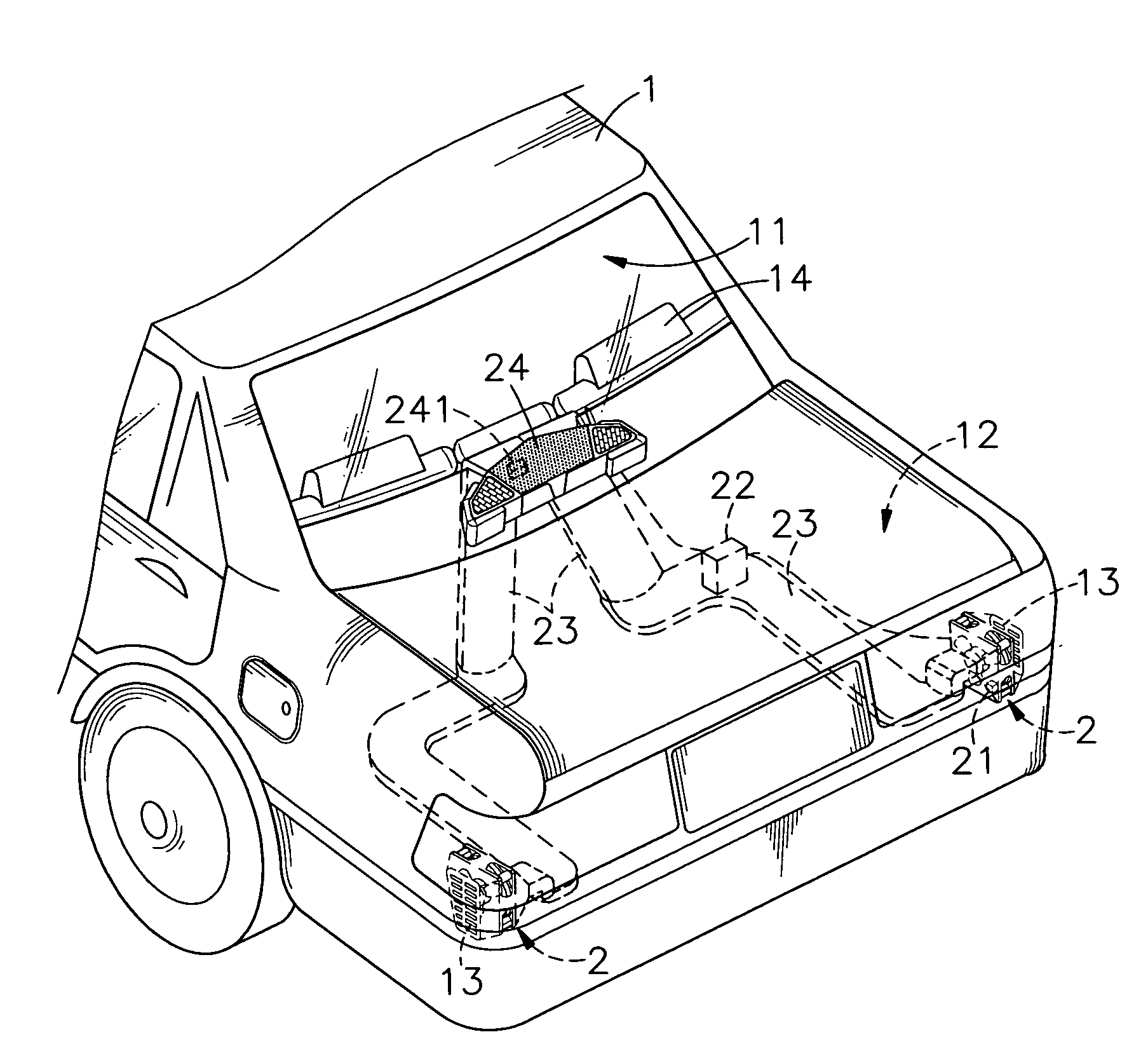

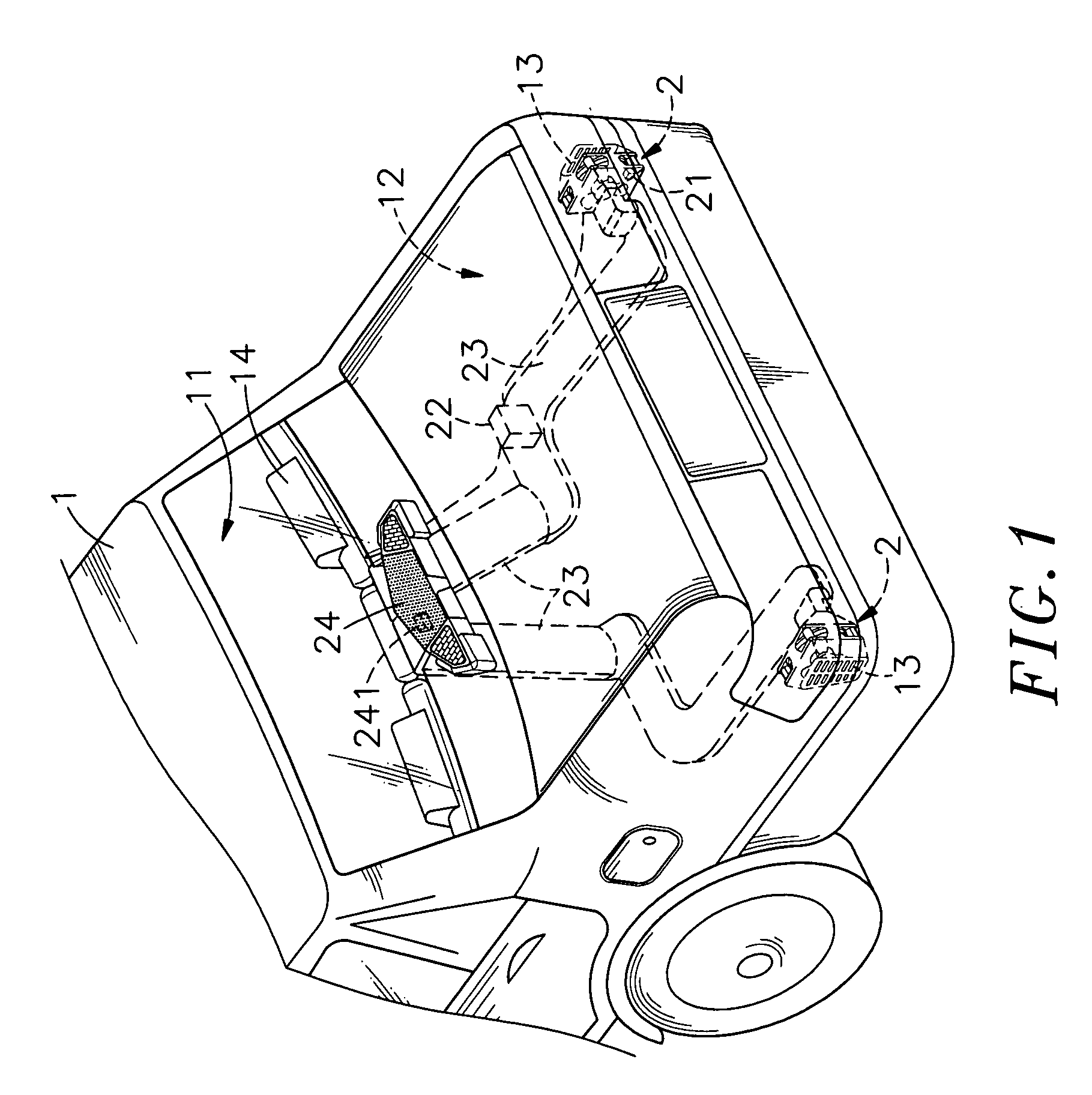

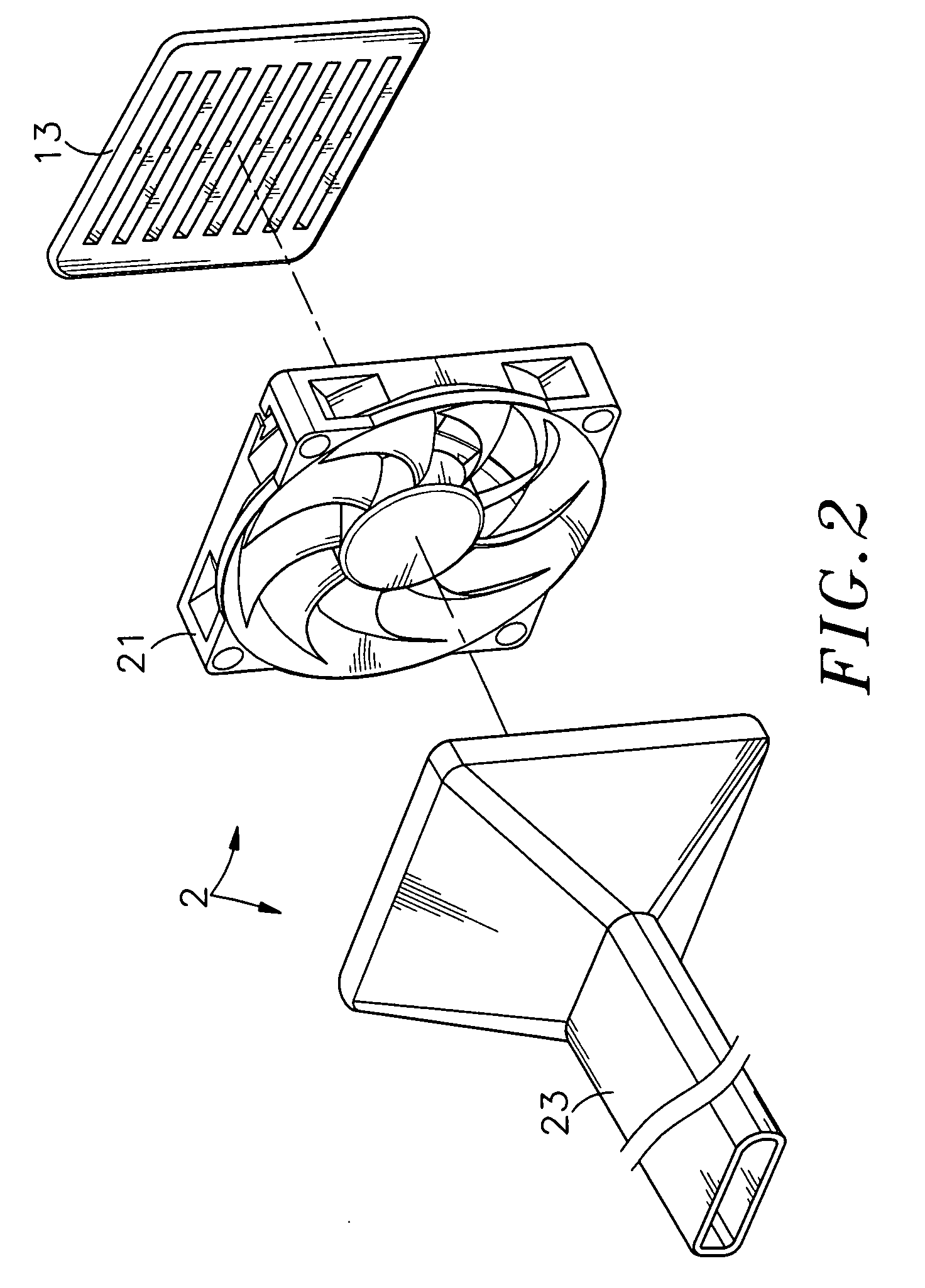

Motor vehicle air cooling method and system

InactiveUS20090088064A1More power consumptionEffective temperatureAir-treating devicesRailway heating/coolingMobile vehicleMotor vehicle part

A motor vehicle air cooling method and system in which electric fans are installed in the rear side of a motor vehicle to draw hot air out of the inside space of the motor vehicle so as to cause negative pressure in the motor vehicle for sucking outside cooling air into the inside of the motor vehicle to have the pressure inside the motor vehicle be in balance with the pressure outside the motor vehicle and to simultaneously lower the temperature in the motor vehicle after an air conditioner ventilation panel of the motor vehicle has been set in an outer loop status.

Owner:LIN CHIEN ERH

Cleaning solution for electronic materials and method for using same

InactiveUS6450181B1Efficient removalReduce the amount requiredDetergent mixture composition preparationSemiconductor/solid-state device manufacturingAtmospheric airAmmonia

A cleaning solution for electronic materials contains dissolved oxygen gas at a concentration greater than atmospheric saturation concentration, 0.1-10,000 mg / liter of ammonia, and 0.1-10,000 mg / liter of hydrogen peroxide in water. Alternatively, the cleaning solution contains dissolved reducing agents, 0.1-10,000 mg / liter of ammonia, and 0.1-10,000 mg / liter of hydrogen peroxide in water. A method for making the cleaning solution of the present invention is provided. A method for cleaning electronic materials using the cleaning solution of the present invention is also provided.

Owner:KURITA WATER INDUSTRIES LTD

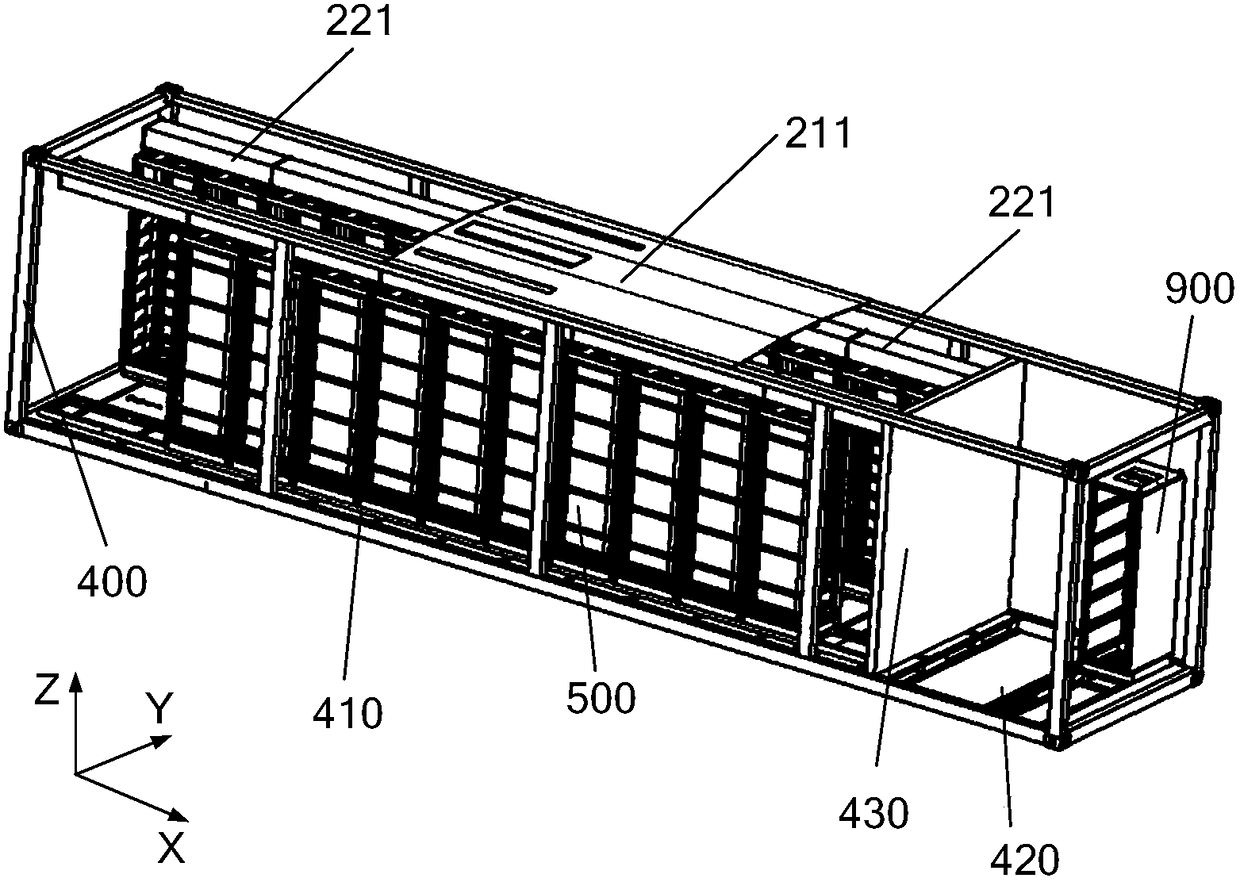

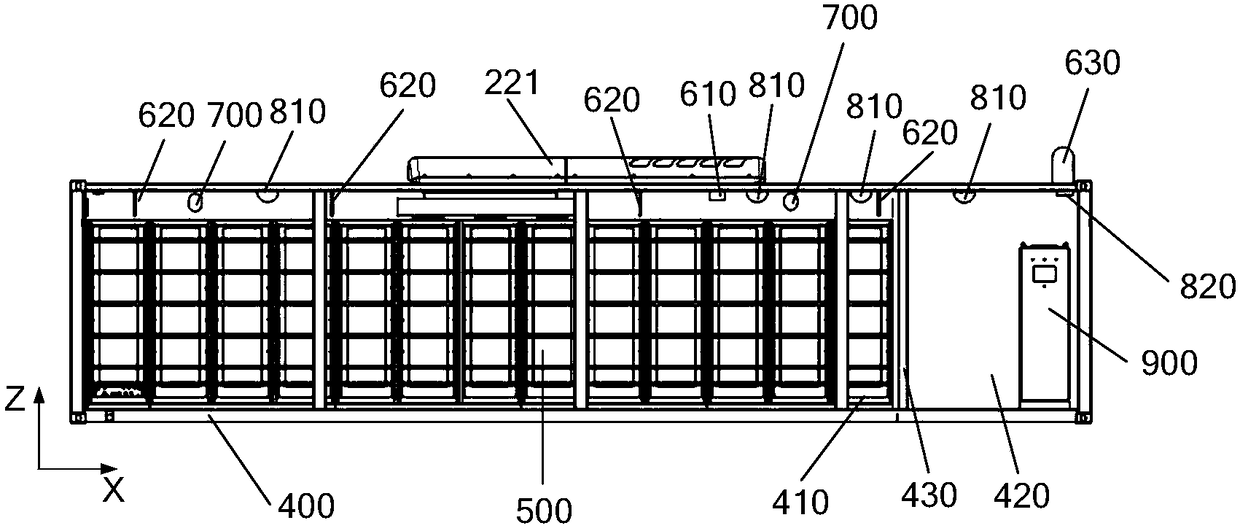

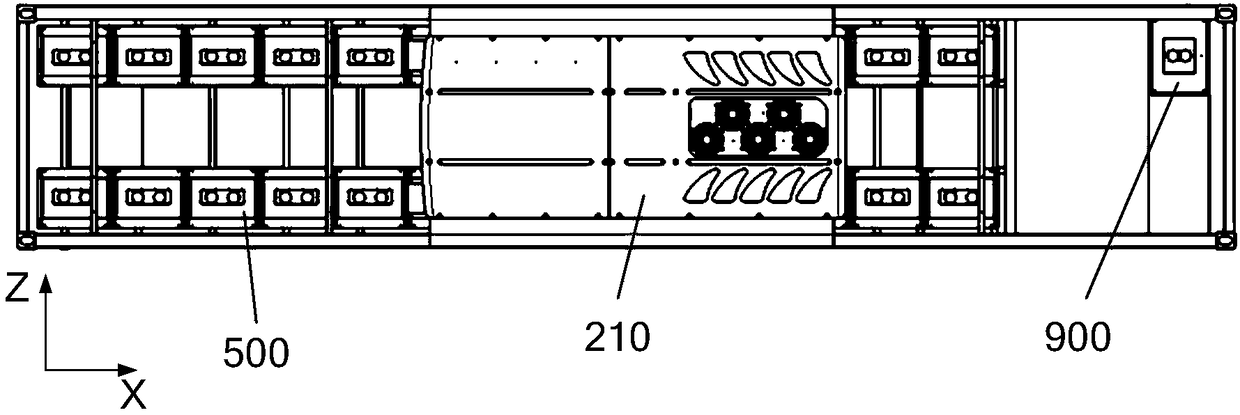

Battery thermal management system and energy storage container

InactiveCN109148999AEffective temperatureGuaranteed to workSecondary cellsCell component detailsRefrigerated temperatureBattery thermal management

The invention provides a battery thermal management system and an energy storage container. The battery thermal management system comprises a control device, a cooling device and a temperature sensor.The temperature sensor is arranged on the battery module and is used for detecting the temperature of the battery module and sending a temperature signal to the control device. The cooling device comprises a refrigerator and an air channel, wherein the air outlet of the refrigerator is communicated with the air inlet of the air channel, and the air outlet of the air channel is arranged on the battery module; the control device is electrically connected with the temperature sensor and the refrigerator respectively; and the control device controls the working state of the refrigerator accordingto the temperature signal. The control device of the invention judges the temperature of the battery module according to the temperature signal, and then controls the refrigerator to work and generate cooling gas, the cooling gas is released to the battery module through an air duct, the battery module is effectively cooled and radiated, the cooling efficiency is high, the cooling requirements ofthe battery module are met, the battery is guaranteed to work effectively, and the service life of the energy storage container is prevented from being influenced by the relatively high temperature of the battery module.

