Patents

Literature

254results about How to "Accurate temperature detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

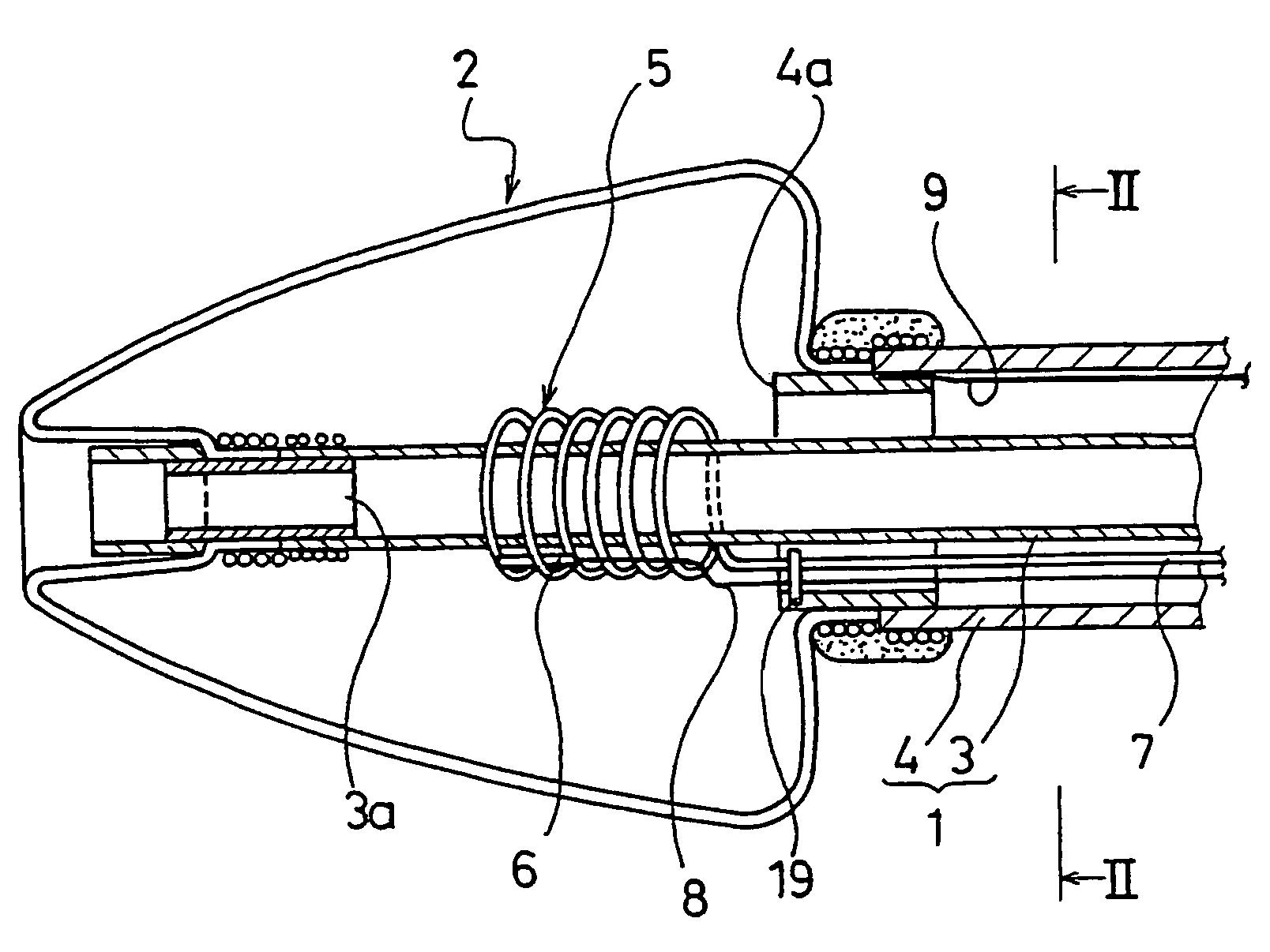

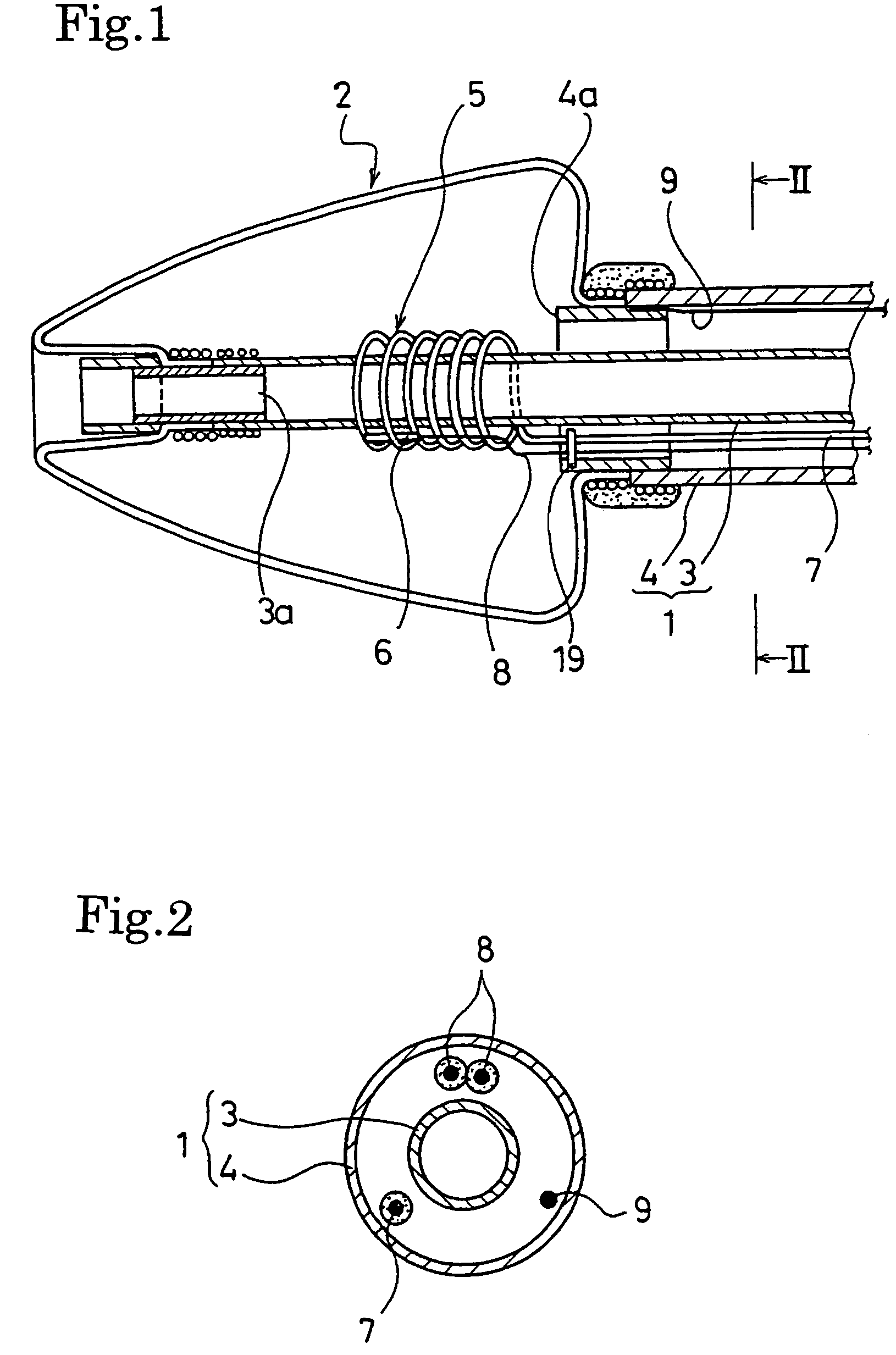

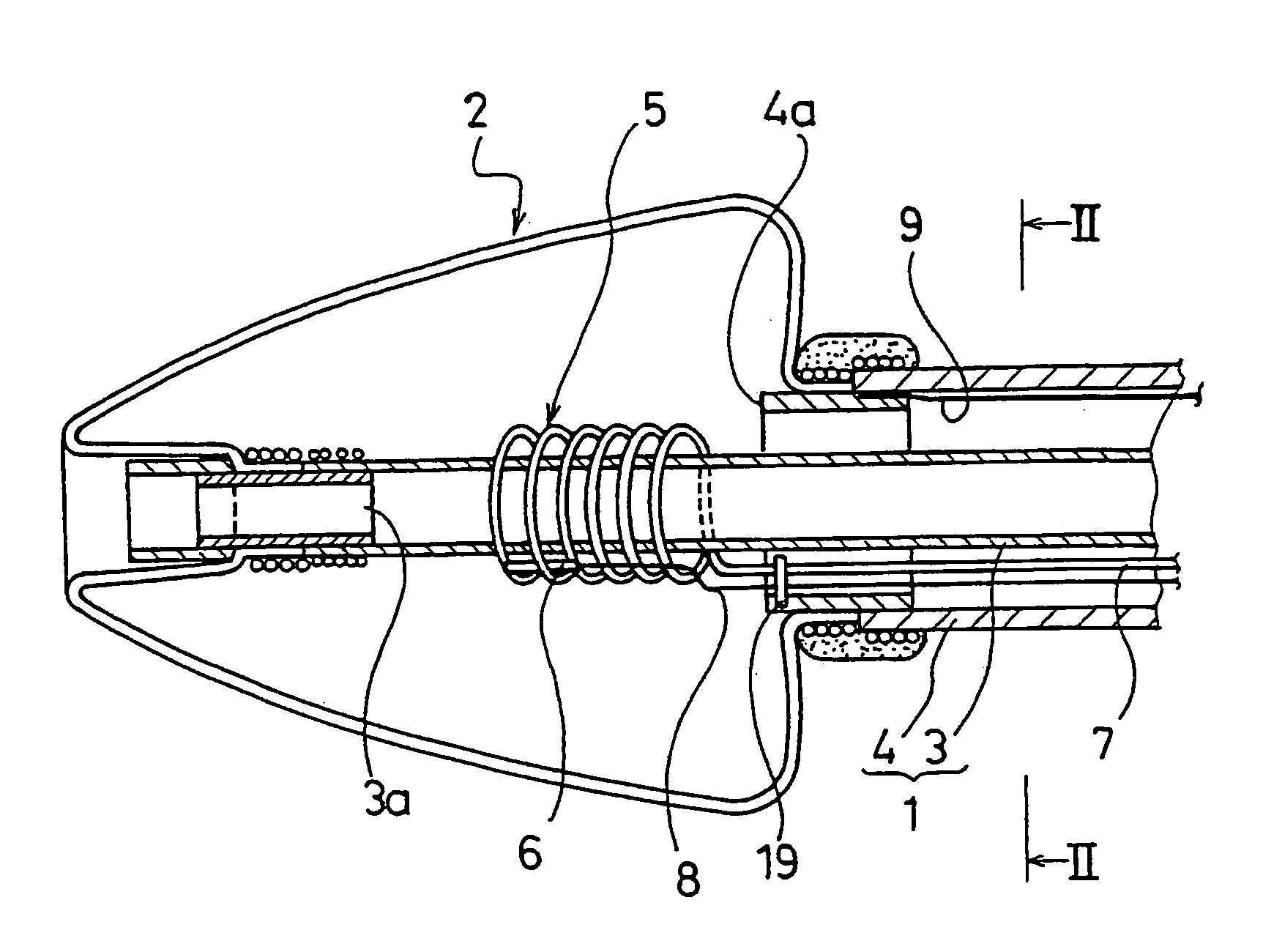

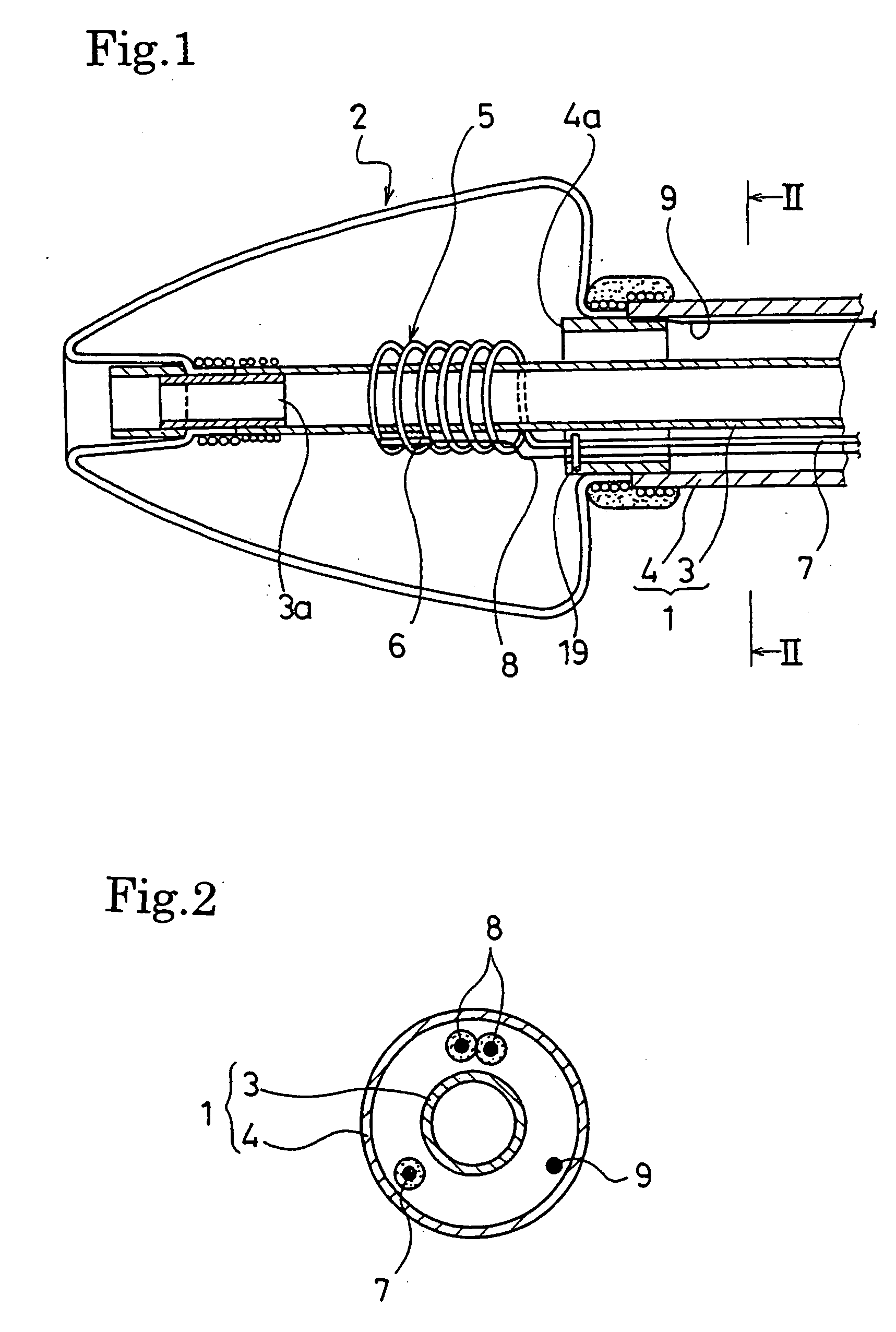

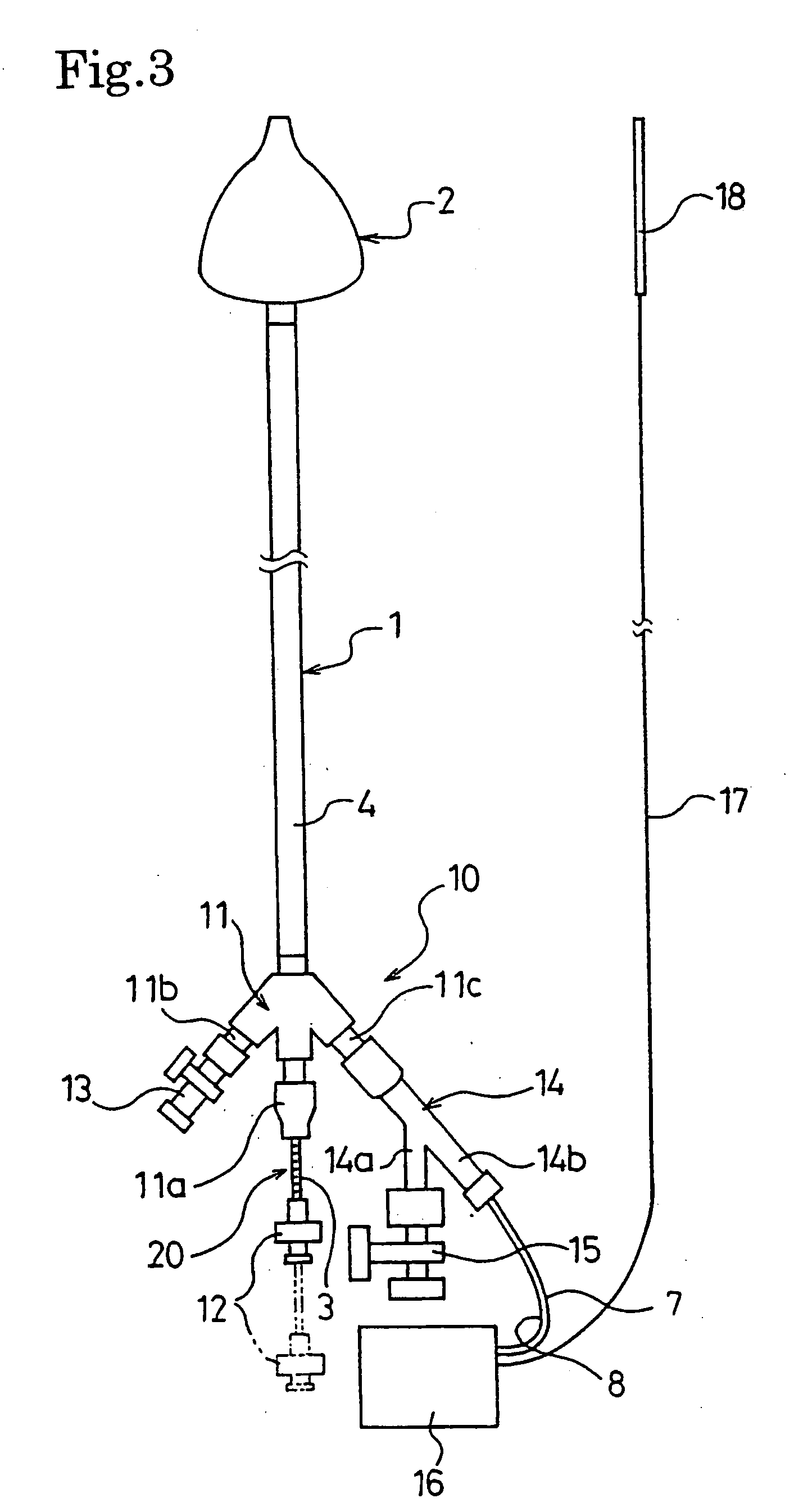

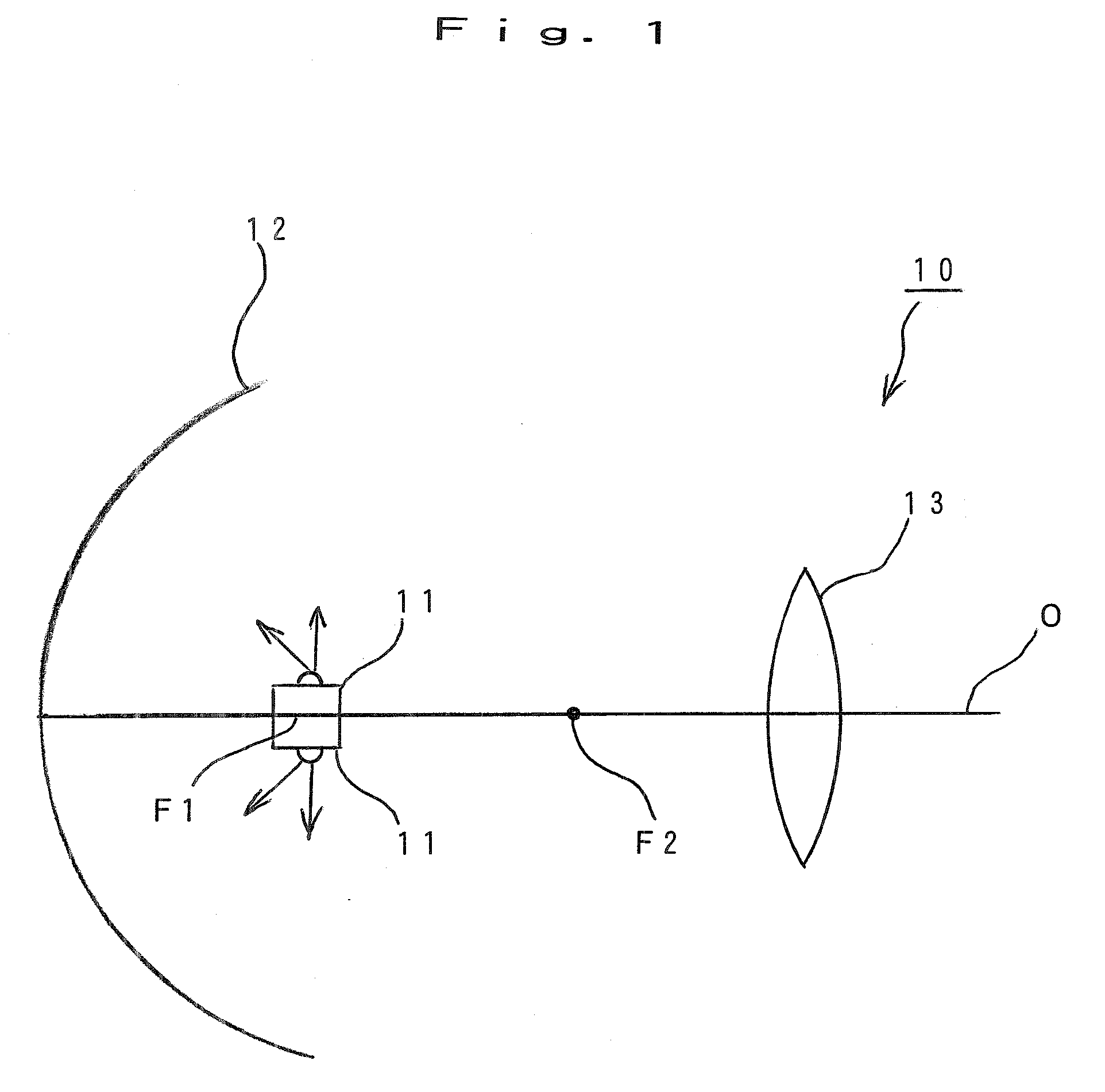

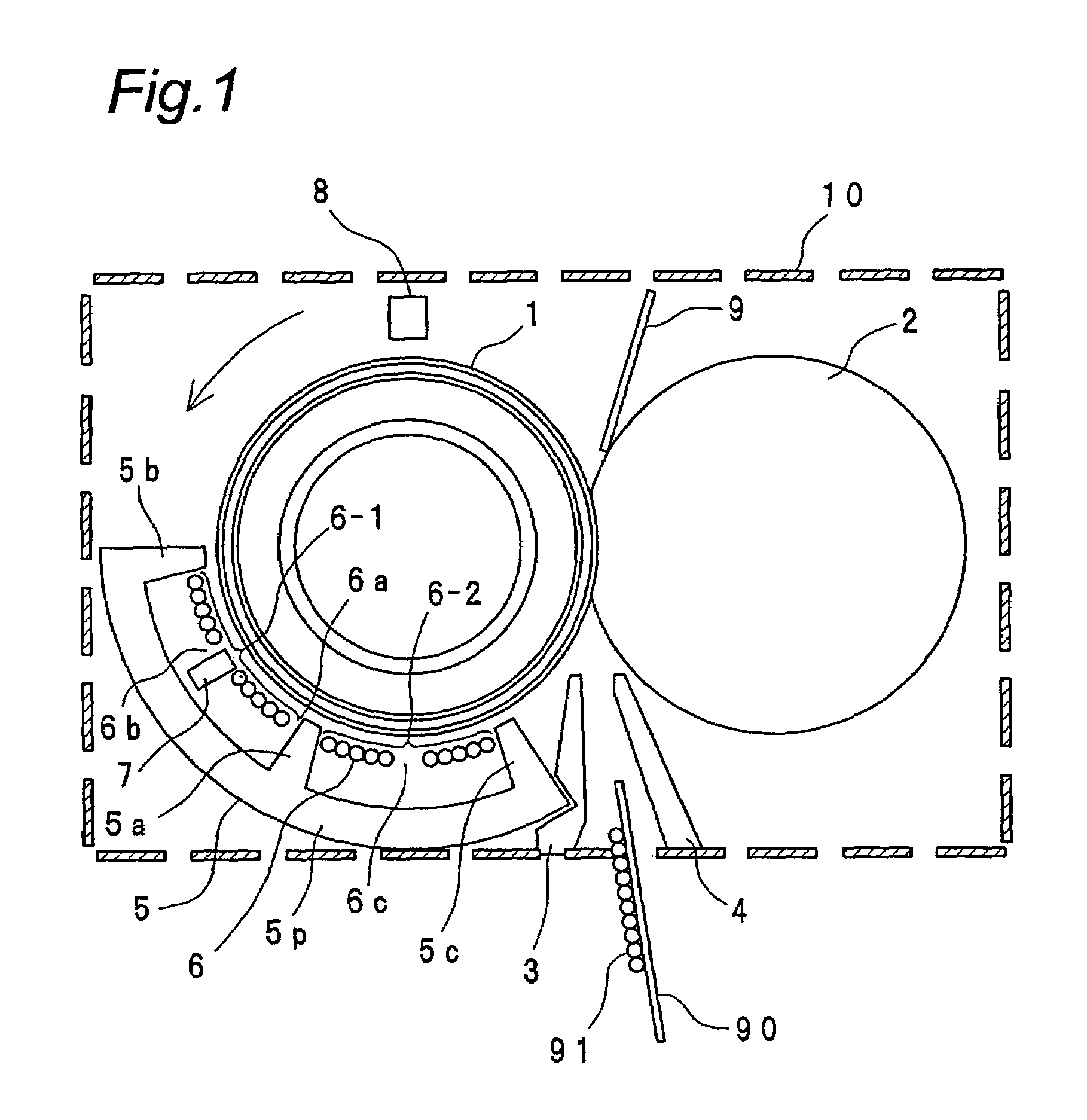

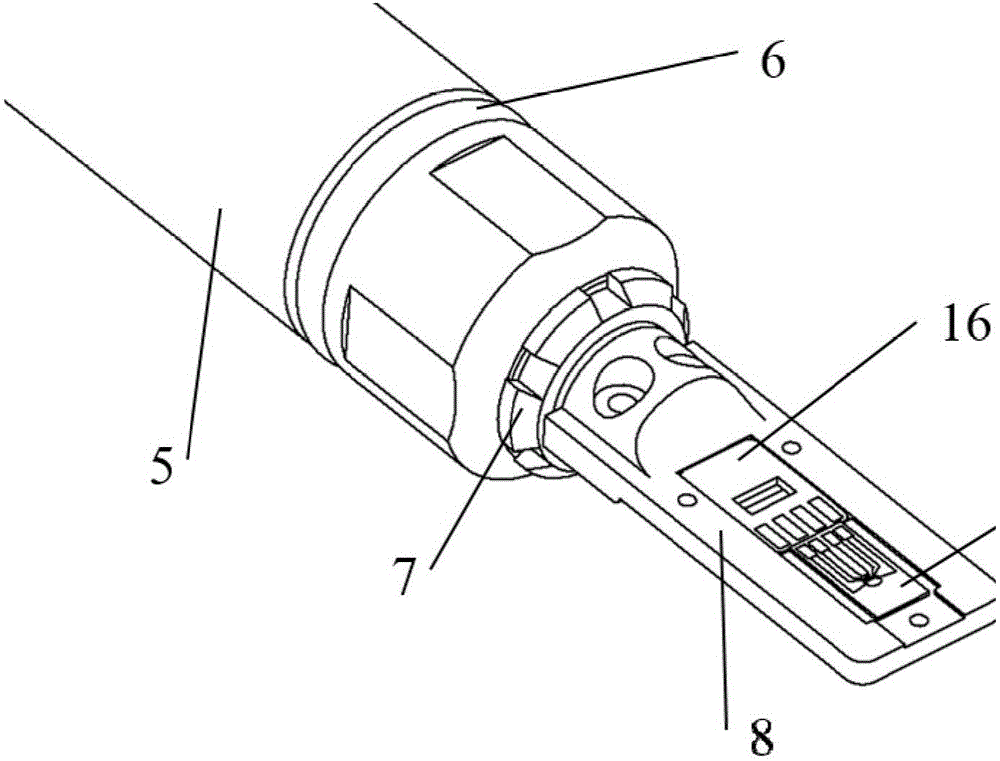

Catheter for treating of arrhythmia

ActiveUS7744594B2Improved ease of insertionHigh-frequency currentDilatorsDiagnostic recording/measuringFront edgeMotor shaft

A catheter for treating arrhythmia comprises a catheter shaft of a double-cylinder structure where an inner shaft is slidably inserted in an outer shaft, a balloon installed so as to straddle between the tip portion of the inner shaft and the tip portion of the outer shaft, a pair of high frequency current-carrying electrodes of which at least one electrode is provided inside the balloon, and a temperature sensor for monitoring the temperature in the balloon. The front edge portion of the balloon at least in a deflated state protrude from the tip portion of the inner shaft. Alternatively, a tube that is more flexible than the inner shaft is provided on the tip portion of the inner shaft.

