Porous ceramic atomization heating component of electronic cigarette

A technology of porous ceramics and heating components, applied in the field of electronic cigarettes, can solve the problems of dry burning smoke volume, poor liquid-conducting performance of fiber ropes, affecting the quality of electronic cigarettes, etc., and achieve the effects of stable quality, effective temperature adjustment, and large smoke volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

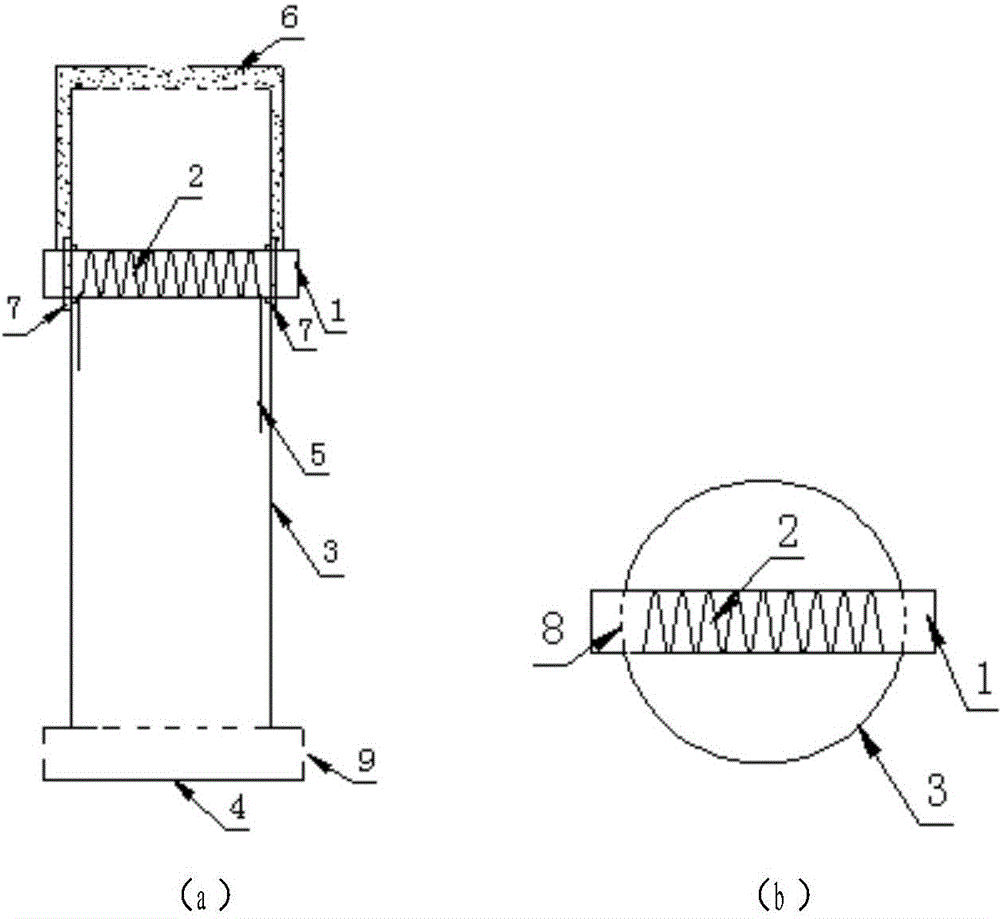

[0023] like figure 1 (a) and figure 1 As shown in (b), an electronic cigarette porous ceramic atomization heating component includes a ceramic rod 1, a heating wire 2, an atomization tube 3 and a base 4, the heating wire 2 is made of a PTC alloy wire, and the heating wire 2 is wound On the surface of the ceramic rod 1 and connected to the battery through the connecting wire 5, the top of the atomization tube 3 is provided with a cutout 8, the ceramic rod 1 is placed horizontally in the top cutout 8, and the atomization tube 3 is installed vertically on the base 4 Above, the cutout 8 of the atomizing tube 3 is provided with a hollow sealing sleeve 6 and a sealing ring 7 in a nested manner (such as Figure 4 shown), wherein the sealing sleeve 6 and the sealing ring 7 are made of silicone rubber, and the base 4 is provided with an air hole 9.

[0024] The ceramic rod 1 is a lipophilic modified porous ceramic, and the lipophilic modified porous ceramic is realized by the followi...