Owner:BEIJING HYPERSTRONG TECH

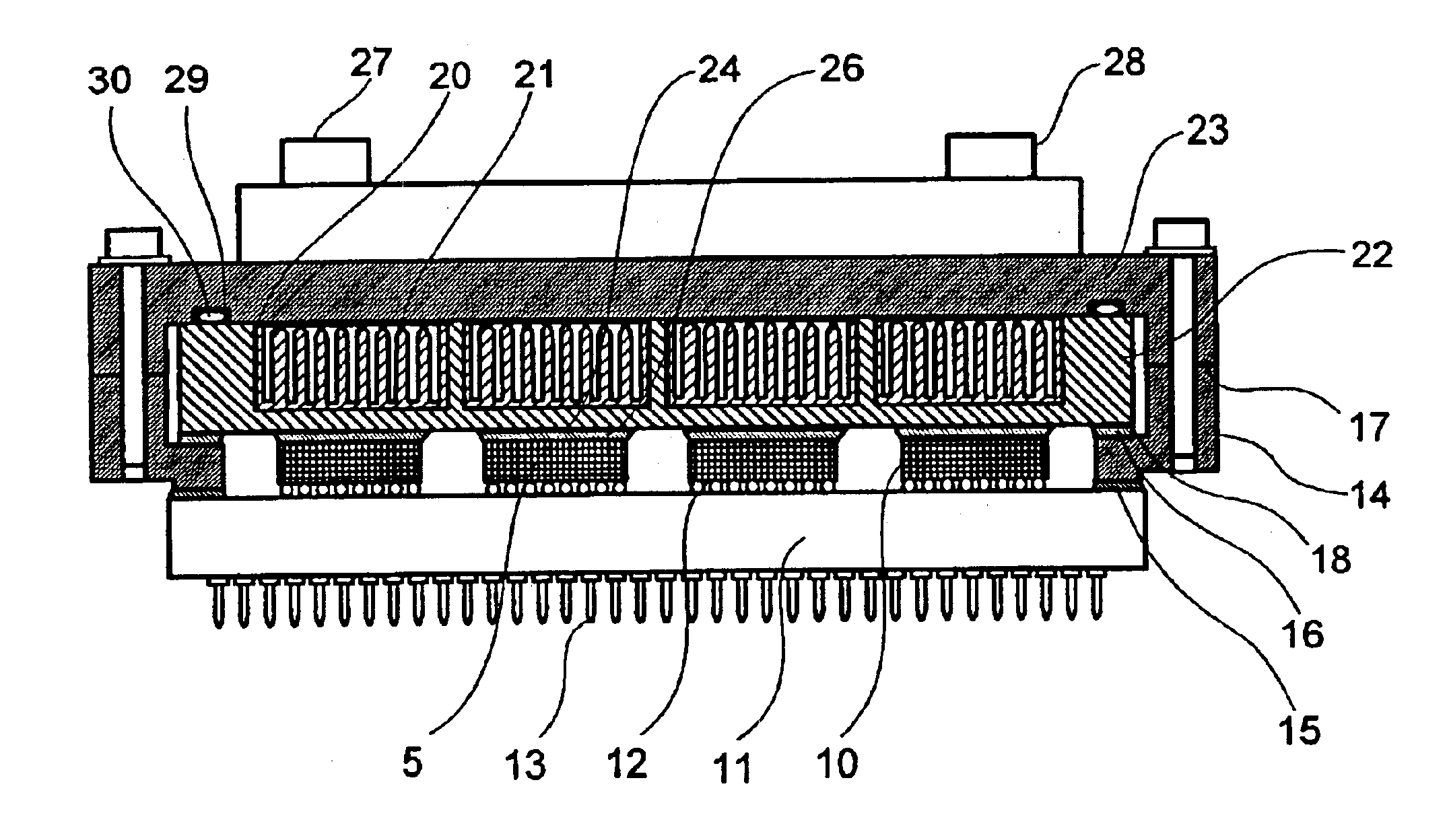

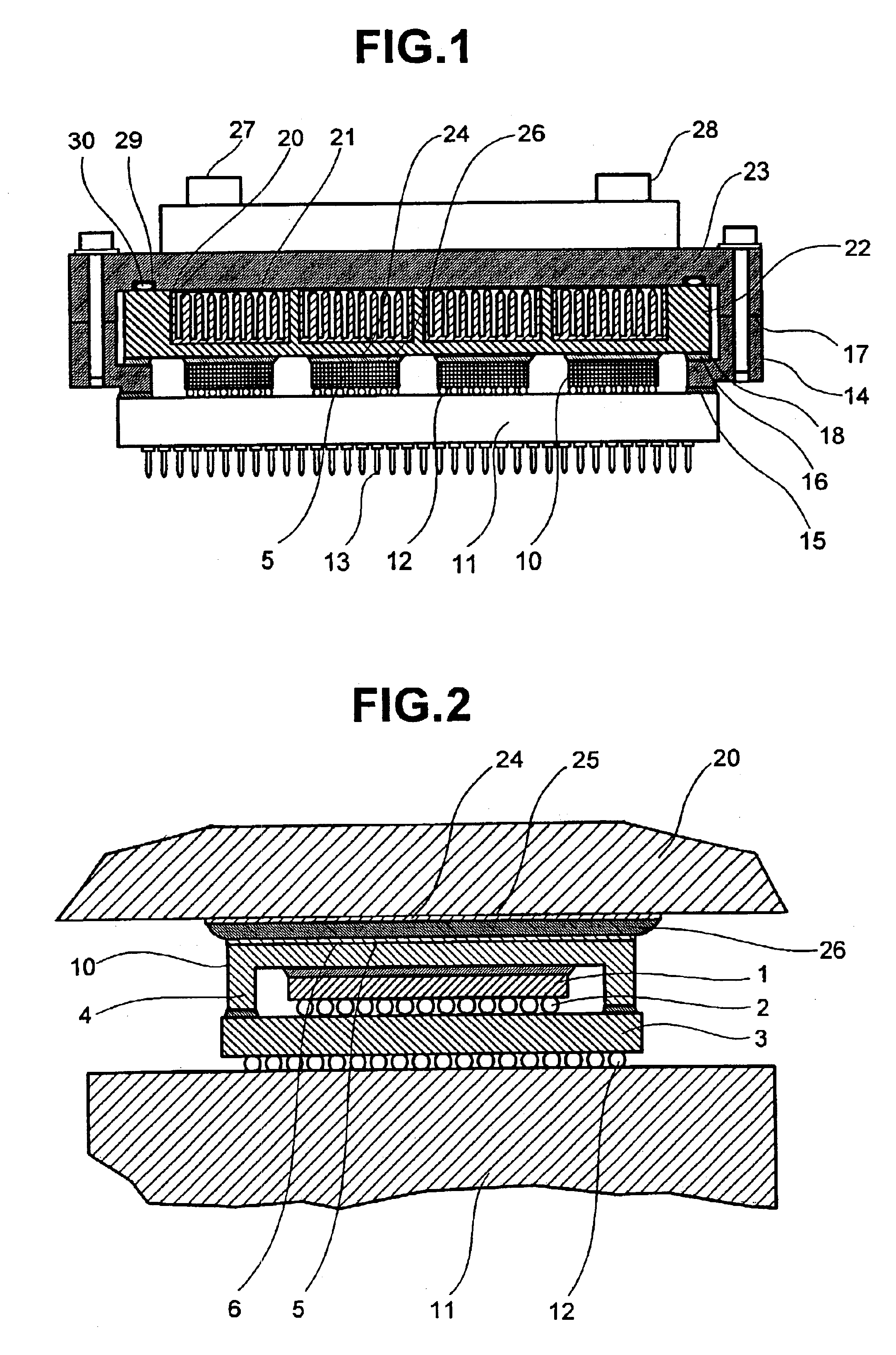

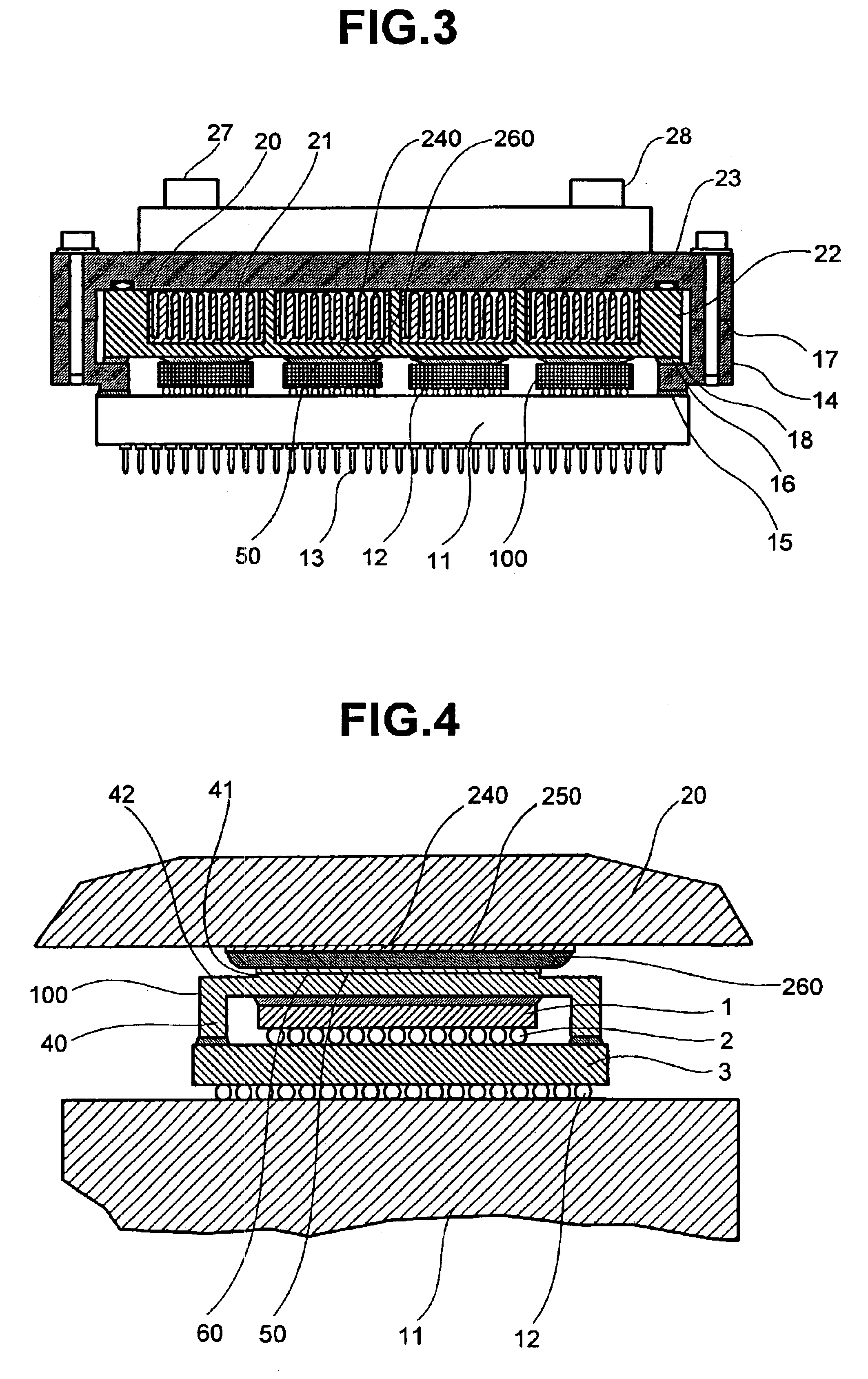

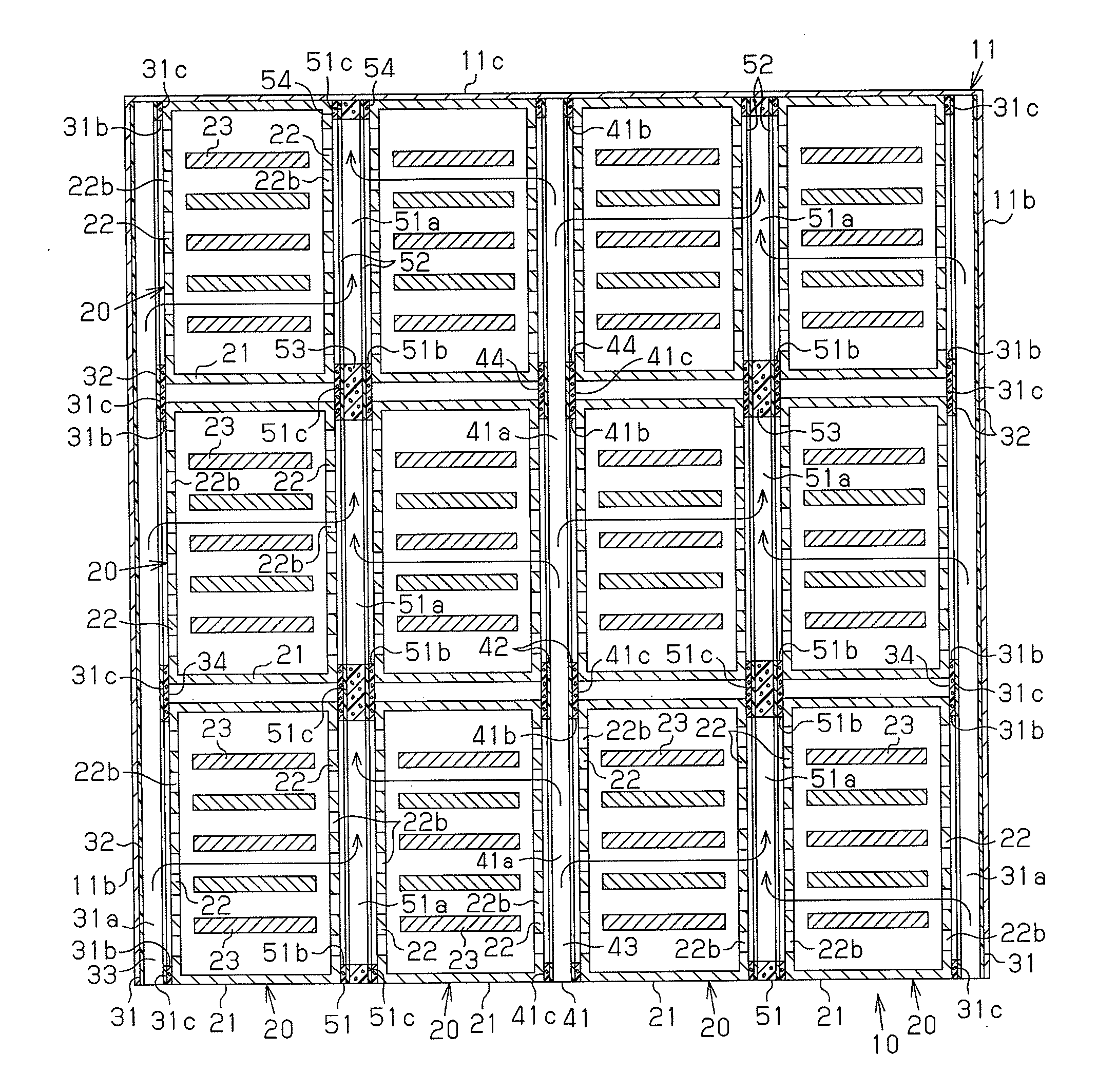

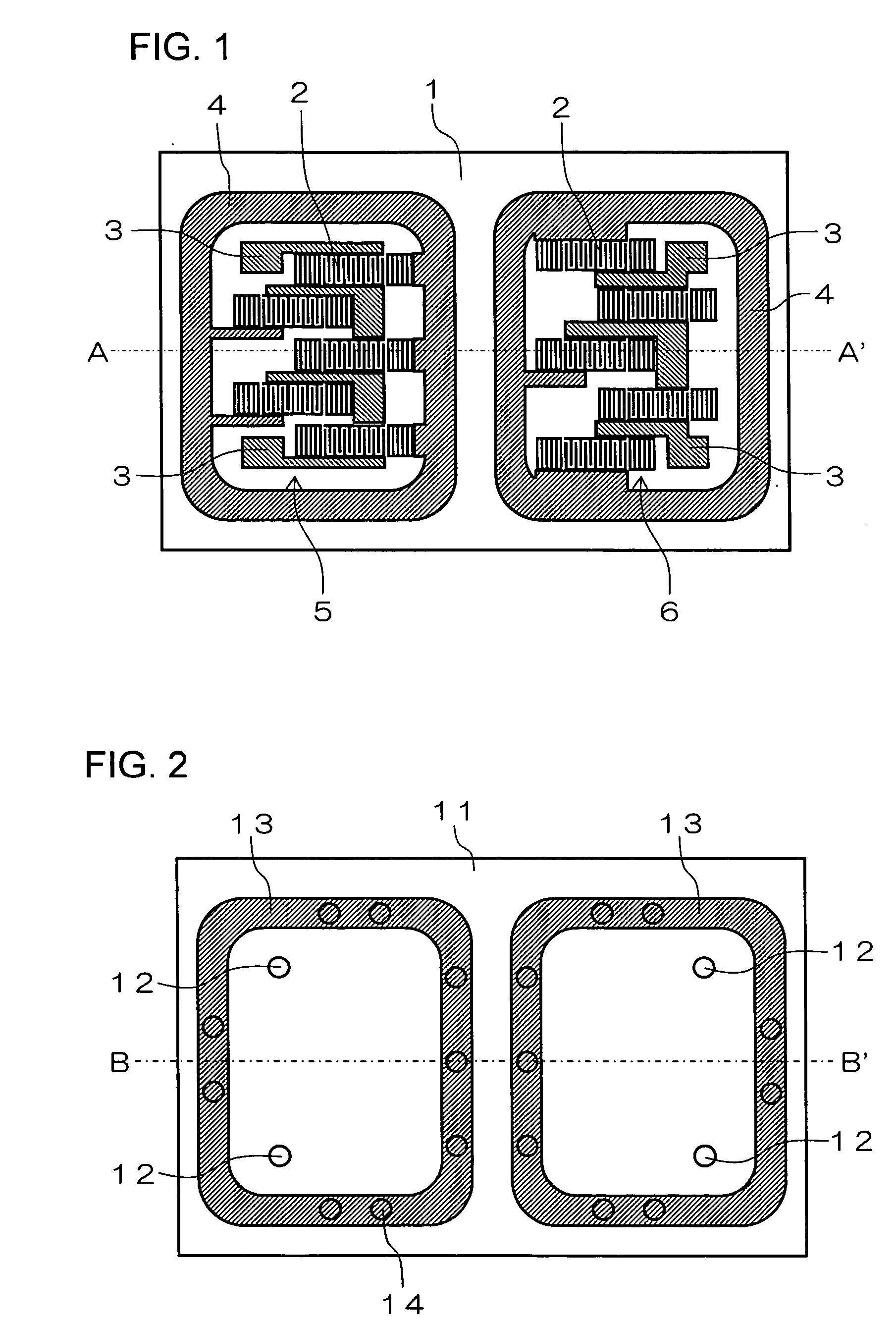

Device for sealing and cooling multi-chip modules

InactiveUS6890799B2Lower the heatReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesThermal expansionPath cover

According to the invention, a sealing top plate in a multi-chip module is formed from a ceramic with high thermal conductivity having a thermal expansion coefficient consistent with that of a multi-layer circuit substrate. A cooling flow path cover covering the entirety of cooling flow path grooves is formed as a separate metallic member. The back surface of the sealing top plate, on which are formed the cooling flow path grooves, is bonded directly to the back surface of a semiconductor device using solder. A thermal-conductive jacket with low thermal resistance is provided. A multi-chip module sealing frame is soldered to the edge of the sealing top plate. Furthermore, a sealing material such as an O-ring is simply interposed between the edge of the sealing top plate and the cooling water path cover, and tightening means is used to tighten the metallic cooling flow path cover and the multi-chip module sealing frame to each other.

Owner:HITACHI LTD

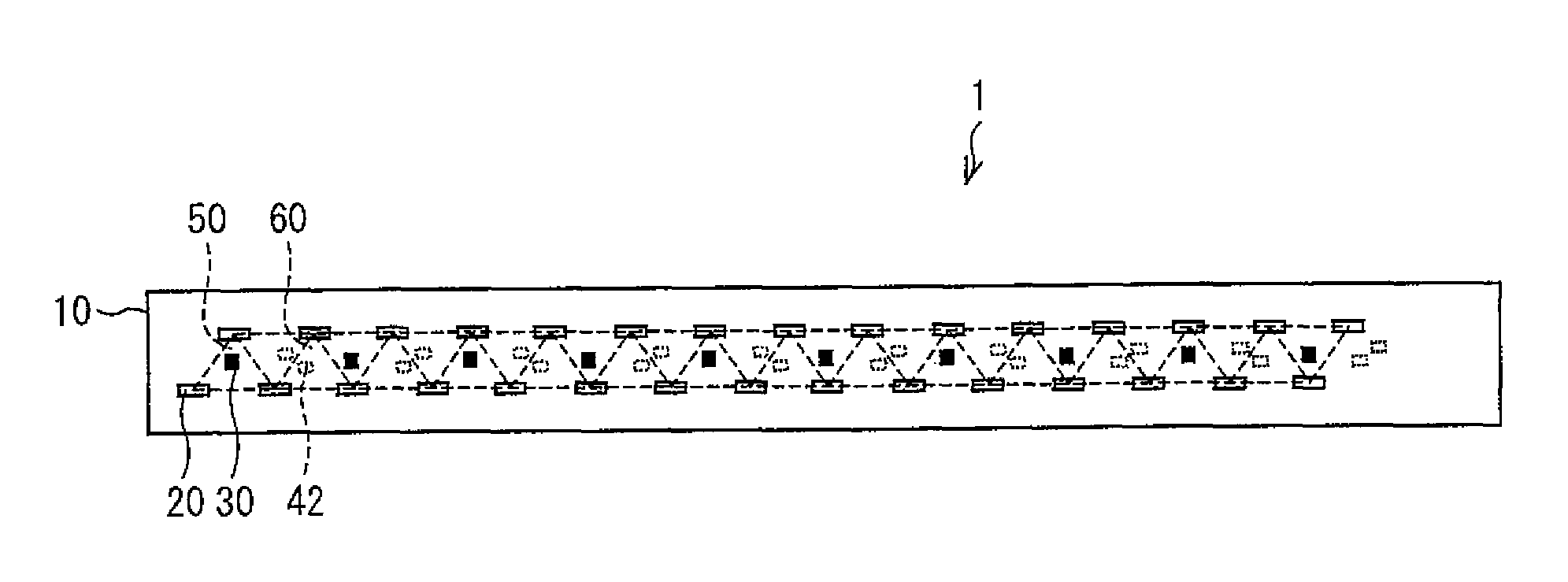

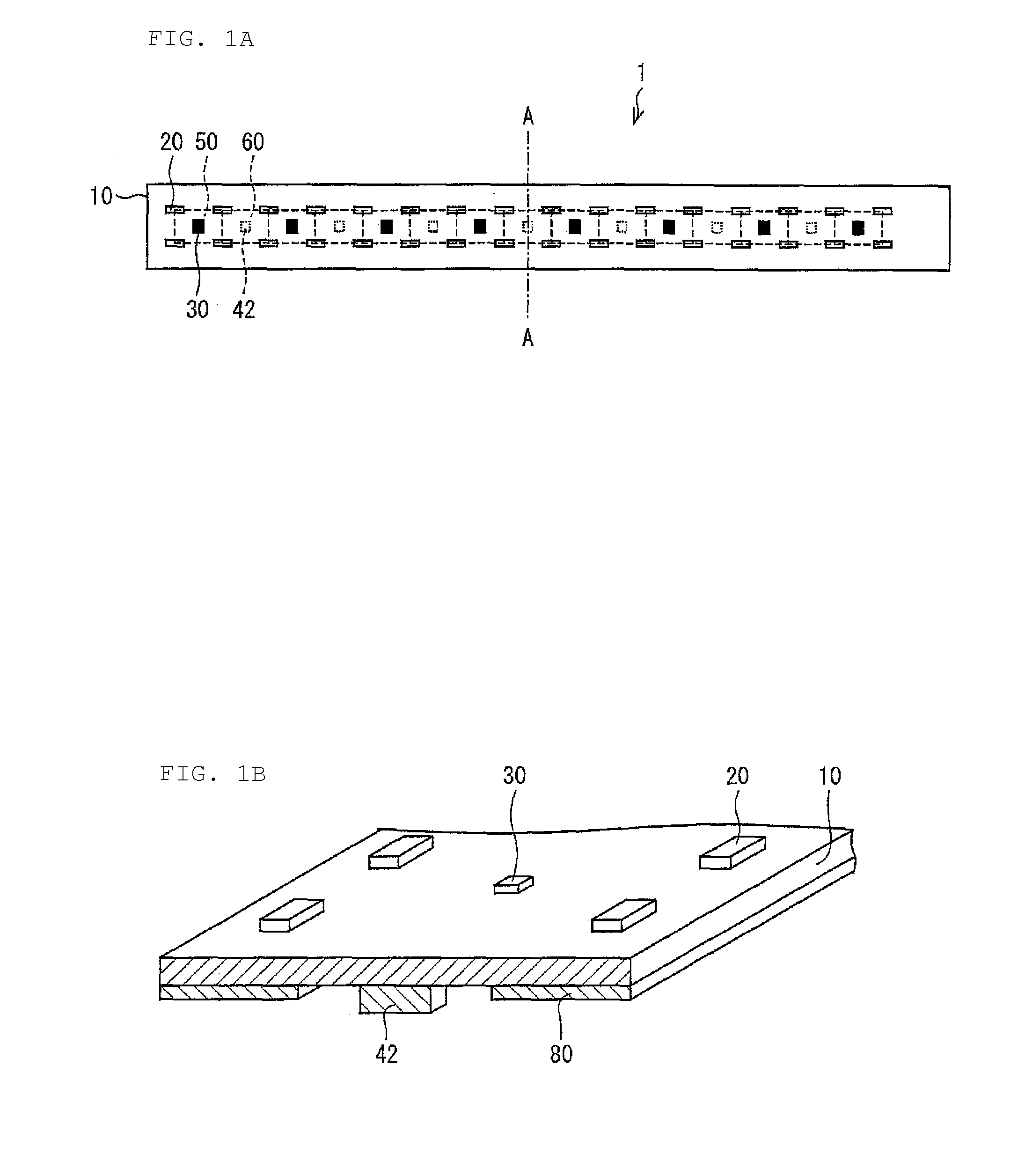

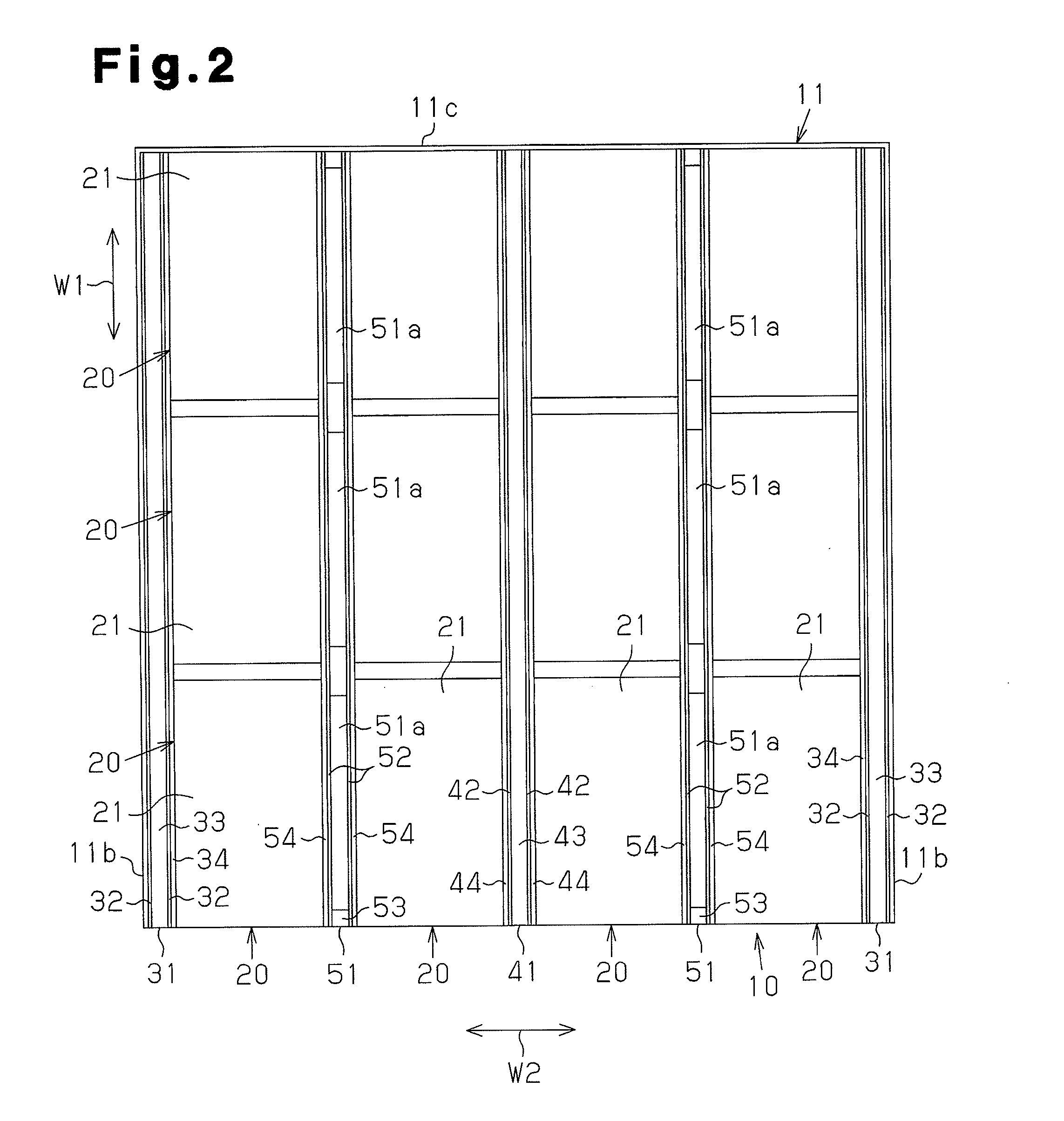

Illumination device and liquid crystal display device

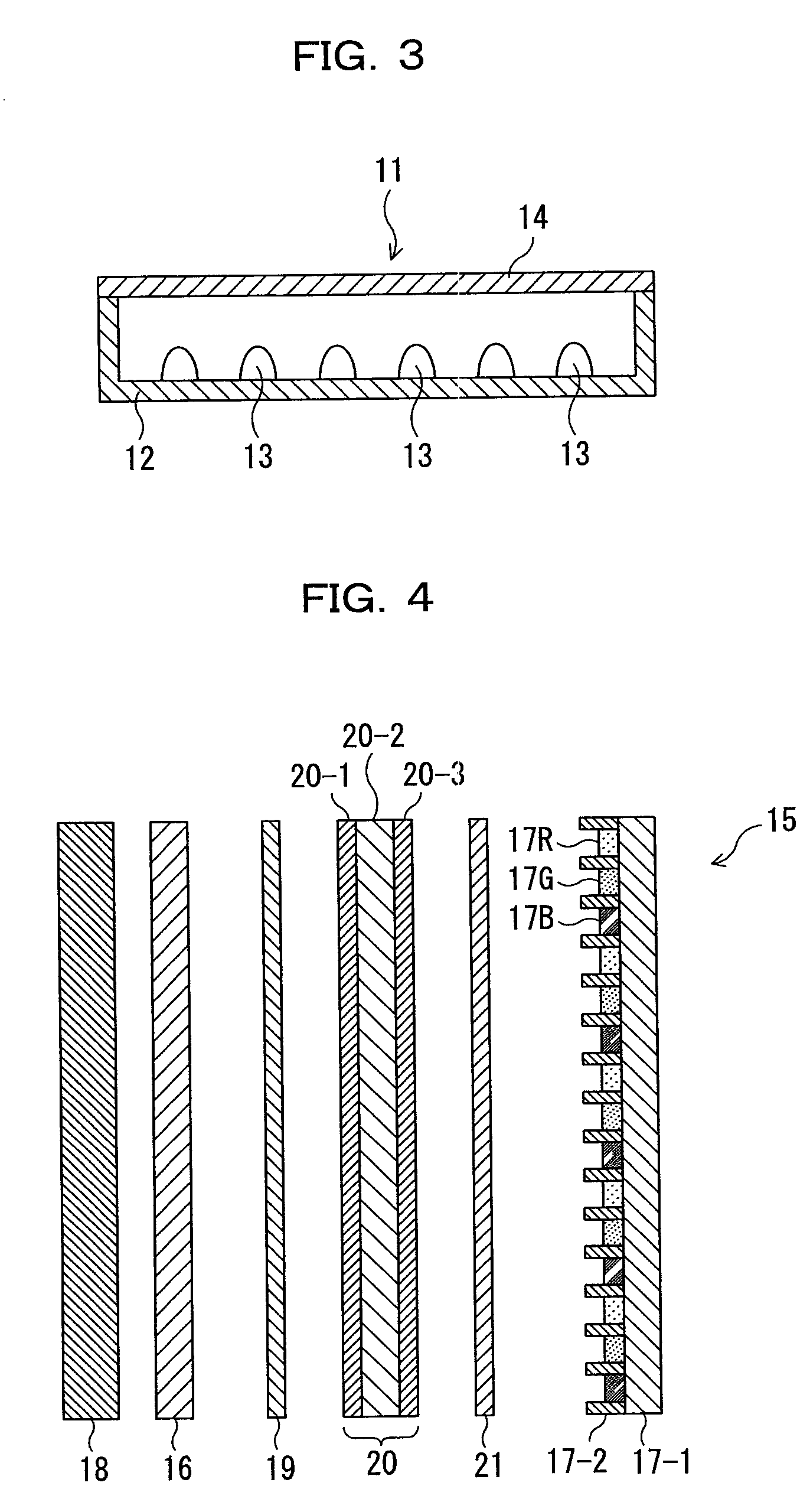

ActiveUS8111371B2Accurate temperature detectionSmall temperature changeStatic indicating devicesLighting heating/cooling arrangementsElectrical resistance and conductanceLiquid-crystal display

An illumination device includes an LED package, an LED driver including an FET, and a thermistor disposed on a substrate. A plurality of such LED packages are disposed on the substrate such that a first area and a second area, each determined by vertices corresponding to LED packages, are defined on the substrate. The thermistor is disposed in the first area, and the FET is disposed in the second area, which is outside of the first area. The thermistor detects a temperature in the first area. Such a configuration allows the thermistor to detect, in accordance with the temperature in the area, the temperature of heat transferred from the LED packages, without being affected by heat generated by the FET. This makes it possible to efficiently make temperature corrections to stabilize color temperature and luminance.