Owner:TORAY IND INC

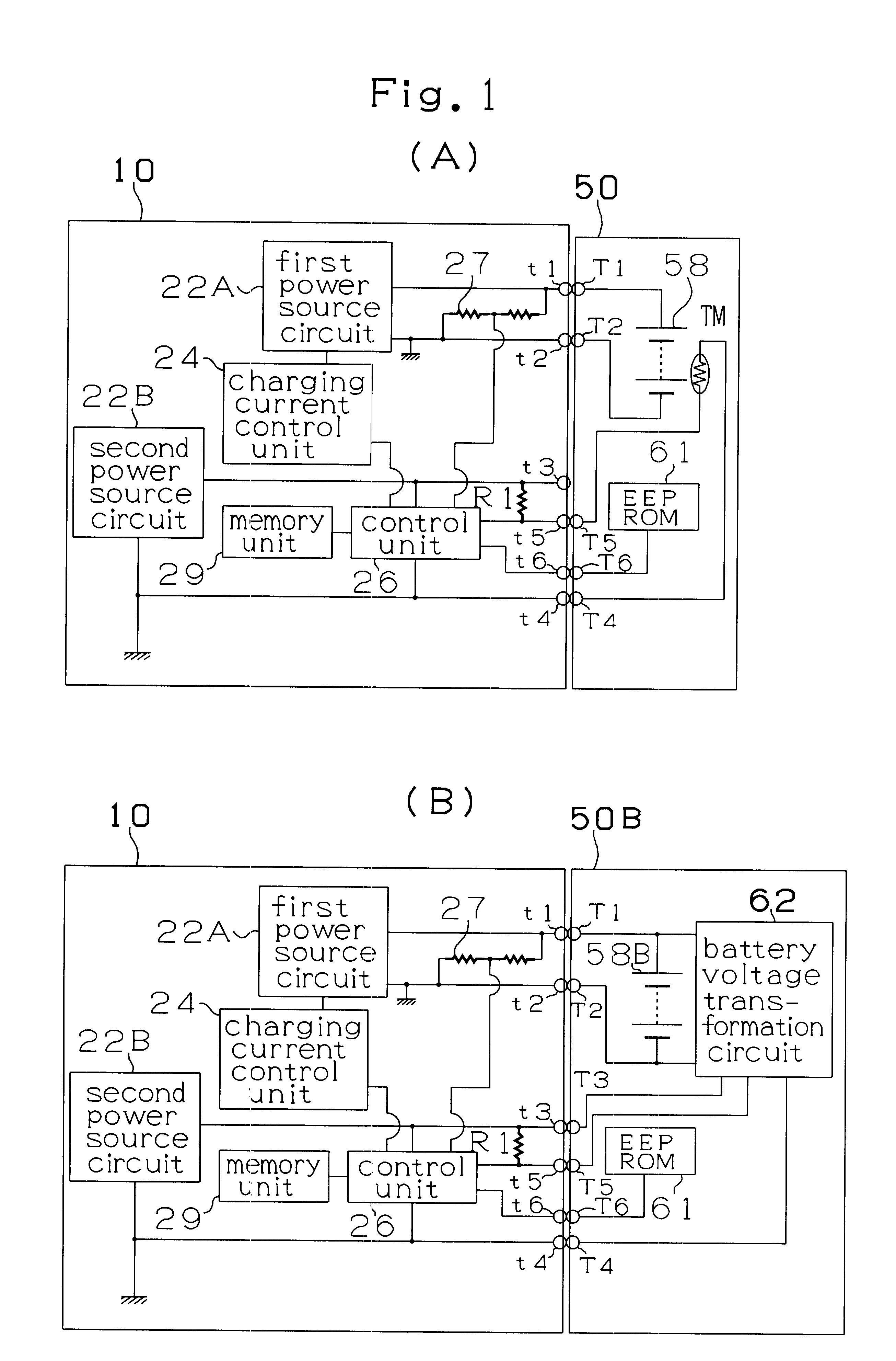

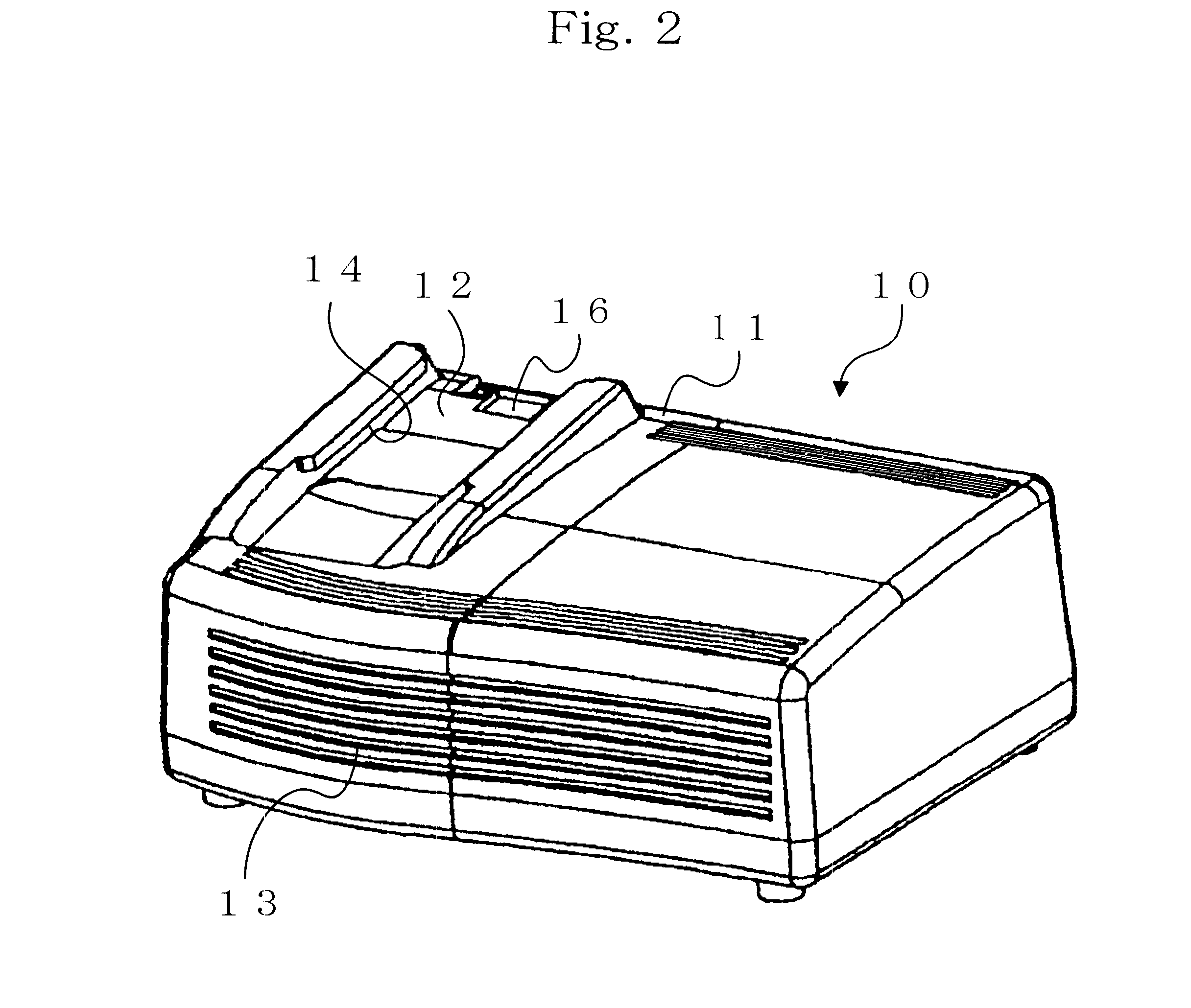

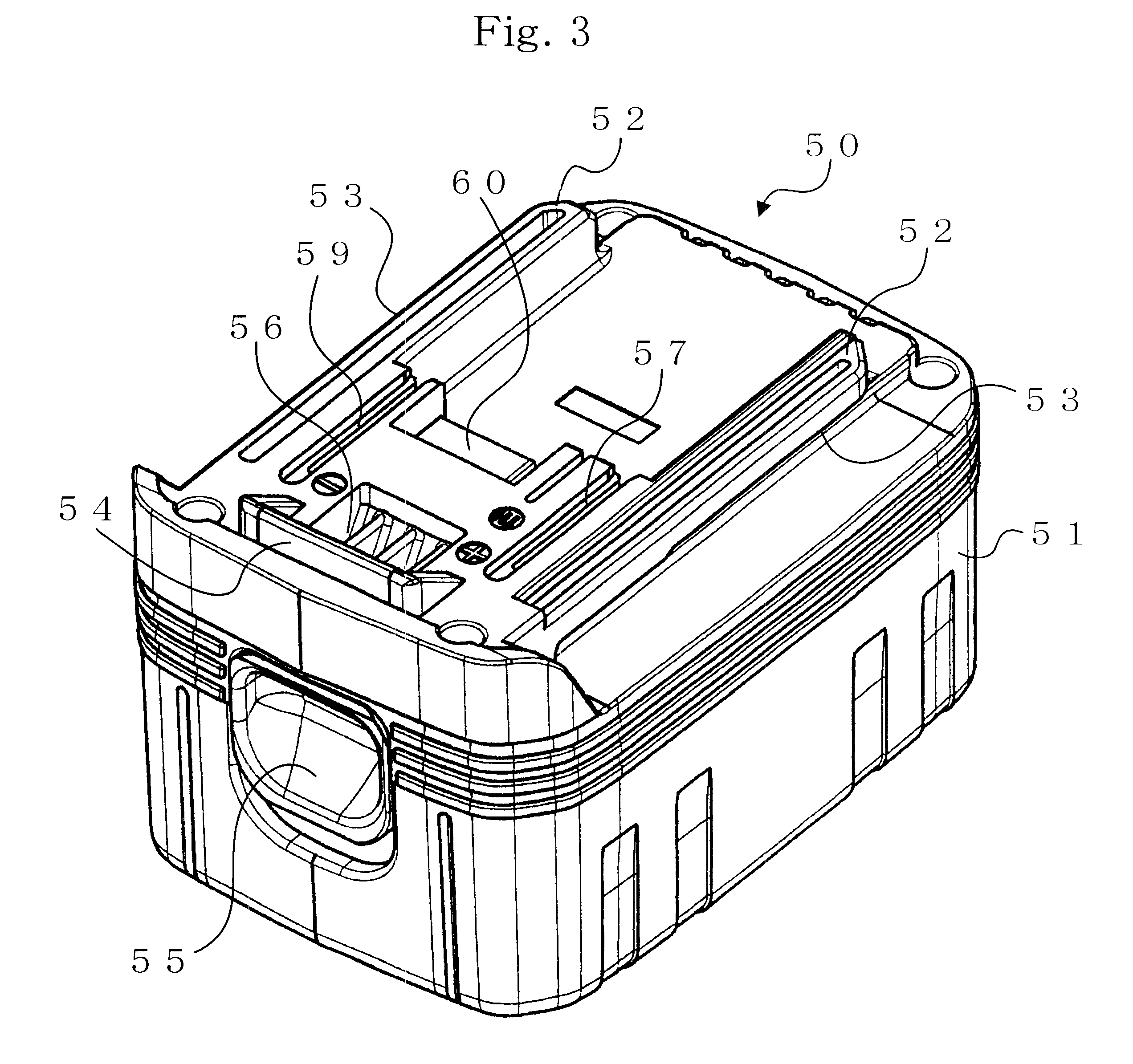

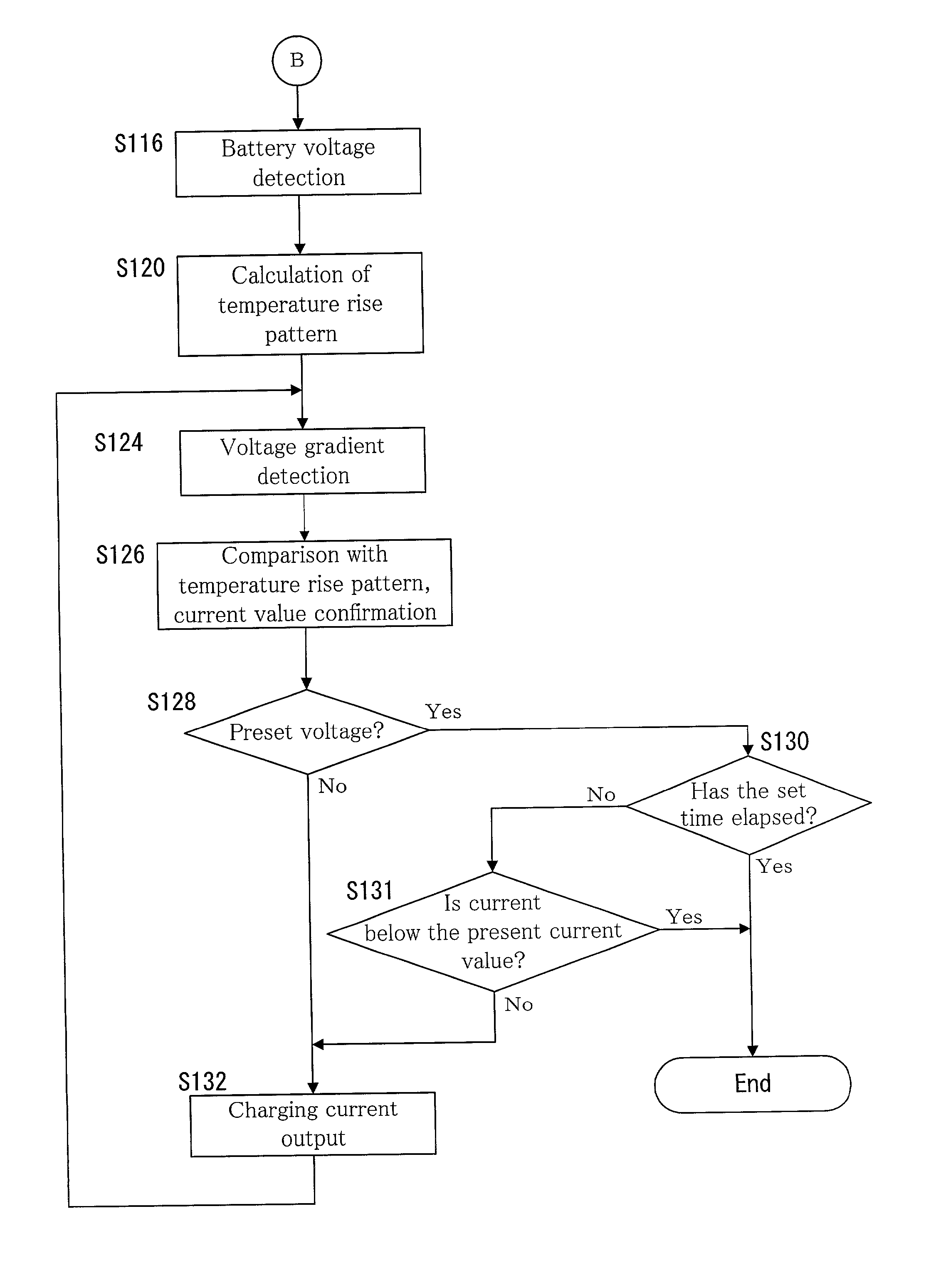

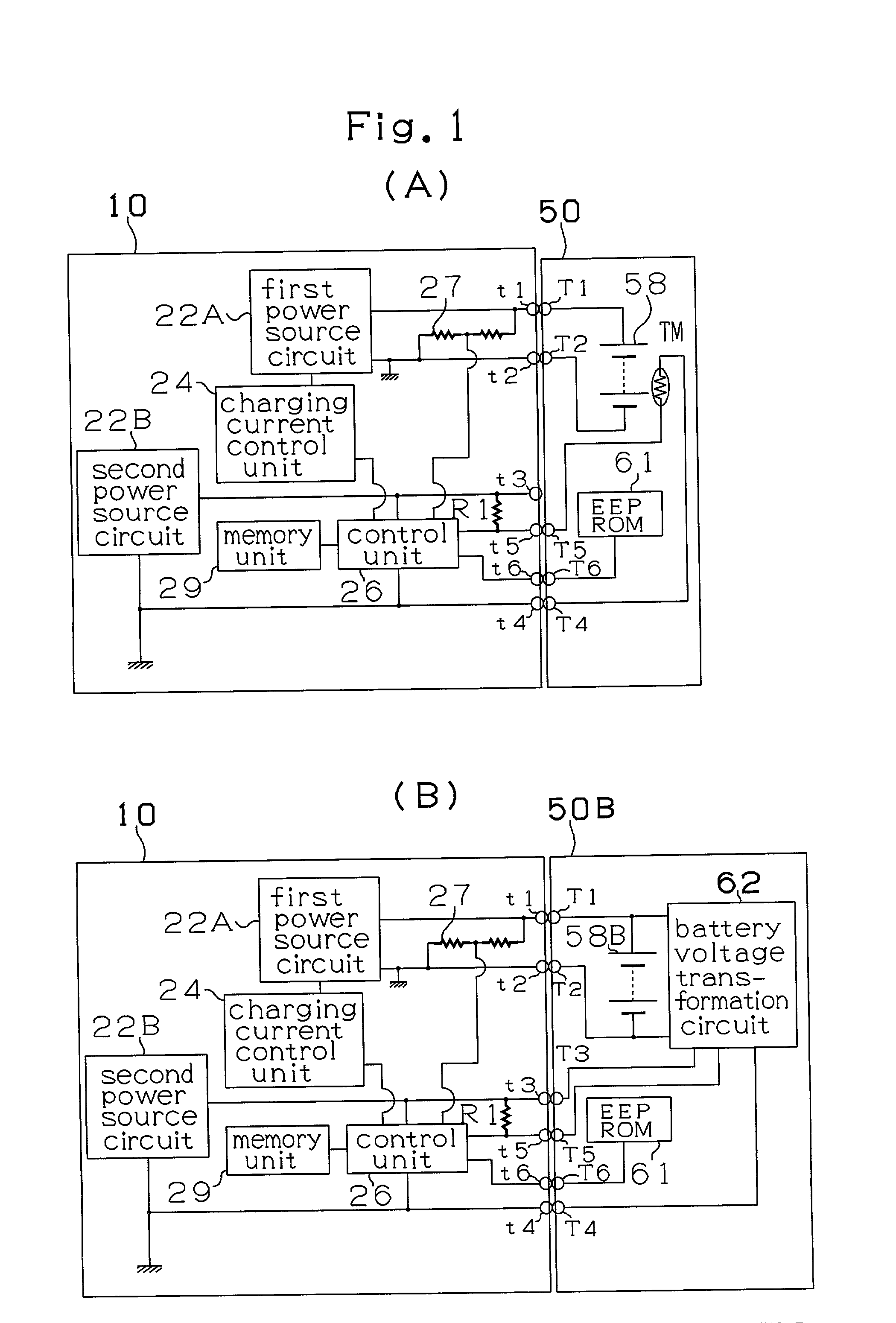

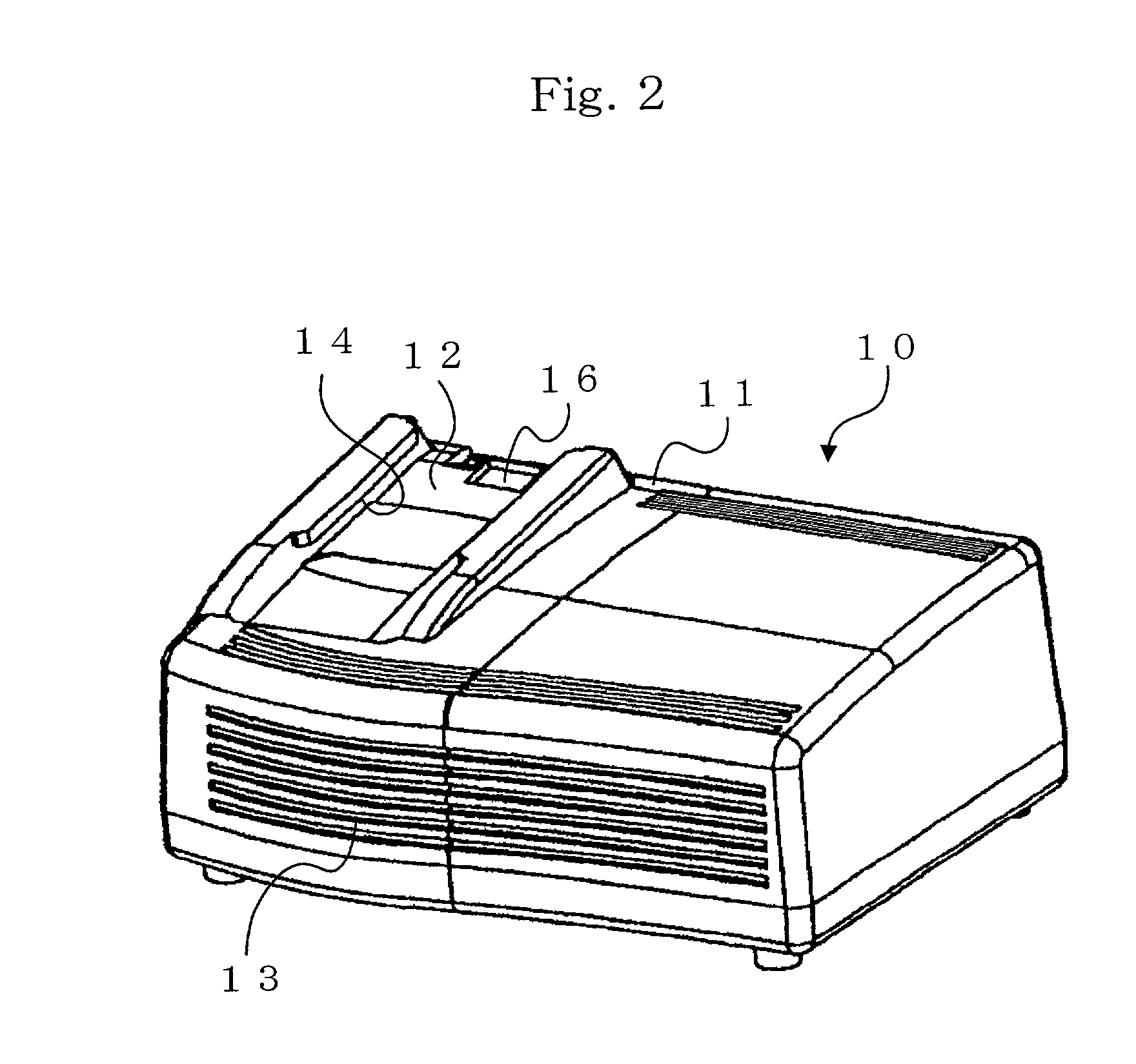

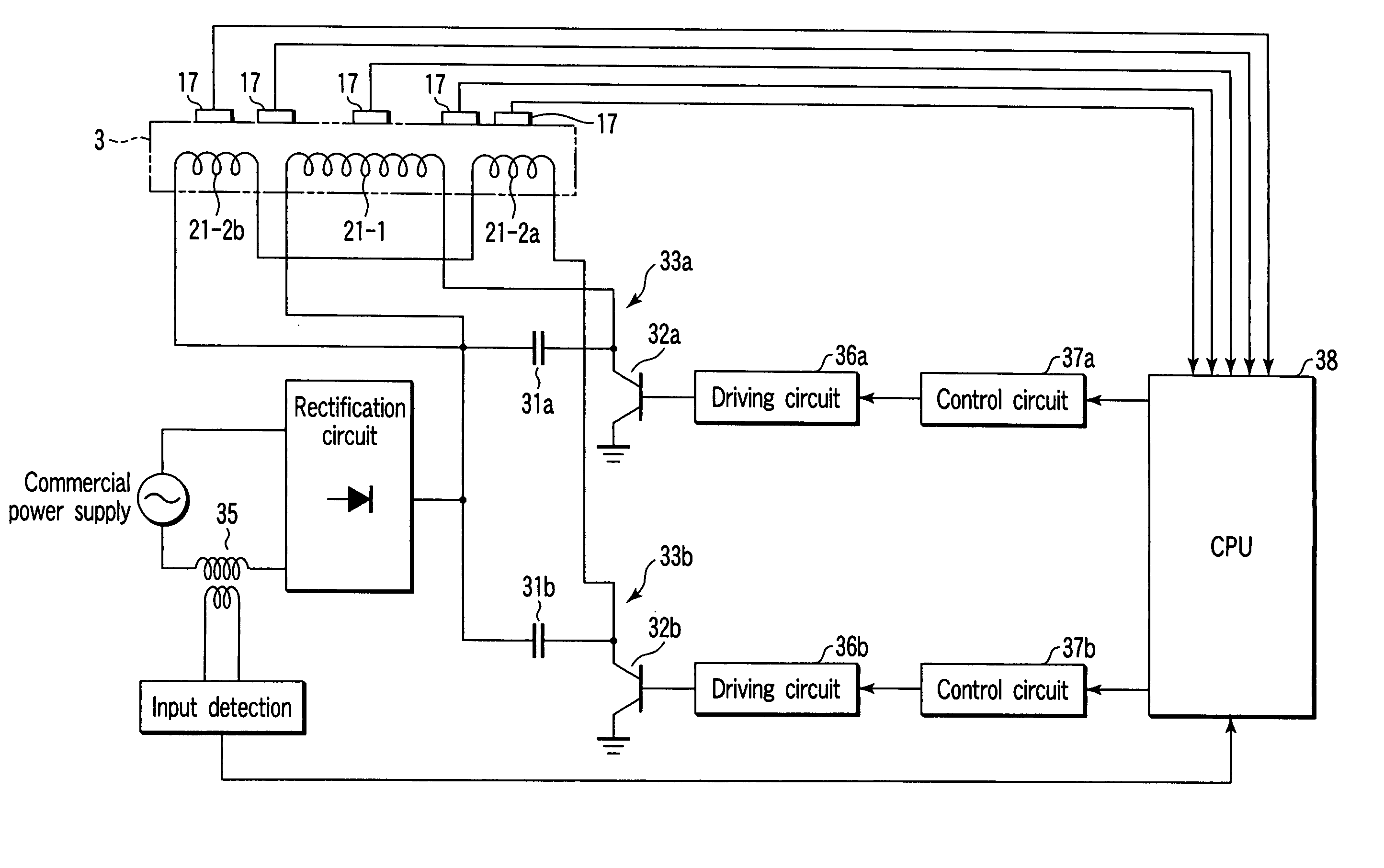

Battery pack charging system and battery pack

InactiveUS6563290B2Accurate temperature detectionBatteries circuit arrangementsSecondary cells charging/dischargingEngineeringLithium-ion battery

Charging device 10 charges nickel-hydrogen batteries 58, while adjusting the current value so that the temperature follows the target temperature rise pattern. Therefore, nickel-hydrogen batteries that demonstrate a large temperature increase can be charged within a short time so that a high temperature is not attained. Furthermore, when lithium ion batteries 58 are charged, the current value is controlled so that the voltage follows the target voltage rise pattern. Therefore, lithium ion batteries can be charged at a potential no higher than the preset level.

