Temperature-controllable dry and wet-open and closed integrated cooling tower system

A closed cooling tower and cooling tower technology, which is applied in the field of cooling towers, can solve the problems of environmental temperature dependence, high cooling water outlet temperature, and can not solve the problems of antifreeze in winter, so as to improve energy utilization and improve heat exchange efficiency. , the economic effect is significant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

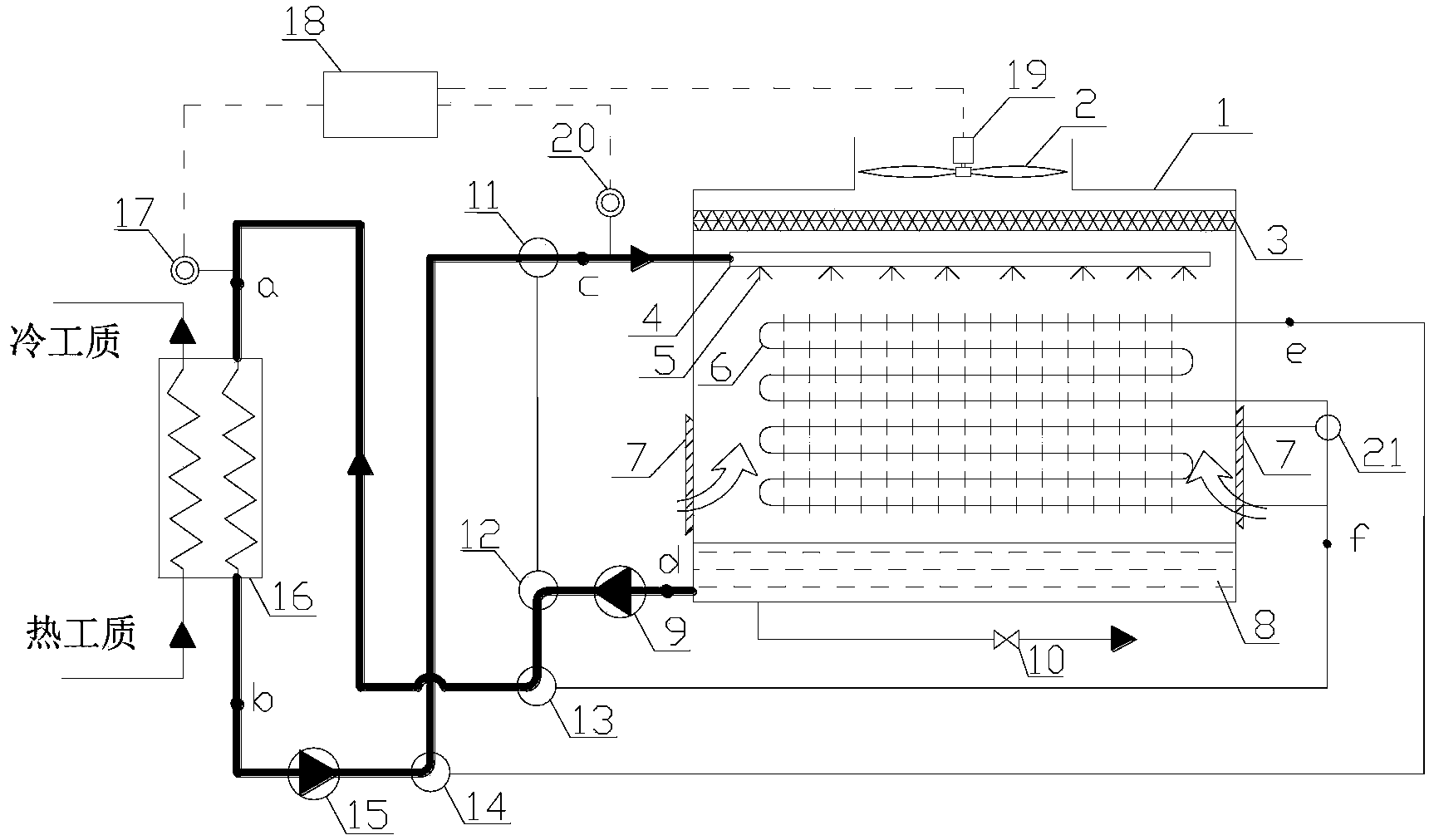

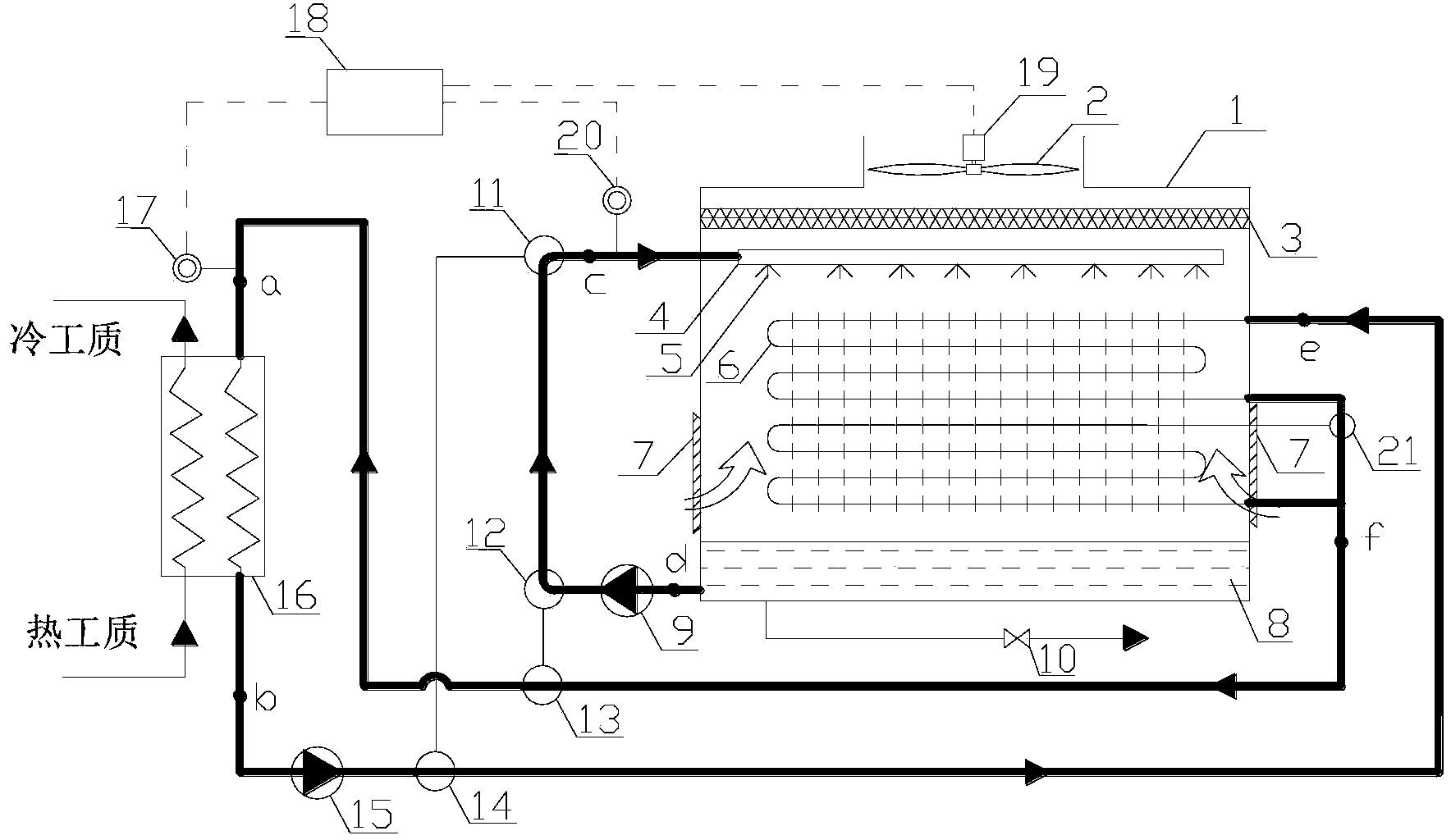

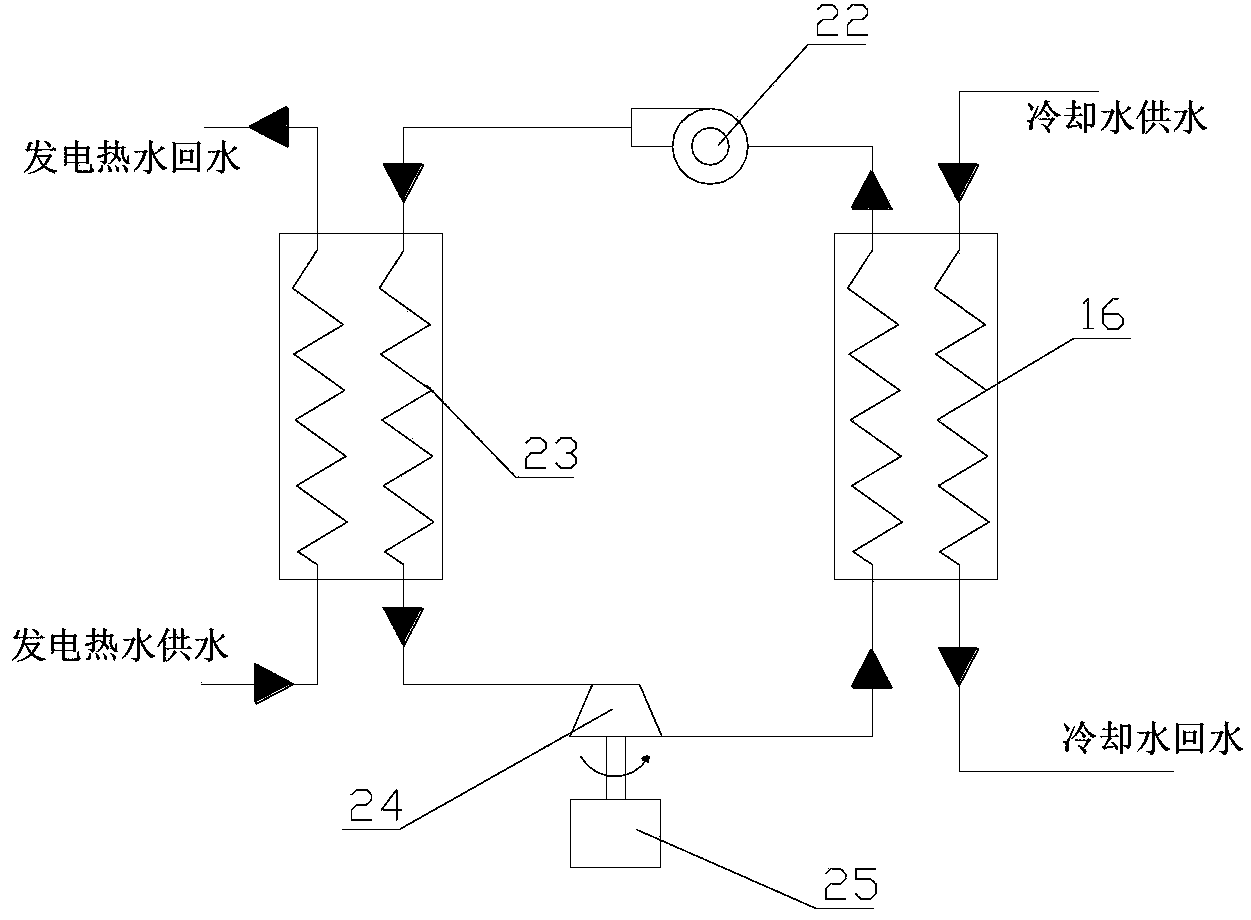

[0024] See Figure 1 ~ Figure 3 , A temperature-controllable dry-wet-open-close integrated cooling tower system, including automatic controller 18, cooling tower, open cooling tower inlet pipe, closed cooling tower inlet pipe, and cooling water return pipe for heat release equipment Circuit, open cooling tower water outlet pipeline, closed cooling tower water outlet pipeline and cooling water supply pipeline of heat release equipment.

[0025] The cooling tower includes a casing 1, a fan 2, a variable frequency motor 19, a baffle plate 3, a spray pipe 4, a cooling coil 6 and a water tank 8. The fan 2 and the variable frequency motor 19 are installed on the inner top of the casing 1, and the fan 2 is Driven by a variable frequency motor 19; the water baffle 3 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com