Owner:SHARP KK

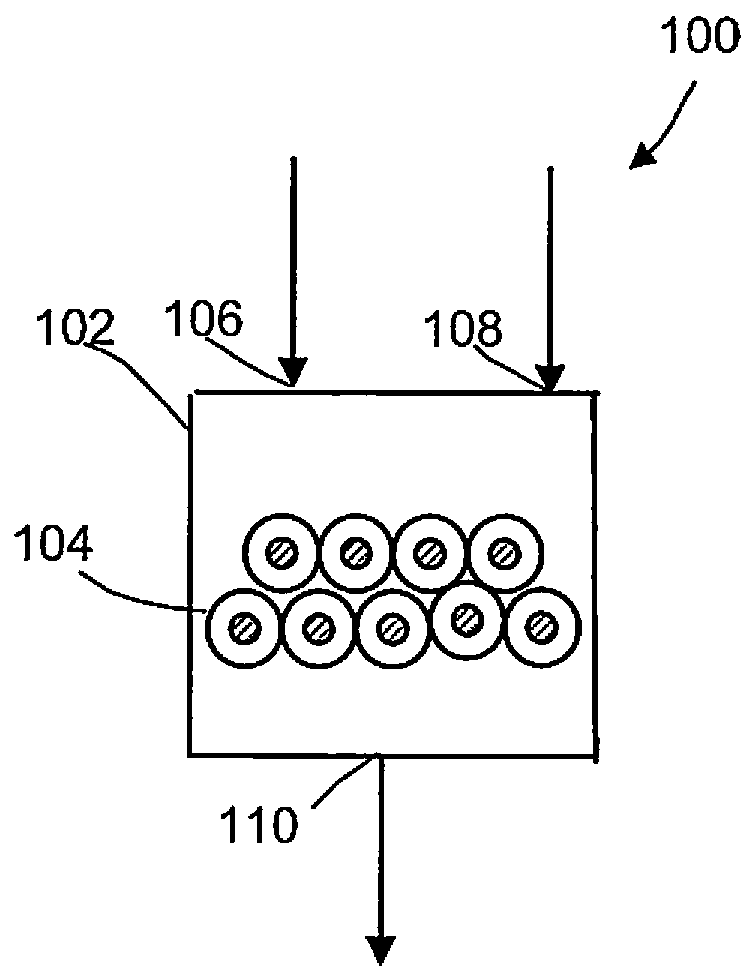

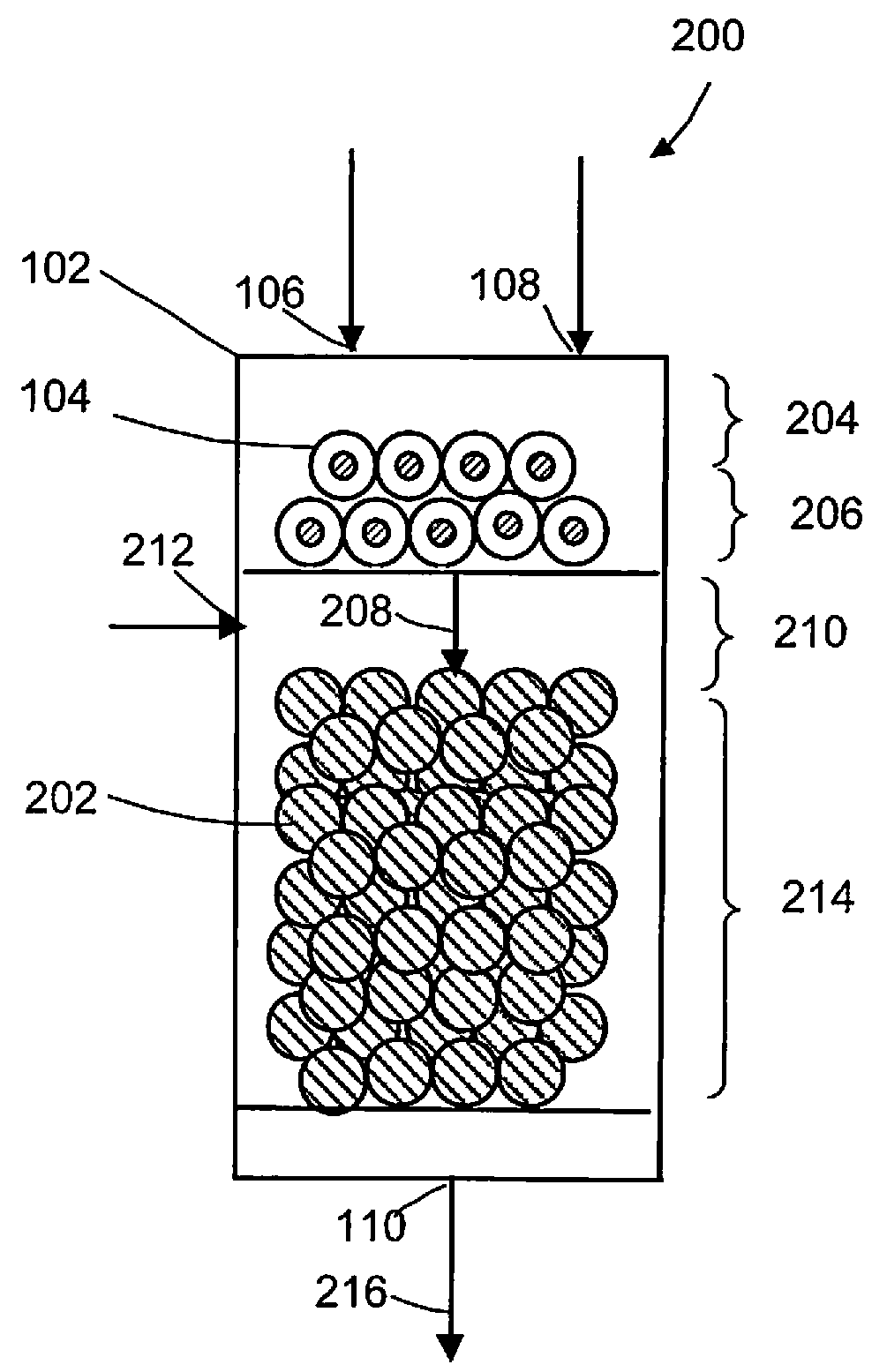

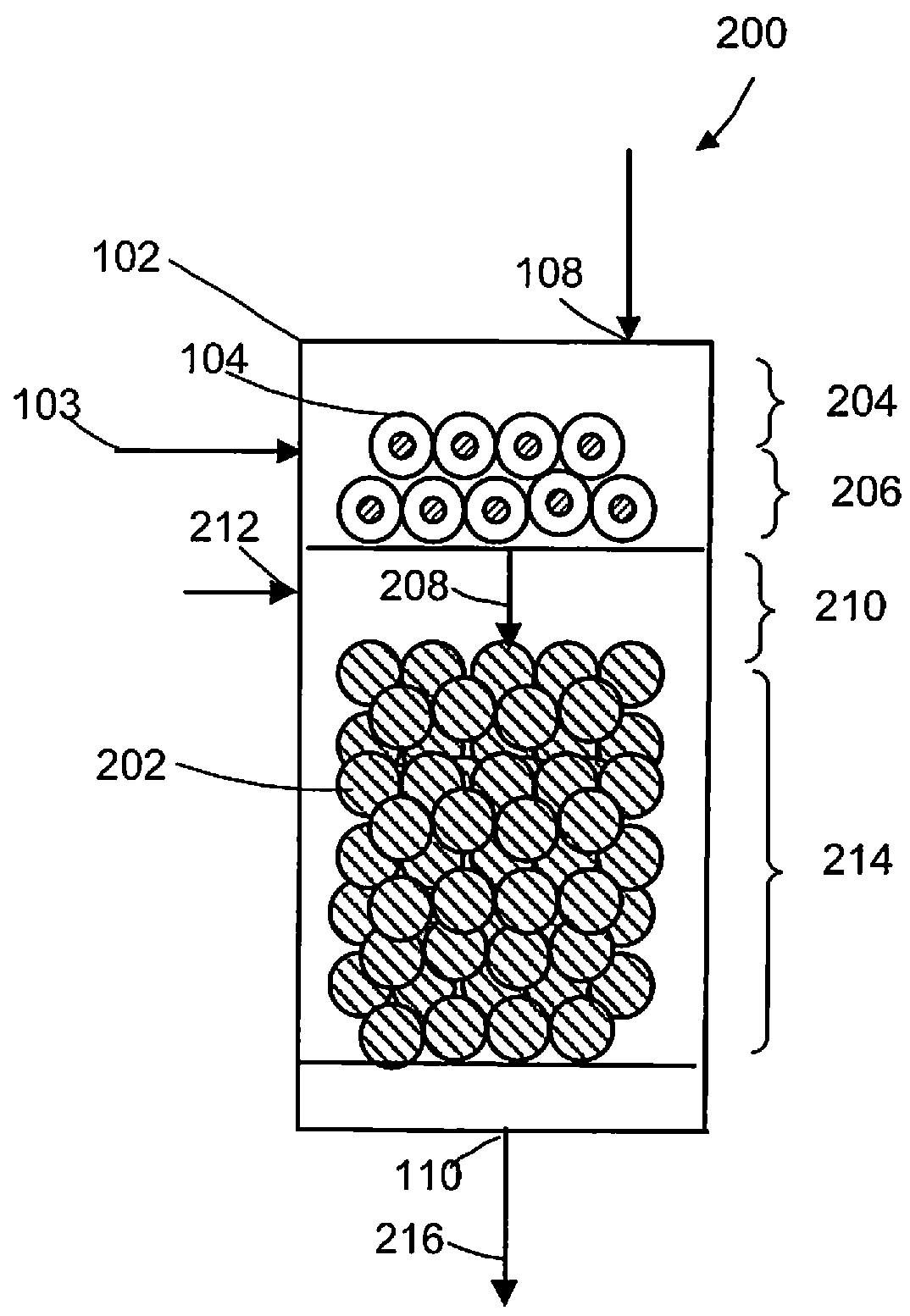

Low inlet temperature for oxidative coupling of methane

ActiveUS20180162785A1Maximizes energy generatedEnergy efficiencyCatalystsHydrocarbon preparation catalystsReaction zoneOxygen

Disclosed is a process for producing C2+ hydrocarbons, and systems for implementing the process, that includes providing a reactant feed that includes methane and an oxygen containing gas to a first reaction zone, wherein the temperature of the reactant feed is less than 700° C. contacting the reactant feed with a first catalyst capable of catalyzing an oxidative coupling of methane reaction (OCM) to produce a first product stream that includes C2+ hydrocarbons and heat, and contacting the first product stream with a second catalyst capable of catalyzing an OCM reaction to produce a second product stream that includes C2+ hydrocarbons, wherein the produced heat is at least partially used to heat the first product stream prior to or during contact with the second catalyst, wherein the amount of C2+ hydrocarbons in the second product stream is greater than the amount of C2+ hydrocarbons in the first product stream.

Owner:SABIC GLOBAL TECH BV

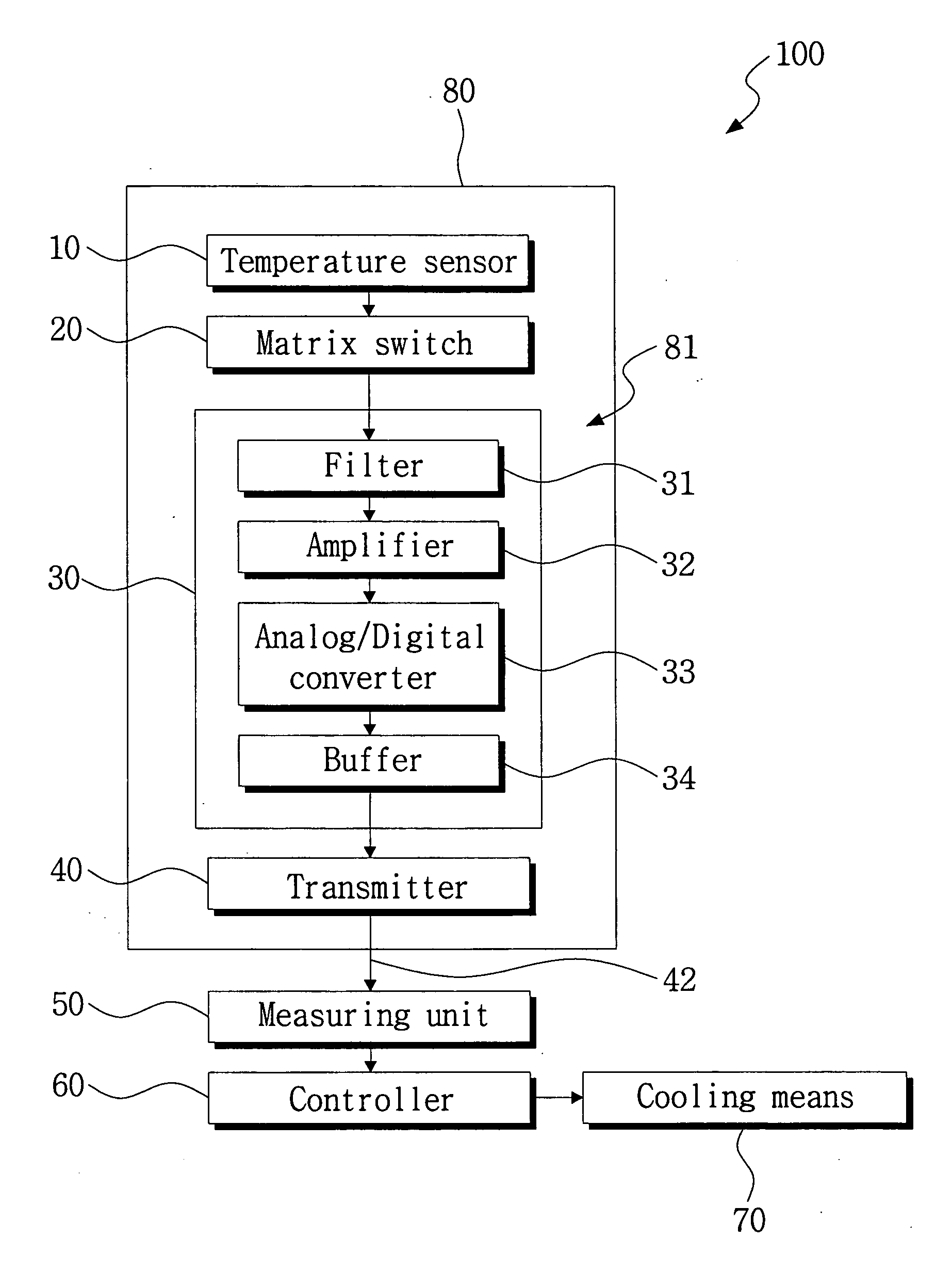

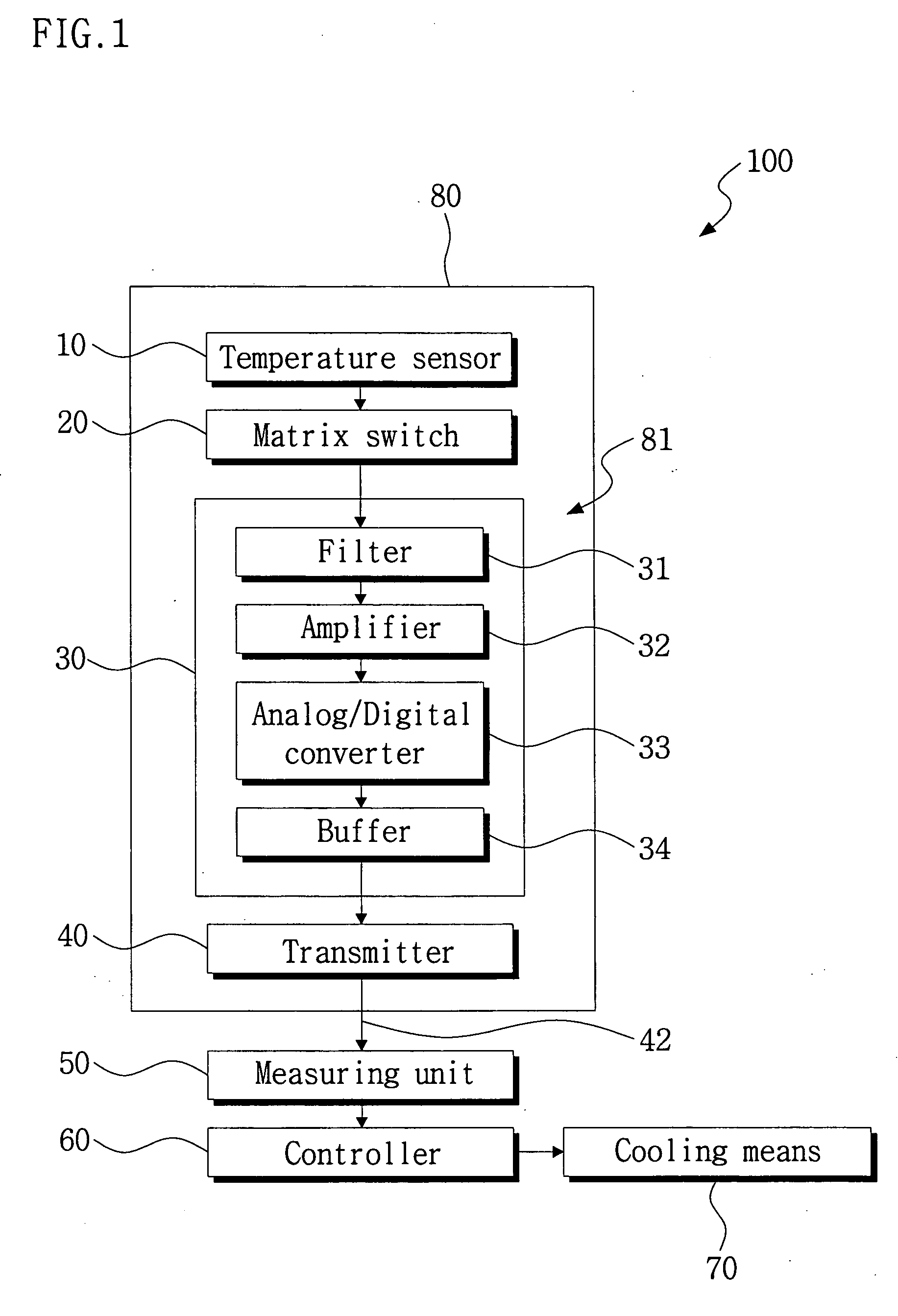

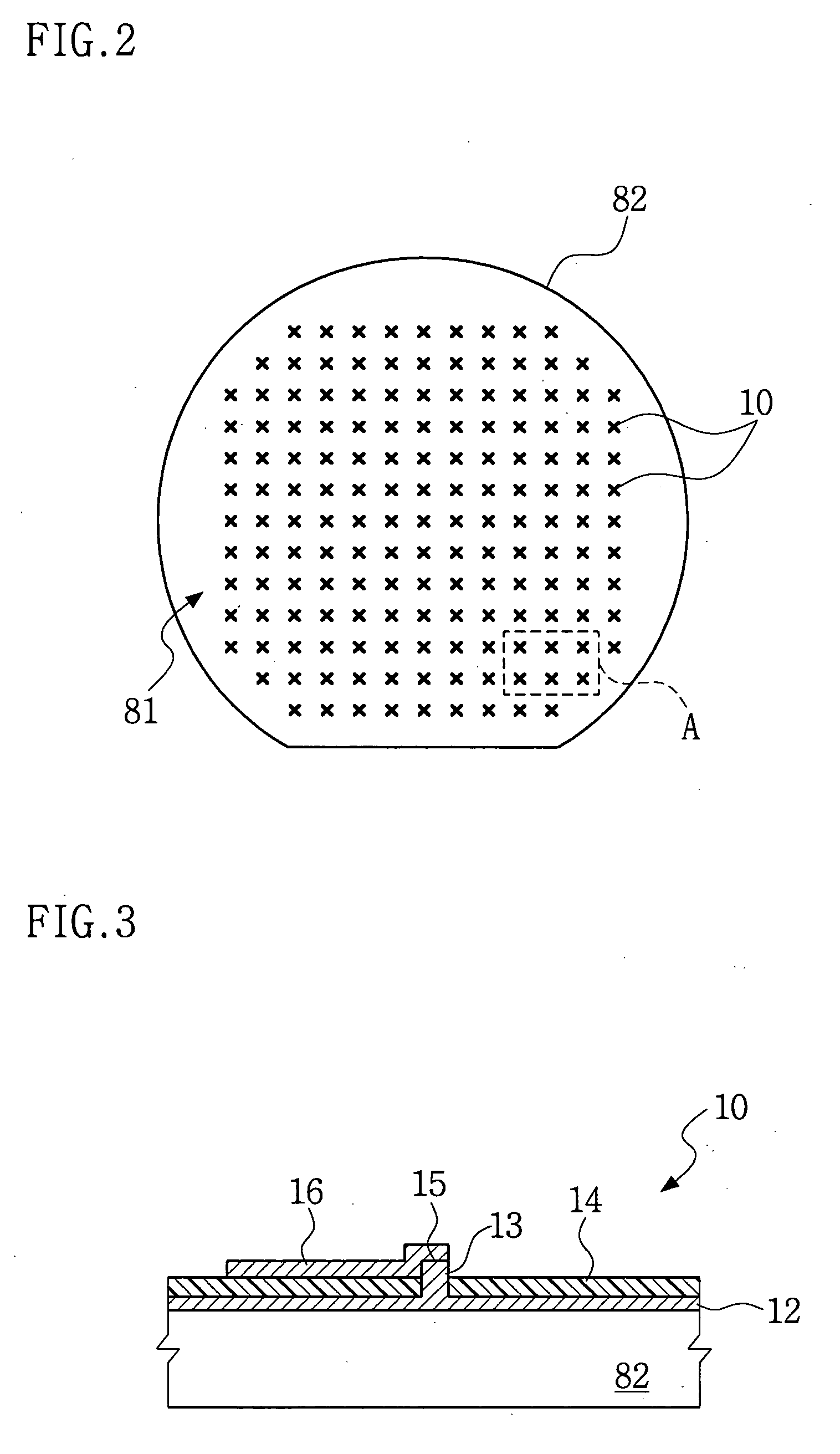

Temperature measuring device using a matrix switch, a semiconductor package and a cooling system

InactiveUS20060075760A1Effectively measuring temperatureEffective temperatureThermoelectric device with peltier/seeback effectDomestic cooling apparatusDevice materialMethod selection

An embodiment relates to a temperature measuring device using a matrix switch, and a semiconductor package. In another embodiment a cooling system may be included. A plurality of temperature sensors may be arranged on a surface of a semiconductor device. The matrix switch may select the temperature sensors by an address method to form a circuit that includes the selected temperature sensor. A measuring unit may receive an output signal of the selected temperature sensor to calculate the temperature at the selected temperature sensor.