Owner:MAKITA CORP

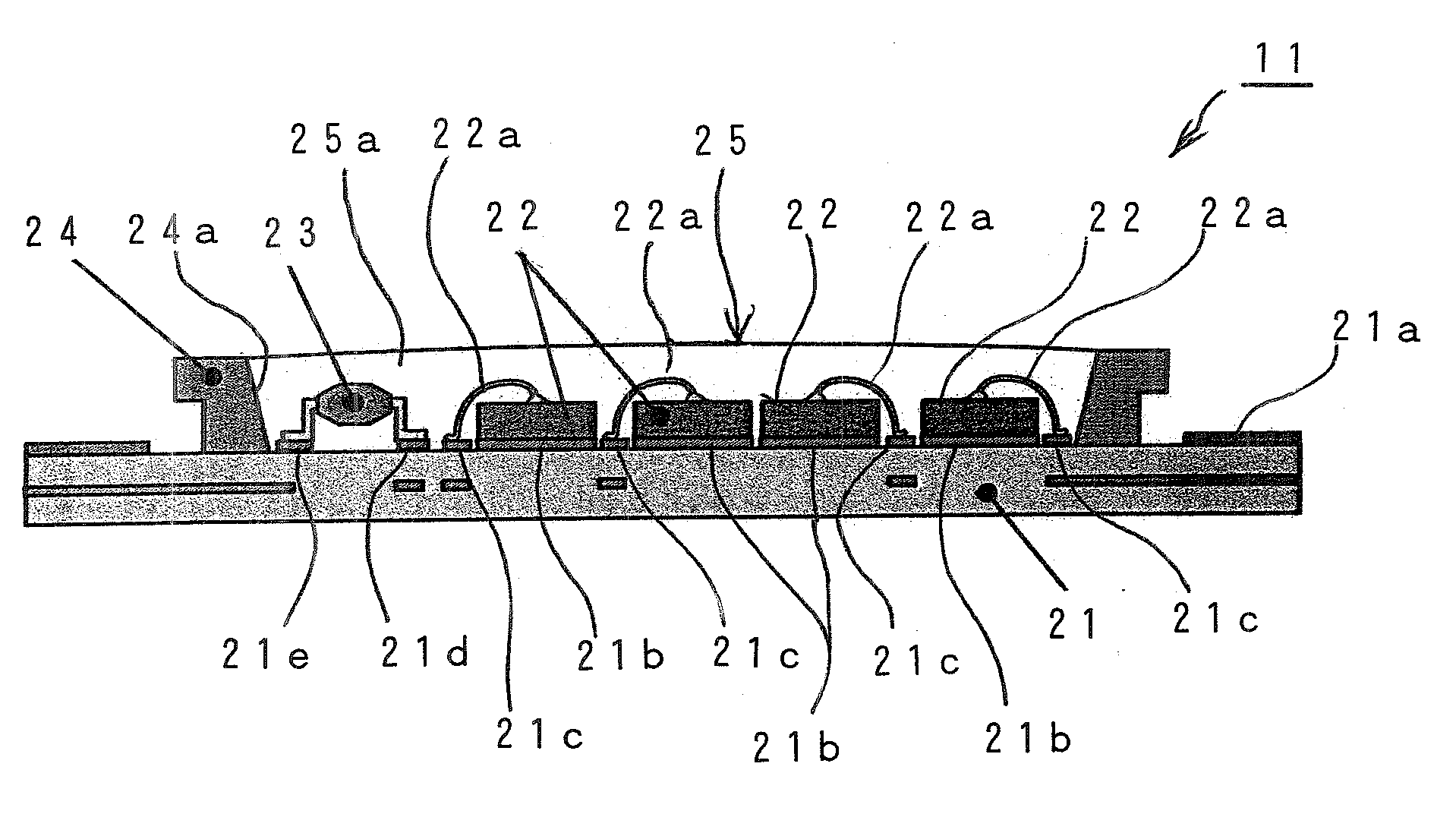

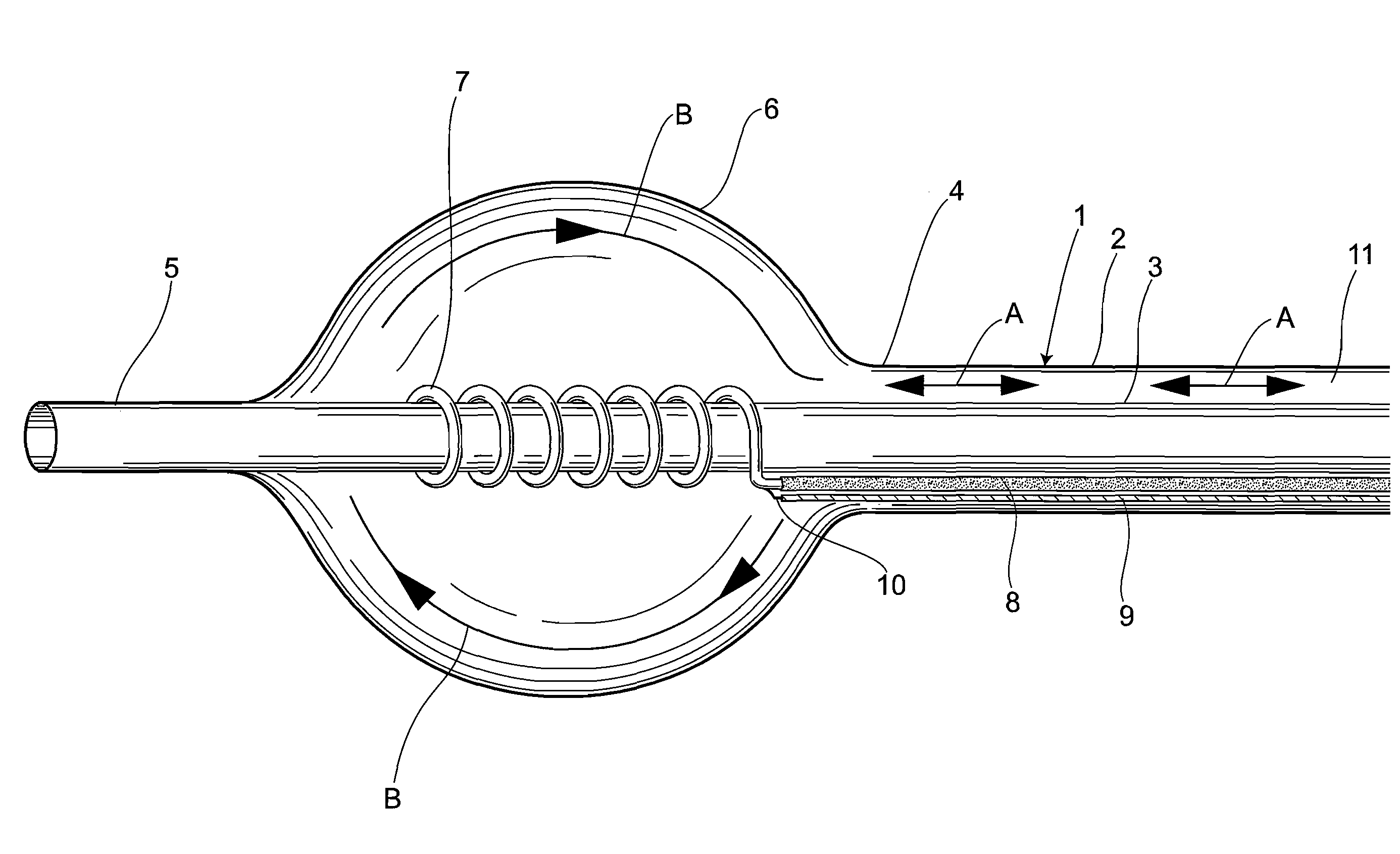

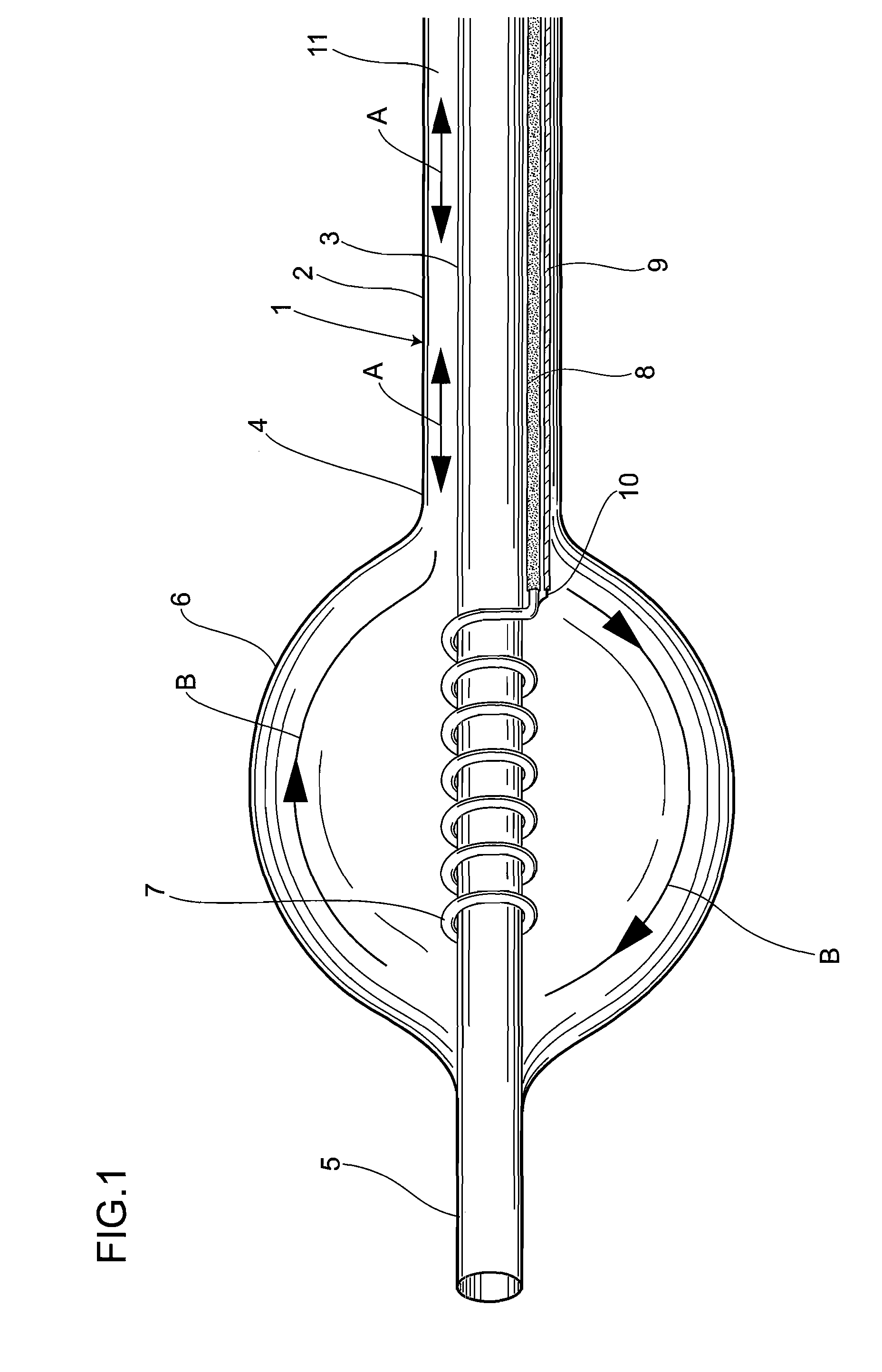

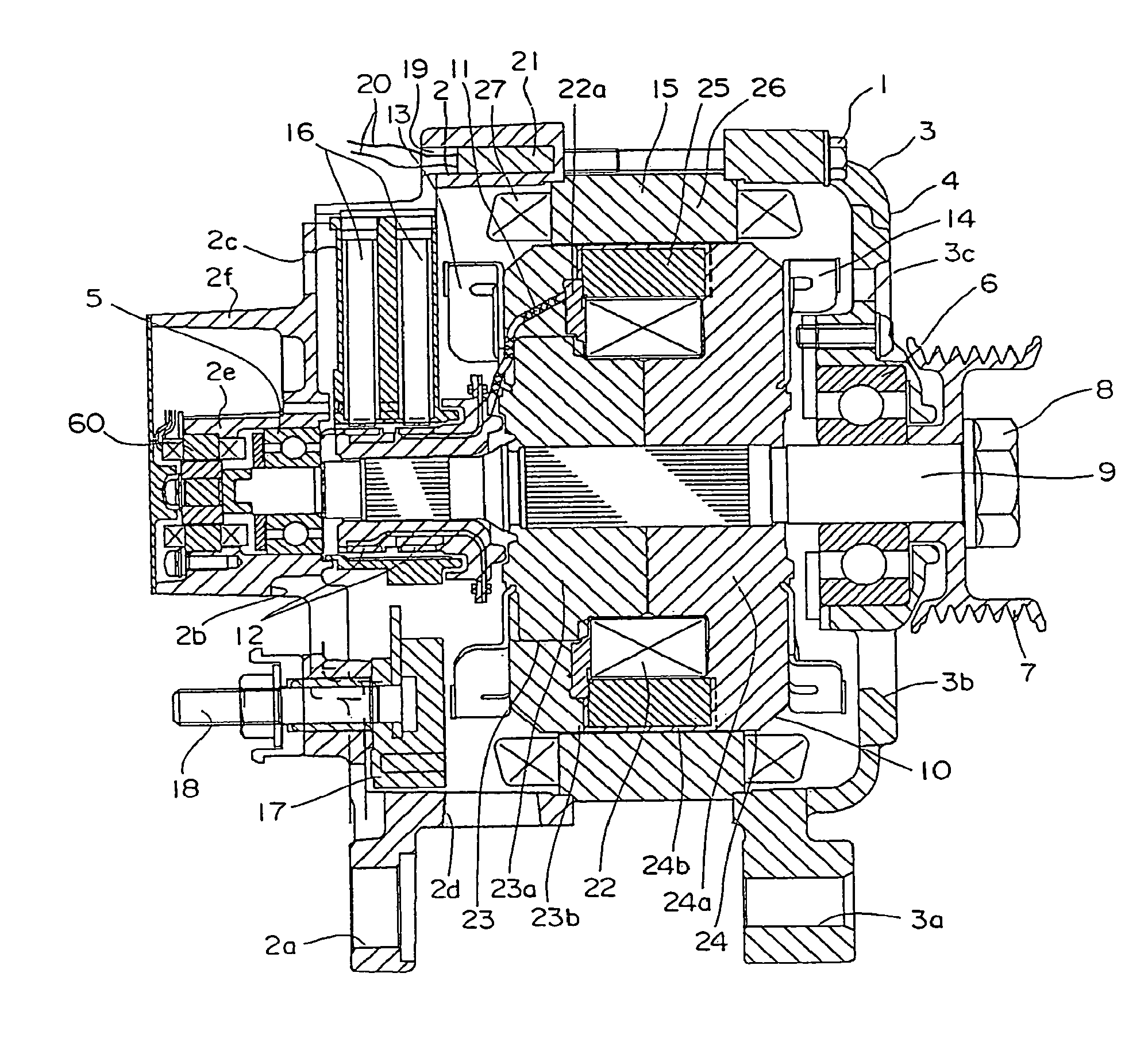

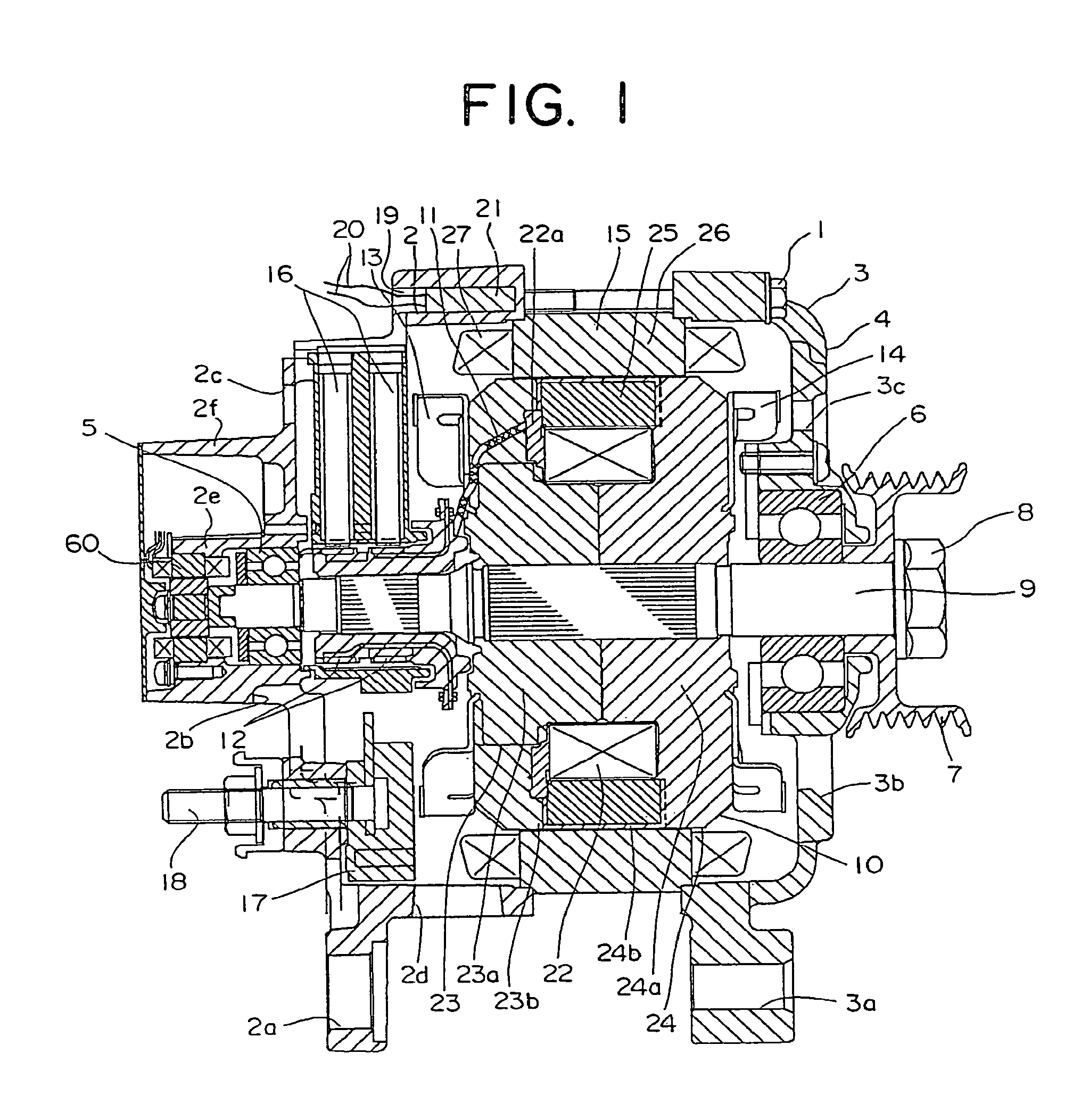

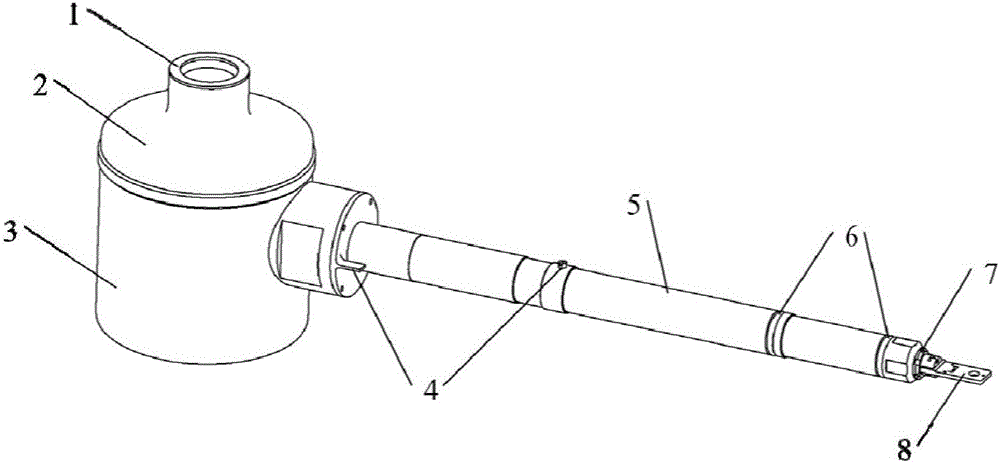

Catheter for treating irregular heart pulse

ActiveUS20050203597A1Insert smoothlyImproved ease of insertionDilatorsDiagnostic recording/measuringCardiac rhythm disturbancesFront edge

A catheter for treating arrhythmia comprises a catheter shaft of a double-cylinder structure where an inner shaft is slidably inserted in an outer shaft, a balloon installed so as to straddle between the tip portion of the inner shaft and the tip portion of the outer shaft, a pair of high frequency current-carrying electrodes of which at least one electrode is provided inside the balloon, and a temperature sensor for monitoring the temperature in the balloon. The front edge portion of the balloon at least in a deflated state protrude from the tip portion of the inner shaft. Alternatively, a tube that is more flexible than the inner shaft is provided on the tip portion of the inner shaft.

Owner:TORAY IND INC

Charging system and battery pack

InactiveUS20020079867A1Accurate temperature detectionBatteries circuit arrangementsSecondary cells charging/dischargingEngineeringLithium-ion battery

Charging device 10 charges nickel-hydrogen batteries 58, while adjusting the current value so that the temperature follows the target temperature rise pattern. Therefore, nickel-hydrogen batteries that demonstrate a large temperature increase can be charged within a short time so that a high temperature is not attained. Furthermore, when lithium ion batteries 58 are charged, the current value is controlled so that the voltage follows the target voltage rise pattern. Therefore, lithium ion batteries can be charged at a potential no higher than the preset level.

Owner:MAKITA CORP

Vehicle Lighting Device and LED Light Source Therefor

InactiveUS20070041185A1Avoid temperature riseAccurate temperature detectionVehicle headlampsDischarge tube luminescnet screensParticulatesFluorescence

The disclosed subject matter aims to provide a vehicle lighting device and an LED light source therefore. Accurate temperature detection of an LED chip and associated phosphor can be monitored in real time. The LED light source can include at least one LED chip mounted on a base and a phosphor layer disposed adjacent the LED chip. A mixed particulate phosphor for generating fluorescence by means of the light emitted from the above LED chip can also be provided. The LED light source can be configured to output mixed color light containing the light from the LED chip and the fluorescence from the phosphor. The LED light source can also include a temperature detecting element located on the base and LED chip to detect the temperature on the periphery of the LED chip.

Owner:STANLEY ELECTRIC CO LTD

Battery protection IC chip

ActiveUS20060164041A1Accurate temperature detectionCoupling device connectionsDynamo-electric motor metersCharge controlEngineering

A lithium-ion battery protection module is disclosed. The lithium-ion battery protection module includes a control IC chip. The control IC chip includes a discharge overcurrent detector, a charge overcurrent detector, and a temperature detector. The control IC chip is mounted on a charge control FET and a discharge control FET so as to highly accurately detect the temperature of the charge control FET and the discharge control FET.