Embodiment 2

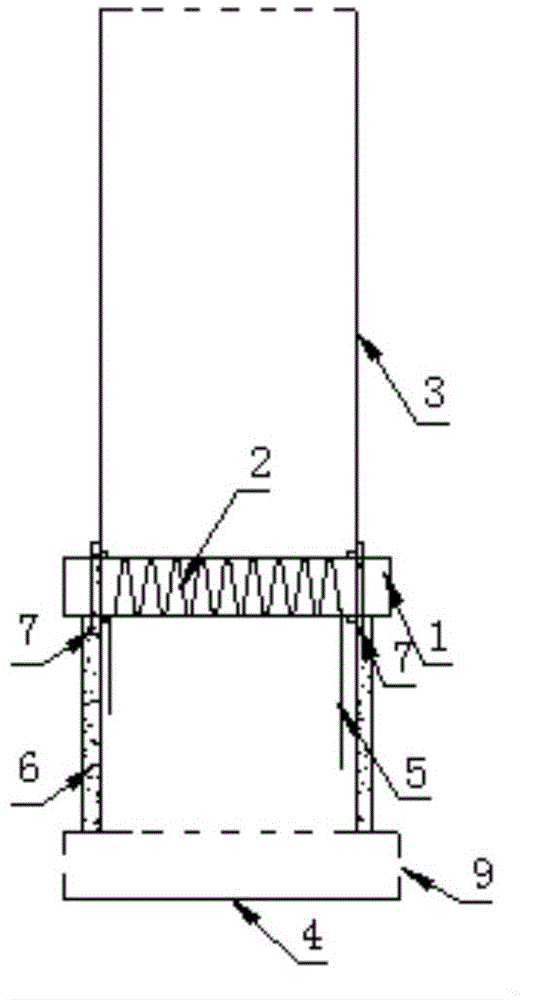

[0026] like figure 2 As shown, a porous ceramic atomizing heating component of an electronic cigarette includes a ceramic rod 1, a heating wire 2, an atomizing tube 3 and a base 4. The heating wire 2 is made of a PTC alloy wire, and the heating wire 2 is wound on the ceramic rod 1. The surface is connected to the battery through the connecting wire 5, the bottom of the atomization tube 3 is provided with a cutout 8, the ceramic rod 1 is placed horizontally in the bottom cutout 8, the atomization tube 3 is installed vertically on the base 4, the The cutout 8 of the atomizing tube 3 is provided with a hollow sealing sleeve 6 and a sealing ring 7 in a nested manner, wherein the material of the sealing sleeve 6 and the sealing ring 7 is silicon rubber, and the base 4 is provided with an air hole 9 .

[0027] The ceramic rod 1 is a lipophilic modified porous ceramic, and the lipophilic modified porous ceramic is realized by the following process: first, the lipophilic solvent is l...

Embodiment 3

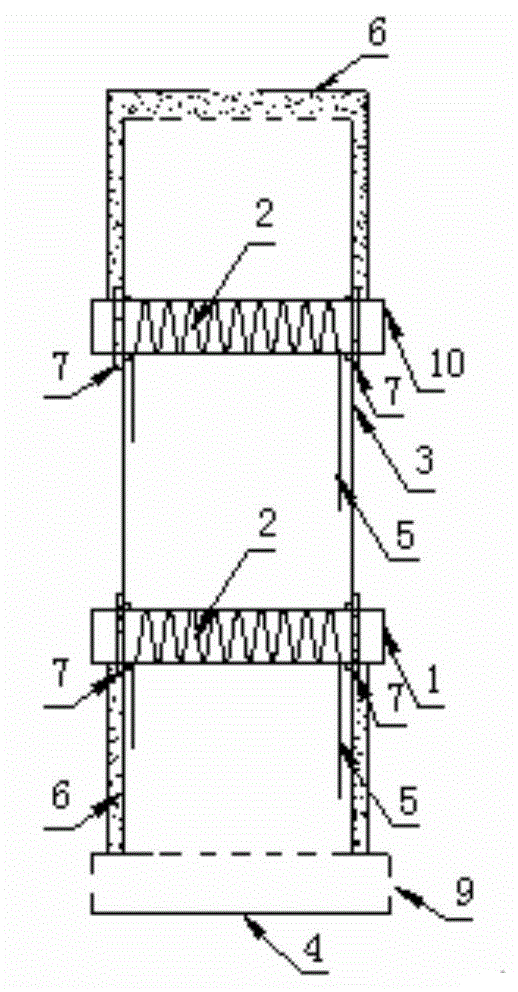

[0029] like image 3 As shown, an electronic cigarette porous ceramic atomization heating component includes a ceramic rod 1, a fiber rope 10, a heating wire 2, an atomizing tube 3 and a base 4, the heating wire 2 is set as a PTC alloy wire, and the heating wire 2 is respectively Wrapped on the surface of the ceramic rod 1 and the surface of the fiber rope 10 and connected to the battery through the connecting wire 5, the top and bottom of the atomization tube 3 are provided with a cutout 8, the ceramic rod 1 is placed horizontally in the bottom cutout 8, and the fiber The rope 10 is placed horizontally in the top cutout 8, the atomization tube 3 is installed vertically on the base 4, and the atomization tube cutout 8 is provided with a hollow sealing sleeve 6 and a sealing ring 7 in a nested manner, wherein the sealing The material of the sleeve 6 and the sealing ring 7 is silicon rubber, and the base 4 is provided with an air hole 9 .

[0030] The ceramic rod 1 is a lipophi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com