Owner:SAMSUNG ELECTRONICS CO LTD

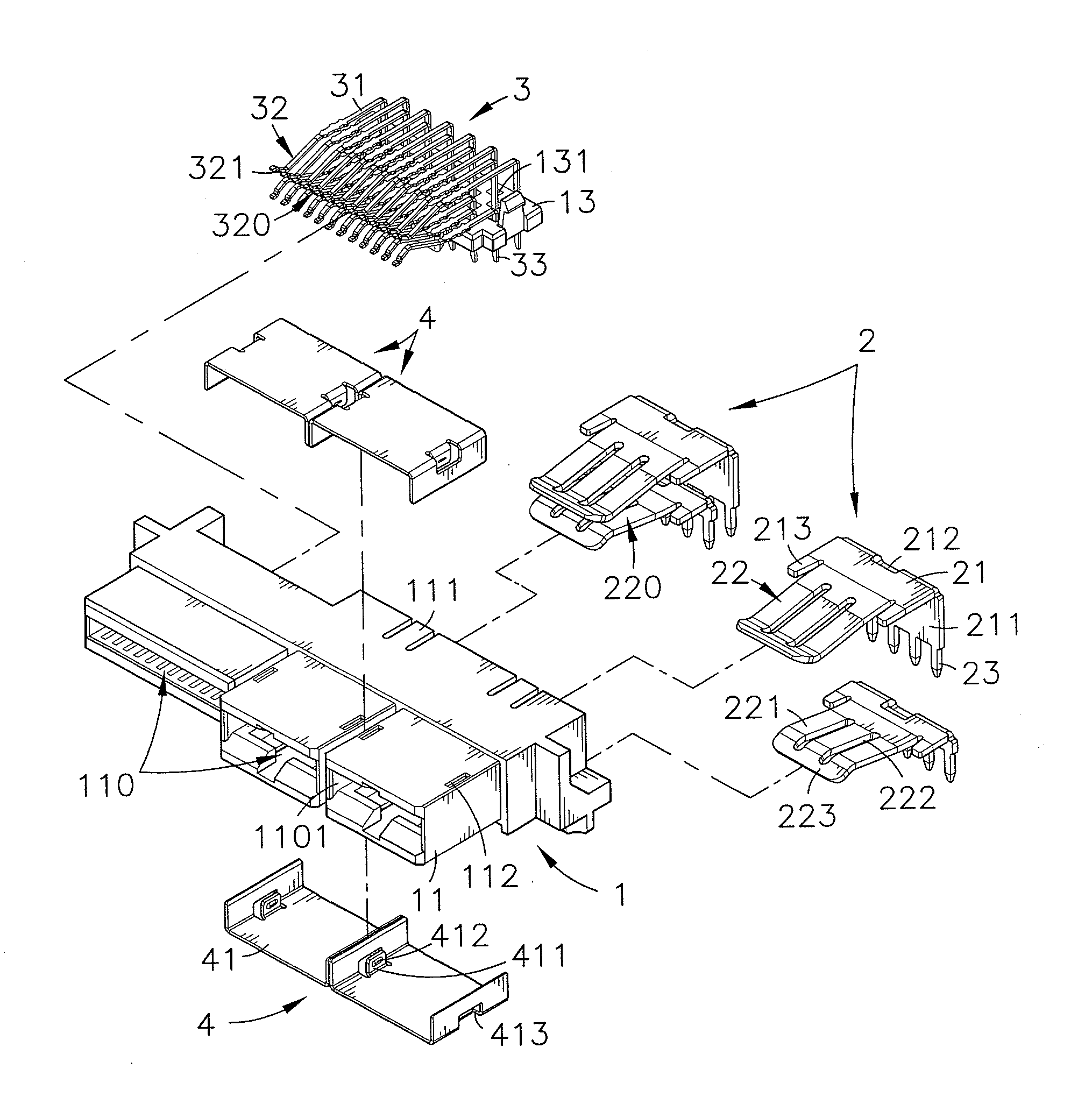

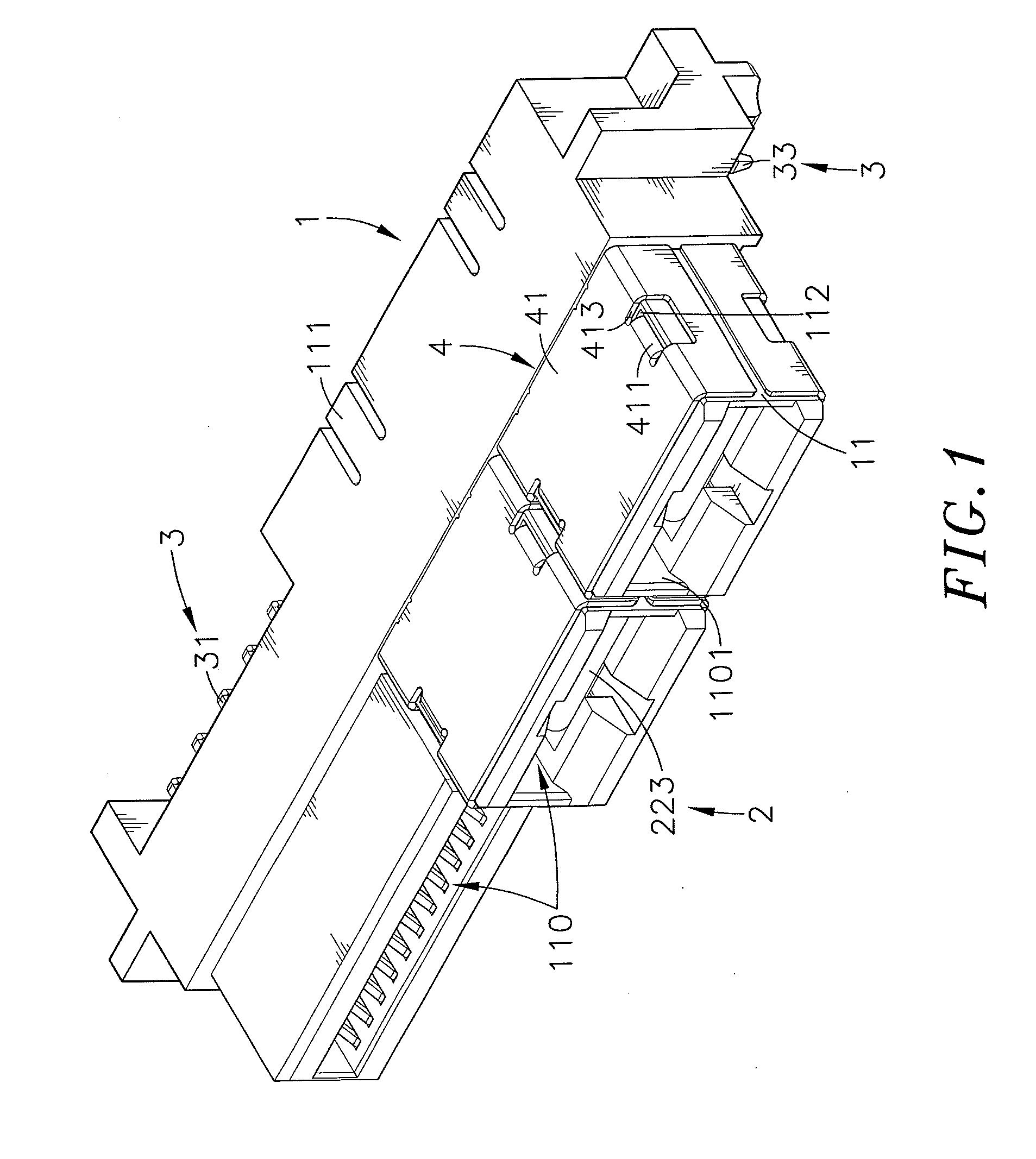

Electrical power connector

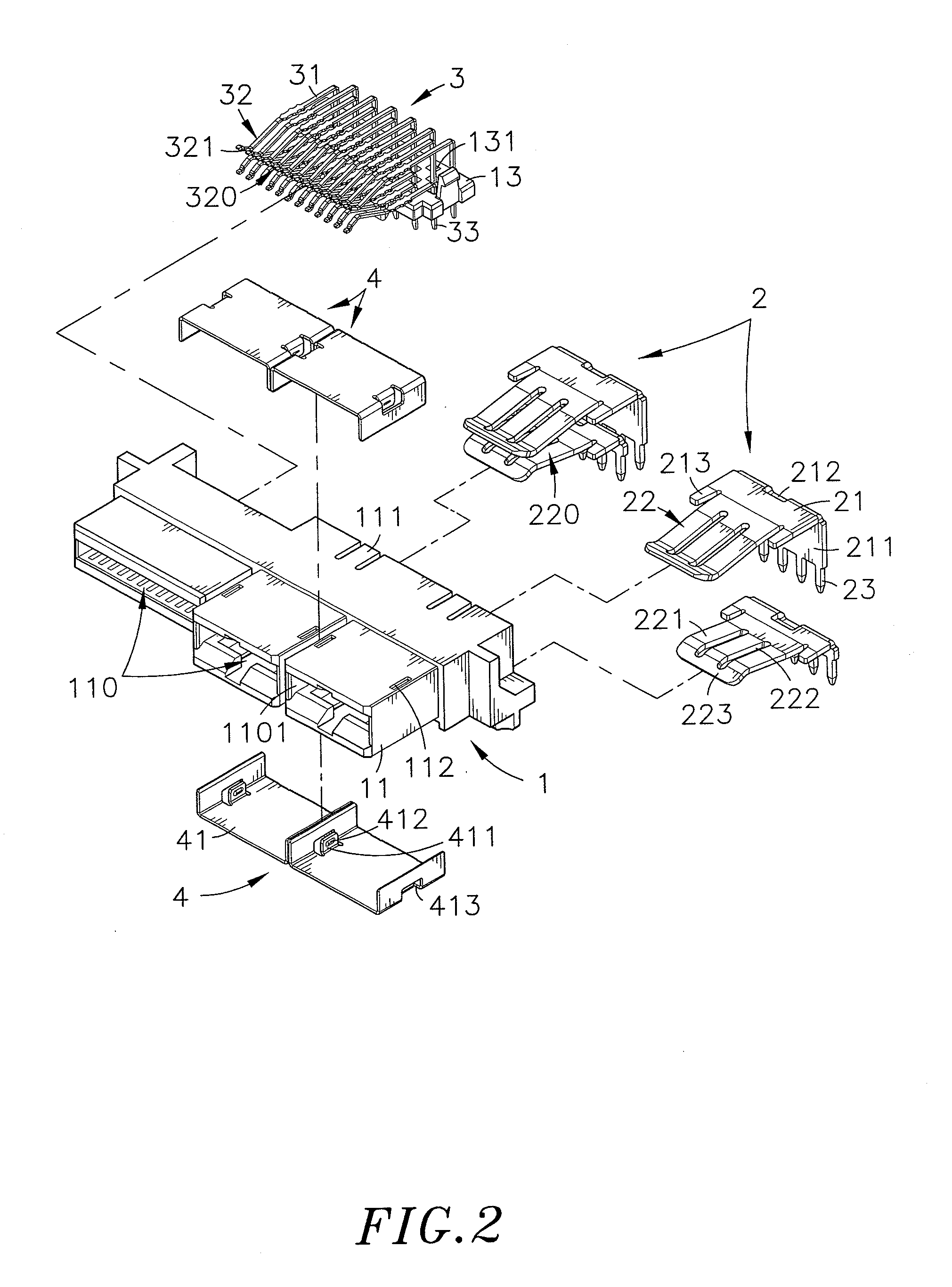

InactiveUS20130109224A1Lower impedanceReduce the temperatureCoupling device detailsElectricityElectrical connector

An electrical power connector includes an electrically insulative housing defining multiple front mating portions, multiple rear partition plates, an accommodation chamber between each two adjacent partition plates corresponding to one respective mating portion, a mating chamber in each mating portion and mounting holes on opposing top and bottom sides of the mating portions, pairs of conducting terminals respectively mounted in the accommodation chambers of the electrically insulative housing, and a heat dissipation mechanism including a plurality of thermal conductive metal plates fastened to the mounting holes of the electrically insulative housing with respective mounting lugs thereof and covered on the mating portions of the electrically insulative housing and for quick dissipation of heat.

Owner:ACES ELECTRONICS CO LTD

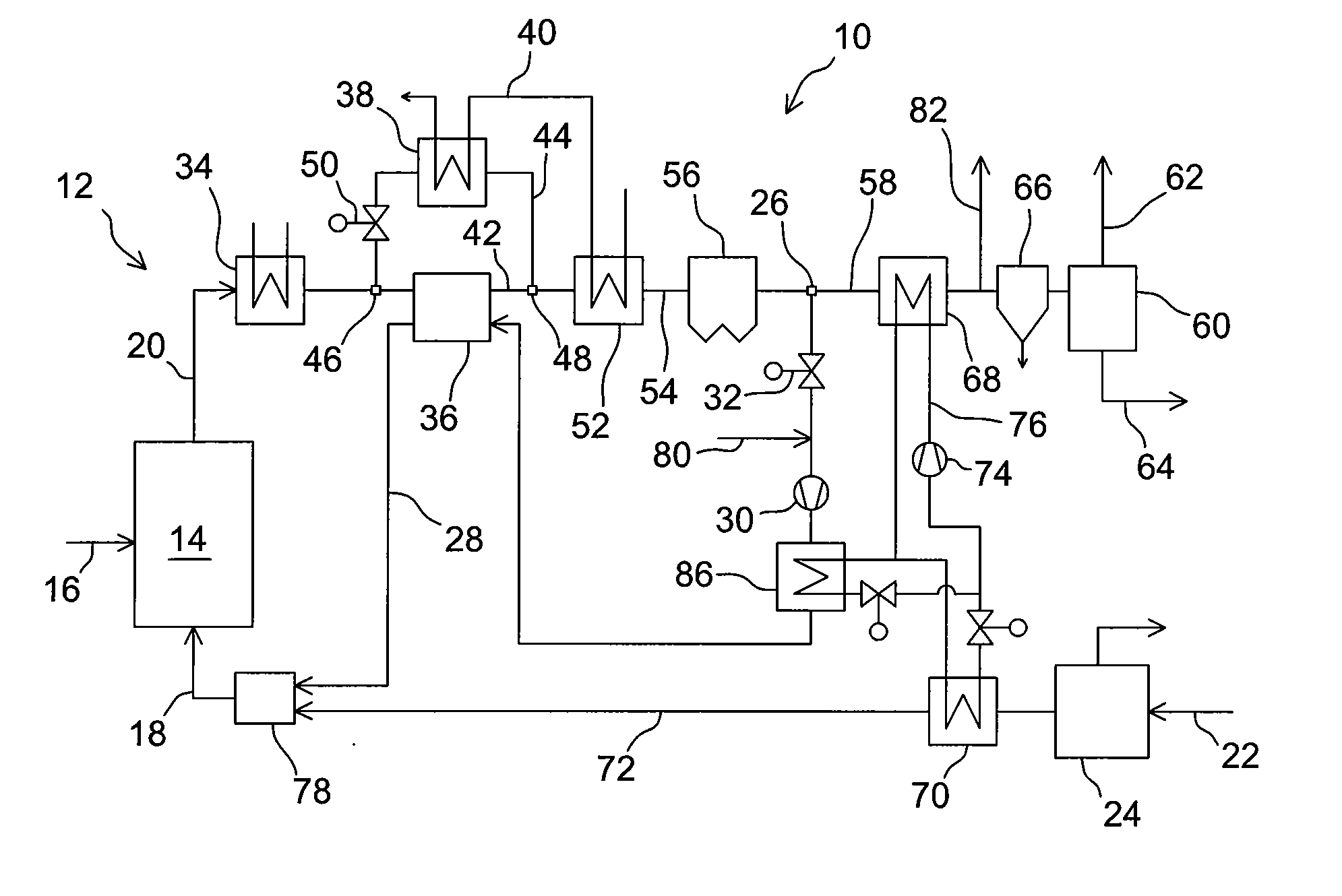

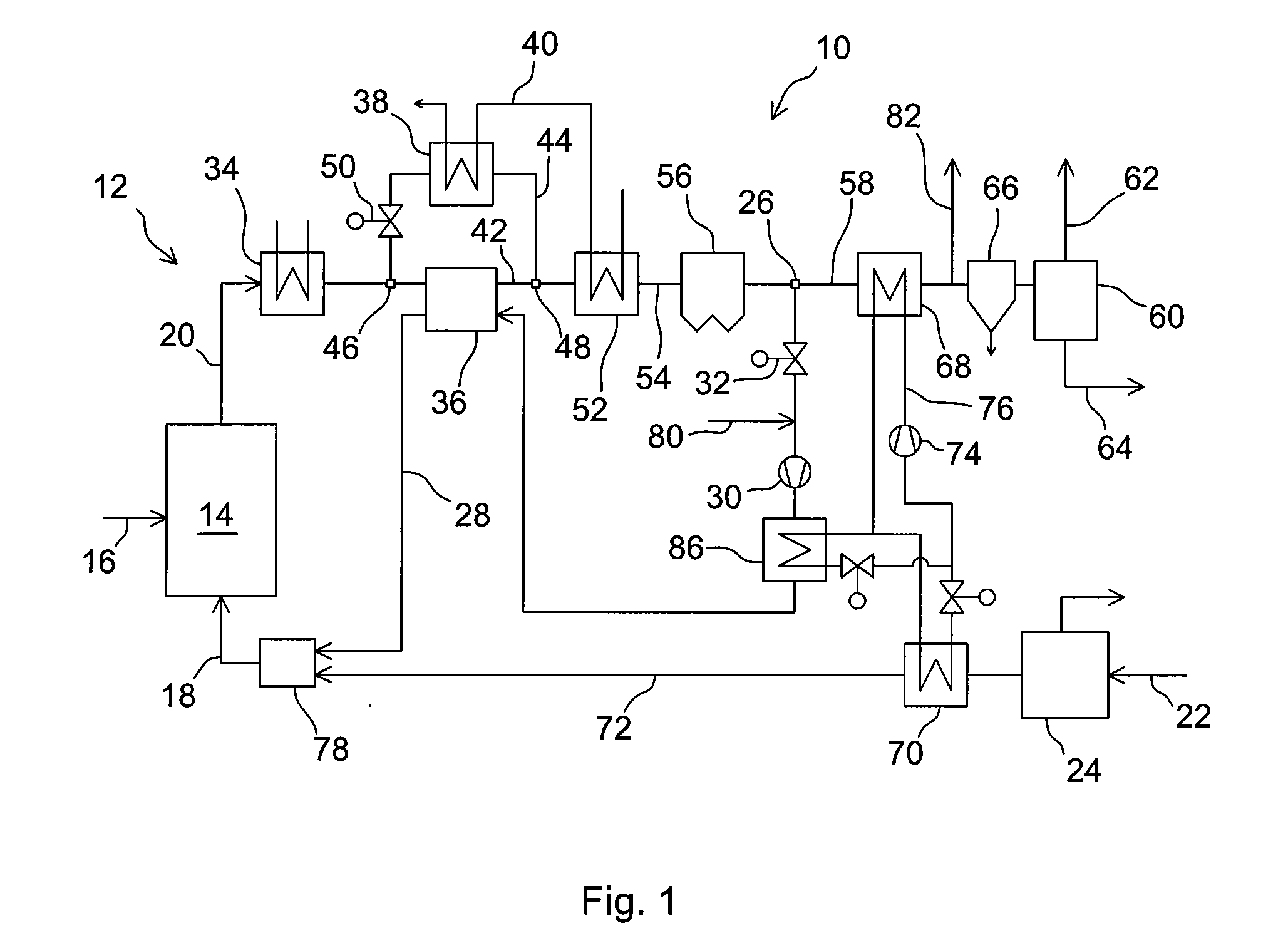

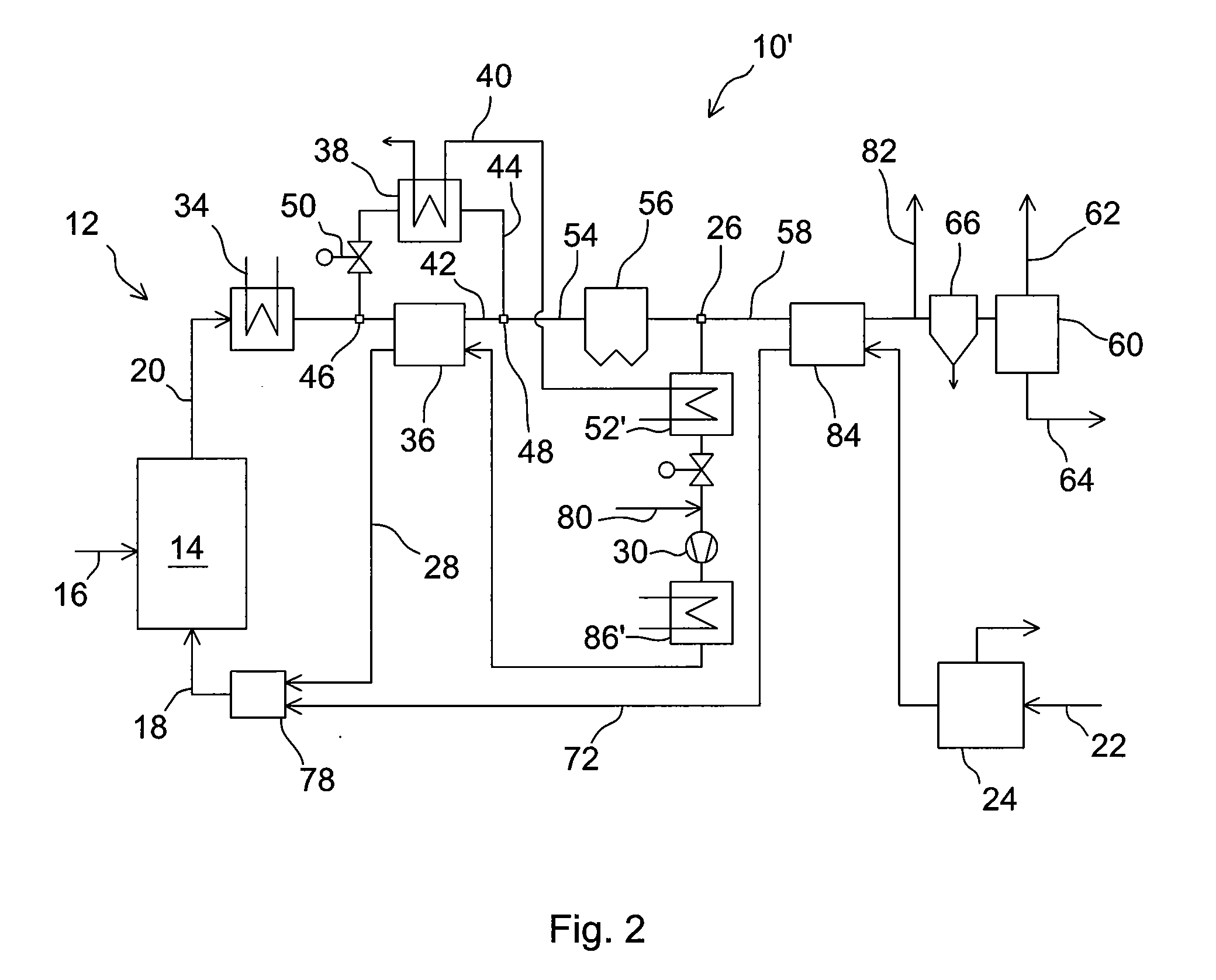

Method of and System For Generating Power By Oxyfuel Combustion

InactiveUS20090297993A1Increase temperatureEasy to switchExhaust apparatusGas turbine plantsCombustion systemExhaust fumes

An oxyfuel combustion system for generating power that includes a furnace for combusting carbonaceous fuel and substantially pure oxygen to produce exhaust gas including mainly carbon dioxide and water. An exhaust gas channel system discharges the exhaust gas from the furnace. The exhaust gas channel system has an upstream channel, an outlet channel and a gas recycling channel. The upstream channel recycles a recycling portion of the exhaust gas through the recycling channel to the furnace, and conveys an end portion of the exhaust gas through the outlet channel for final processing. The upstream channel is divided between a first divider piece and a connecting piece into a first exhaust gas channel portion and a second exhaust gas channel portion. A gas-gas heat exchanger arranged in the first exhaust gas channel portion transfers heat from exhaust gas in the first exhaust gas channel portion to gas in the gas recycling channel. A first economizer arranged in the second exhaust gas channel portion transfers heat from exhaust gas in the second exhaust gas channel portion to a flow of feedwater in a feedwater line, and a second economizer arranged in the exhaust gas channel system downstream of the connecting piece transfers heat from gas in the exhaust gas channel system to the flow of feedwater in the feedwater line.