Owner:MITSUMI ELECTRIC CO LTD

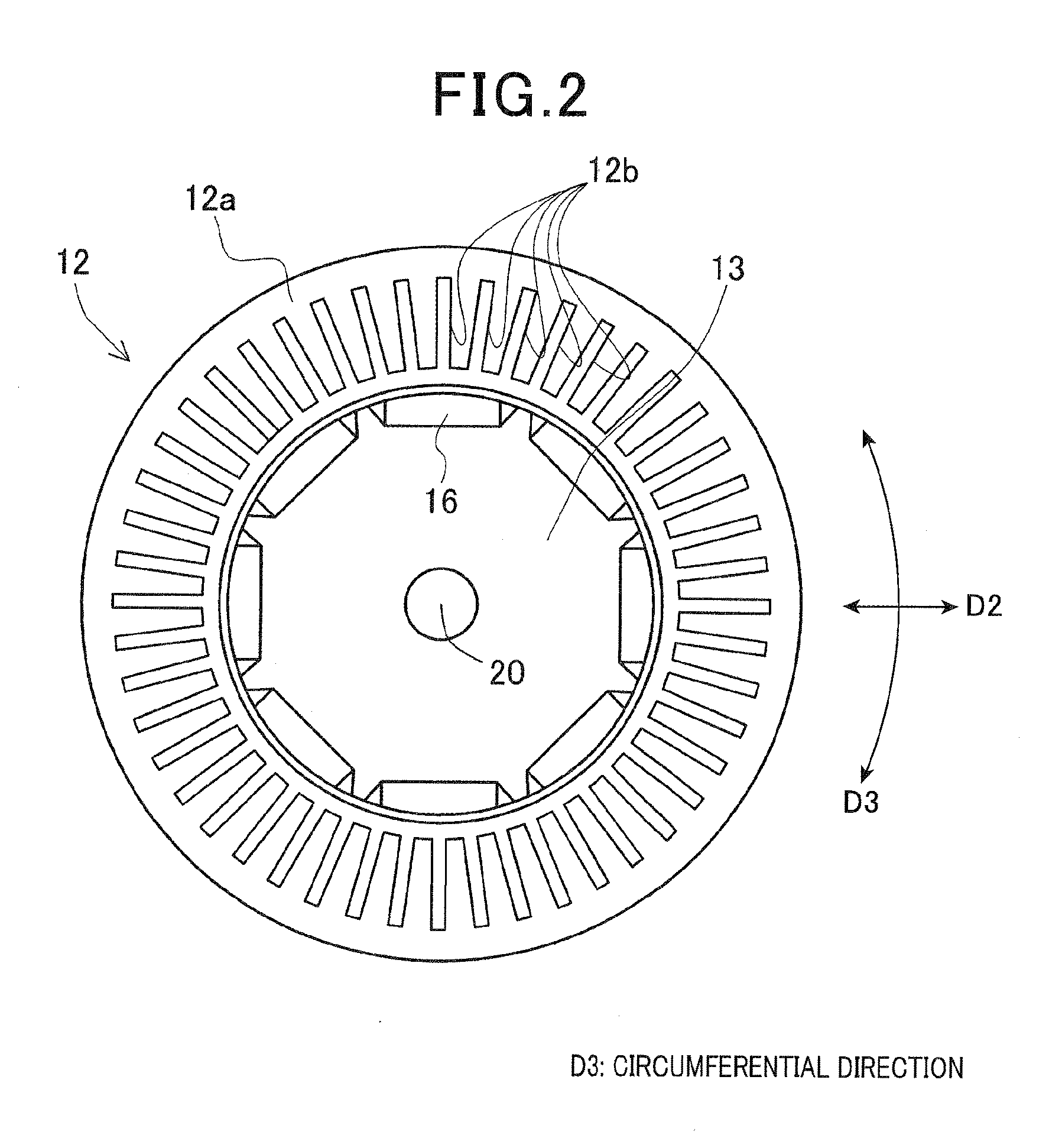

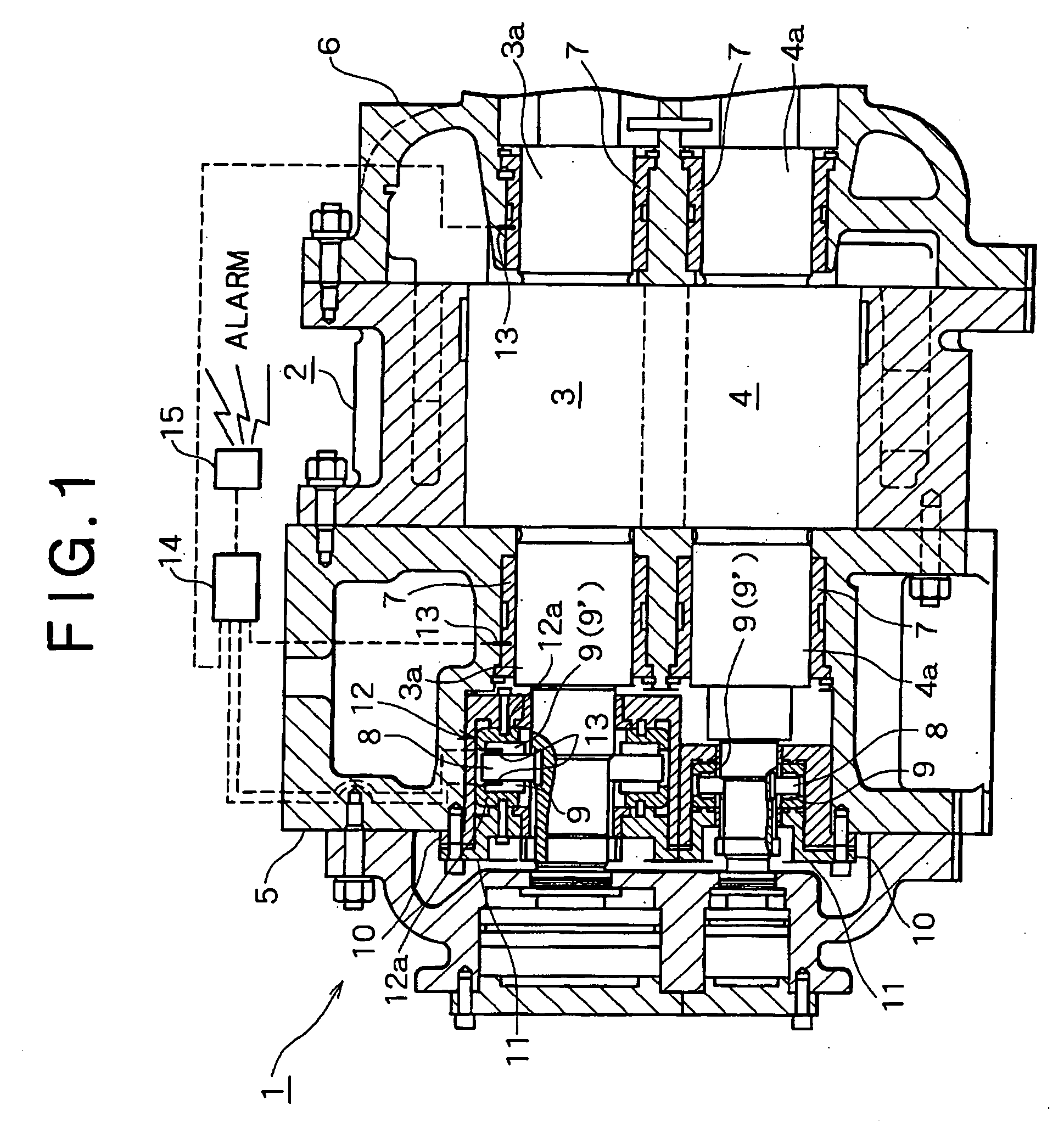

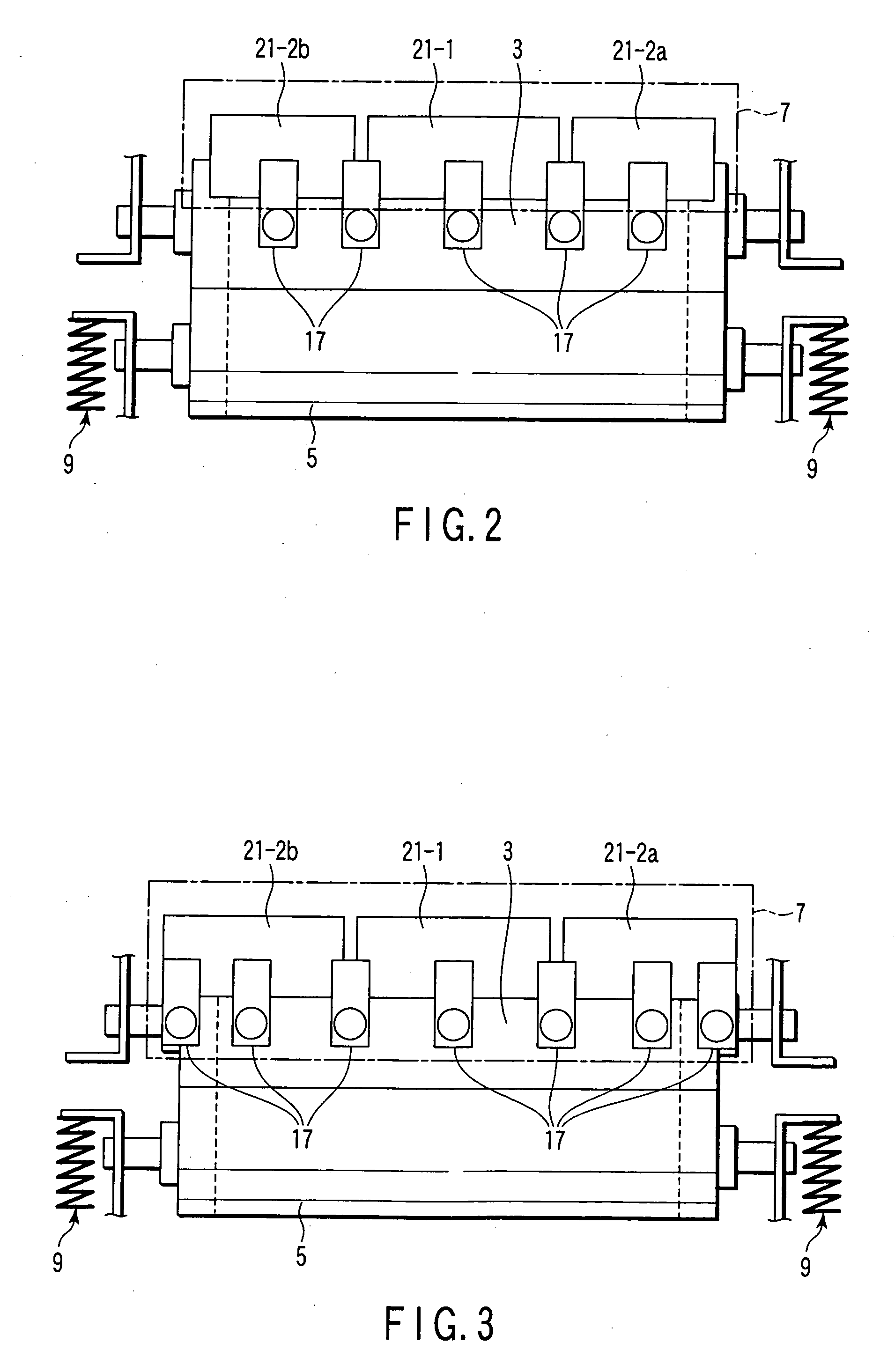

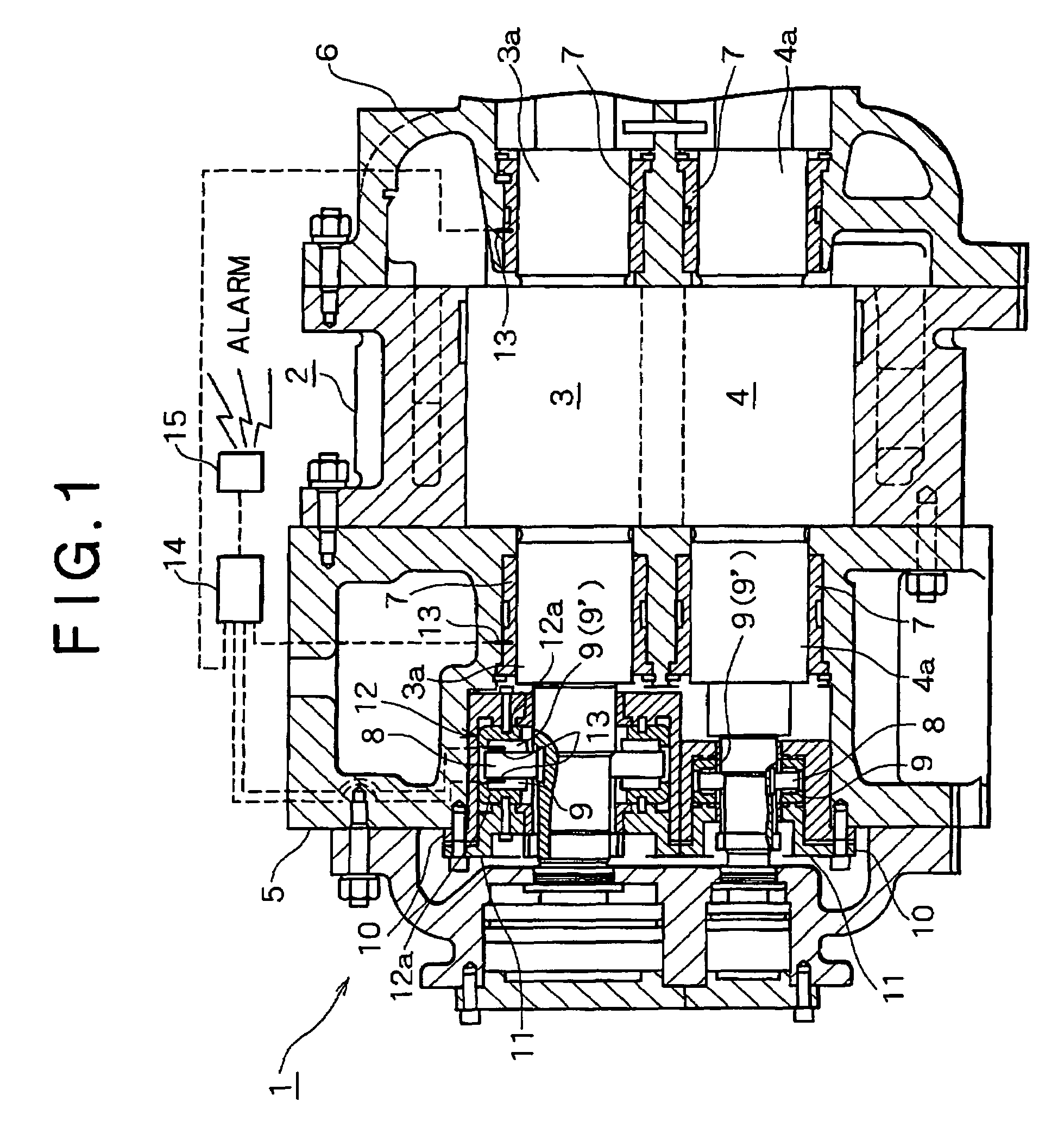

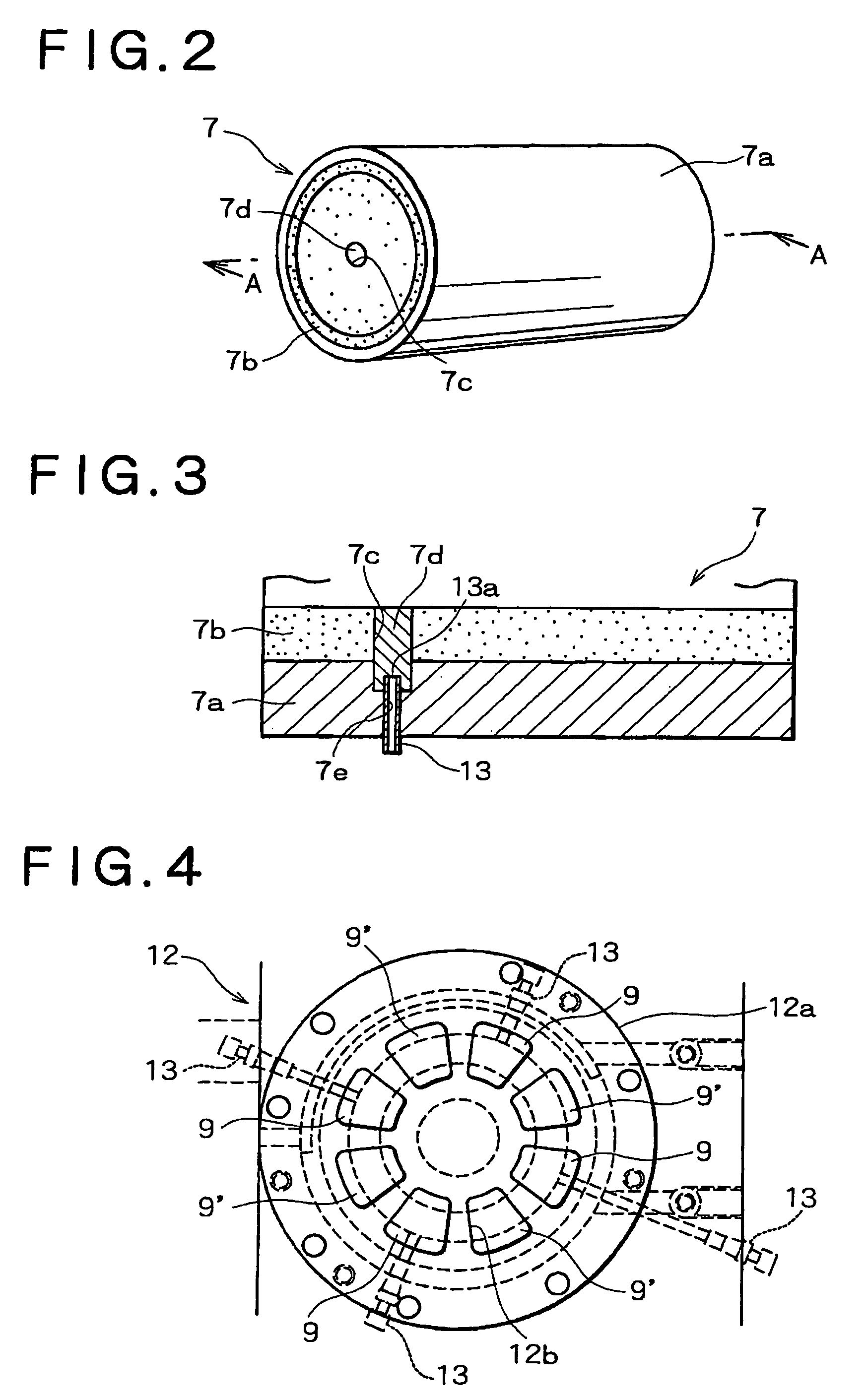

Stator and rotating electric machine including the same

ActiveUS20140191629A1Accurate temperature detectionAccurate detectionWindings insulation shape/form/constructionStructural associationElectrical conductorElectric machine

A stator includes a stator core, a winding, and a temperature sensor. In the stator core, a plurality of slots are formed in a circumferential direction of the stator. The winding is formed by a plurality of conductors which are housed in the slots and are electrically connected. The slots are formed such that a predetermined number of the conductors are housed and arrayed in a radial direction of the stator. The temperature sensor is located in at least one of the slots and detects temperature of the conductors.