Owner:FOSTER WHEELER ENERGIA OY

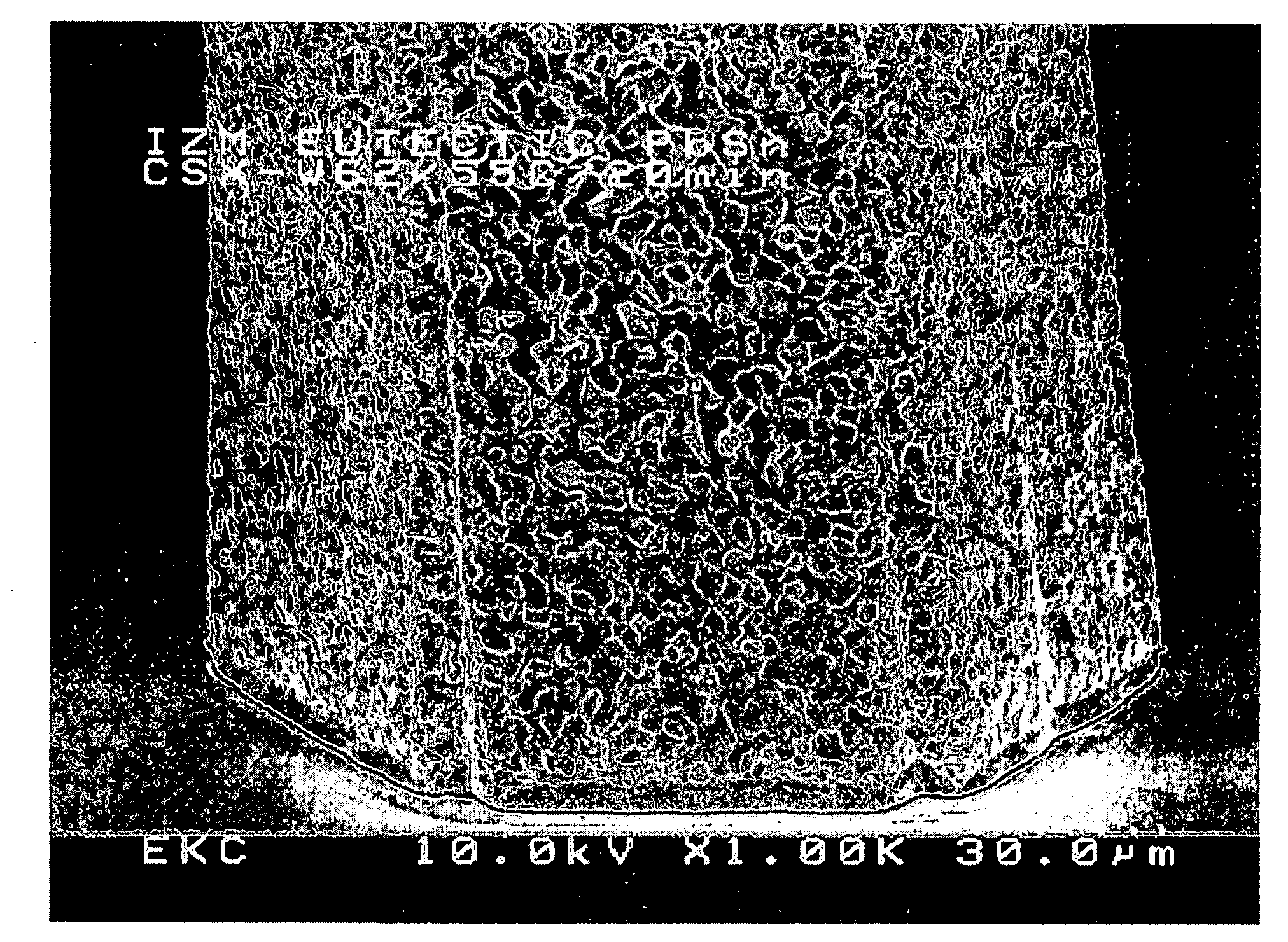

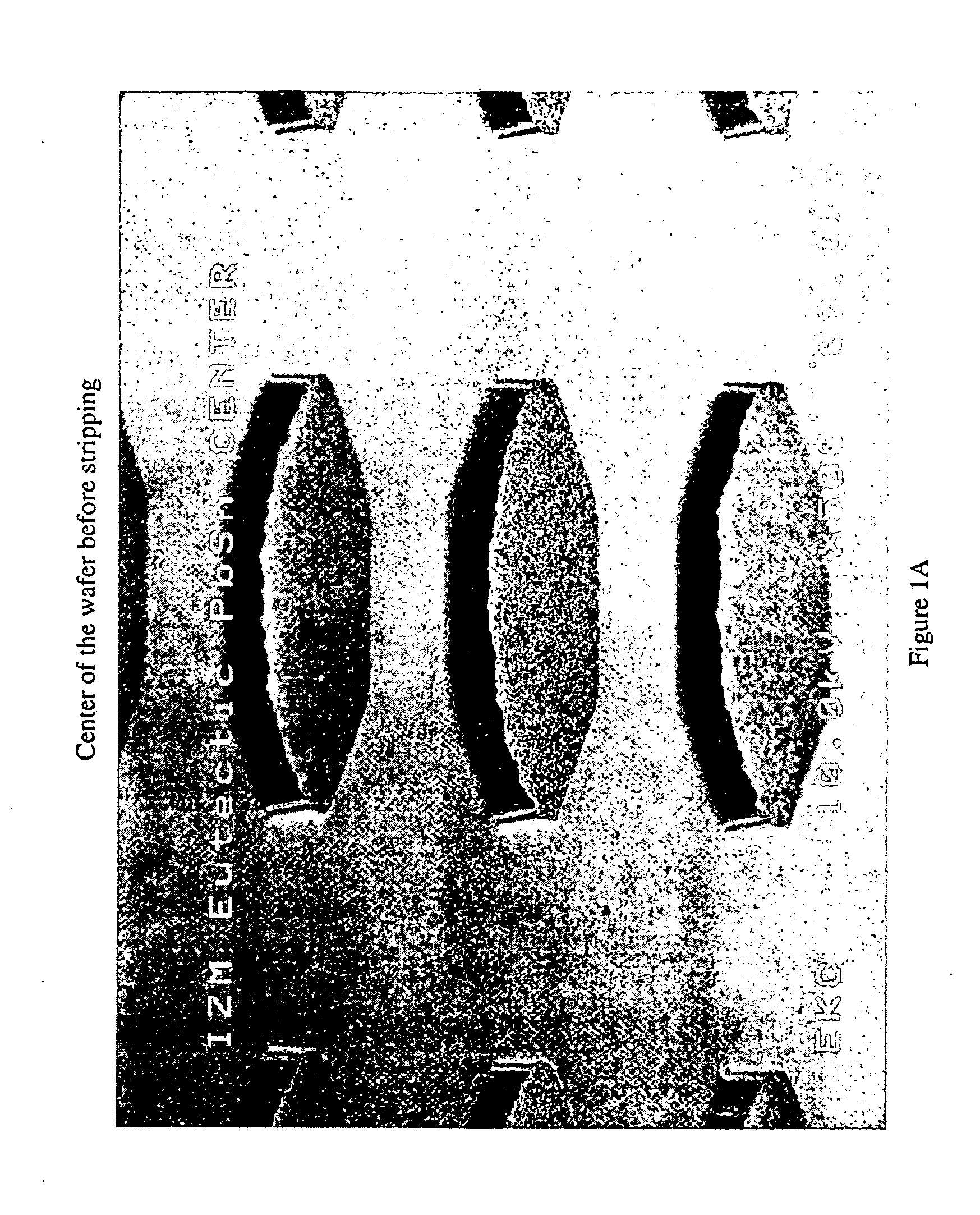

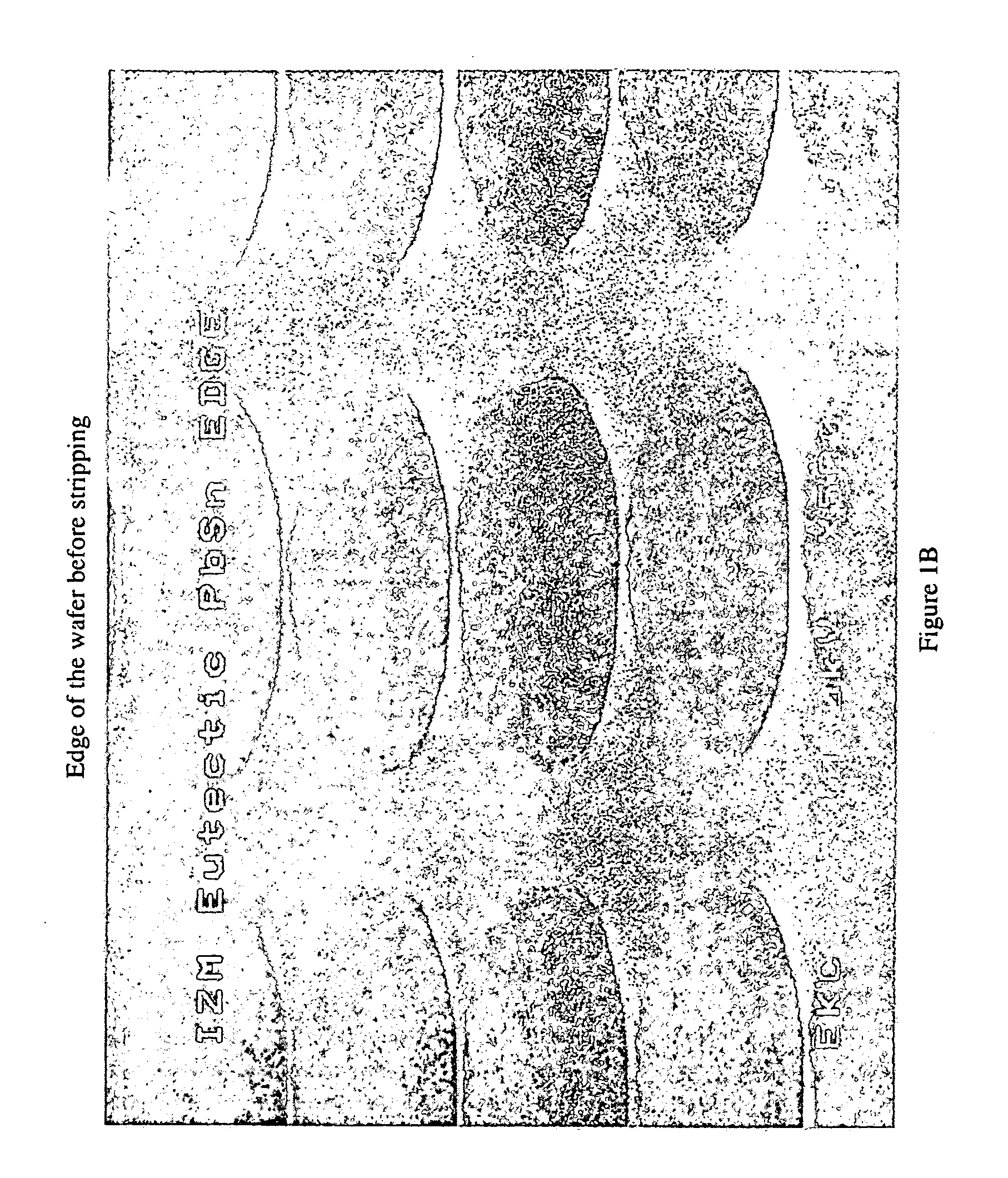

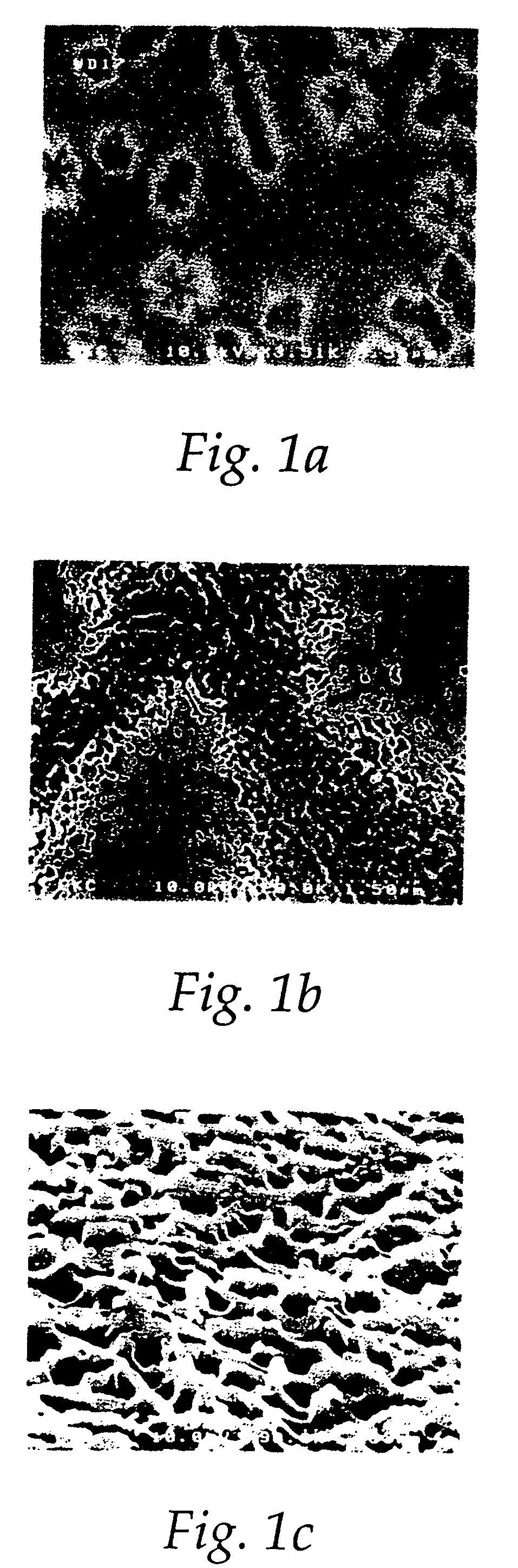

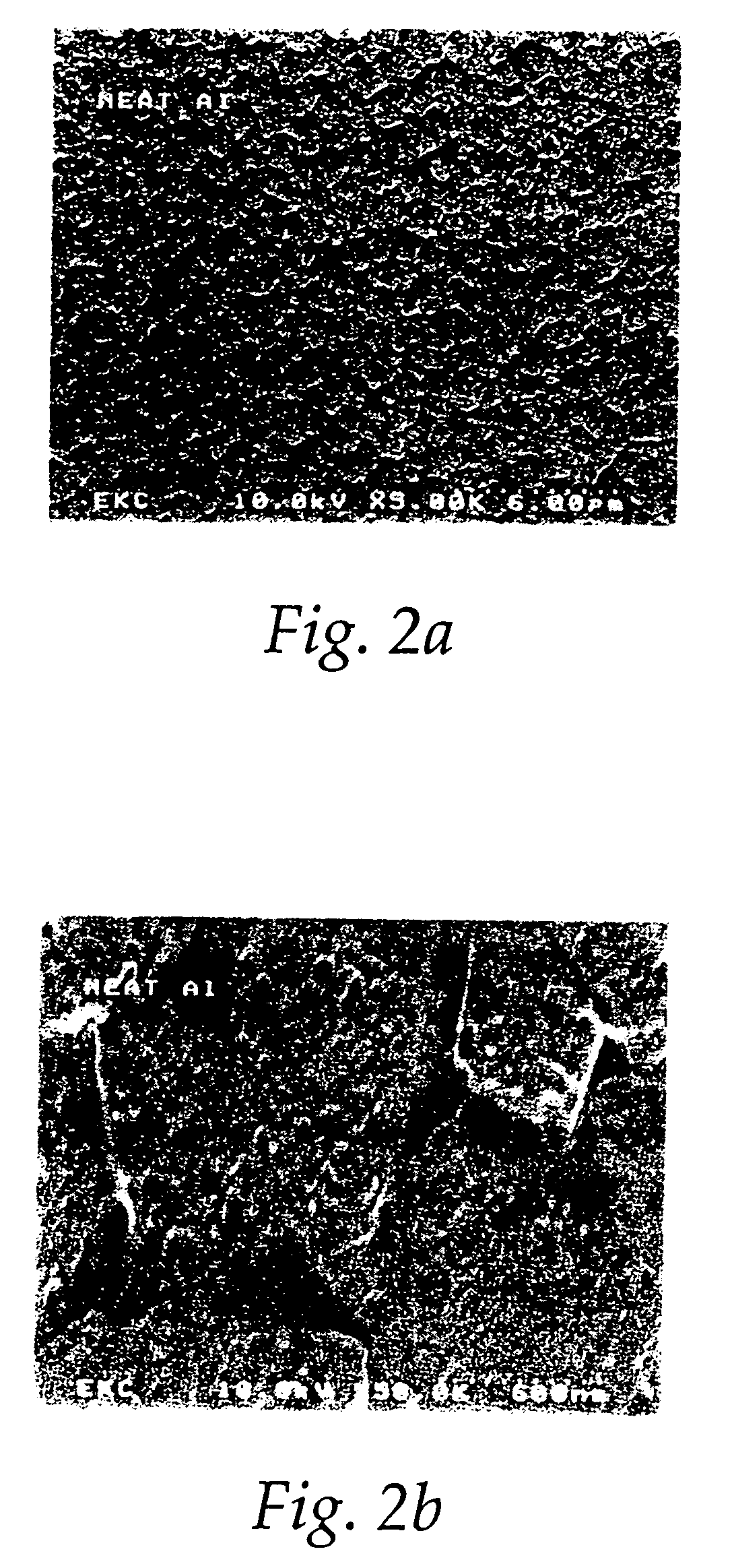

Compounds for Photoresist Stripping

InactiveUS20090111726A1Enhanced cleaning actionIncrease cleaning capacityPhotosensitive material processingOrganic solventAmmonium compounds

A composition for removing undesired matter from a substrate, the composition comprising hydroxylamine or a hydroxylamine derivative, a quaternary ammonium compound and at least one polar organic solvent. The composition is capable of removing photoresist from wafer level packaging and solder bumping applications.

Owner:EKC TECH

Battery pack

InactiveUS20130143081A1Easy to operateEfficiently drawnCell temperature controlPropulsion by batteries/cellsEngineeringBattery pack

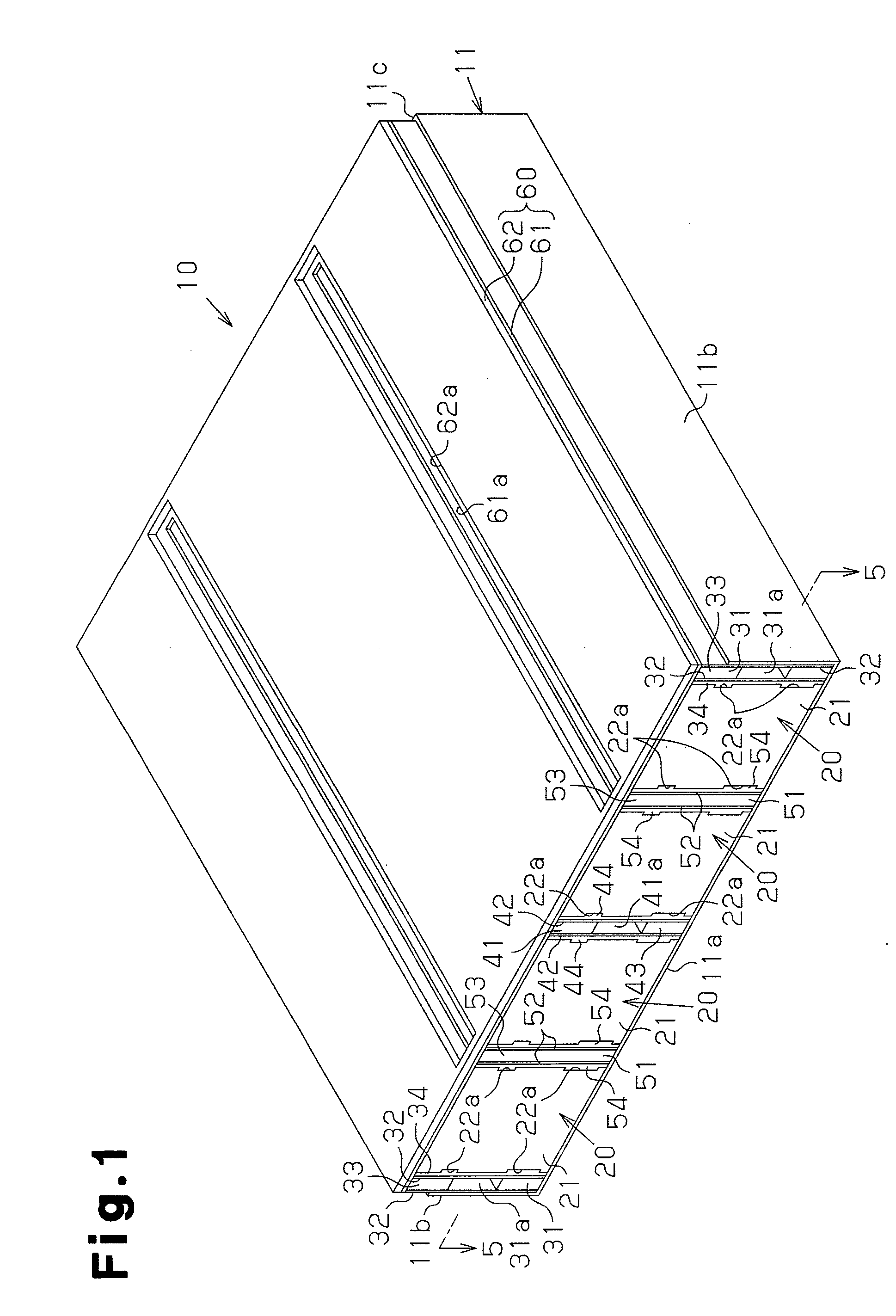

A battery pack includes a plurality of battery cases and passage formation members. Each battery case has an inlet for sucking in operating fluid and an outlet for discharging operating fluid. The passage formation members extend along the direction in which the plurality of battery cases are arranged in parallel, and are arranged so as to face the inlets. The passage formation members include a flow passage, a plurality of introduction openings, a closed section, and an adhesion member. The flow passage allows operating fluid to circulate along the direction in which the battery cases are arranged in parallel. The introduction openings introduce operating fluid from the flow passage to each of the battery case inlets. The closed section is arranged between adjacent introduction openings, and blocks off the spillage of operating fluid from the flow passage toward the intervals between battery cases that are adjacent in the parallel-arrangement direction.

Owner:TOYOTA IND CORP

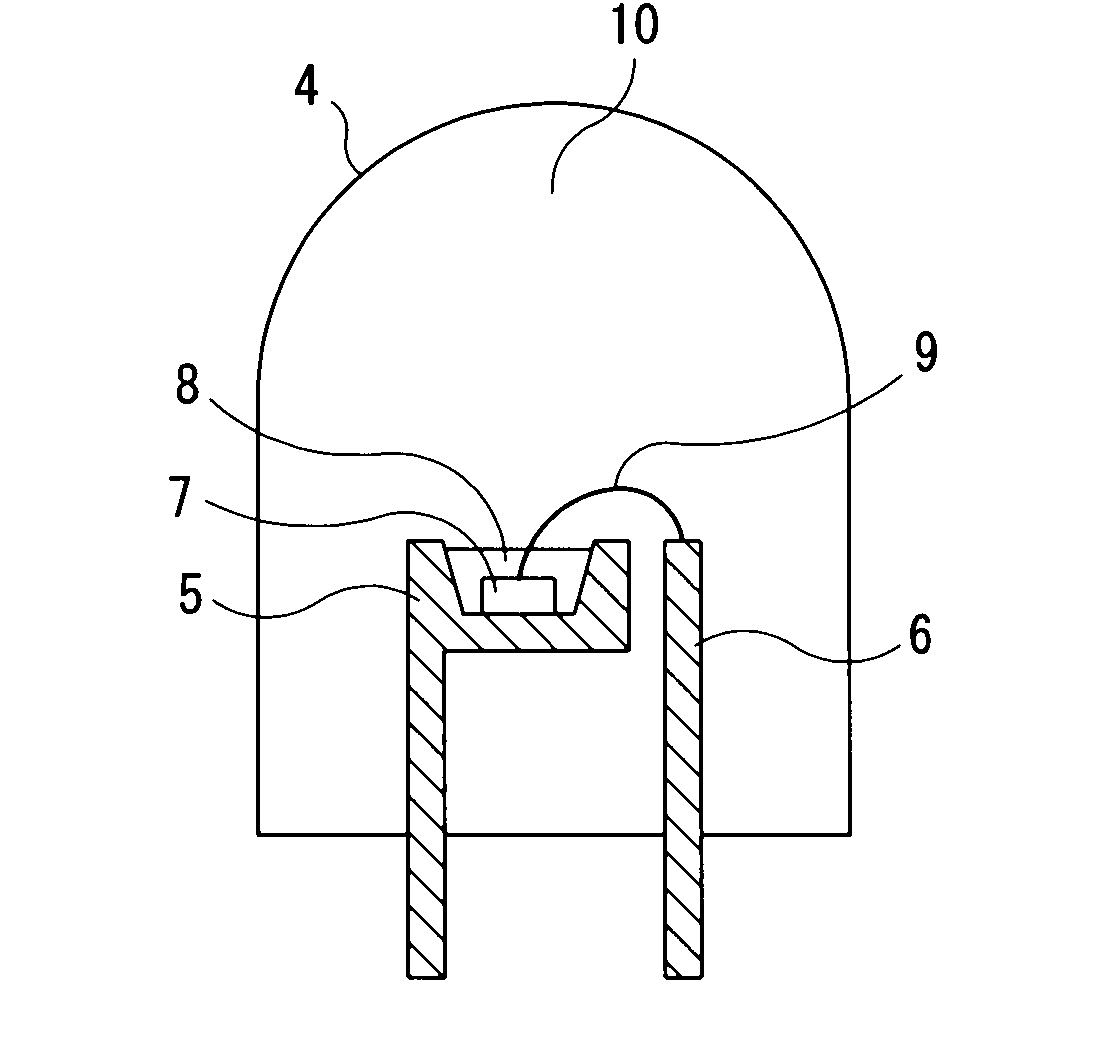

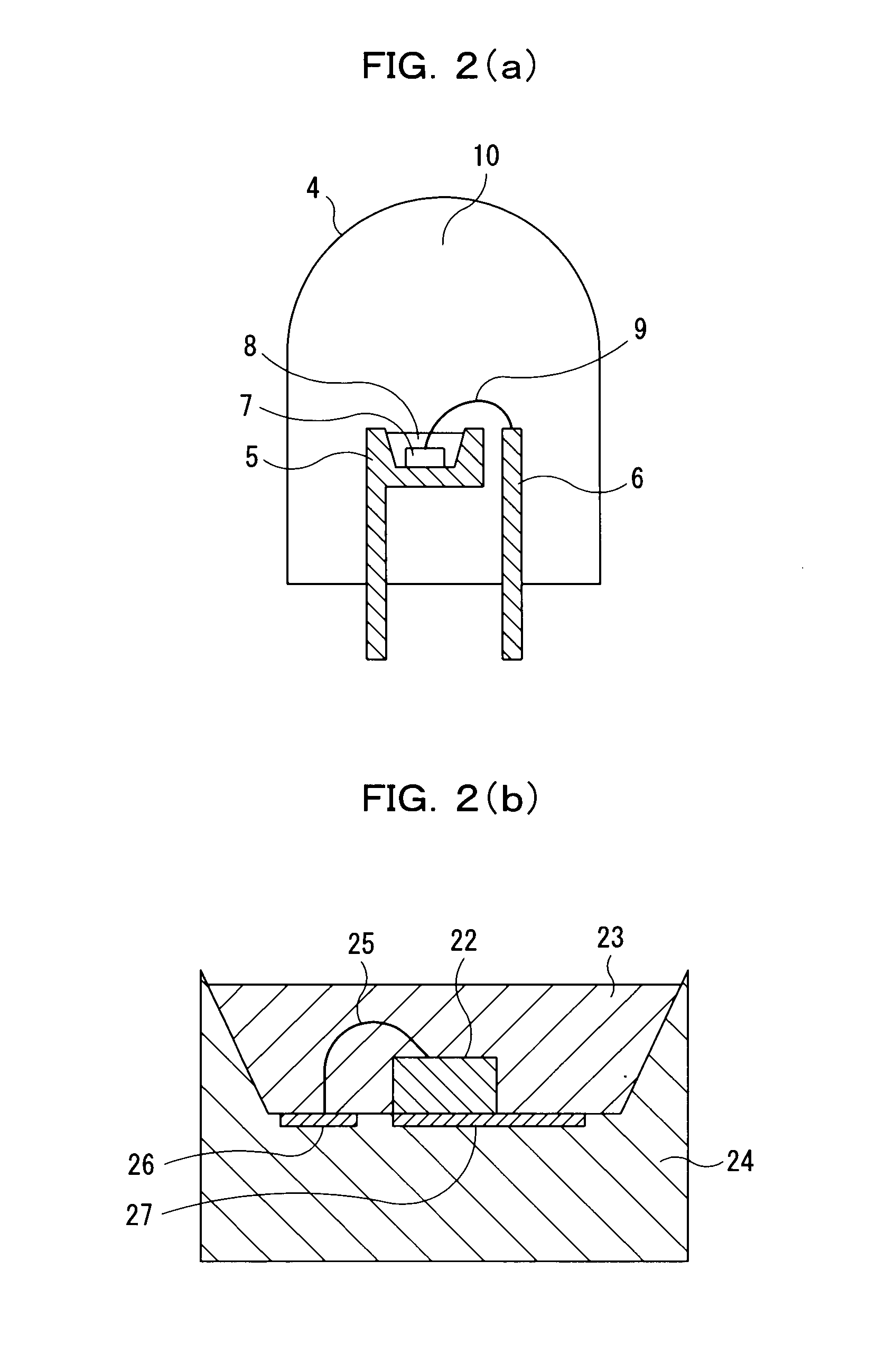

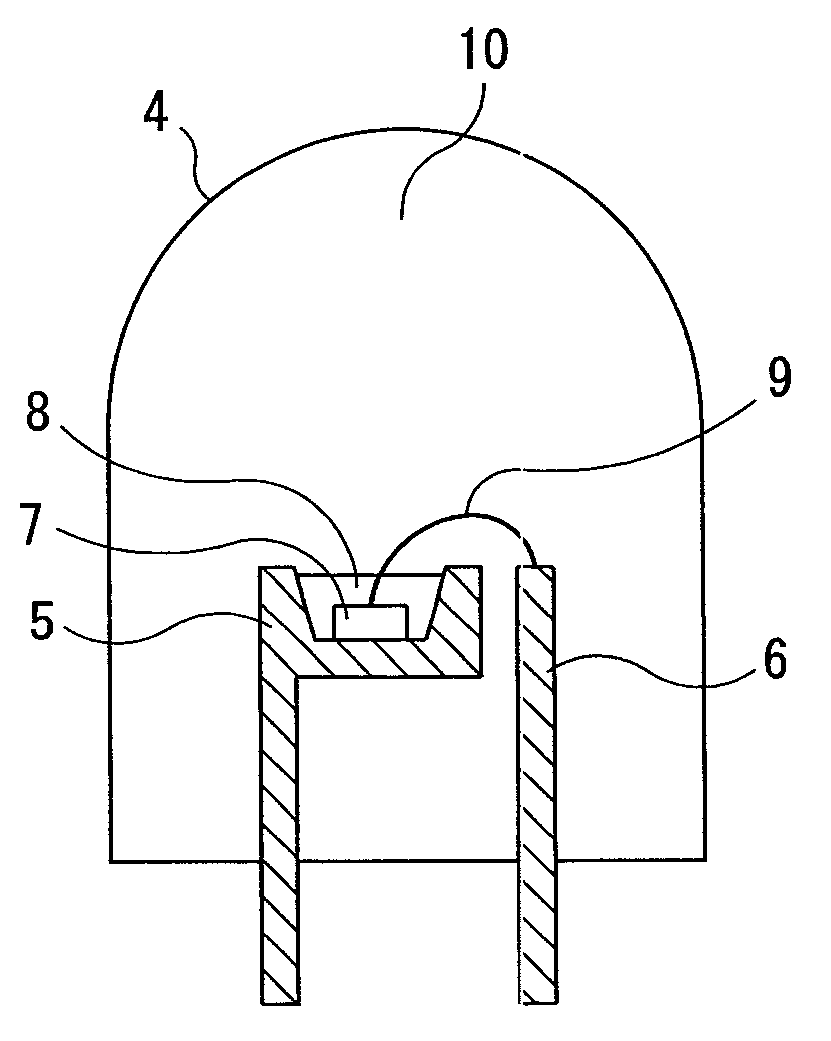

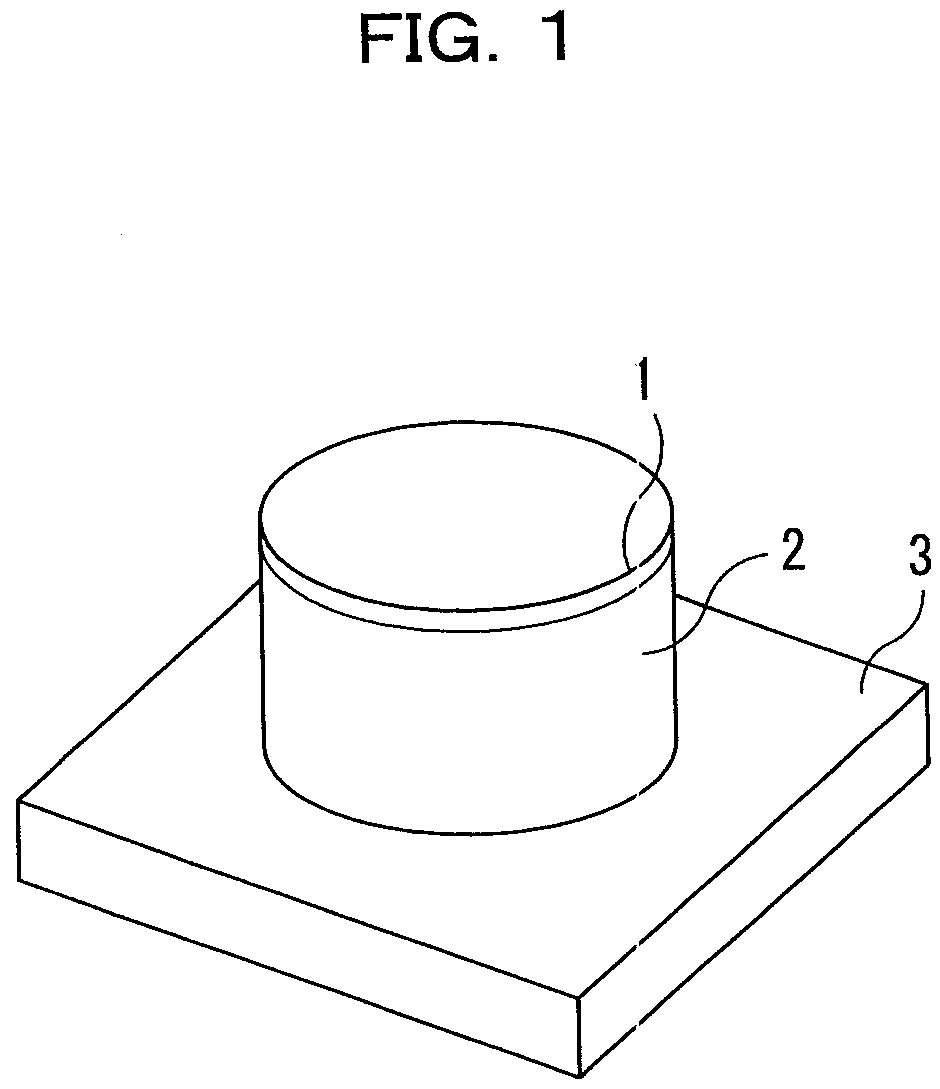

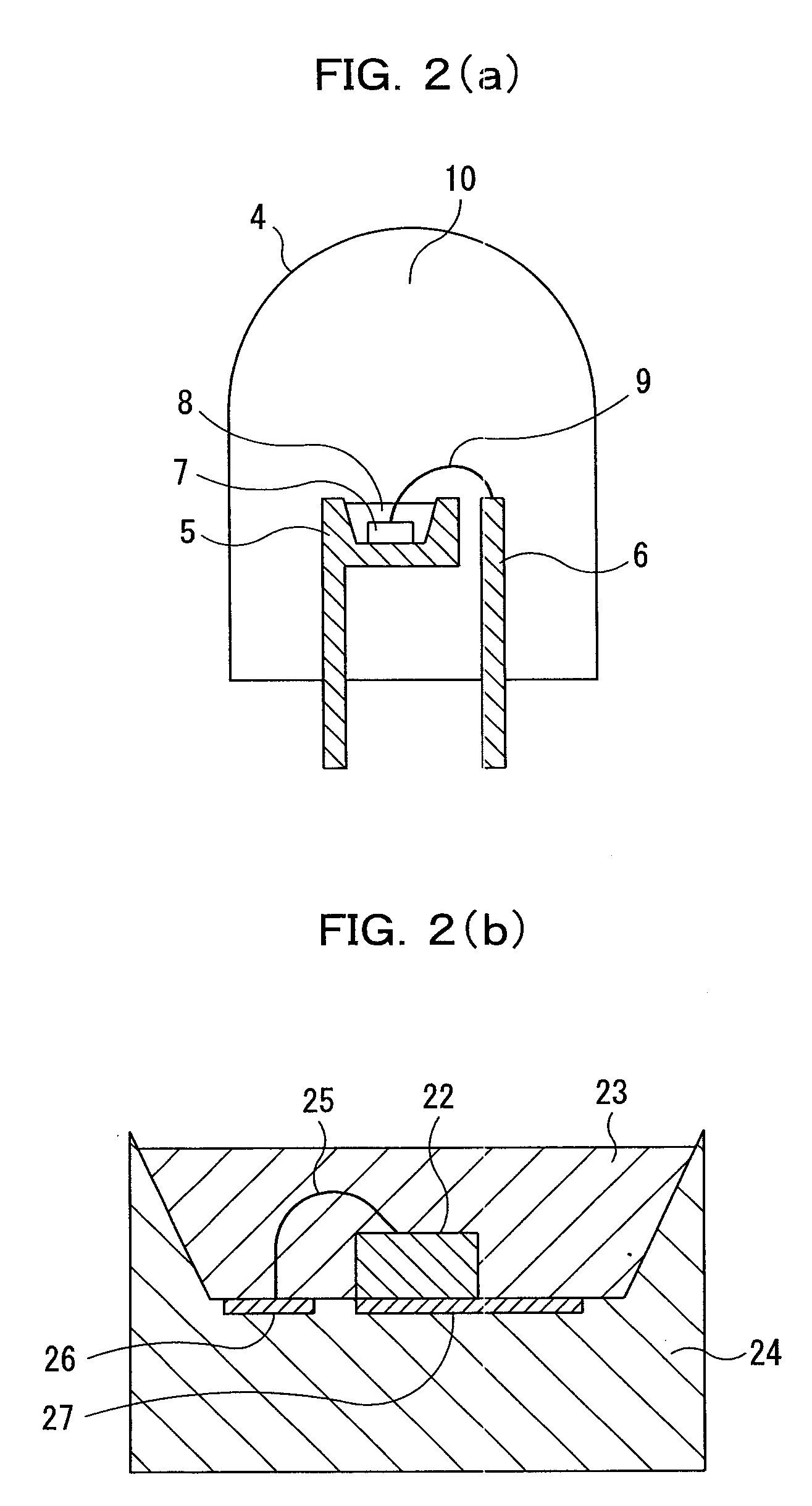

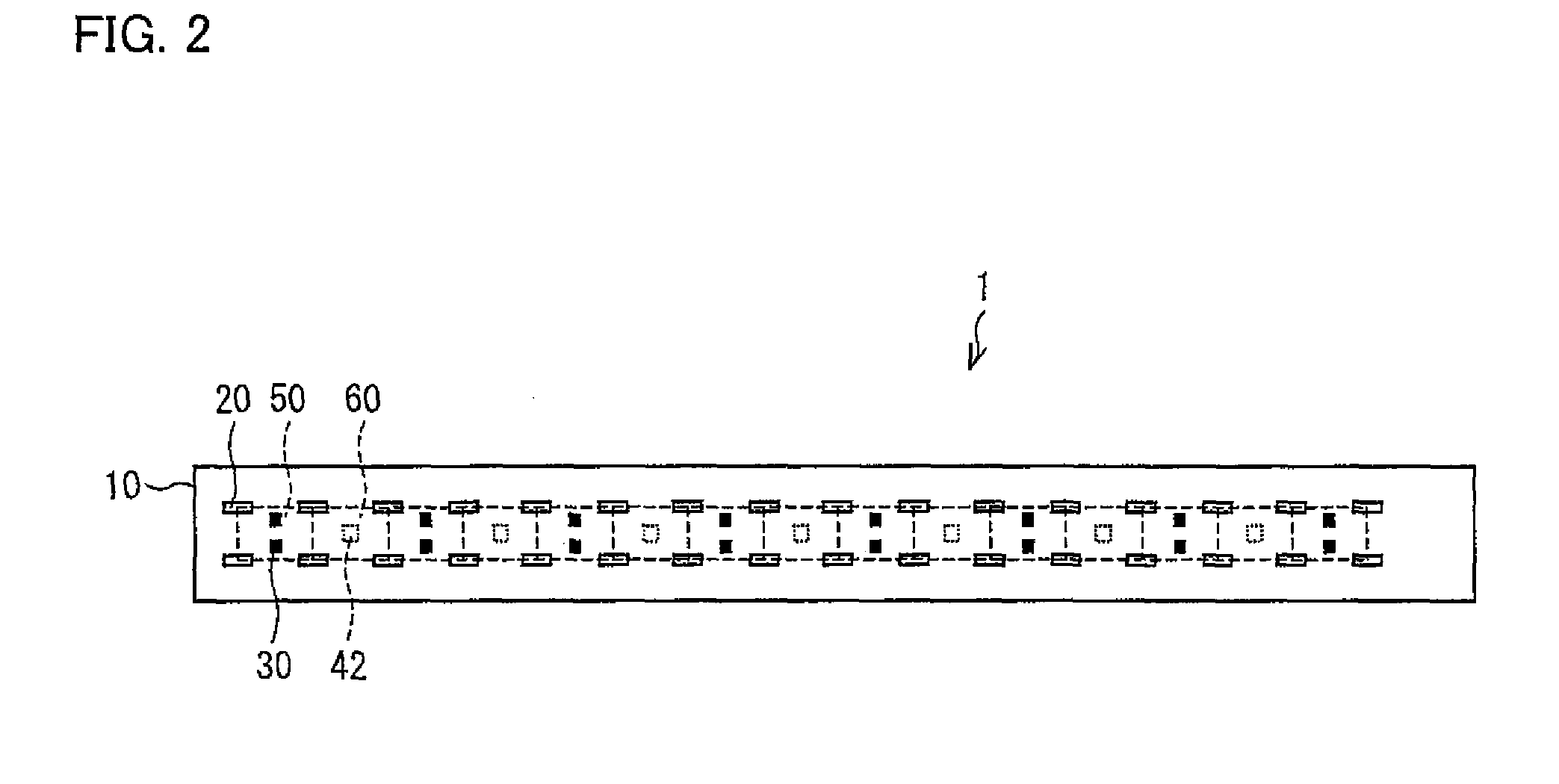

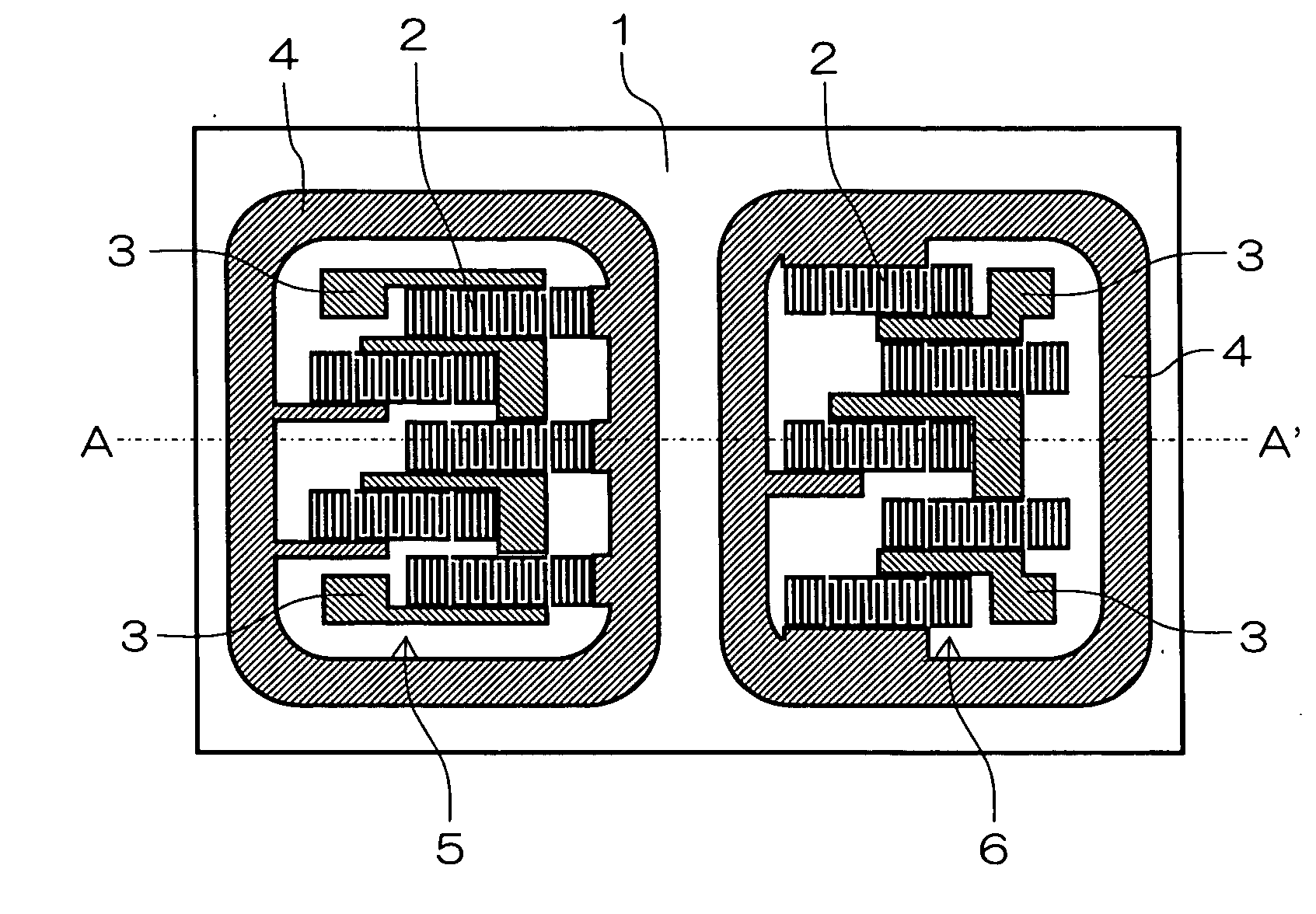

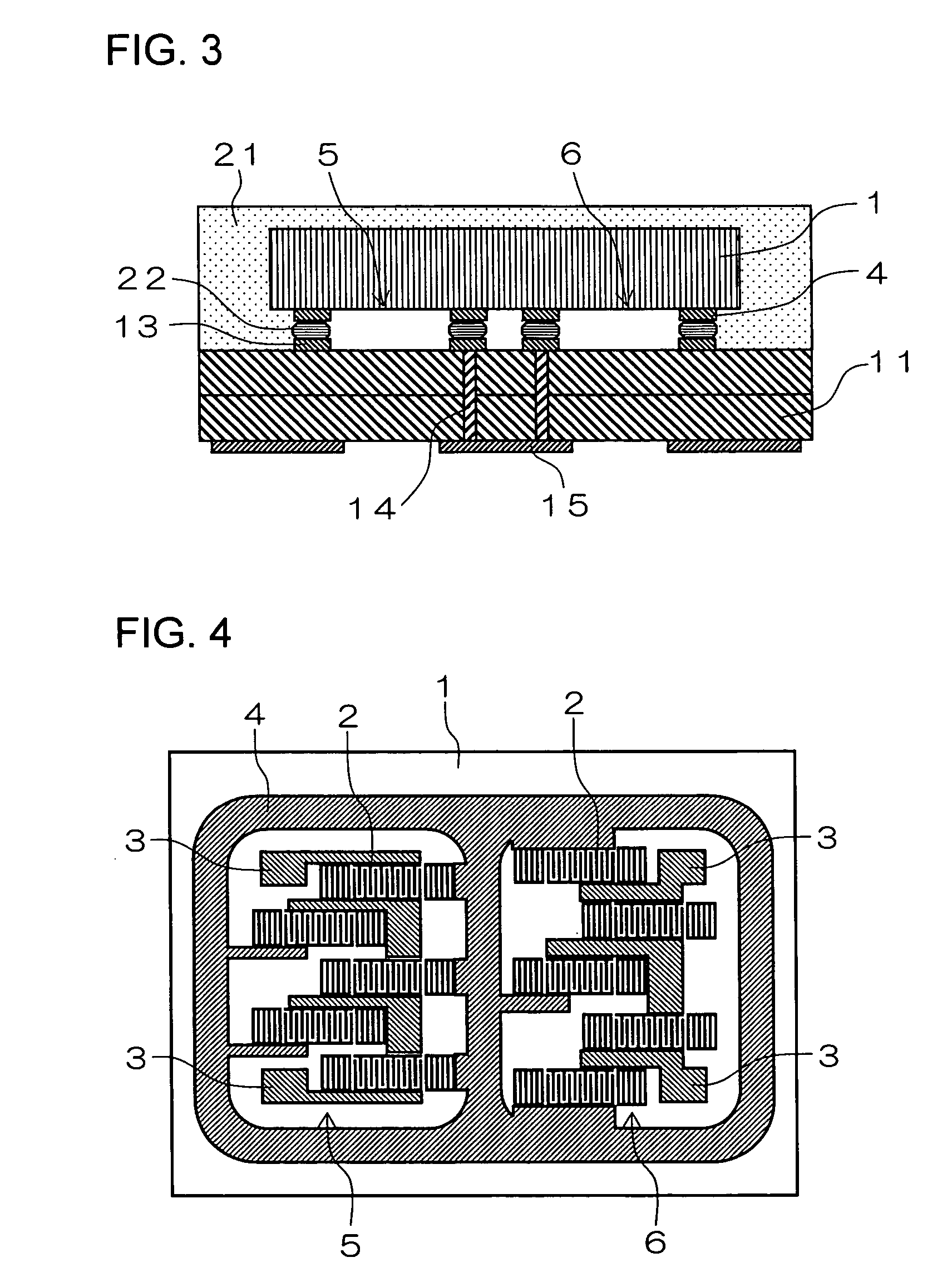

Surface acoustic wave apparatus and communications equipment

InactiveUS20050285700A1Efficient releaseEffective temperatureImpedence networksPiezoelectric/electrostrictive/magnetostrictive devicesElectrical conductorAcoustic wave

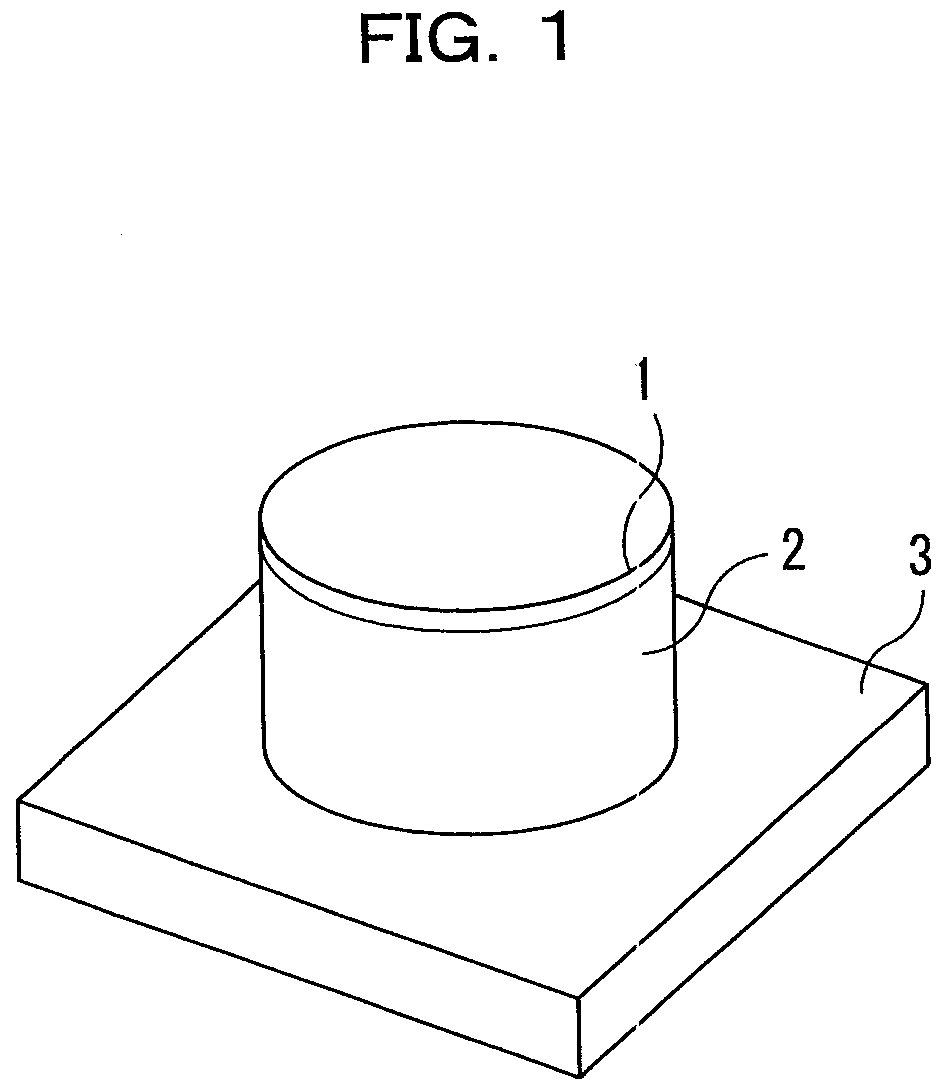

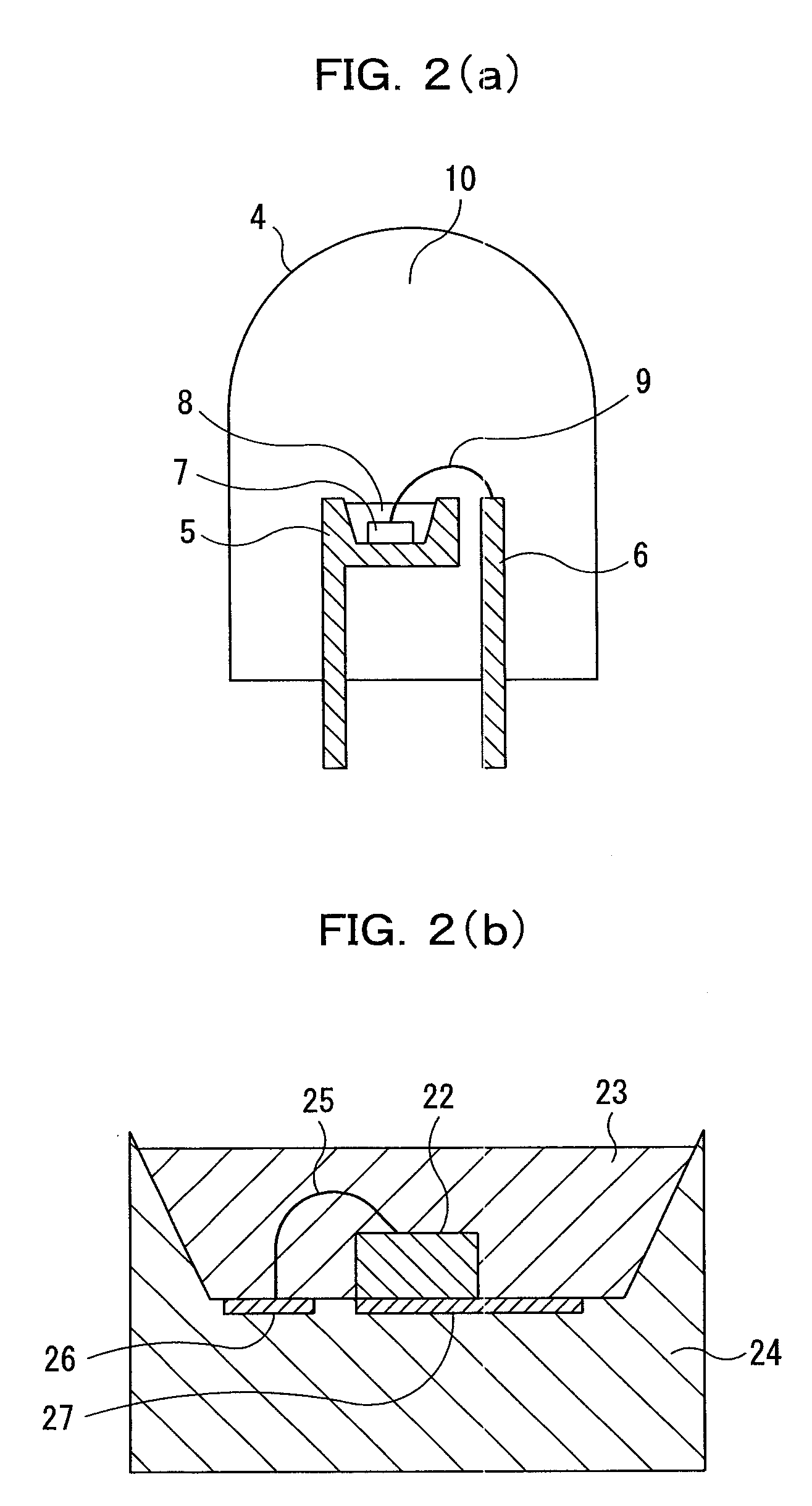

An IDT electrode 2 and an electrode pad 3 are formed on one principal face of a piezoelectric substrate 1 and a circular electrode 4 is formed so as to surround these components. The circular electrode 4 is connected to a radiating conductor 15 formed on a bottom face of a circuit board 11 through a via conductor 14 formed within the circuit board 11. Thus, since heat generated in the IDT electrode 2 is easy to be released to the outside through the circular electrode 4, the via conductor 14 and the radiating conductor 15, adverse effects due to the heat can be prevented, thereby improving high power durability.

Owner:KYOCERA CORP

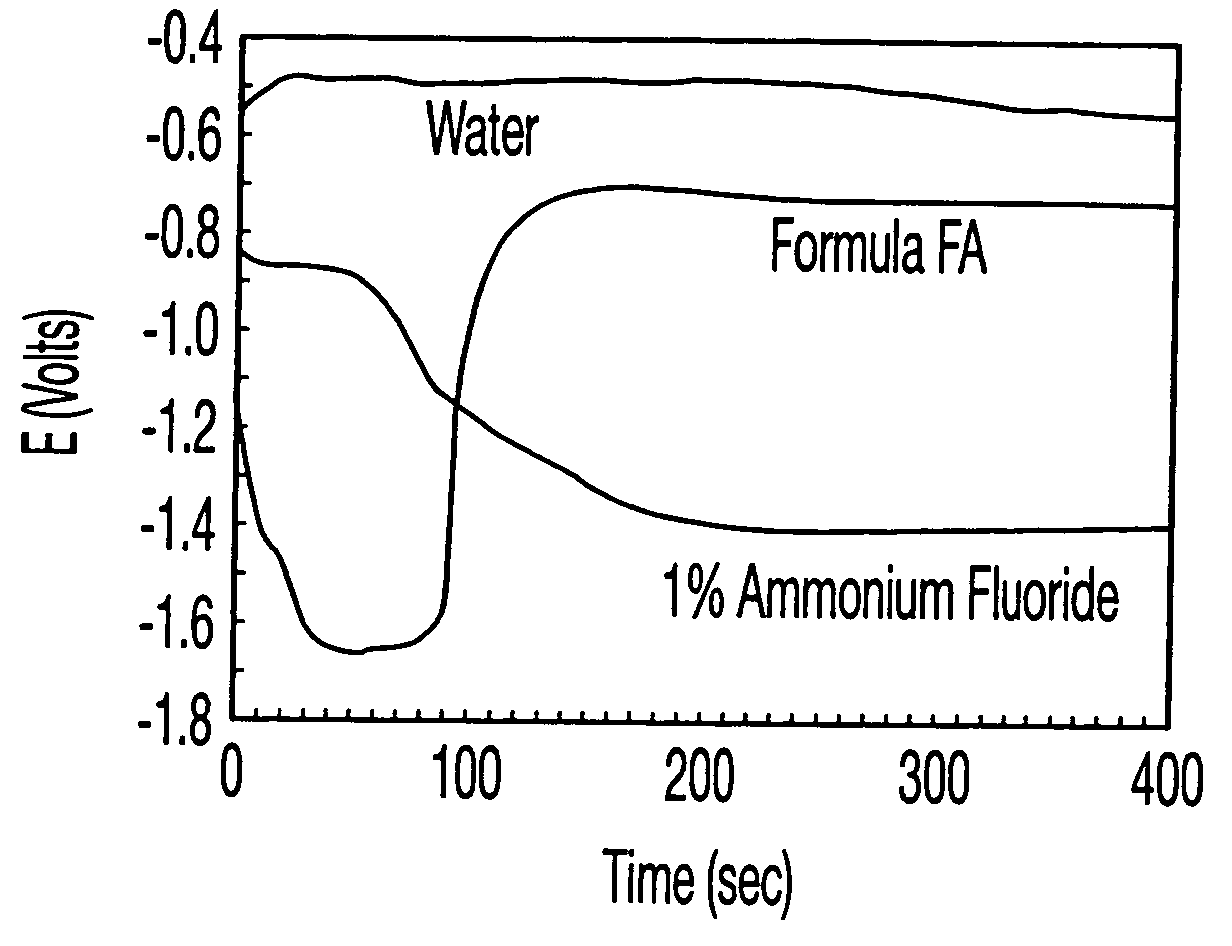

Forming a passivating aluminum fluoride layer and removing same for use in semiconductor manufacture

InactiveUS20060000492A1Enhance clean action and cleaning capabilityEffective temperatureDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSolventFluoride salt

A composition for the cleaning of residues from substrates can contain from about 0.01 percent by weight to about 5 percent by weight of one or more fluoride compounds, from about 20 percent by weight to about 50 percent by weight water, from about 20 percent by weight to about 80 percent by weight of an organic amide solvent and from 0 to about 50 weight percent of an organic sulfoxide solvent. The composition can have a pH between about 7 and about 10, alternately from greater than 8 to about 10. Additionally, the composition optionally can contain corrosion inhibitors, chelating agents, surfactants, acids, and / or bases. In use of the composition, a substrate can advantageously be contacted with the composition for a time and at a temperature that permits cleaning of the substrate.

Owner:EKC TECH

Constant temperature liquid bath

ActiveUS20050086947A1Increase speedEffective regulationContainer filling methodsDomestic refrigeratorsLiquid temperatureEngineering

The present invention provides a constant temperature liquid bath using a thermo-module in which even if an article whose temperature is to be controlled exists in the bath, heat is efficiently exchanged between a heat source and liquid, and the temperature of the liquid is efficiently adjusted to a constant value, and the temperature can easily and swiftly be adjusted. A constant temperature liquid bath which adjusts temperature of liquid in the bath by a heat supply apparatus having a thermo-module that adjusts temperature by Peltier effect comprises an outer bath for storing the liquid, an inner bath disposed in the outer bath through a gap, and provided at its sidewall with holes which the liquid flows into the inner bath from the outer bath and provided with at a central portion of its bottom with an opening, and an agitator which introduces upward the liquid which flows from the opening of the bottom of the inner bath between sidewalls of the inner and outer baths by means of a rotor blade disposed on a central portion of a bottom between the outer bath and the inner bath, the thermo-module is mounted on an outer surface of the sidewall of the outer bath, the temperature of the liquid flowing between the inner and outer baths is controlled to a set value.