Owner:DENSO CORP

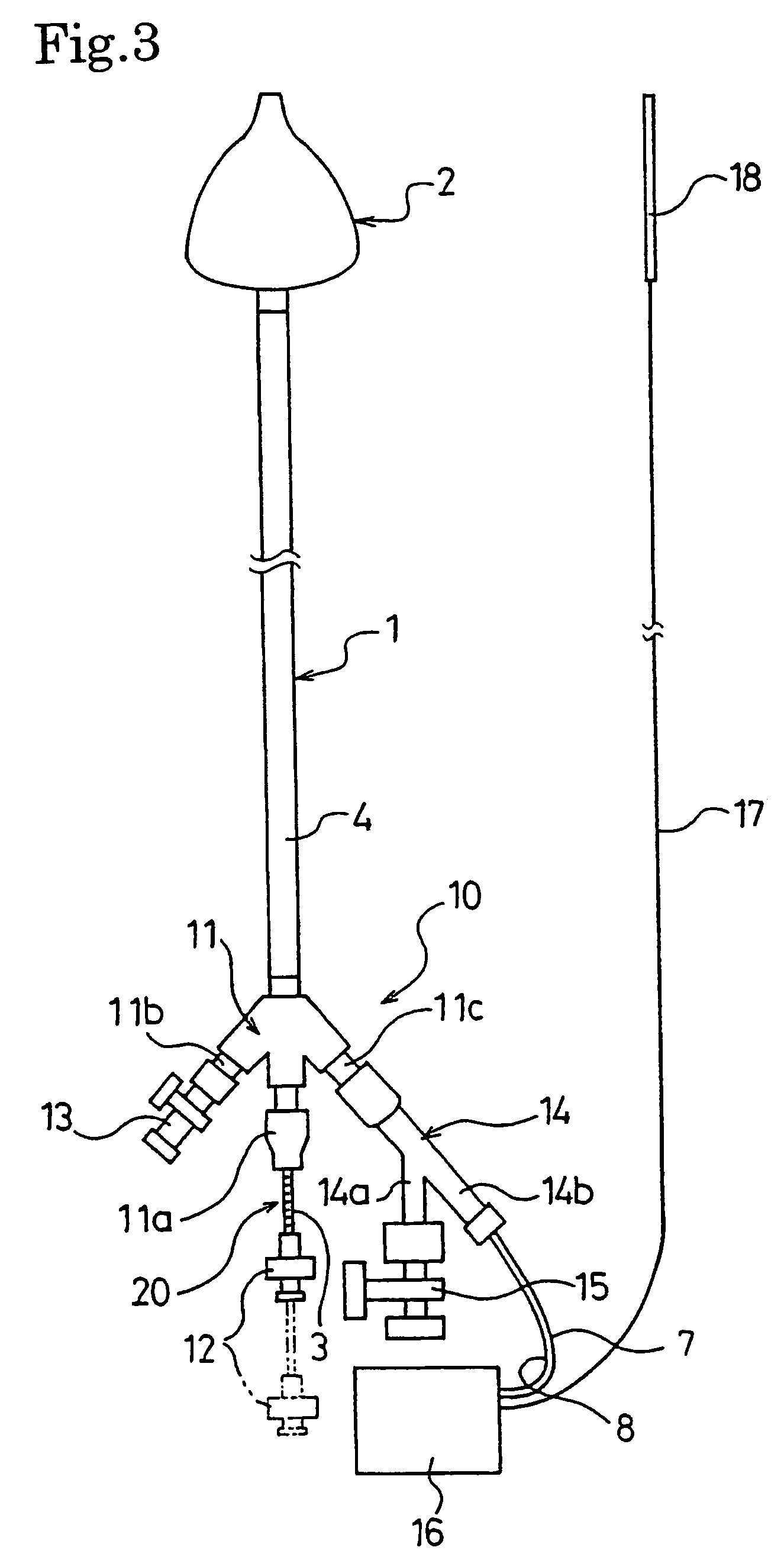

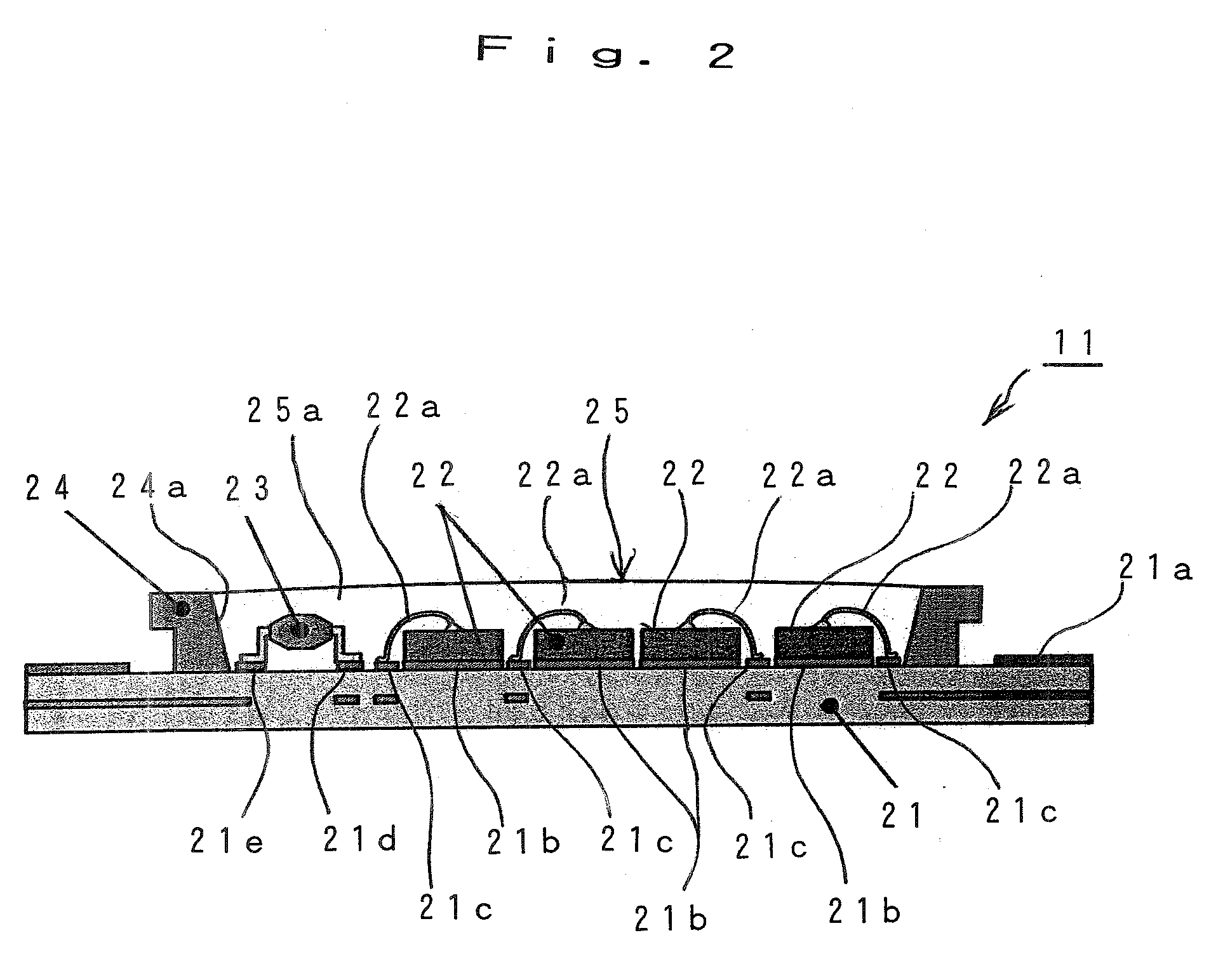

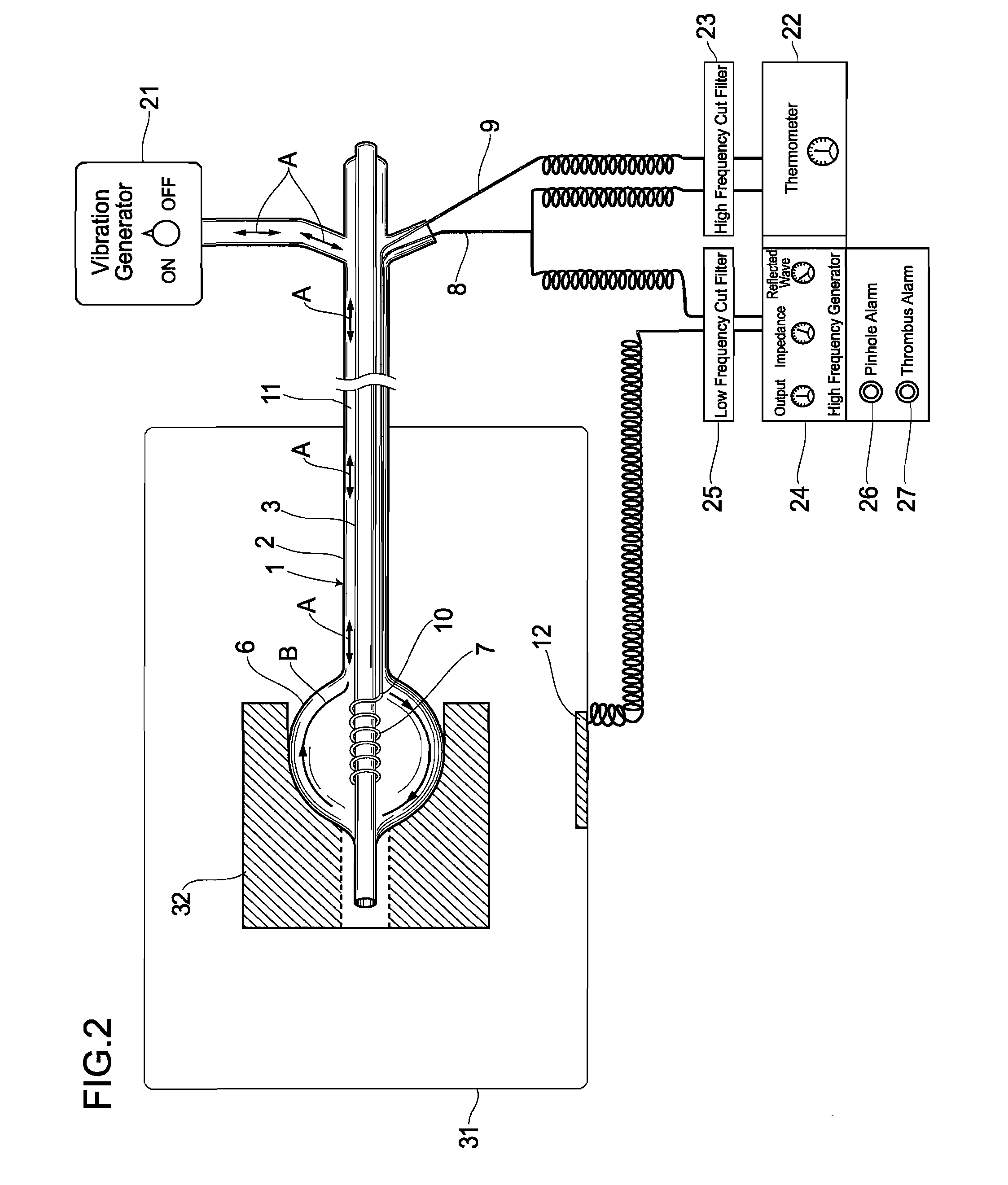

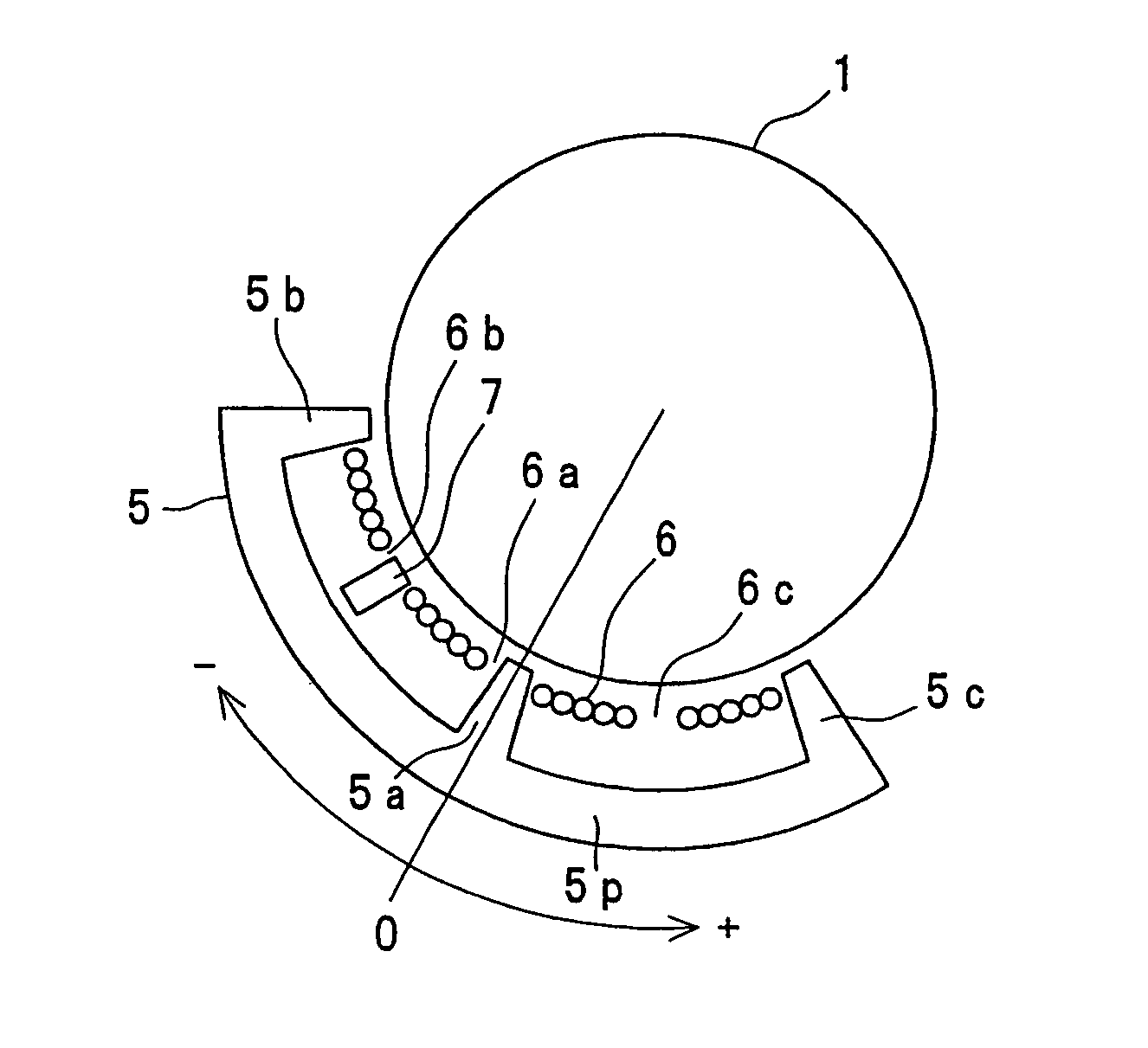

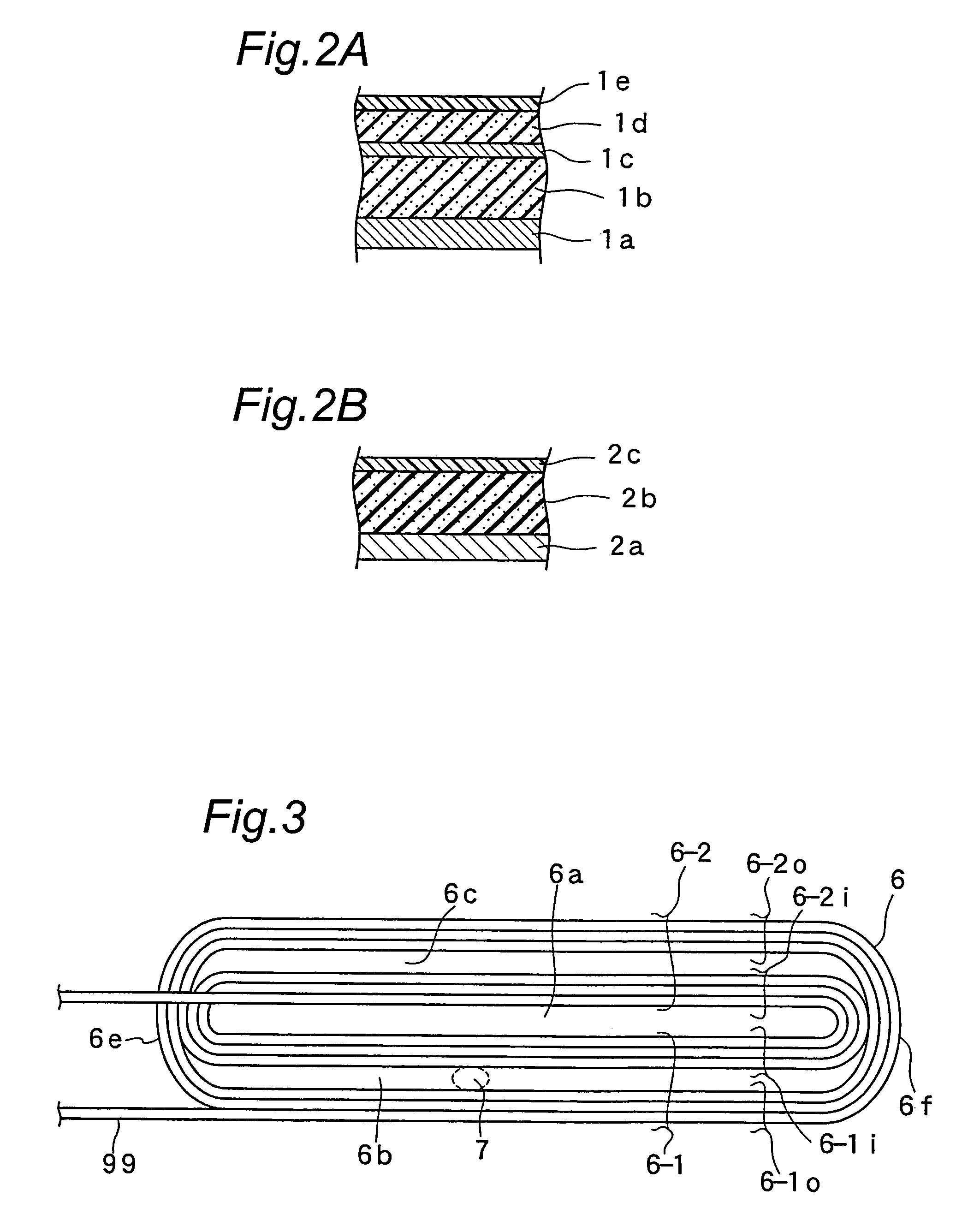

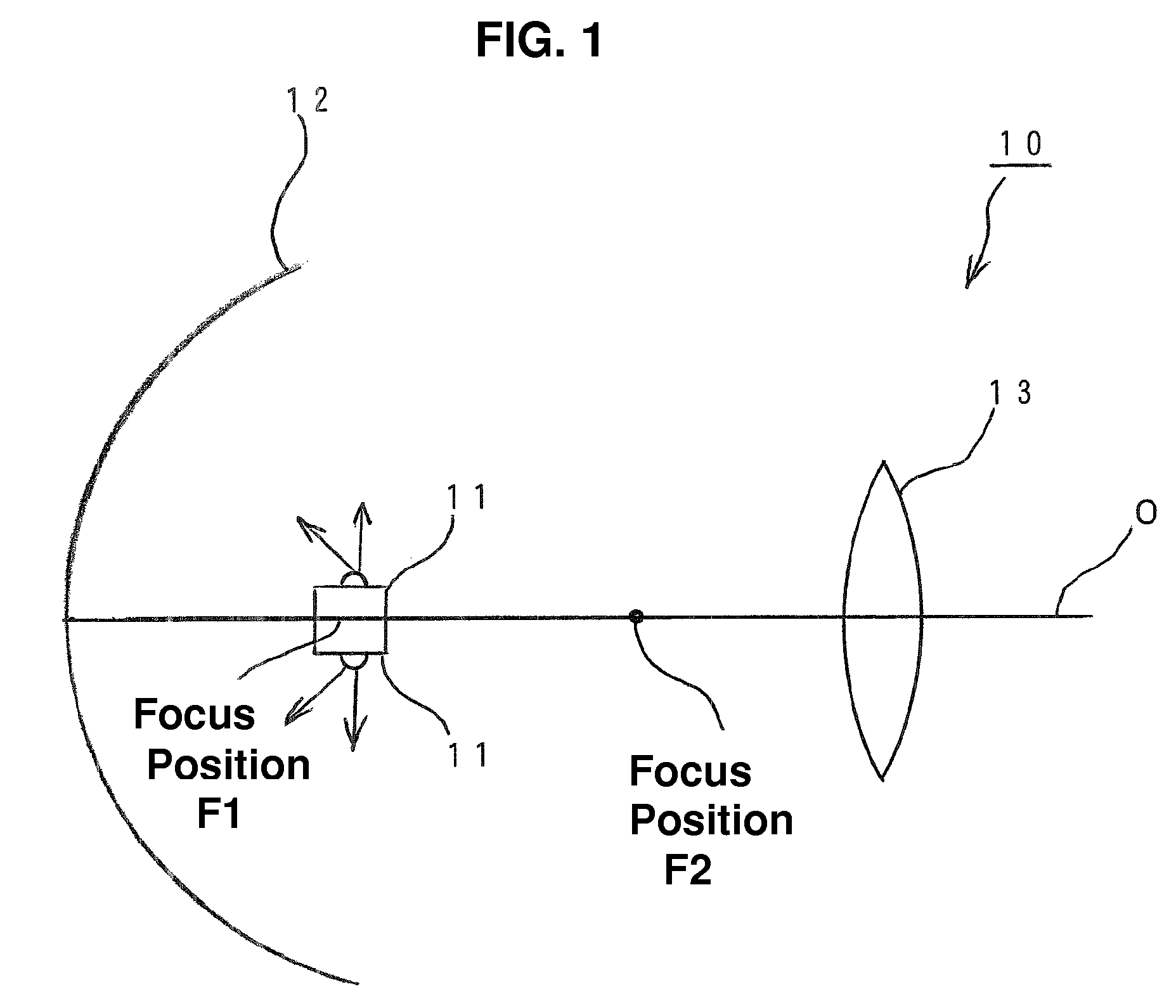

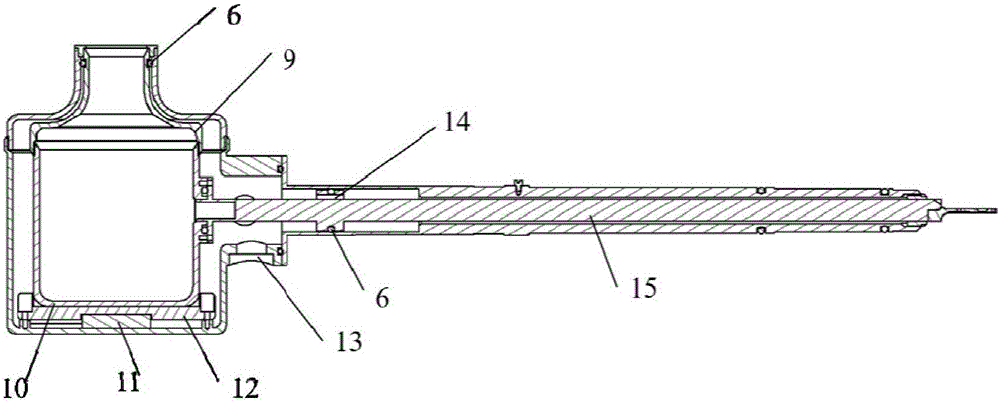

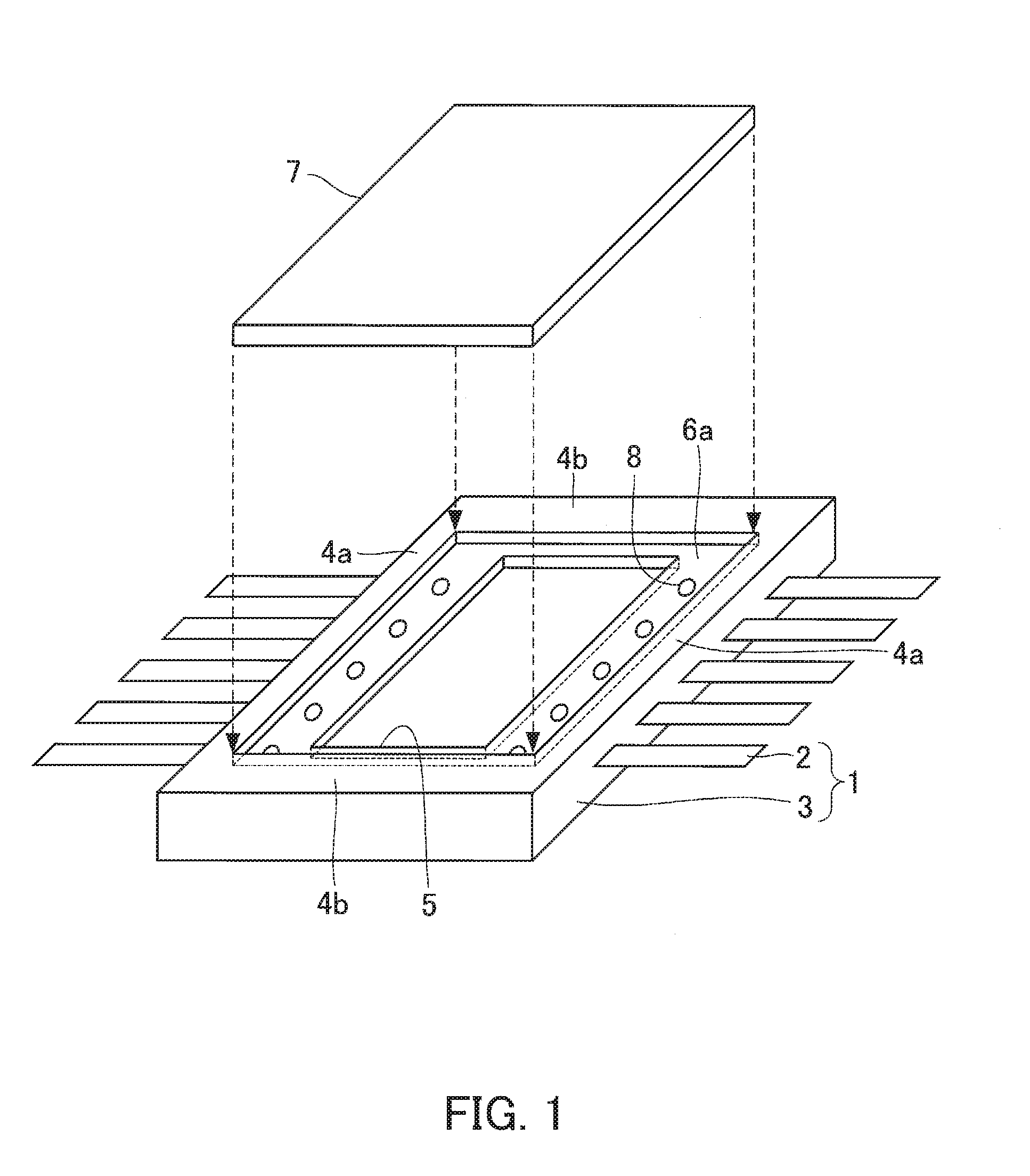

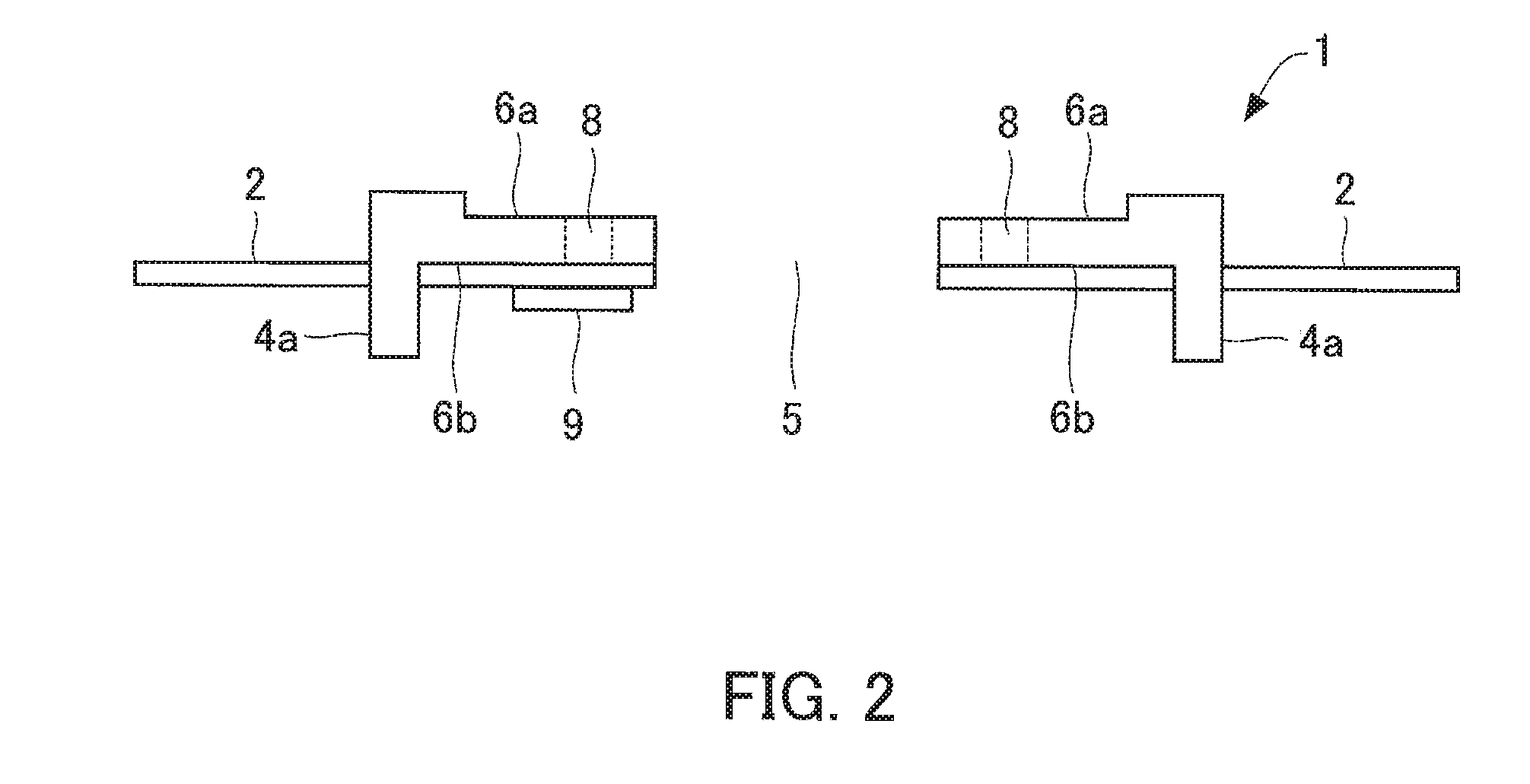

Radiofrequency thermal balloon catheter system

InactiveUS20080172050A1Small heat capacityAccurately and instantaneously detectedSurgical instruments for heatingAutomatic controlMiniaturization

A radiofrequency thermal balloon catheter system which is accurate in the detection temperature, capable of miniaturization compared to conventional systems, reliably detecting pinholes and adhesion of thrombi. A thermocouple is composed of a radiofrequency transmission line and a single metal wire joined to the distal end thereof. A coiled electrode is formed in a coil shape by extending the distal end of the radiofrequency transmission line. The distal end of the metal wire is brought into pin-point connection with the proximal end of the coiled electrode. A radiofrequency generator monitors the radiofrequency output, total impedance, and reflection waves, while supplying the coiled electrode and a counter electrode plate with a radiofrequency of 1 to 5 MHz, and automatically controls the radiofrequency output, so that the temperature of the coiled electrode can be kept at a target value.

Owner:JAPAN ELECTEL

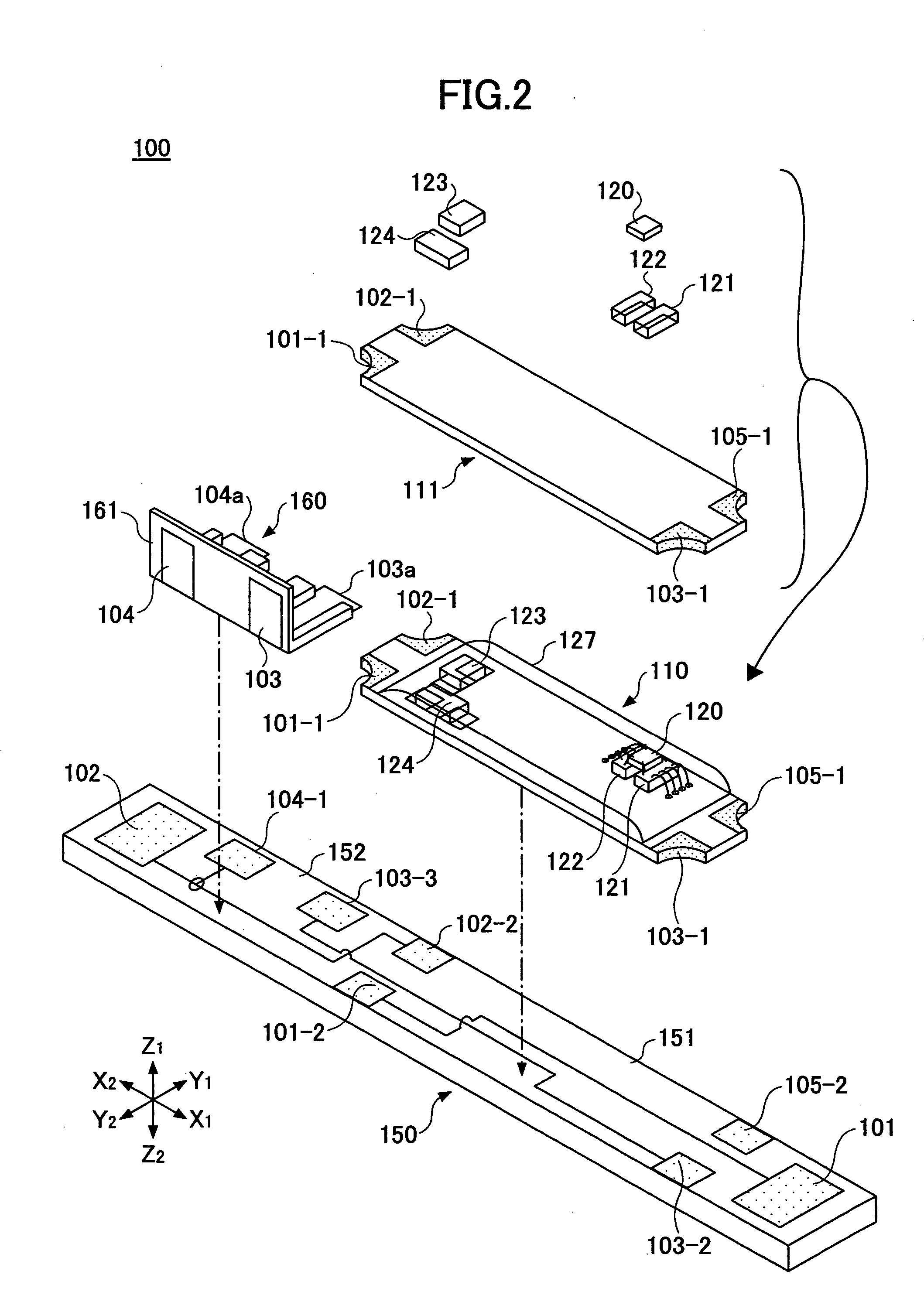

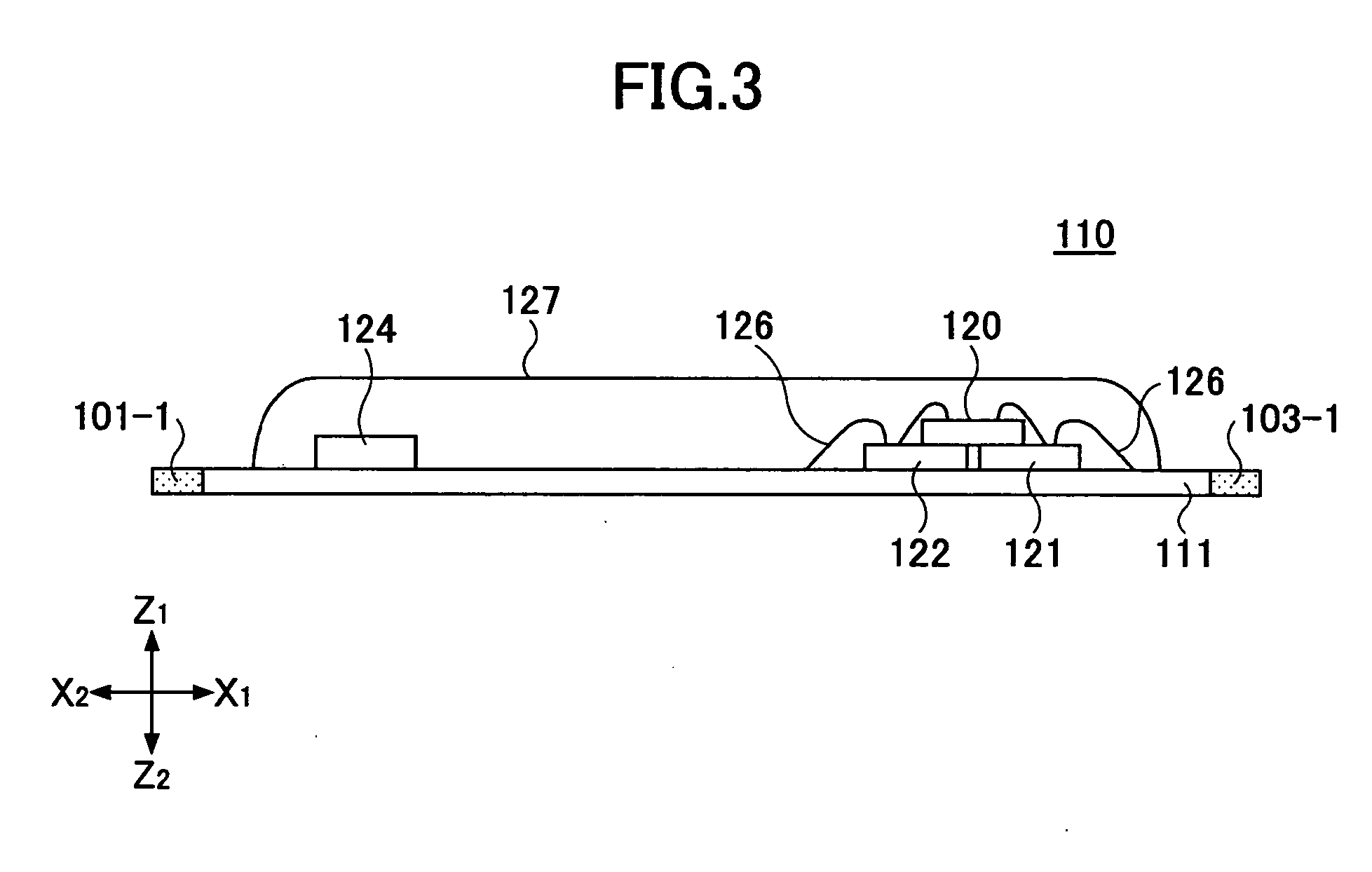

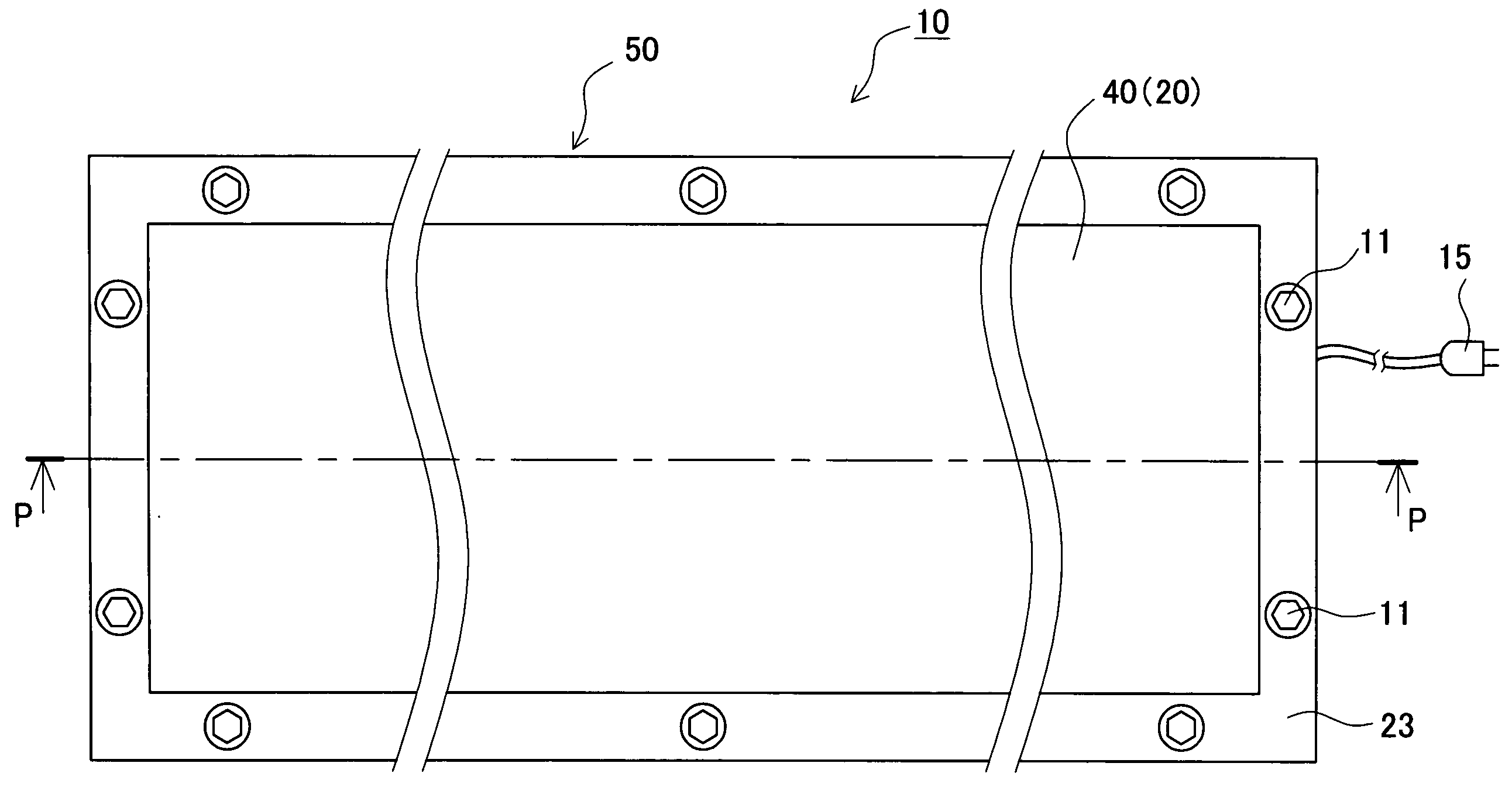

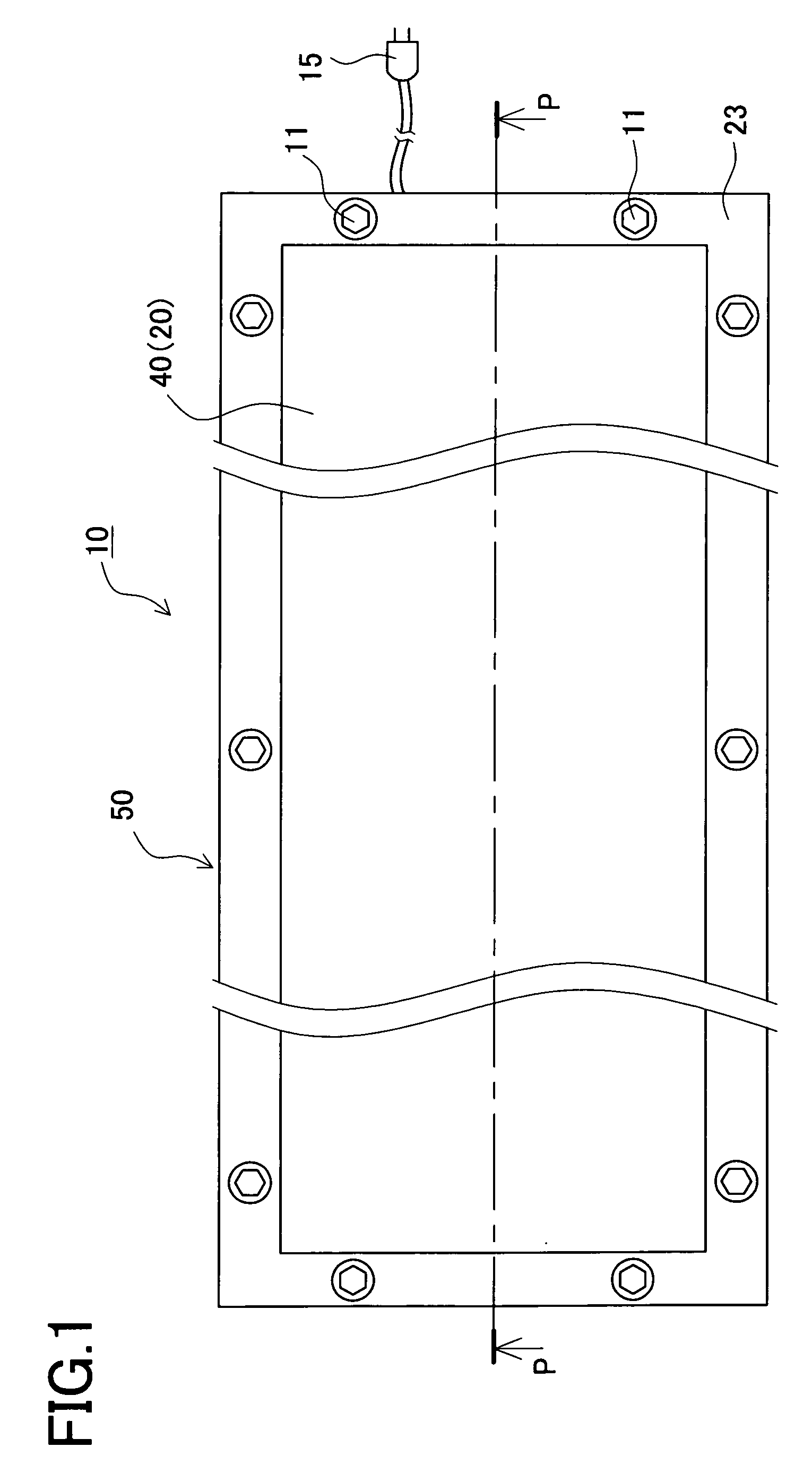

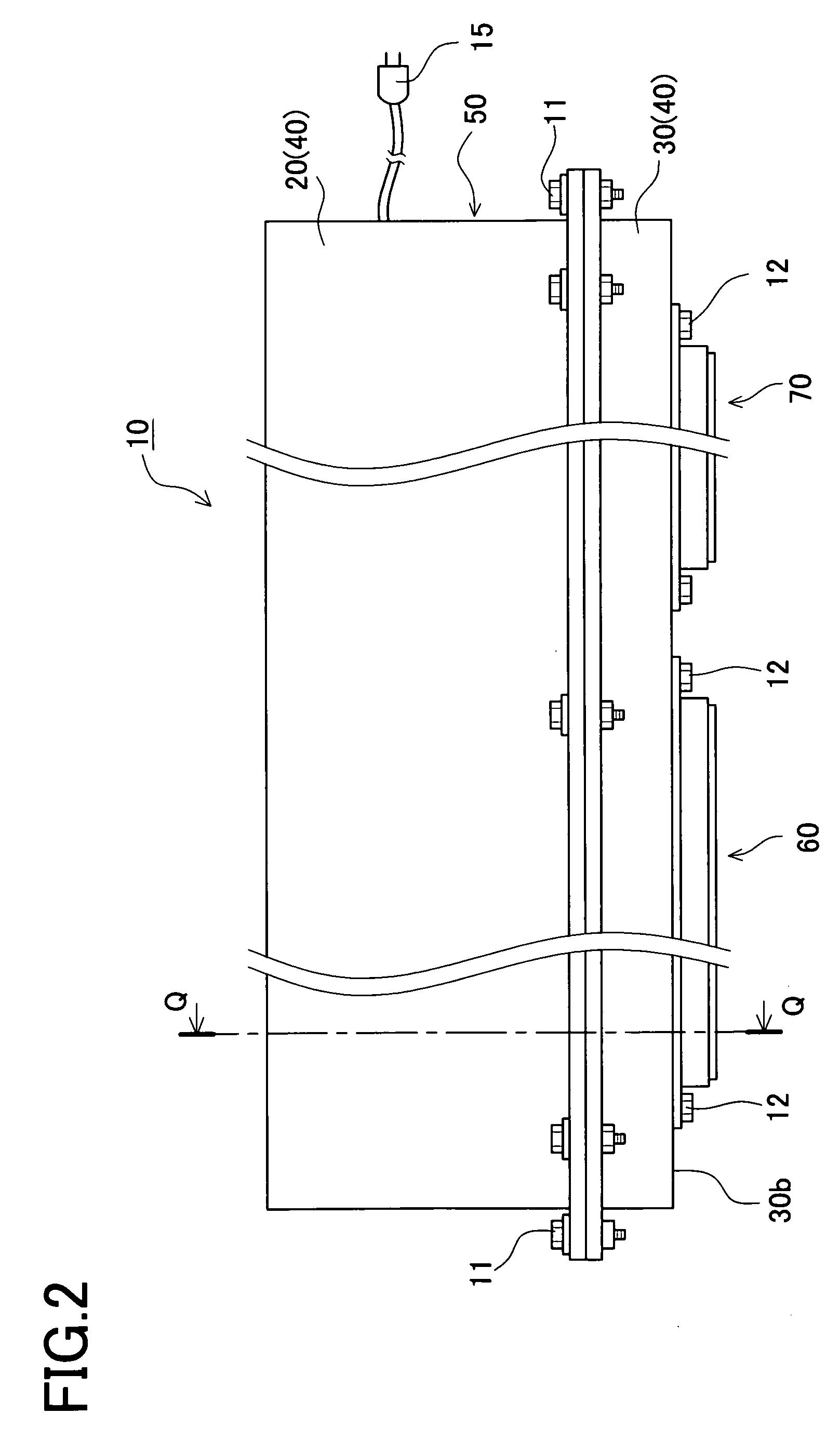

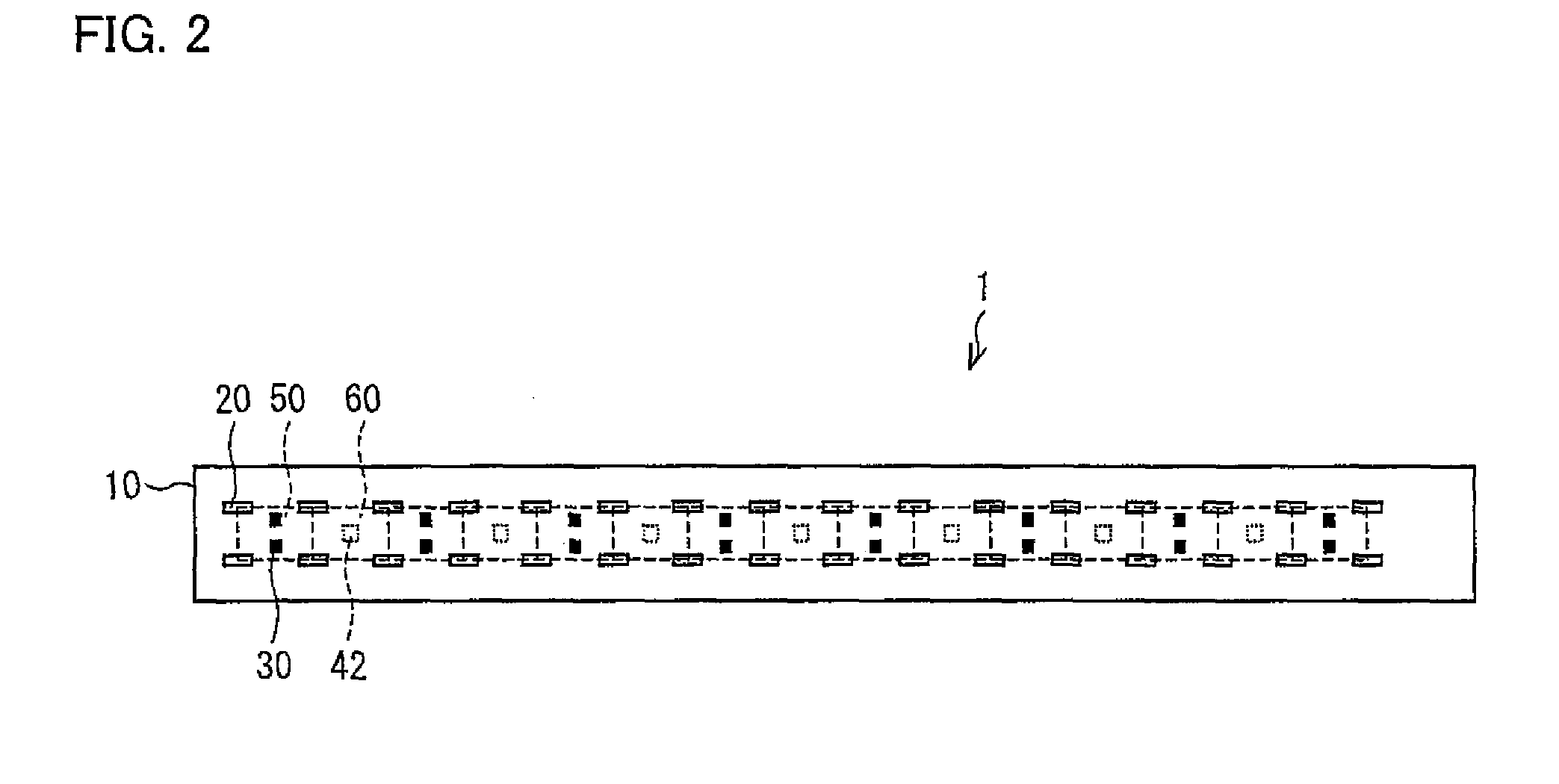

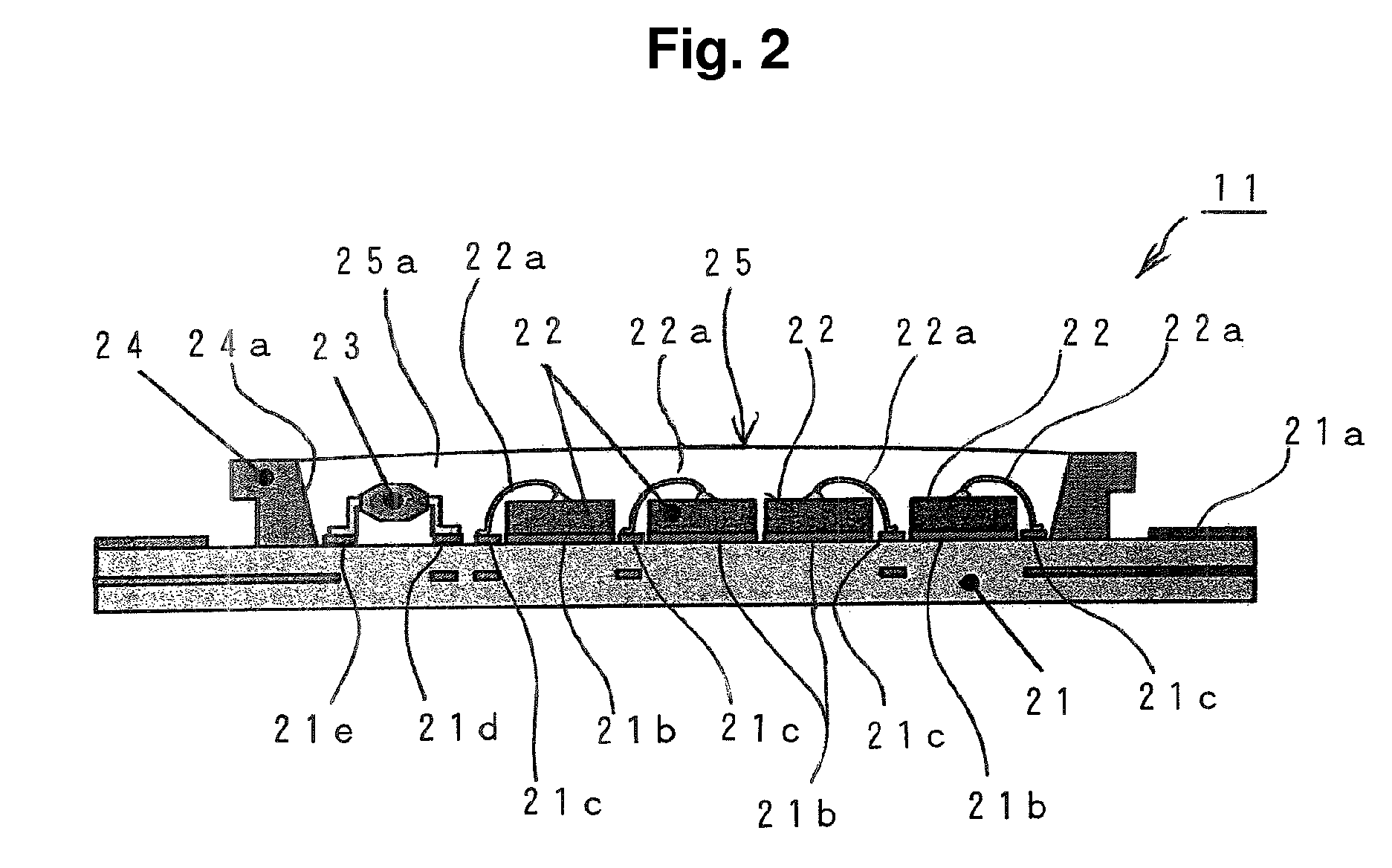

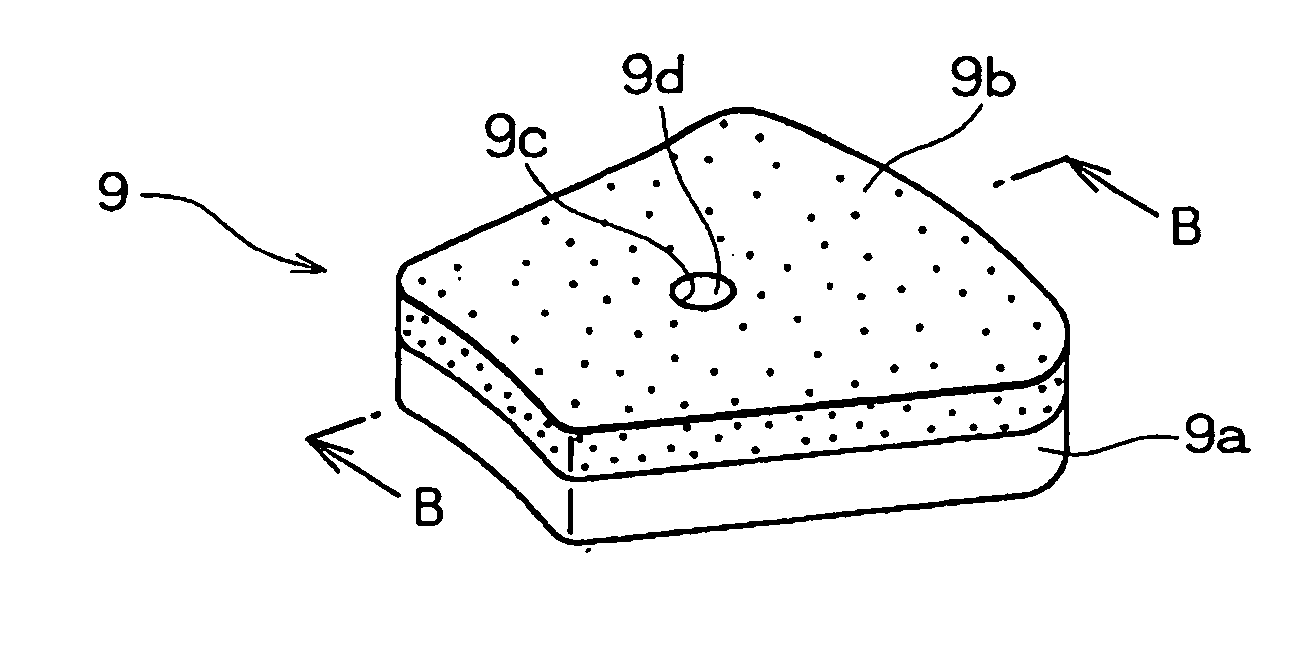

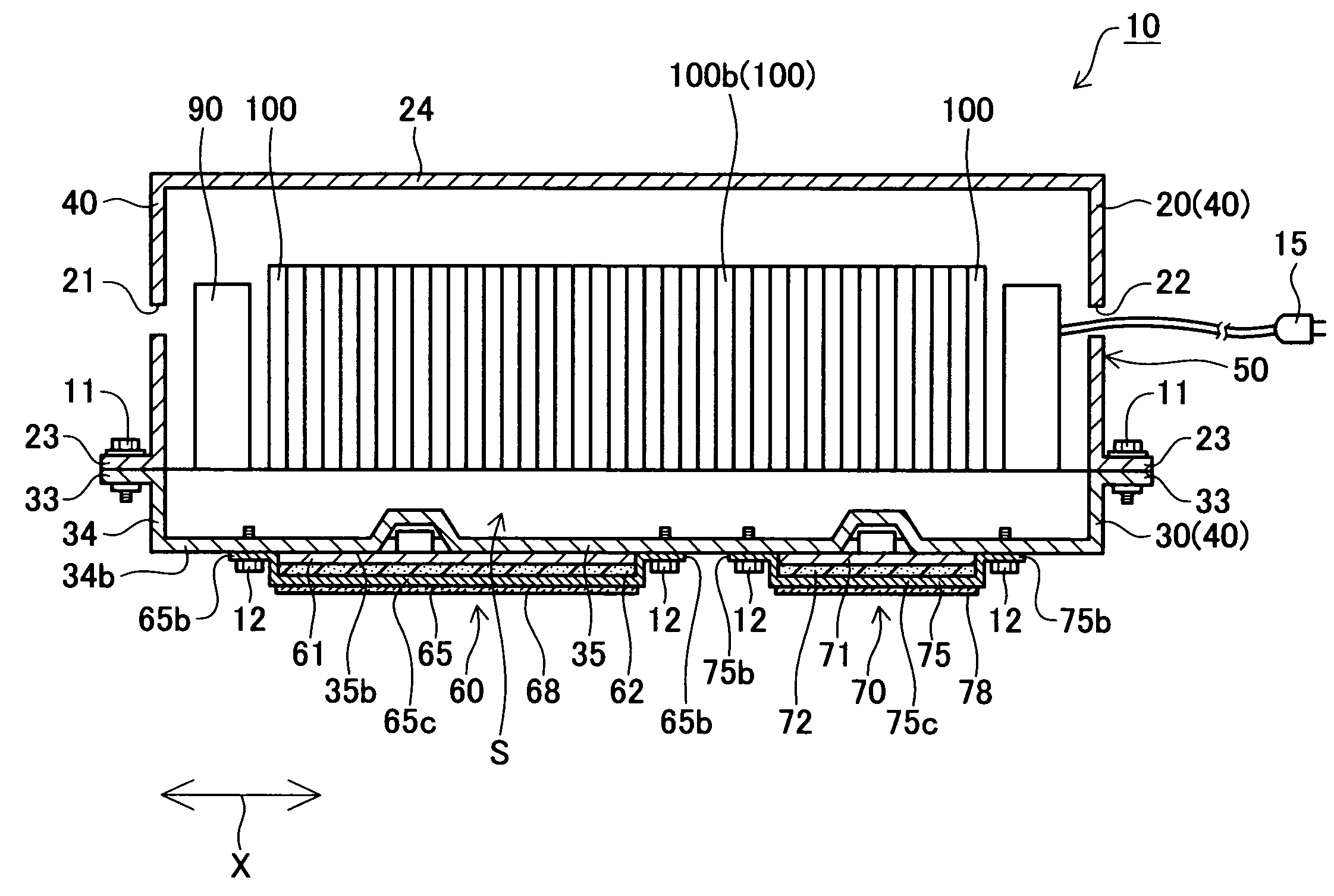

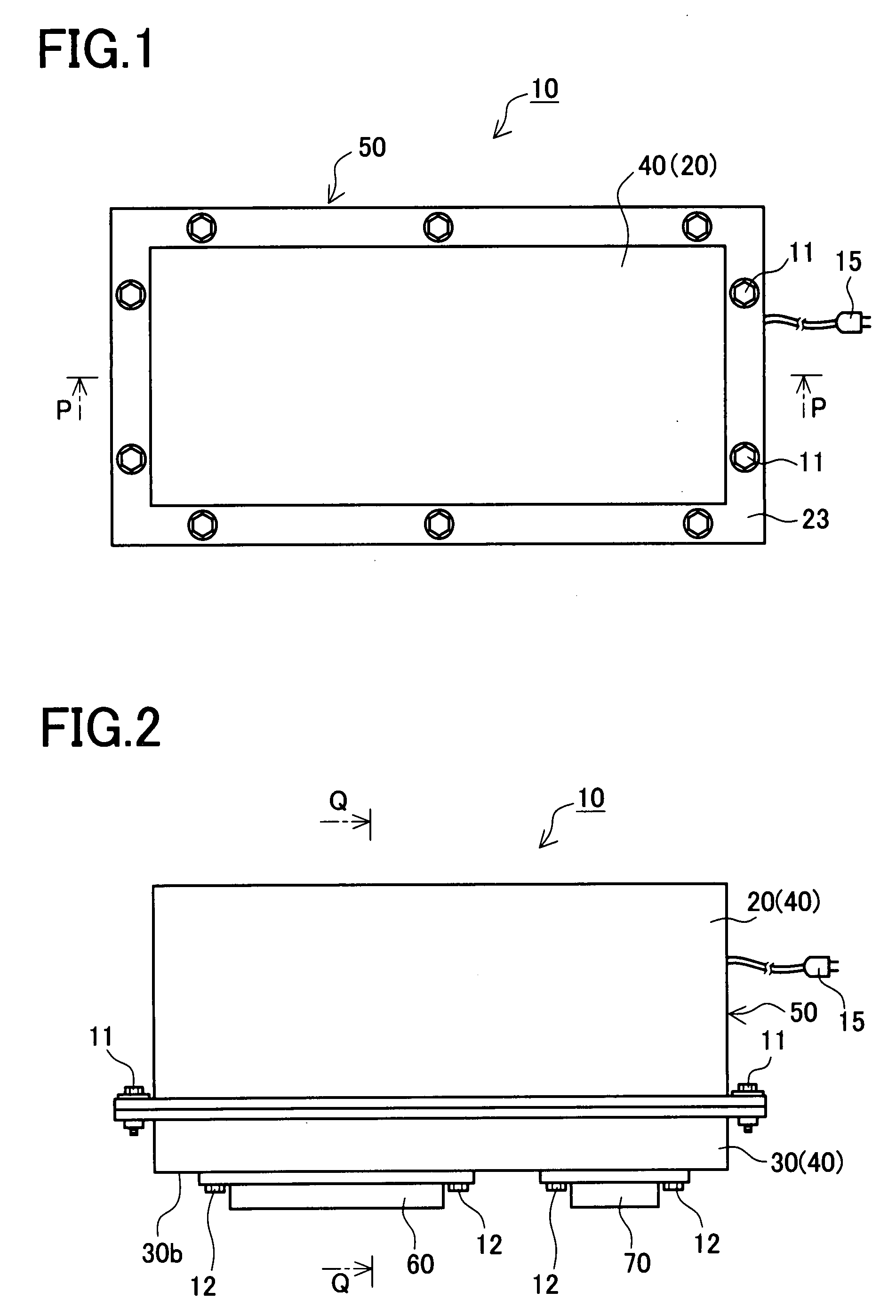

Heater with temperature detecting device, battery structure with heater, and heater unit

InactiveUS20080198897A1Accurate temperature detectionThermometer detailsCell temperature controlMetal sheetEngineering

There are provided a heater with temperature detecting device capable of accurately detecting the temperature of a laminated sheet heater (the temperature of a heater element) by a temperature detecting device, a battery structure provided with this heater with temperature detecting device, and a heater unit. A first heater with temperature detecting device includes a first laminated sheet heater and a temperature detecting device. In this first heater, a first metal sheet includes a part protruding outward in a lamination direction of a laminated heater to provide at least part of an accommodation space in which the temperature detecting device is accommodated.