Owner:SMC CORP

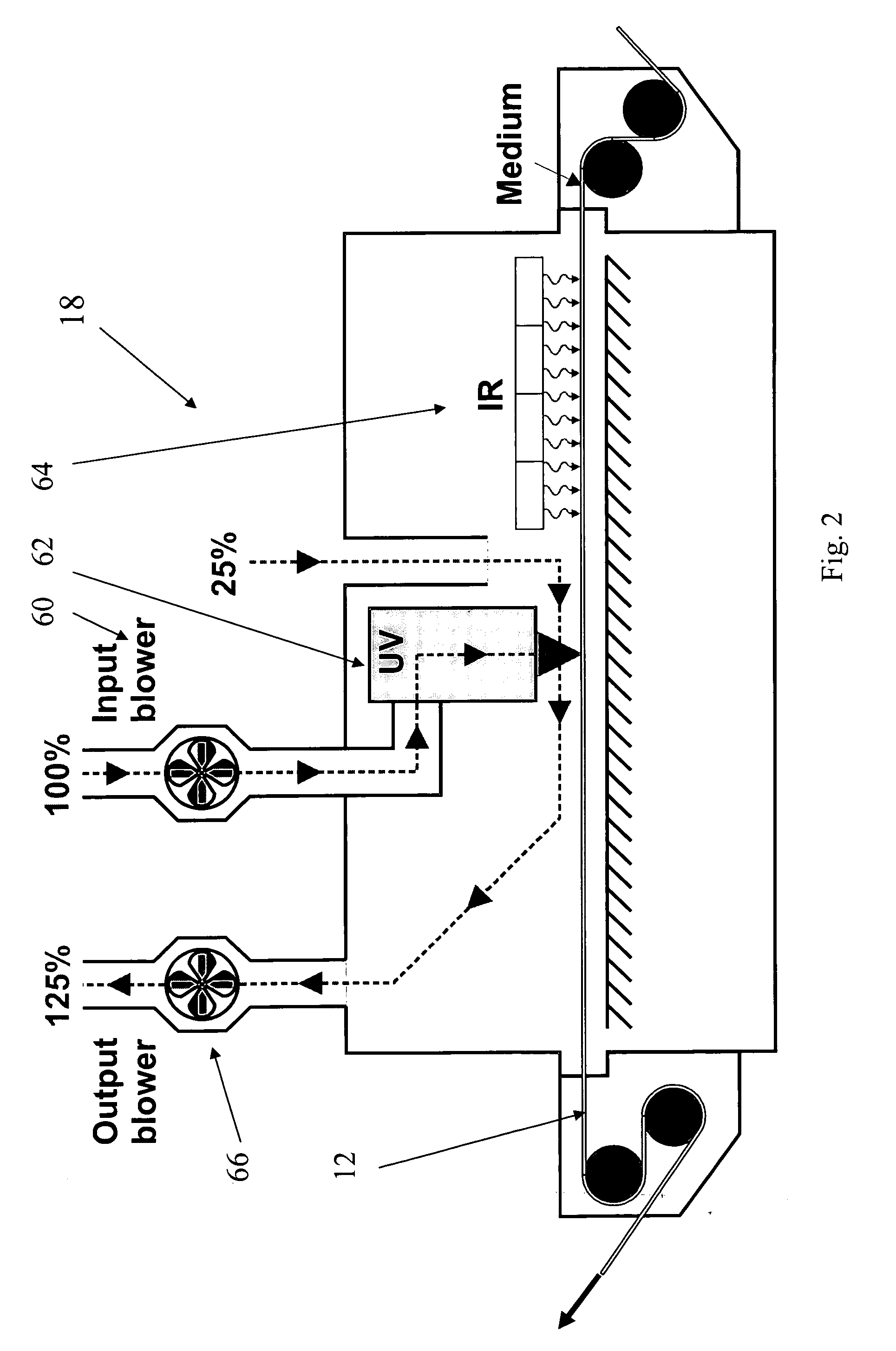

Rounded radiation curable toner

ActiveUS20080176160A1Improved transfer efficiency lower fuser temperatureImprove printing qualityDevelopersElectrographic process apparatusCharge controlEngineering

The present invention provides dry toner particles comprising at least a radiation curable resin, and a colouring agent, wherein the circularity of the toner particles is between 0.95 and 0.99 and a charge control agent in a concentration between 0.025% and 1.0% by weight is present preferably as an external additive.The toners of this invention are useful for printing any substrate and for use in any form of printing or marking device.

Owner:XEIKON MFG NV +1

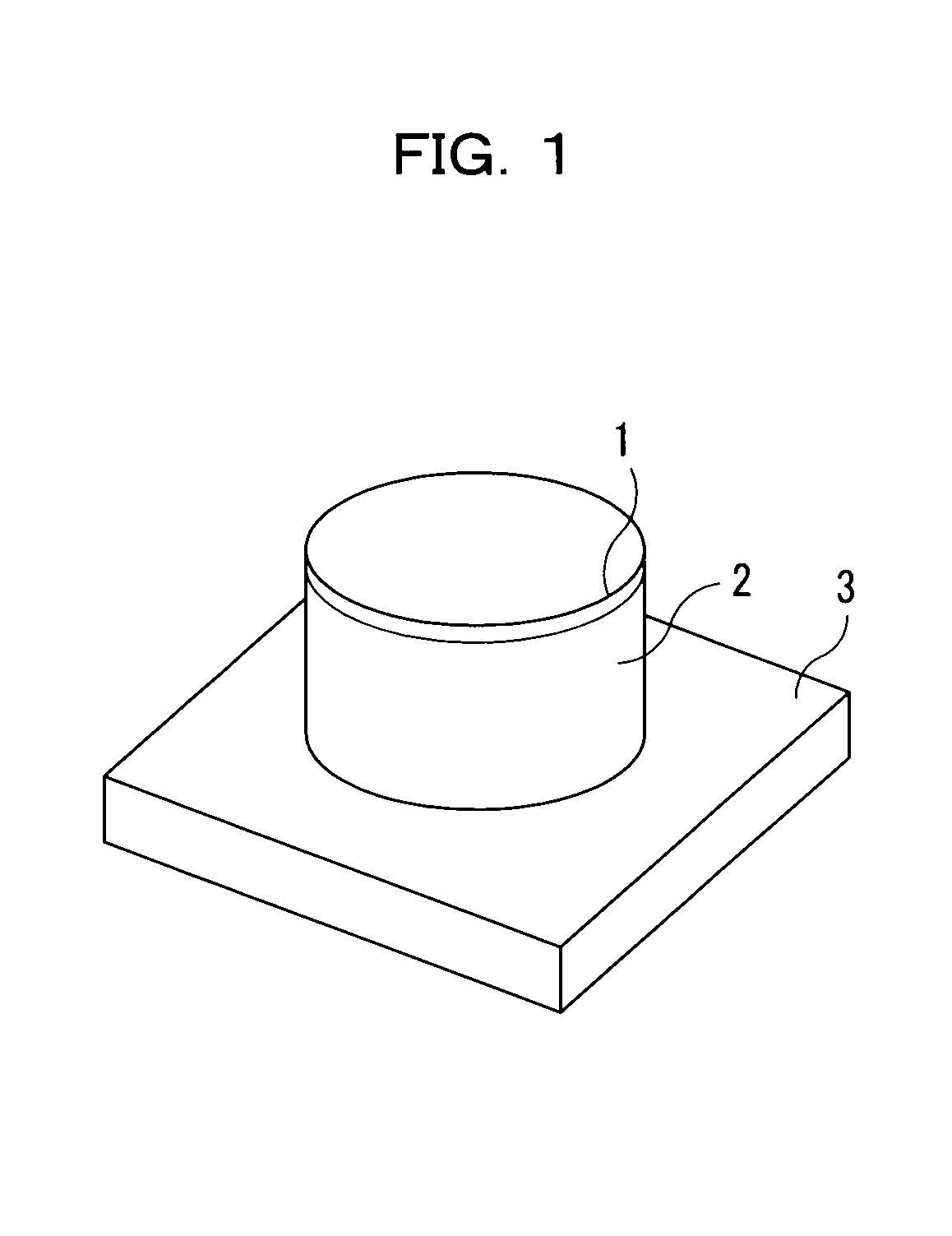

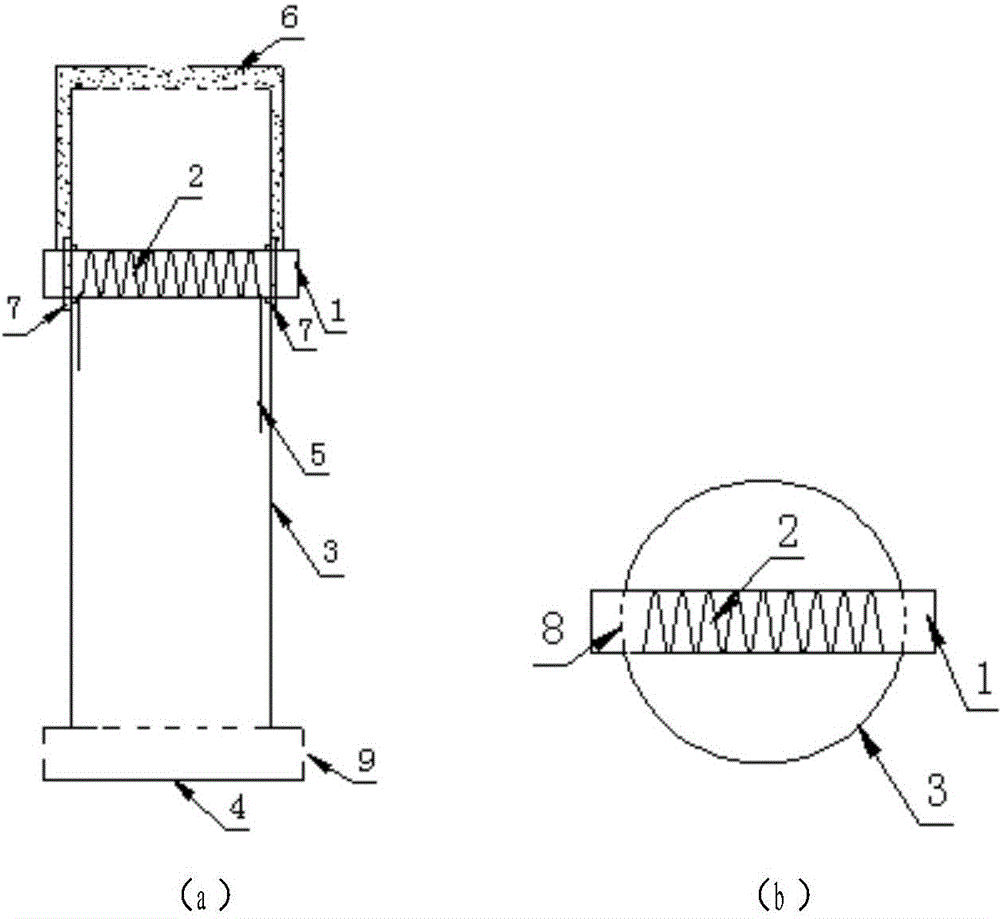

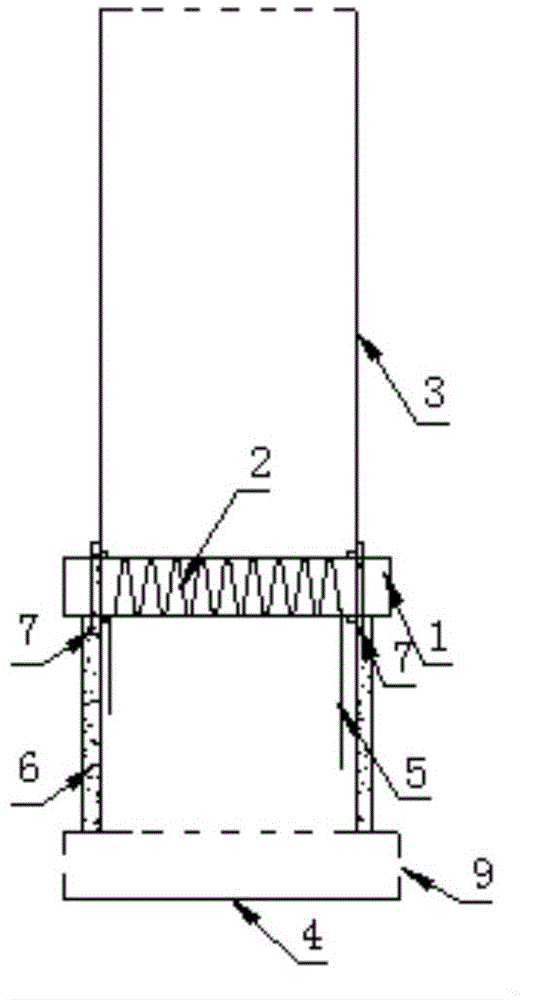

Porous ceramic atomization heating component of electronic cigarette

ActiveCN104886785APrevention of dry burningAvoid disadvantages such as burnt smellTobacco devicesElectrical resistance and conductanceTar

The invention discloses a porous ceramic atomization heating component of electronic cigarette. The porous ceramic atomization heating component of the electronic cigarette comprises a ceramic rod, a heating wire, an atomization pipe and a pedestal, the atomization pipe is vertically arranged on the pedestal, a notch is formed in the top or bottom of the atomization pipe, the ceramic rod is transversely arranged in the notch in the top or bottom, wherein the ceramic rod is made of oleophilic modified porous ceramic, the heating wire winds the surface of the ceramic rod, the heating wire is connected with a battery through a lead, a hollow sealing sleeve and a sealing ring are arranged at the notch of the atomization pipe, and an air hole communicated with the outside is opened in the pedestal. The porous ceramic atomization heating component of the electronic cigarette is capable of avoiding the disadvantages of dry burning, burnt smell and the like of a fiber rope, the oleophilic modified high-porosity porous ceramic is capable of more quickly conducting tobacco tar, the atomized smoke amount is large, and meanwhile, the PTC alloy heating wire can change the resistance thereof along with the temperature change so as to effectively regulate the temperature, and the smoke quality is more stable.

Owner:HUBEI CHINA TOBACCO IND +1

Two-component composition

ActiveUS20170292050A1Reduce the smellHigh strengthPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsHeat resistanceRoom temperature

A two-component composition, containing at least one silane-group-containing polymer that is liquid at room temperature, at least one epoxide liquid resin, at least one polyetheramine, and at least one aminosilane or mercaptosilane. The composition has low odor, cures quickly and without blistering at room temperature, and, when cured, forms a tough elastic material of high strength, high adhesive force, and good thermal resistance that has no tendency toward yellowing or substrate discoloration. The composition is excellently suitable as a tough elastic adhesive for structural adhesive joints in the field of construction and in industrial production.

Owner:SIKA TECH AG

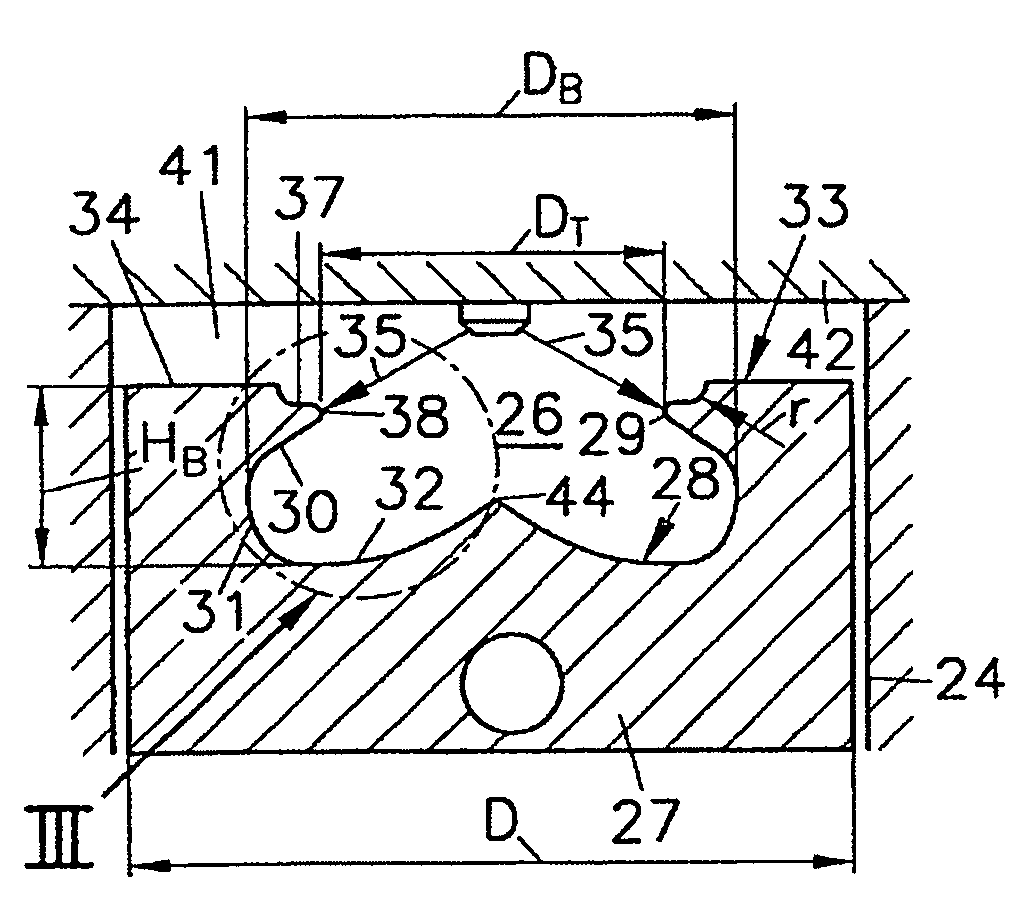

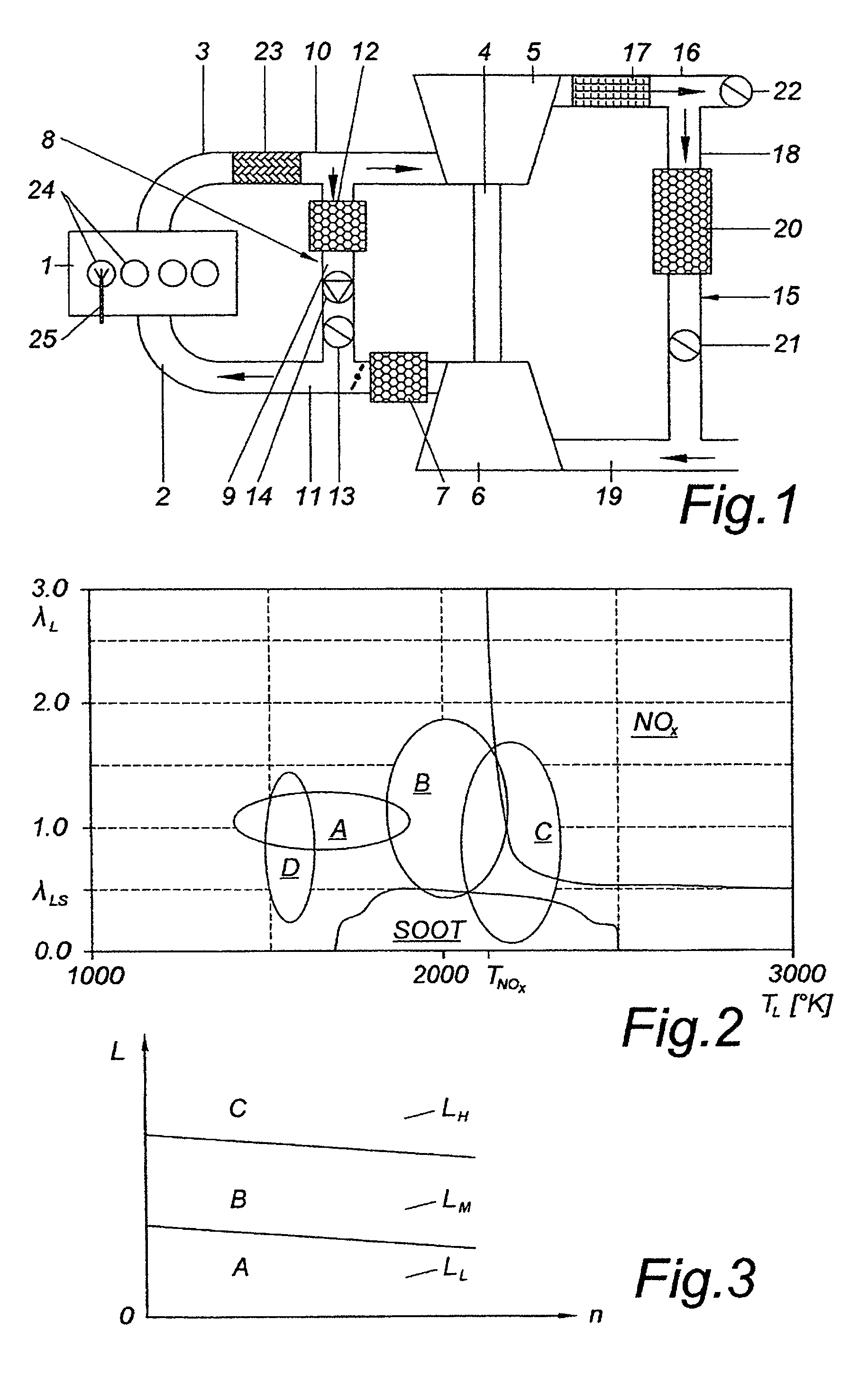

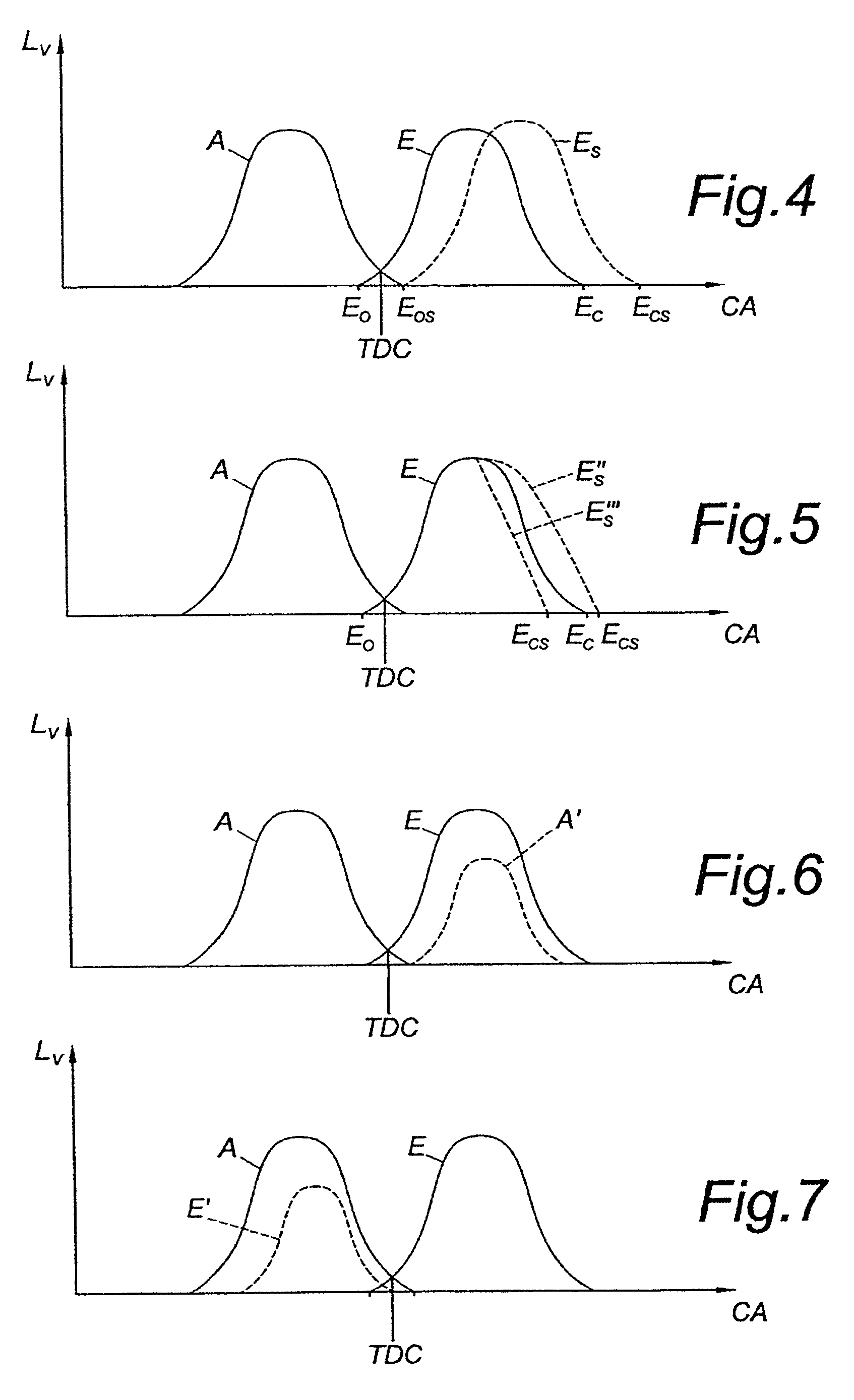

Method for operating an internal combustion engine

InactiveUS7415963B2Shorten injection timeEasy to igniteElectrical controlInternal combustion piston enginesNitrogen oxidesInternal combustion engine

The invention relates to a direct-injection internal combustion engine that is operated in a first operating range associated with the low part load, with largely homogeneous combustion of the mixture and subsequent injection. Said internal combustion engine is operated in a second operating range associated with the middle part load, with low-temperature combustion of the mixture. In this way, minimum nitrogen oxide and soot emissions and a high degree of efficiency can be achieved both in the lower part load region and up to the full load region.