Owner:PANASONIC EV ENERGY CO LTD

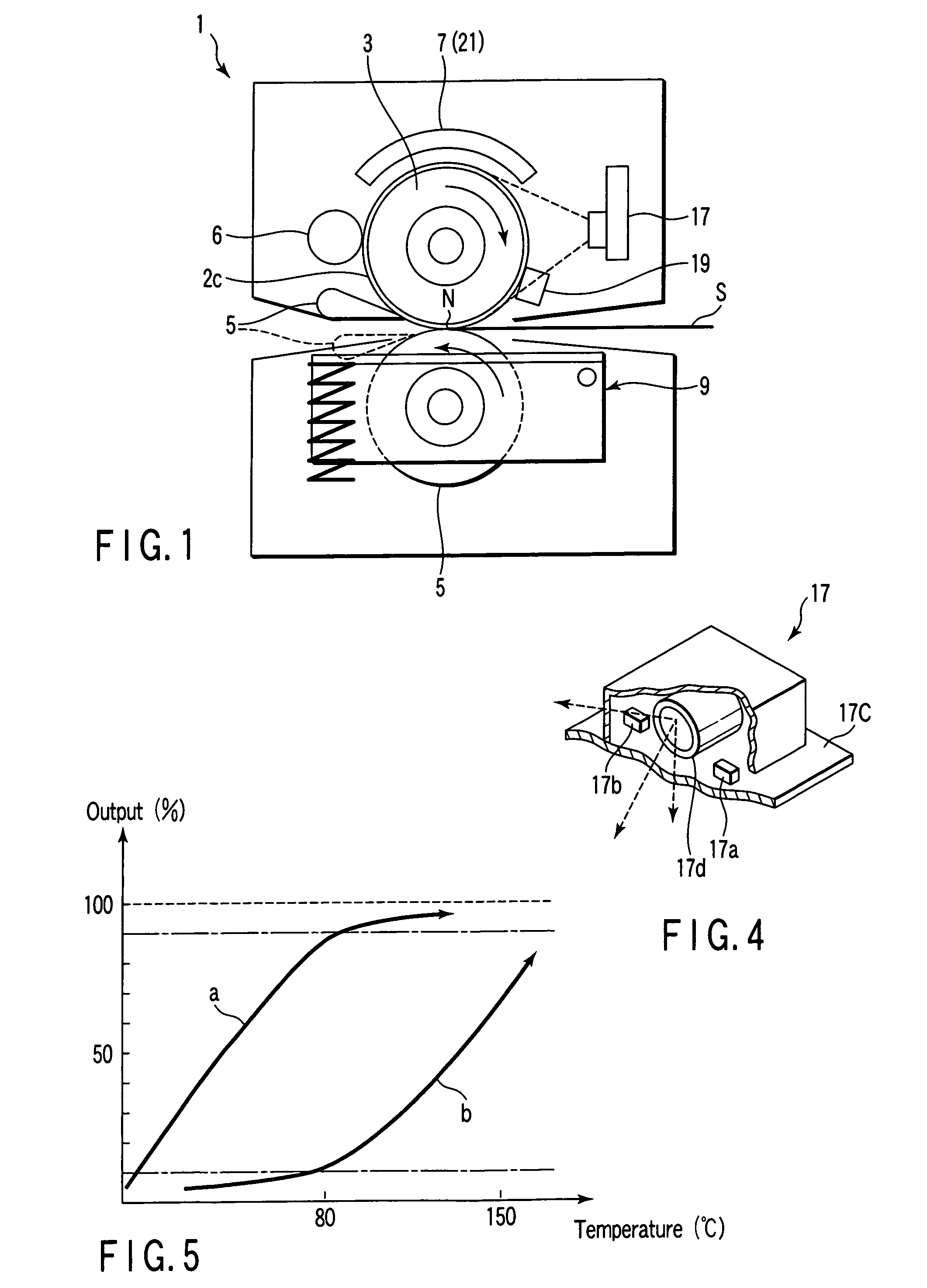

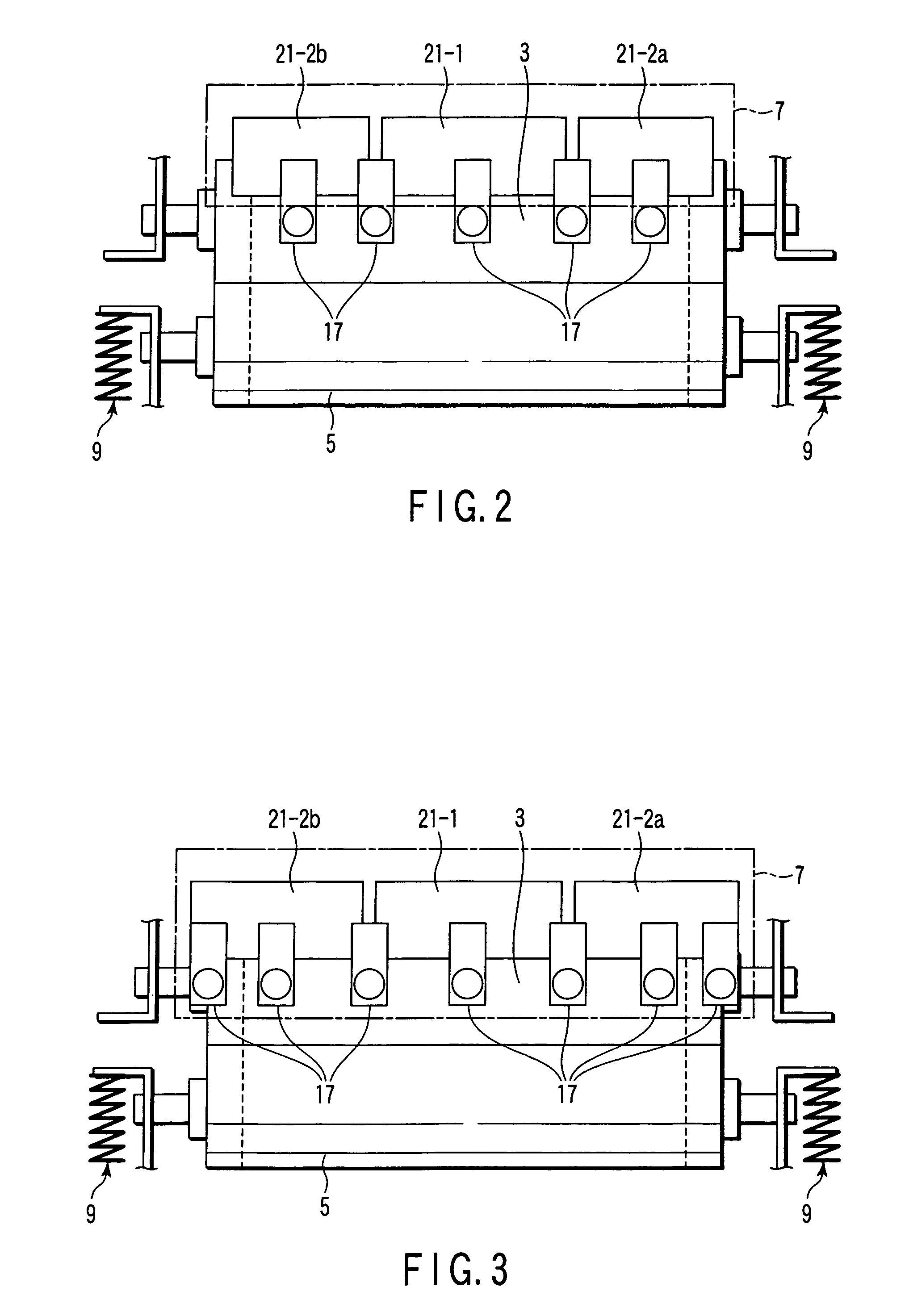

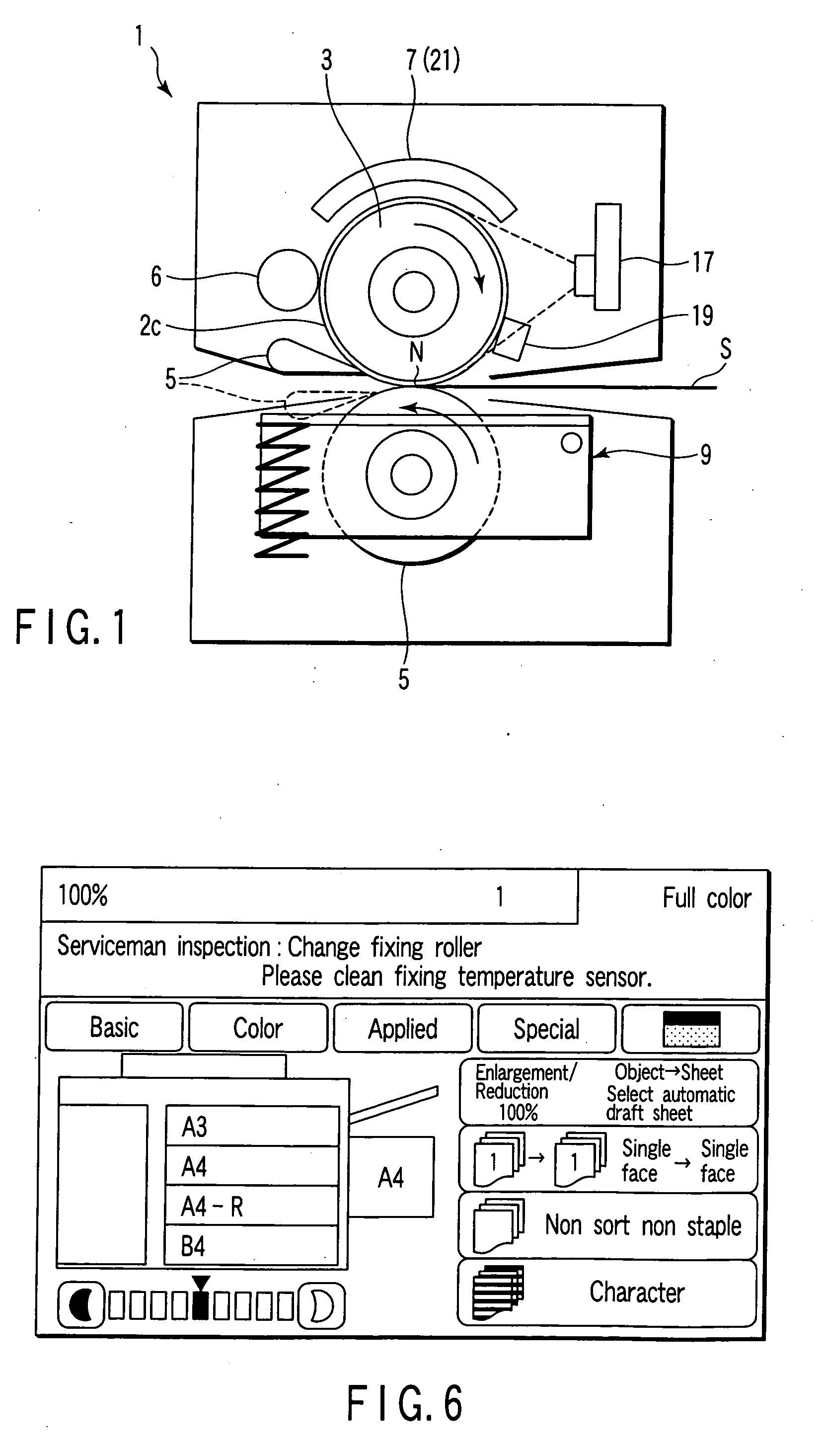

Apparatus for fixing toner on transferred material

ActiveUS20060062585A1Accurate temperature detectionStably fixing a tonerElectrographic process apparatusAtmospheric temperatureHigh heat

The present invention relates to a temperature detection apparatus having a radiant temperature detection section including at least a ray emission portion which radiates at least rays and a ray detection portion which detects the rays, and capable of detecting temperature without contacting a detection object, a first atmospheric temperature detection section which outputs temperature information having a high temperature follow-up property in a case where the atmospheric temperature of the radiant temperature detection section is not more than predetermined temperature, and a second atmospheric temperature detection section which outputs temperature information having a high temperature follow-up property in a case where the atmospheric temperature of the radiant temperature detection section exceeds the predetermined temperature.

Owner:KK TOSHIBA +1

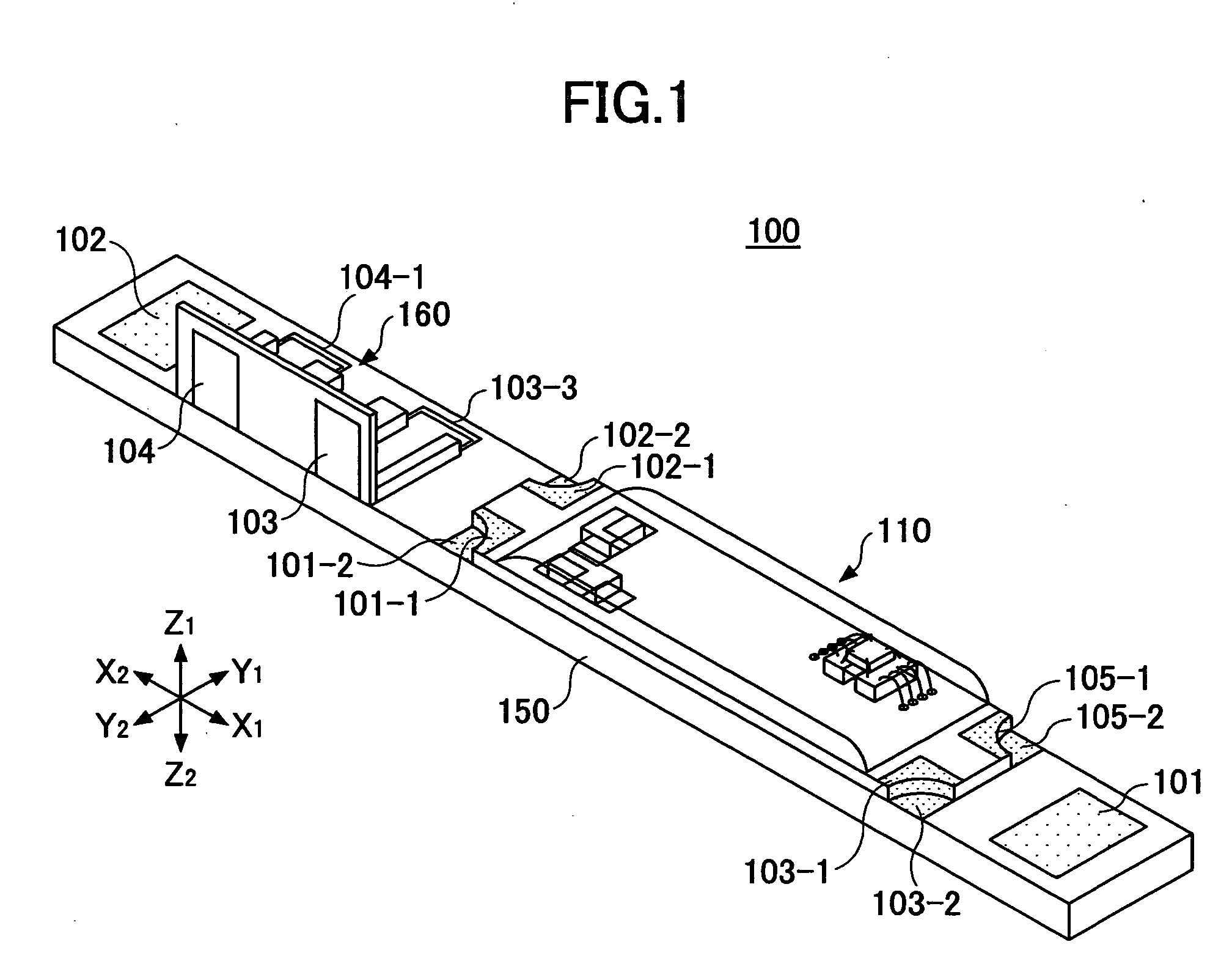

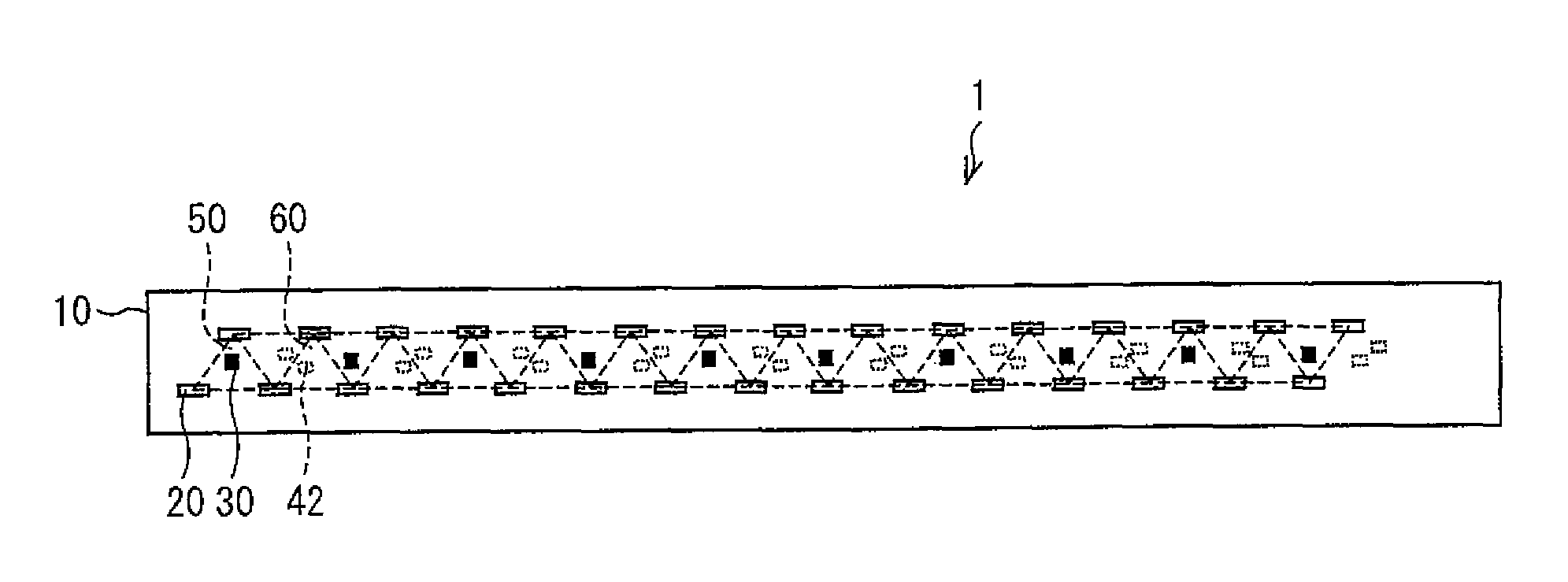

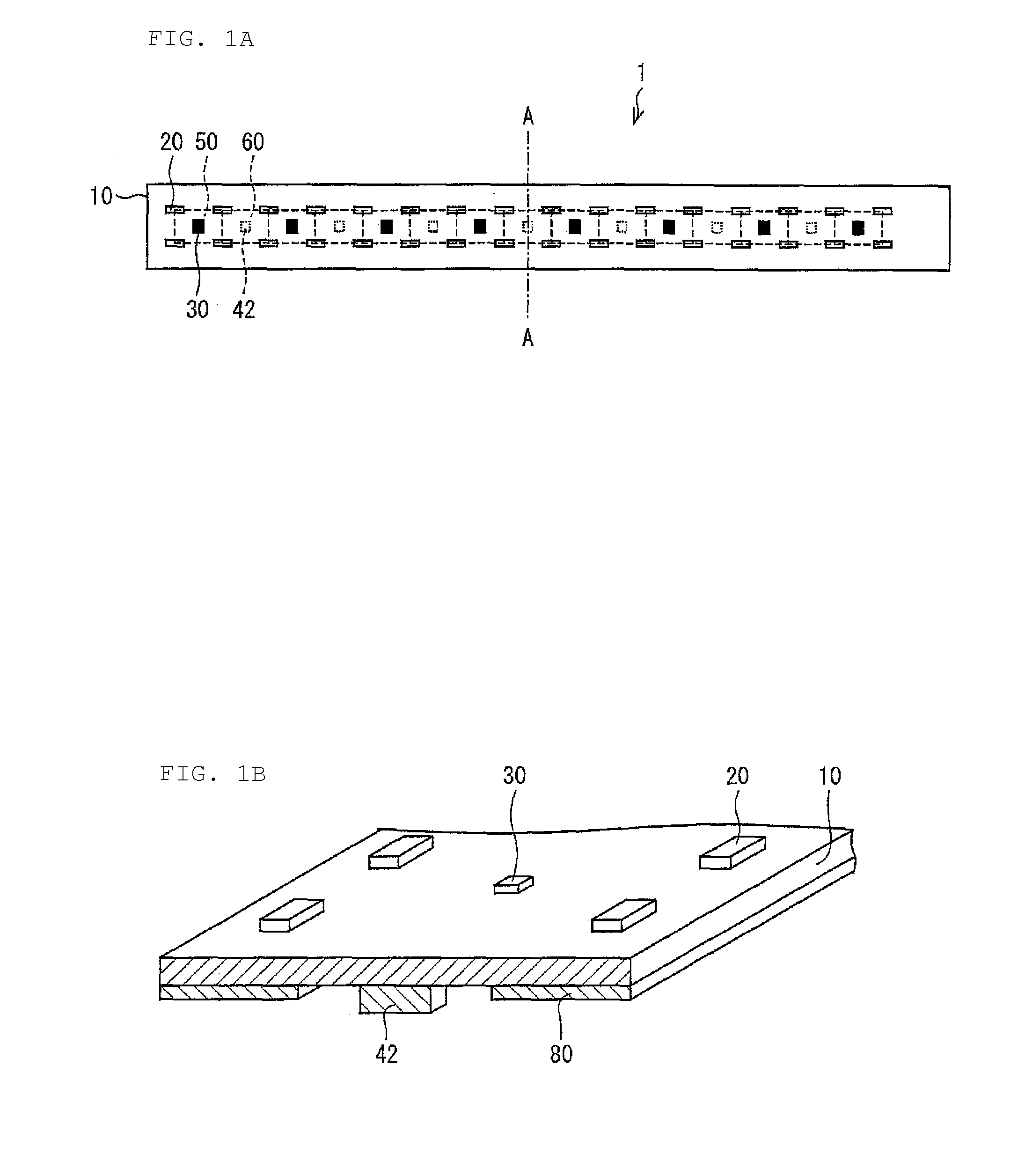

Illumination device and liquid crystal display device

ActiveUS8111371B2Accurate temperature detectionSmall temperature changeStatic indicating devicesLighting heating/cooling arrangementsElectrical resistance and conductanceLiquid-crystal display

An illumination device includes an LED package, an LED driver including an FET, and a thermistor disposed on a substrate. A plurality of such LED packages are disposed on the substrate such that a first area and a second area, each determined by vertices corresponding to LED packages, are defined on the substrate. The thermistor is disposed in the first area, and the FET is disposed in the second area, which is outside of the first area. The thermistor detects a temperature in the first area. Such a configuration allows the thermistor to detect, in accordance with the temperature in the area, the temperature of heat transferred from the LED packages, without being affected by heat generated by the FET. This makes it possible to efficiently make temperature corrections to stabilize color temperature and luminance.

Owner:SHARP KK

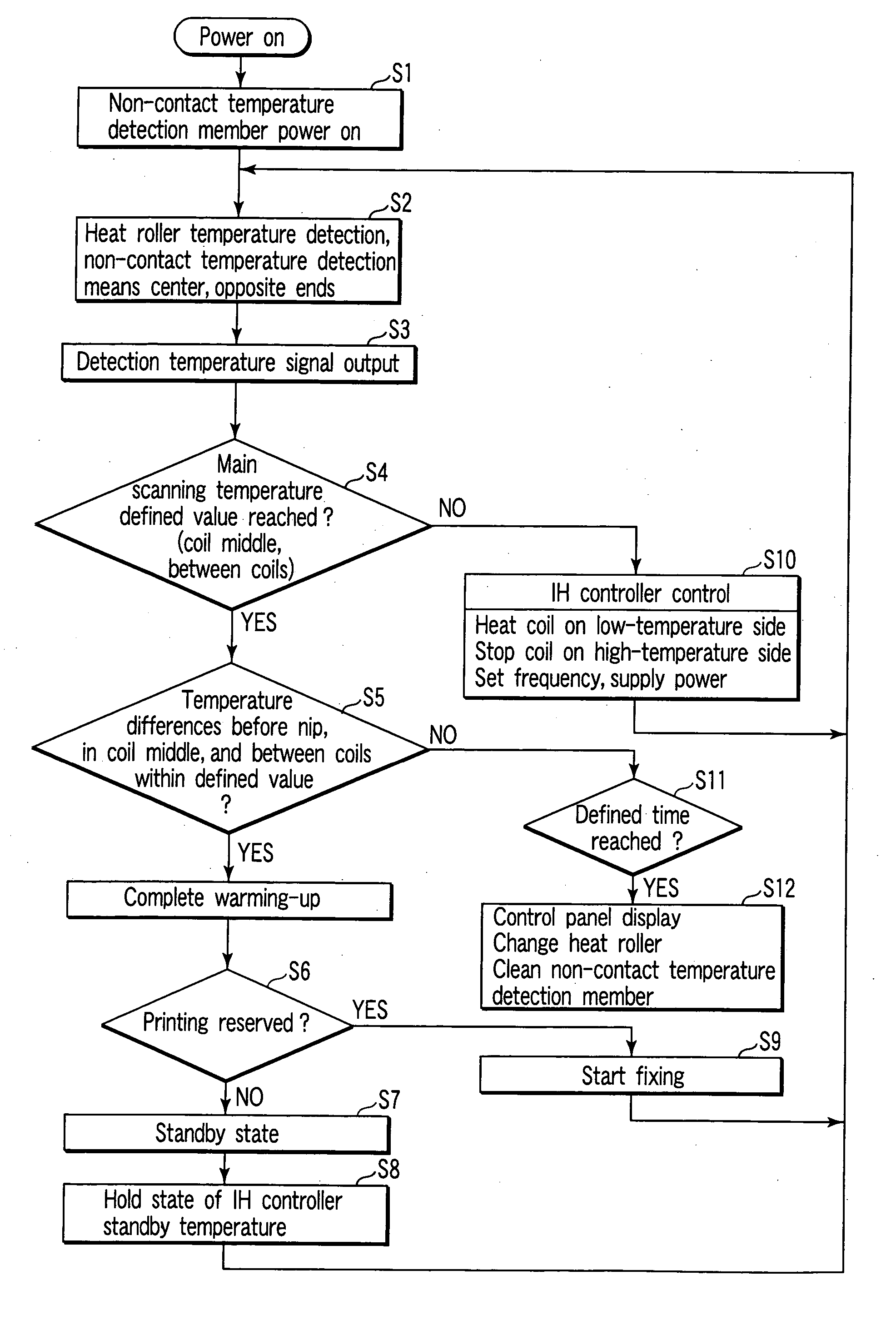

Induction heating device, induction heating fixing device and image forming apparatus

ActiveUS7049562B2Accurate temperature detectionLow costCoil arrangementsElectrographic process apparatusEngineeringConductive materials

An induction heating device for inductively heating an object to be heated which is formed of conductive material has a holder. The device also has a coil for inductively heating the object. The coil is supported by the holder. The coil is composed of a plurality of turns of conductor forming a layer, which is positioned along the object. Between conductor sections of the coil through which electric currents respectively flow in the same direction is formed a gap through which temperature of the object is detected. The device is capable of accurately detecting the temperature of heating region of the object, at low cost, and capable of increasing stability and safety in control of the temperature.