Owner:AVL LIST GMBH

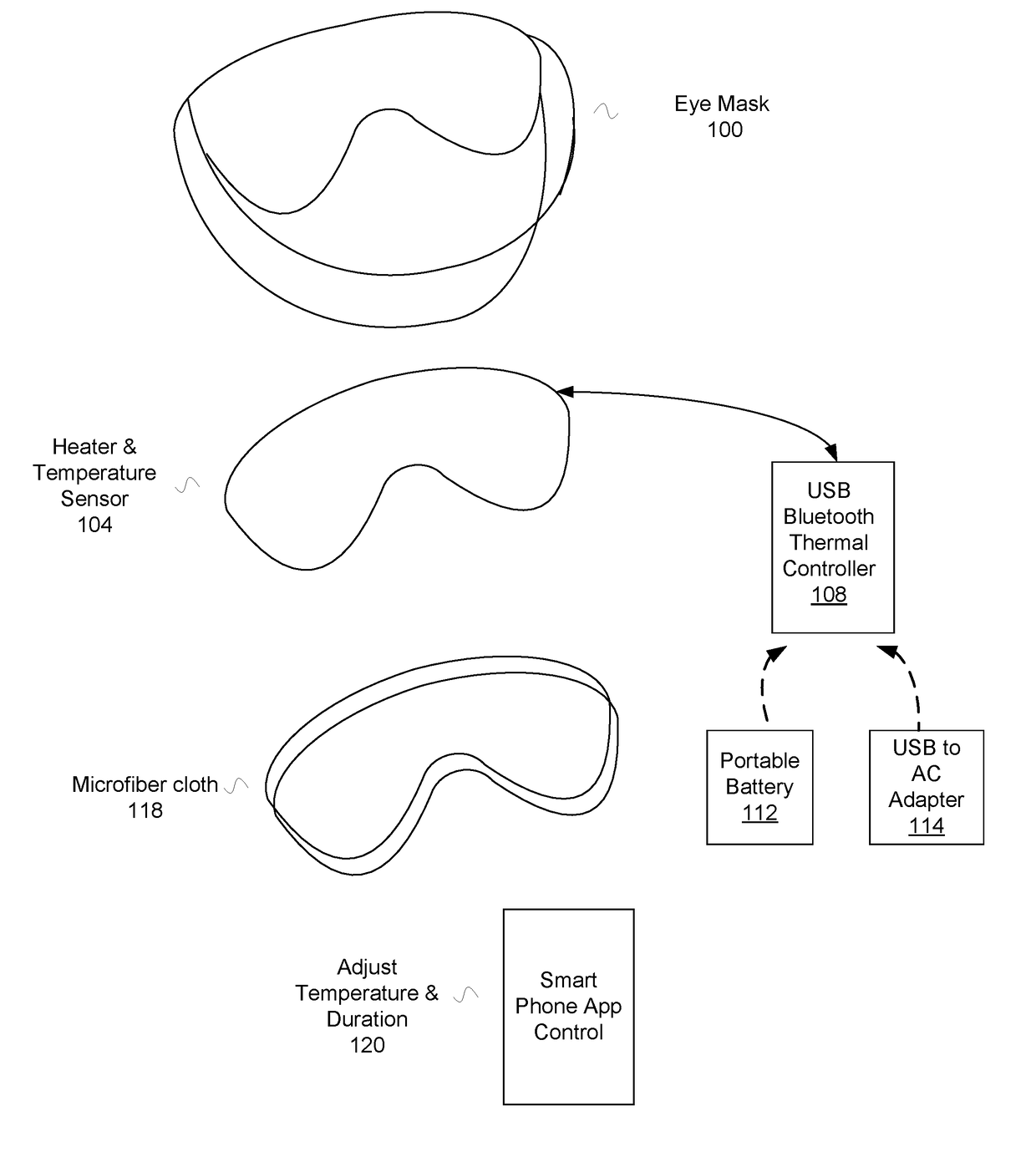

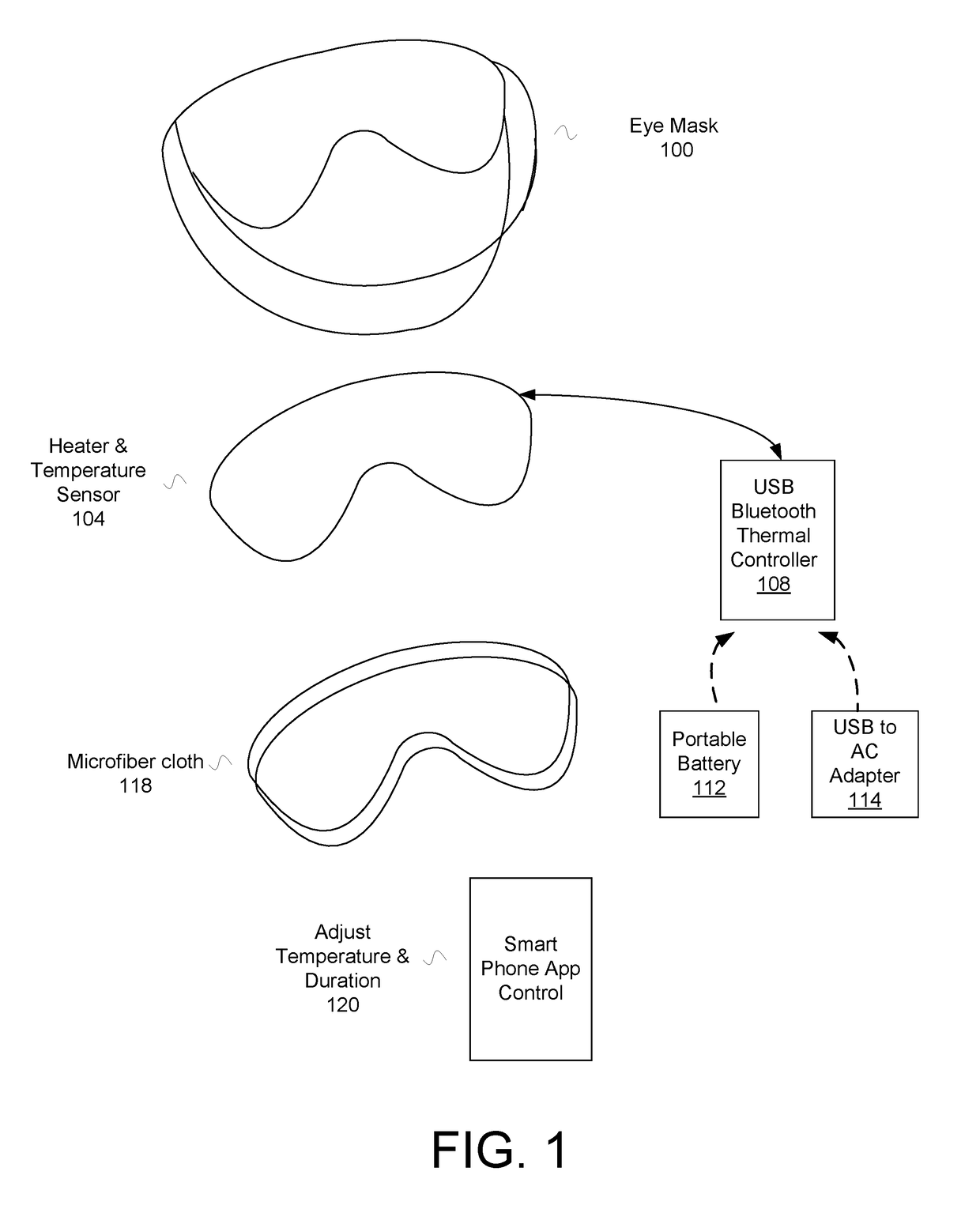

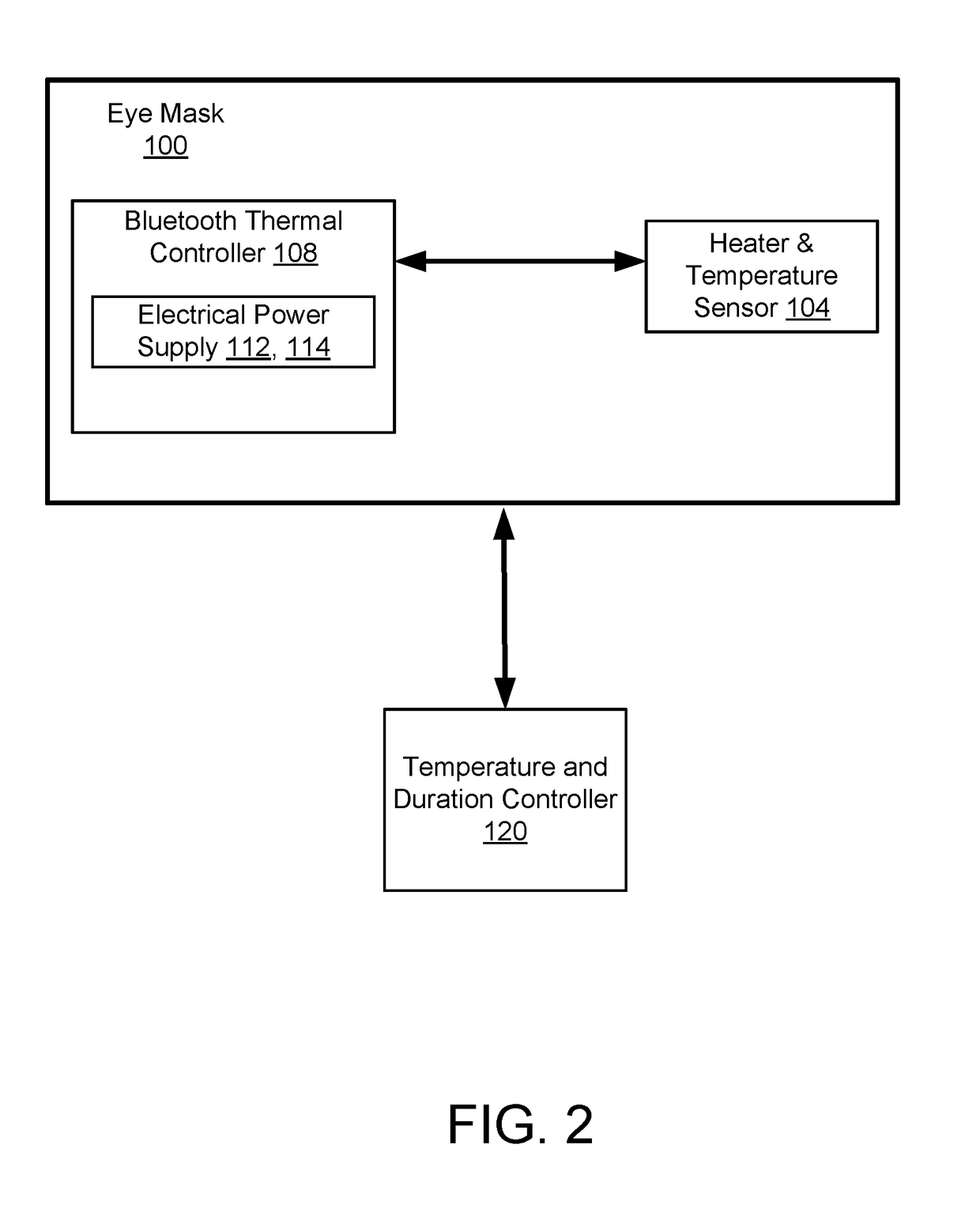

Wireless-controlled therapeutic warming eye wear device

InactiveUS20170266035A1Effectively control temperatureSafety concernTransmission systemsOhmic-resistance heatingEngineeringHeat setting

A therapeutic eye mask having a wireless temperature and duration controller is disclosed. The therapeutic eye mask comprises an eye mask configured to fit over an user's face, a heater and temperature sensor attached to the eye mask configured to heat and sense a temperature, and a wireless thermal controller coupled to the heater and temperature sensor configured to control the heater and temperature sensor to a particular temperature in response to a heat setting on the wireless temperature and duration controller. Such an arrangement allows a user to operate the wireless temperature and duration controller to set the heater and temperature sensor so as to achieve therapeutic warmth and flexible regulation of the temperature and long keeping the temperature constant to the therapeutic eye mask.

Owner:KUO BRIAN YOUNG MING

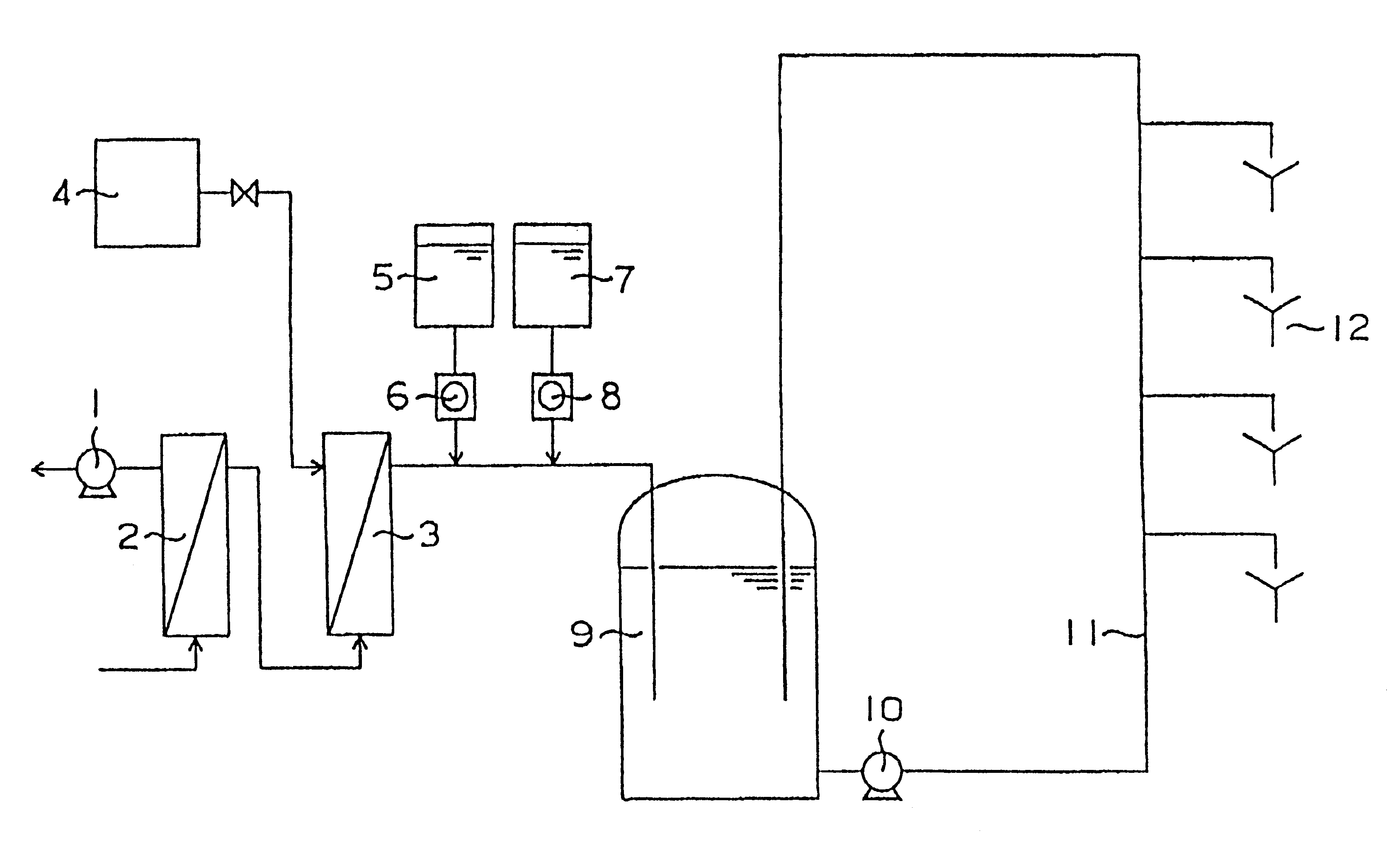

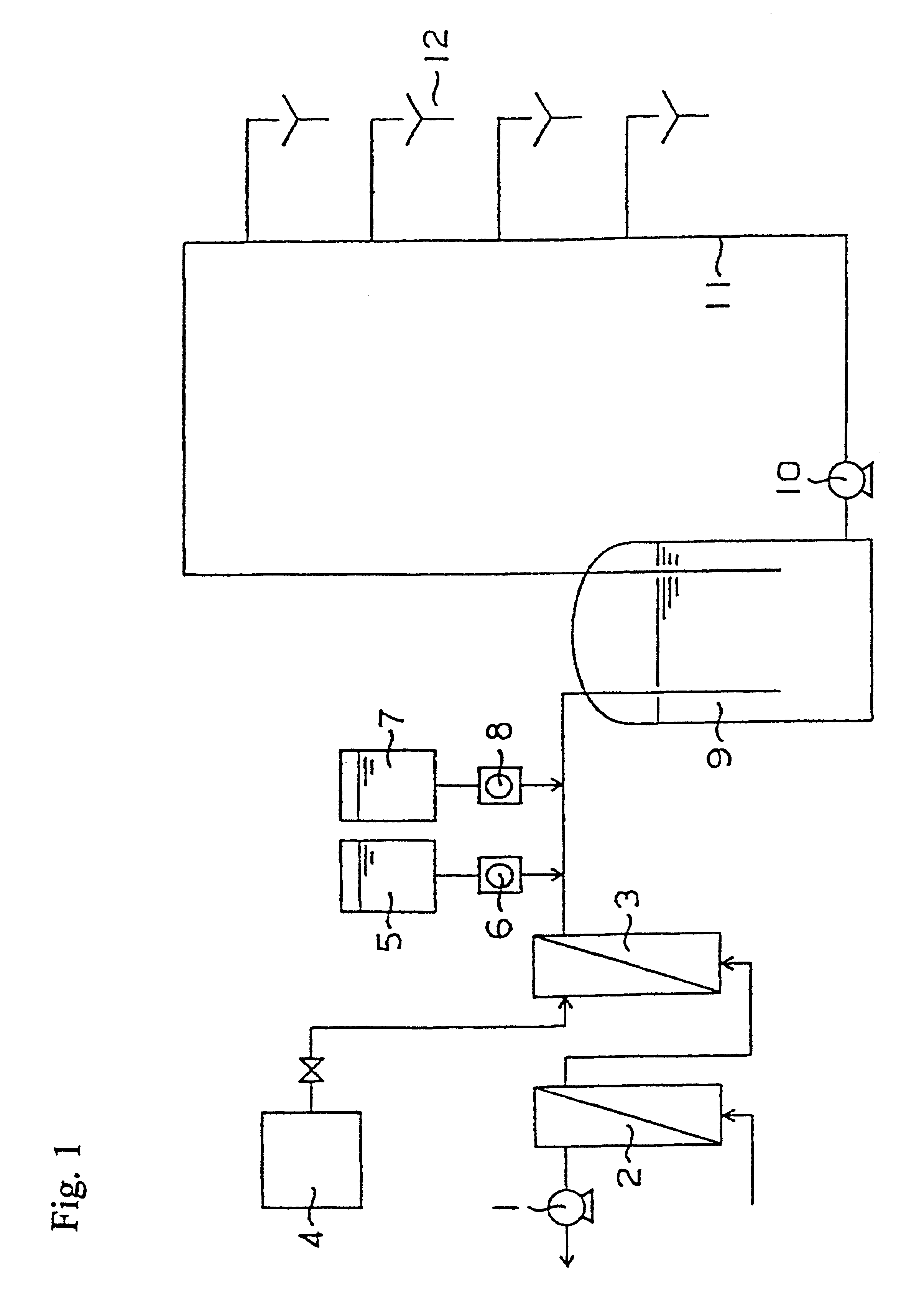

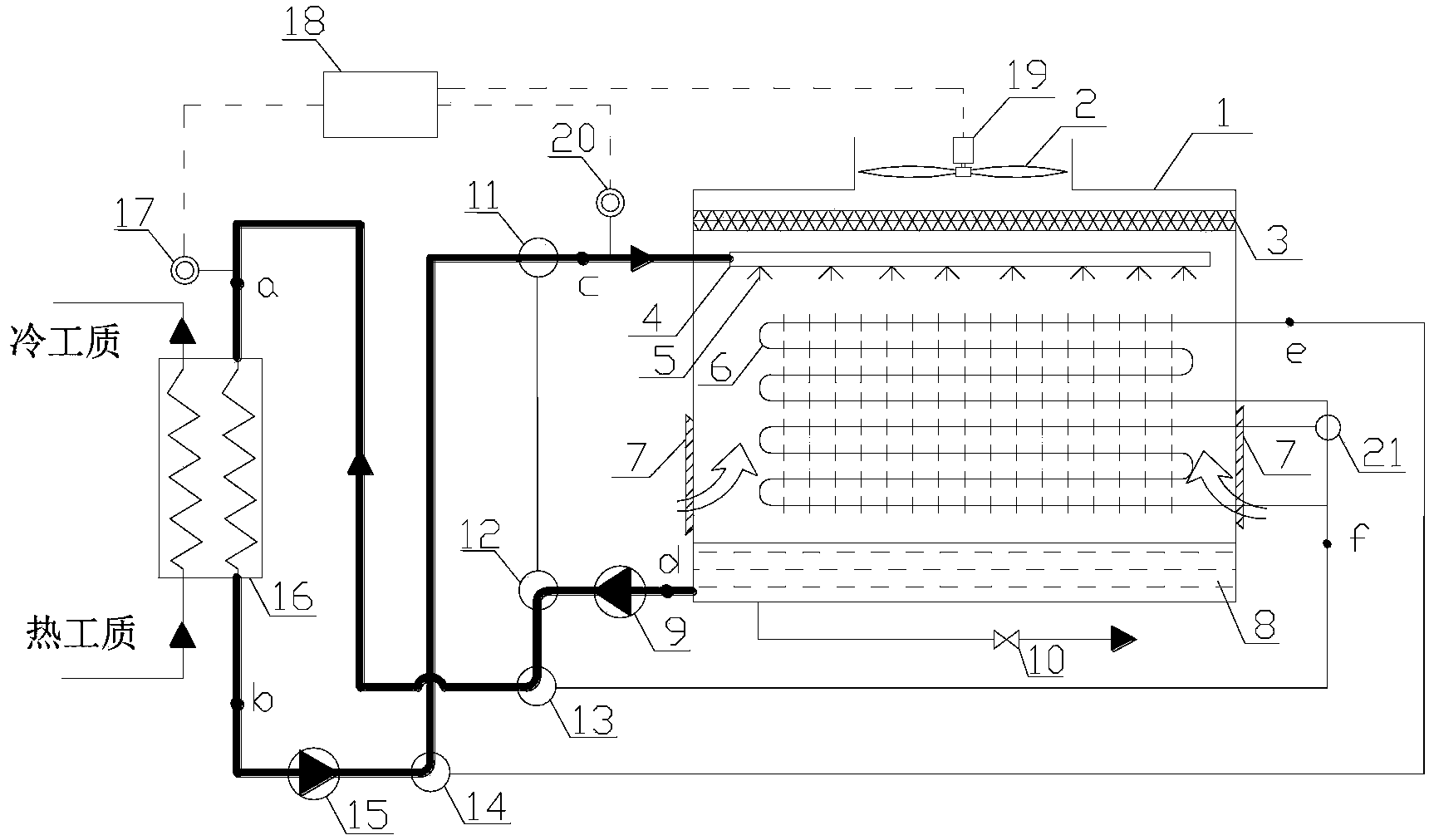

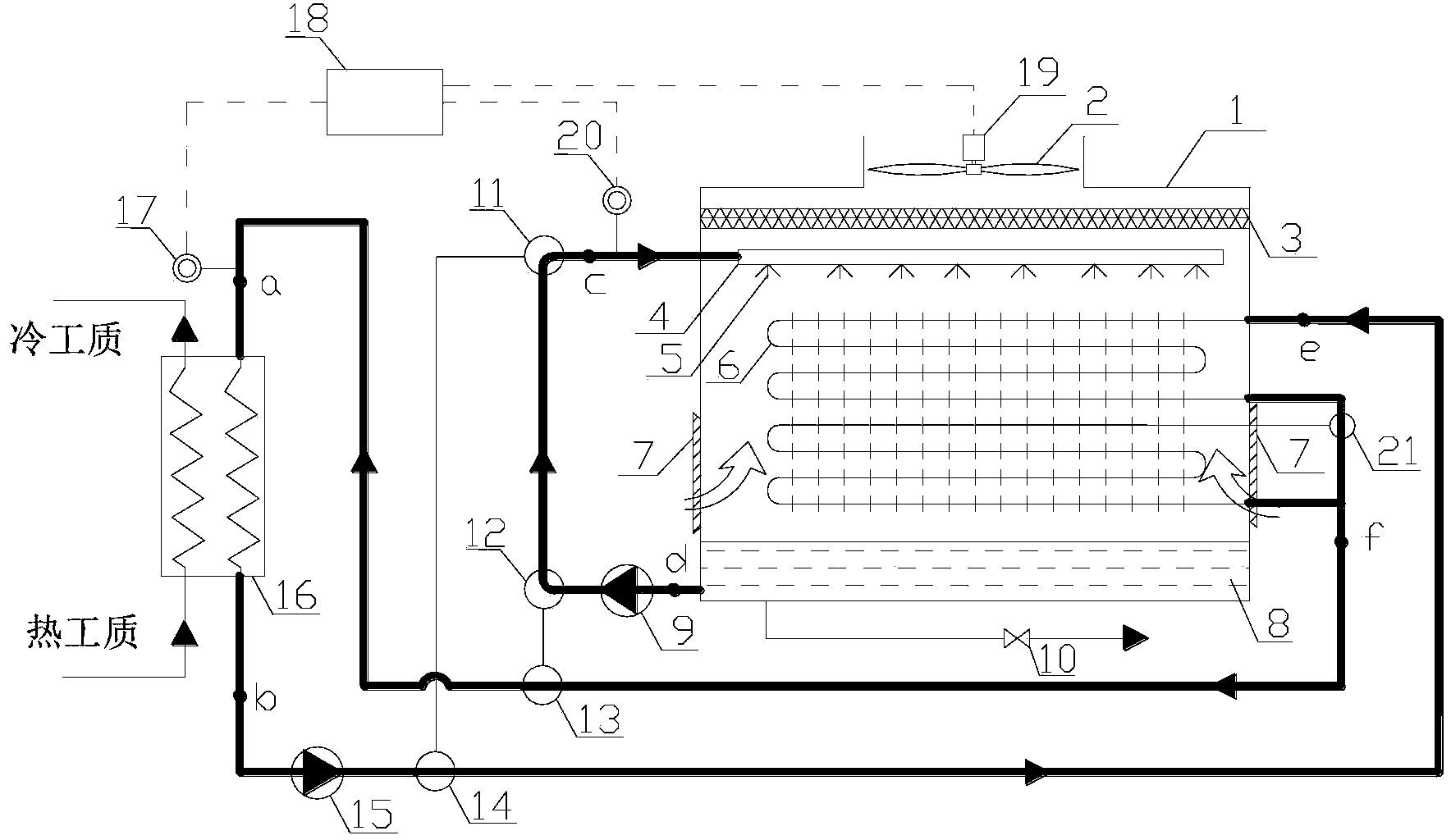

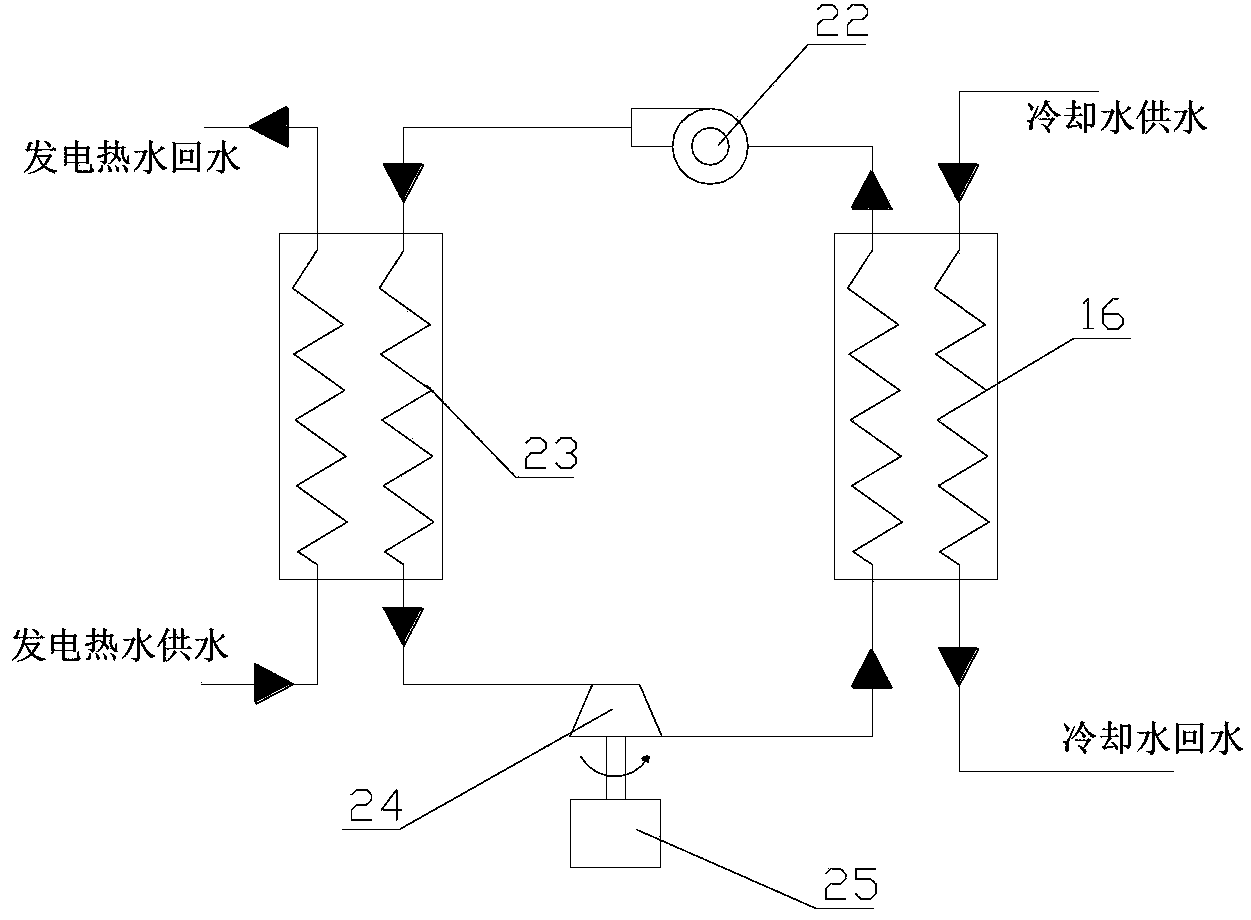

Temperature-controllable dry and wet-open and closed integrated cooling tower system

ActiveCN103353242AImprove heat transfer efficiencyWater temperature is easy to controlEfficient regulation technologiesTrickle coolersCooling towerNuclear engineering

The invention discloses a temperature-controllable dry and wet-open and closed integrated cooling tower system which comprises a cooling tower, an automatic controller, an open cooling tower water inlet pipeline, a closed cooling tower water inlet pipeline, a heat release equipment cooling water return pipeline, an open cooling tower water outlet pipeline, a closed cooling tower water outlet pipeline, and a heat release equipment cooling water supply pipeline, wherein the automatic controller is used for controlling running of a variable frequency motor of the cooling tower and starting or stopping of a circulating water pump; and the automatic controller is also used for controlling the conduction paths of the pipelines by controlling a three-way reversing valve. According to the integrated cooling tower system, surrounding air can be fully utilized to perform a cooling operation in summer, the high-efficiency cooling effect of cooling water is achieved on the basis of effectively preventing frostbite in winter, open and closed heat exchange modes can be switched from one another and can be also combined for operation, and the high-efficiency heat exchange of the cooling tower is achieved.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com