Owner:KONICA MINOLTA INC

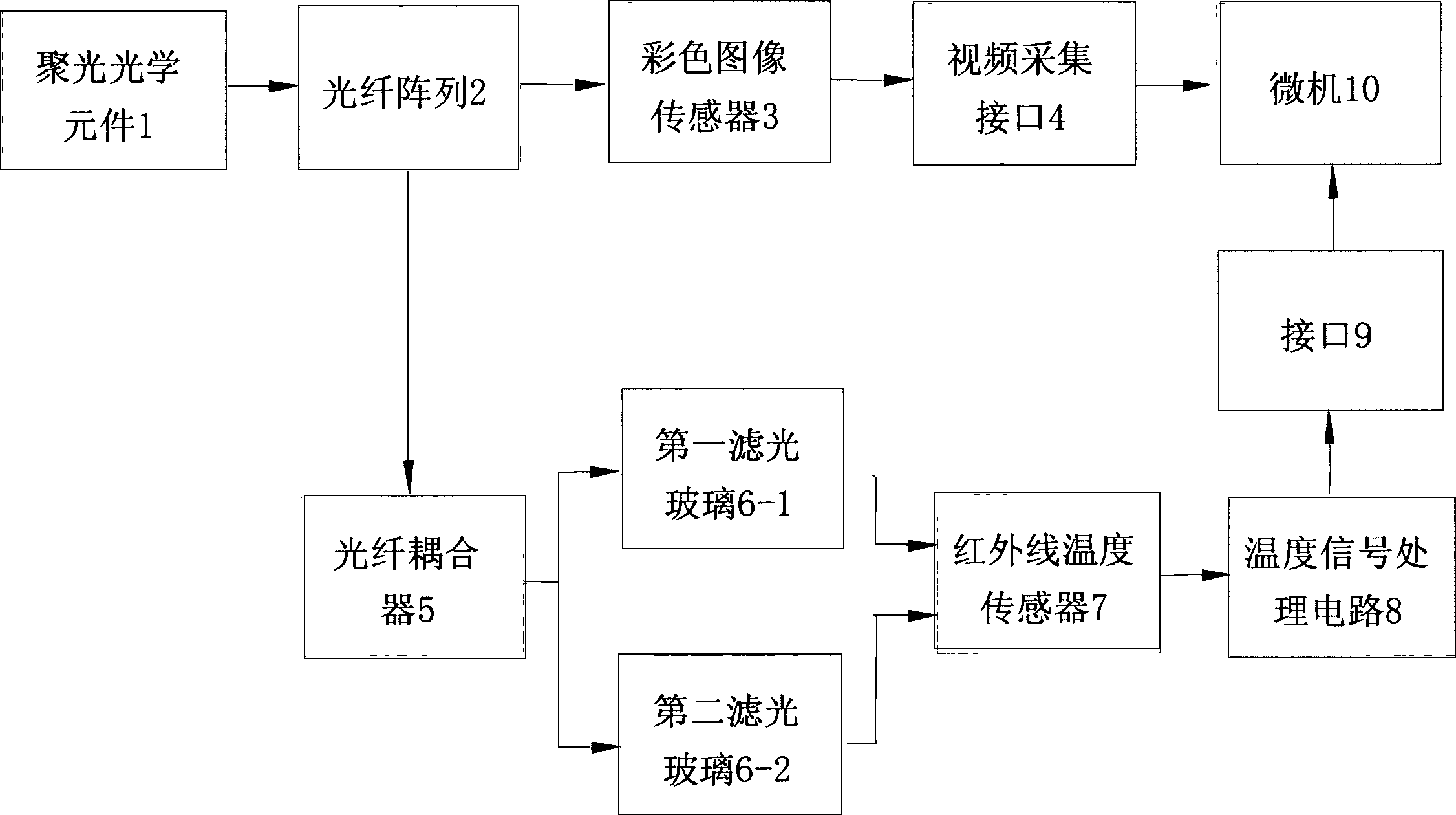

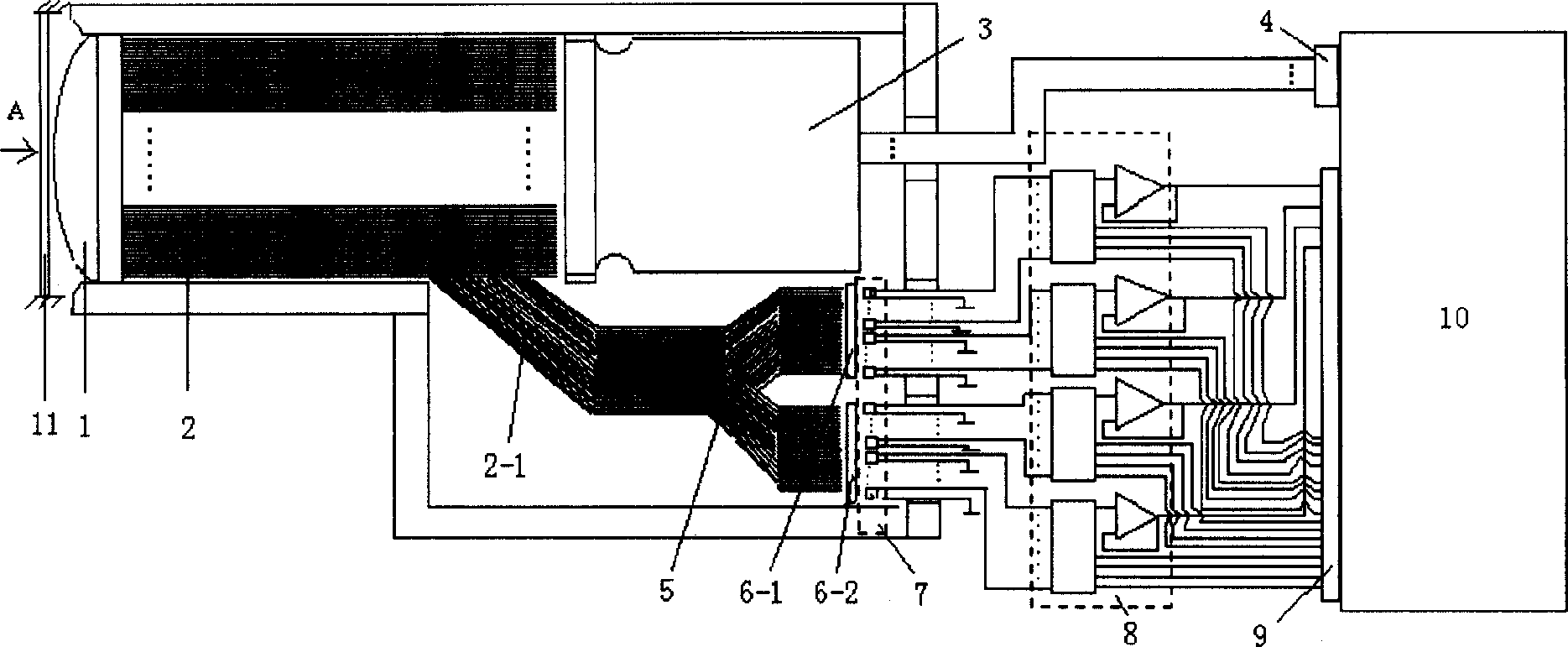

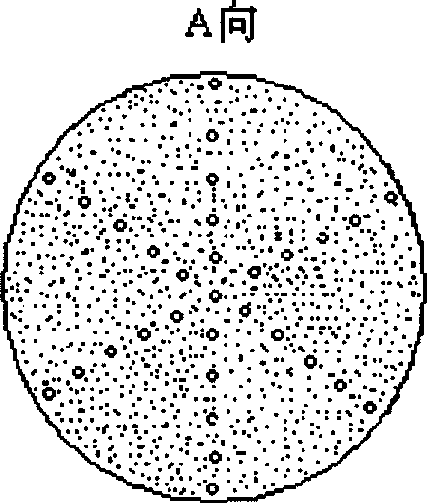

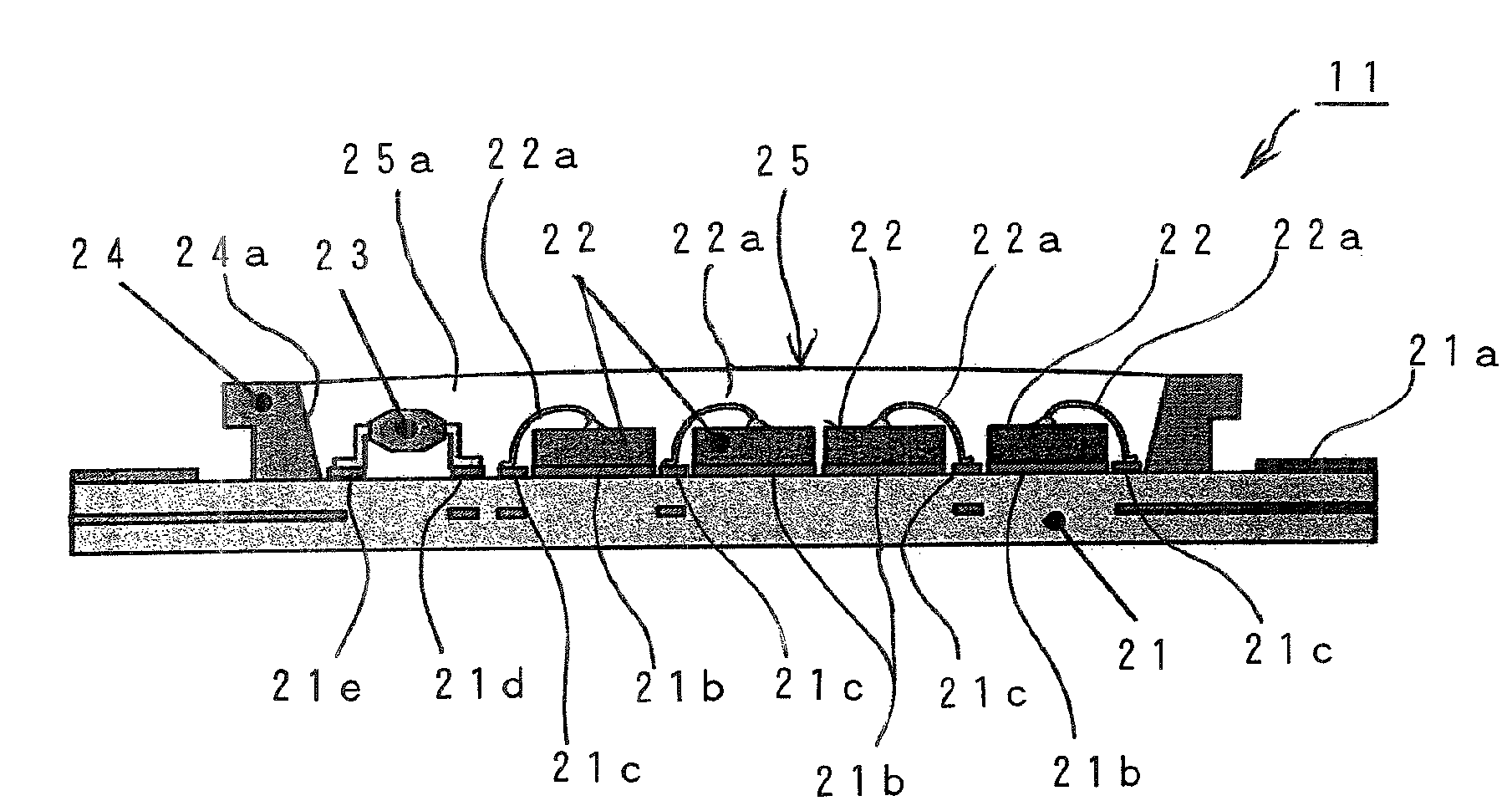

Detection apparatus for high-temperature temperature field and flame image and deteting method

InactiveCN1851419AAccurate temperature detectionAccurate calculation of temperaturePyrometry using electric radation detectorsCombustion regulationFiber arraySet point

The invention discloses a high temperature field and fire image detecting device and detecting method that could supply high temperature field image in time by adopting mixing image receiving fiber array and computer temperature field video processing, and testing the temperature any points in the temperature field by color comparison temperature measuring technology. Taking temperature field interpolation process by computer, it could accurately calculate the other points in the high temperature field. The invention has wide application field.

Owner:JIANGSU TEACHERS UNIV OF TECH

Vehicle lighting device and LED light source therefor

InactiveUS7656307B2Accurate temperature detectionEasy to implementVehicle headlampsPoint-like light sourceParticulatesFluorescence

The disclosed subject matter aims to provide a vehicle lighting device and an LED light source therefore. Accurate temperature detection of an LED chip and associated phosphor can be monitored in real time. The LED light source can include at least one LED chip mounted on a base and a phosphor layer disposed adjacent the LED chip. A mixed particulate phosphor for generating fluorescence through light emitted from the above LED chip can also be provided. The LED light source can be configured to output mixed color light containing the light from the LED chip and the fluorescence from the phosphor. The LED light source can also include a temperature detecting element located on the base and LED chip to detect the temperature on the periphery of the LED chip.

Owner:STANLEY ELECTRIC CO LTD

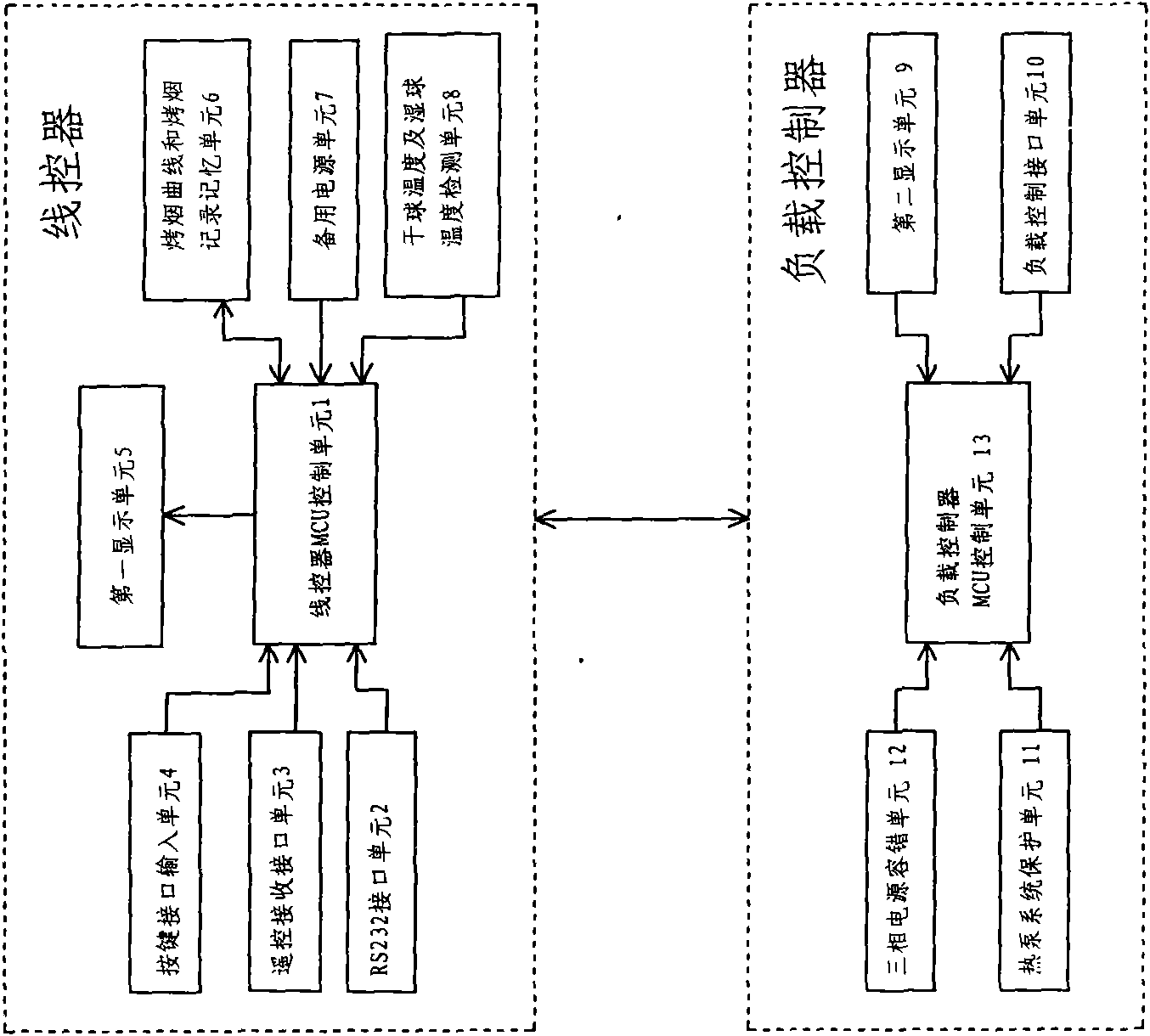

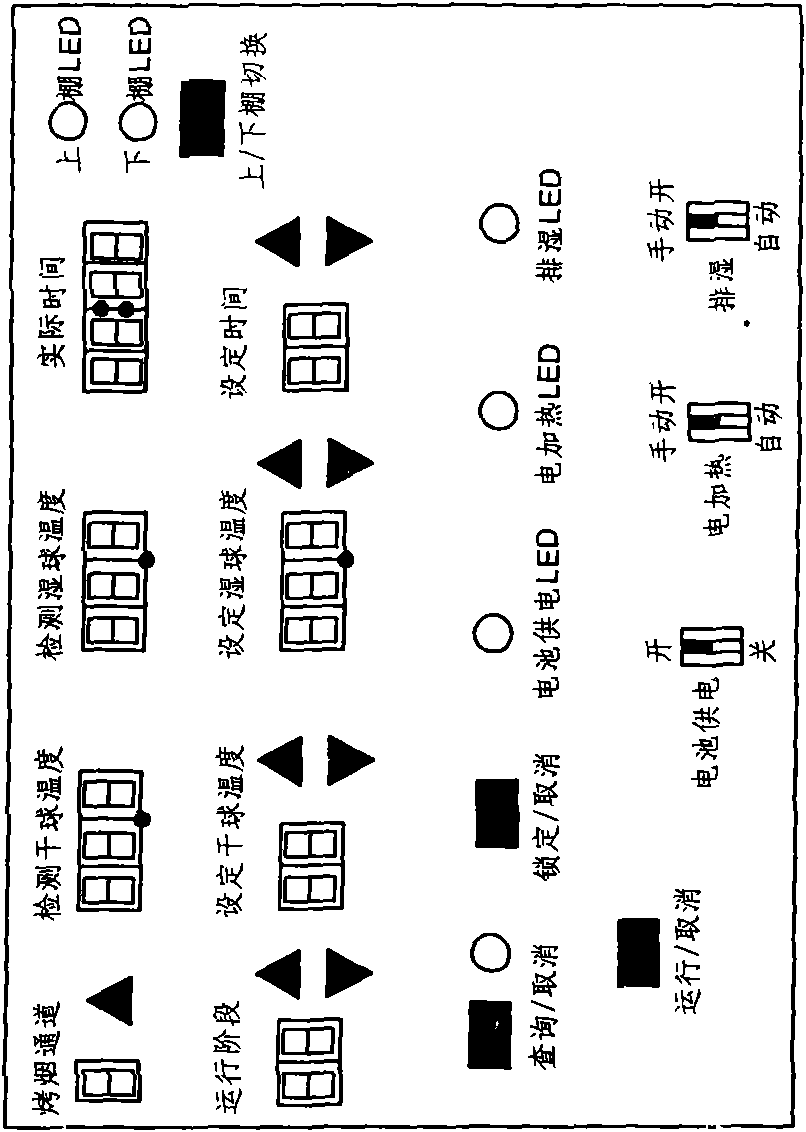

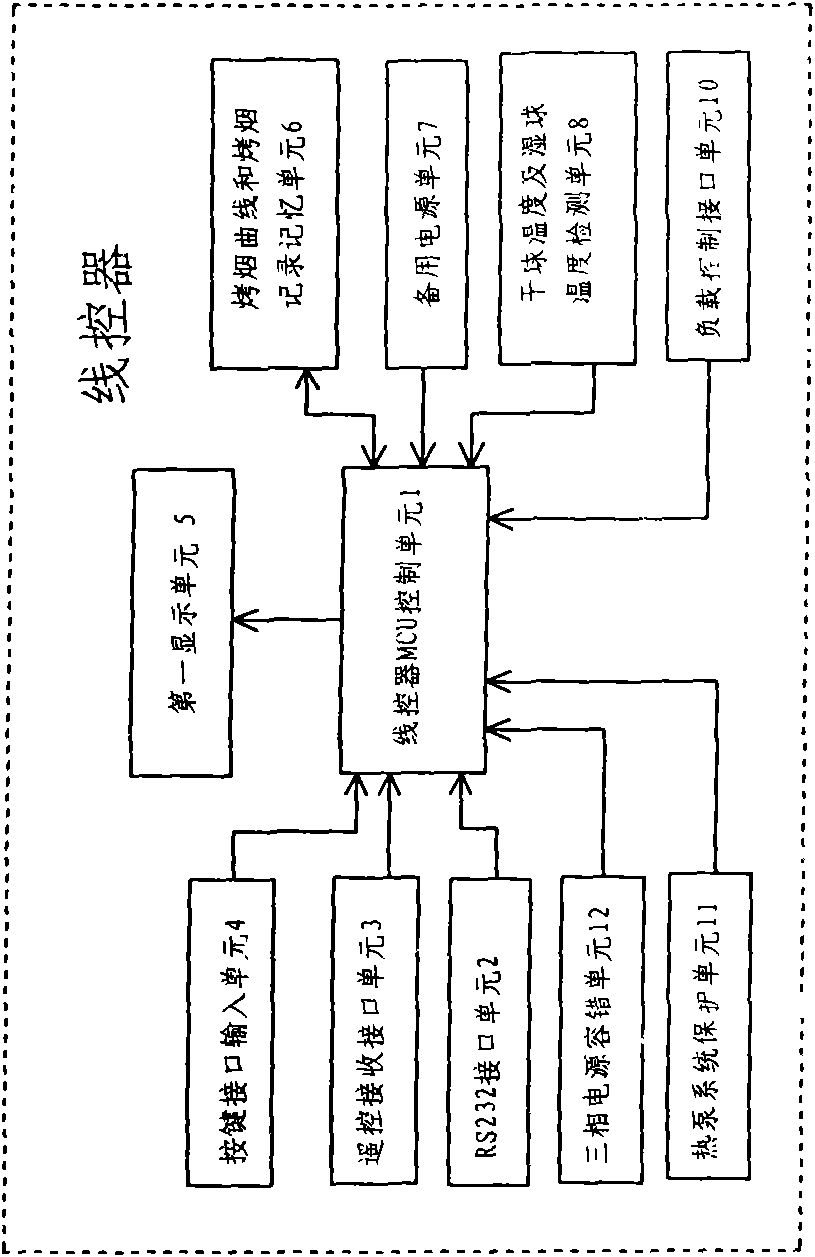

Air conditioning controller special for curing tobacco and control method thereof

InactiveCN101526256ALow baking work intensityReduce heat lossTobacco preparationSpace heating and ventilation safety systemsWork statusElectric heating

The invention relates to an air conditioning controller special for curing tobacco and a control method thereof. The special air conditioning controller for curing tobacco comprises a wire controller; the wire controller comprises an input unit and an MCU of the wire controller, which are connected; the MCU of the wire controller is respectively connected with a first display unit, a cured tobacco curve, a tobacco-curing recording memory unit, a spare power supply unit, a dry-bulb temperature and wet-bulb temperature detection unit, a load control interface unit, a heat pump system protective unit and a three-phase power fault tolerant unit; and the MCU of the wire controller receives a control instruction from the input unit so as to control the working states of a heat pump and an electric heating and dehumidifying device. The air conditioning controller utilizes the heat pump heating technology and a heat recovery device in the process of curing tobacco, can reduce the air pollution and save energy, can also improve the curing quality of the tobacco and reduce the working intensity of curing tobacco, control the dry-bulb temperature and the wet-bulb temperature in a curing room precisely and greatly improve the automation degree and the control precision.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

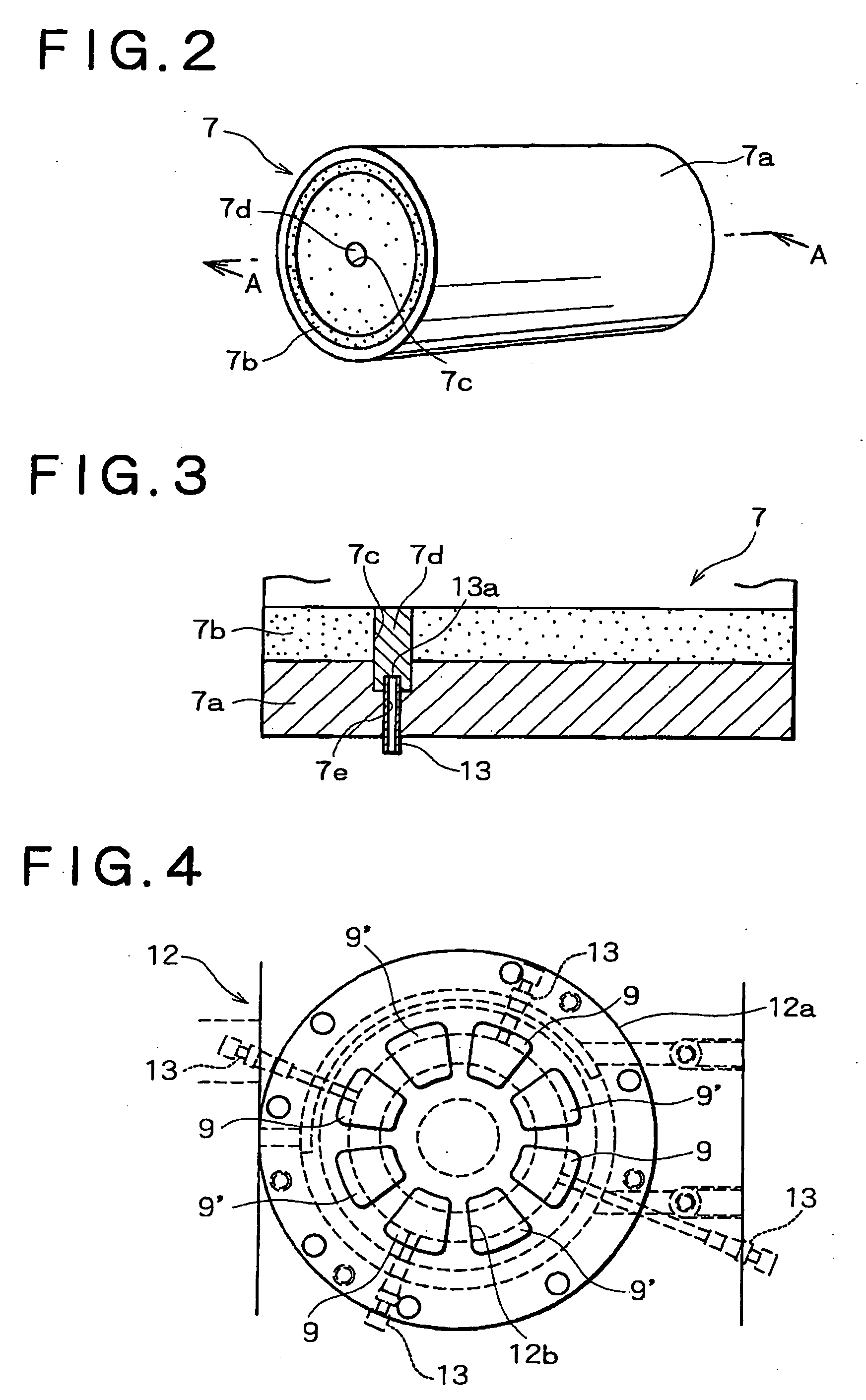

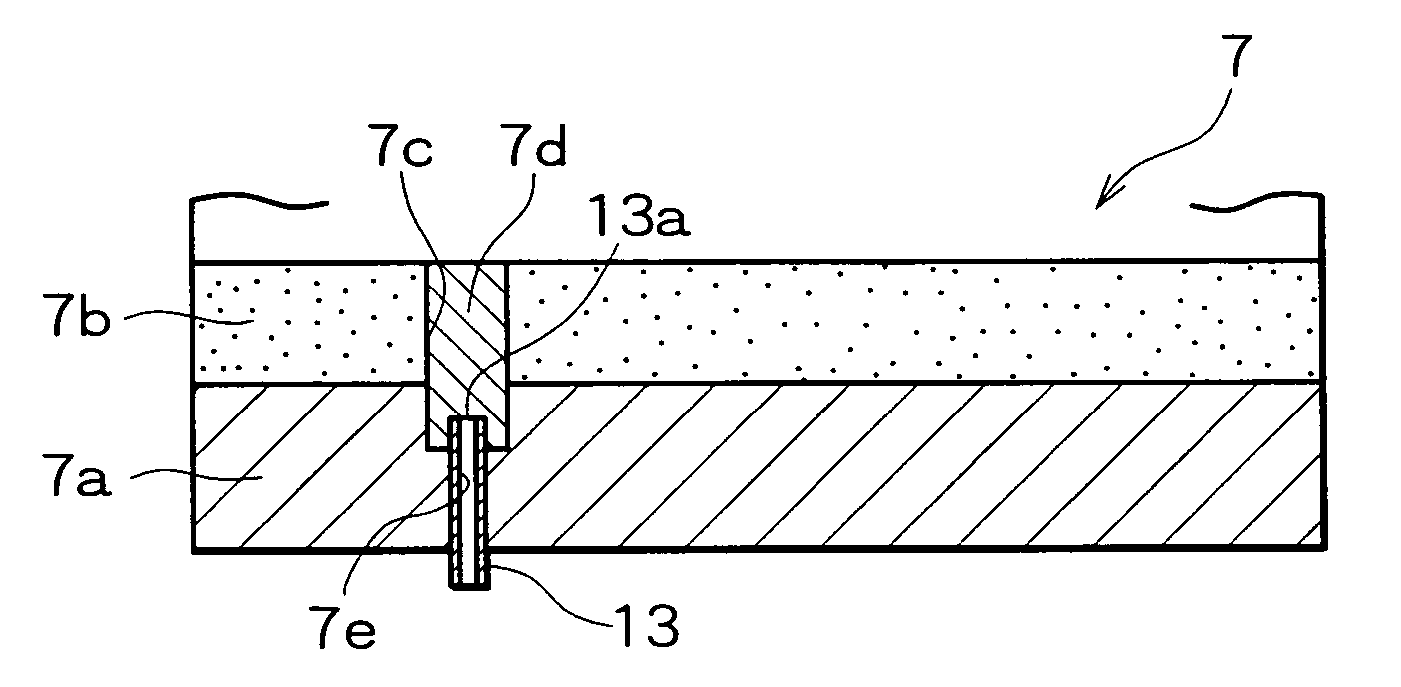

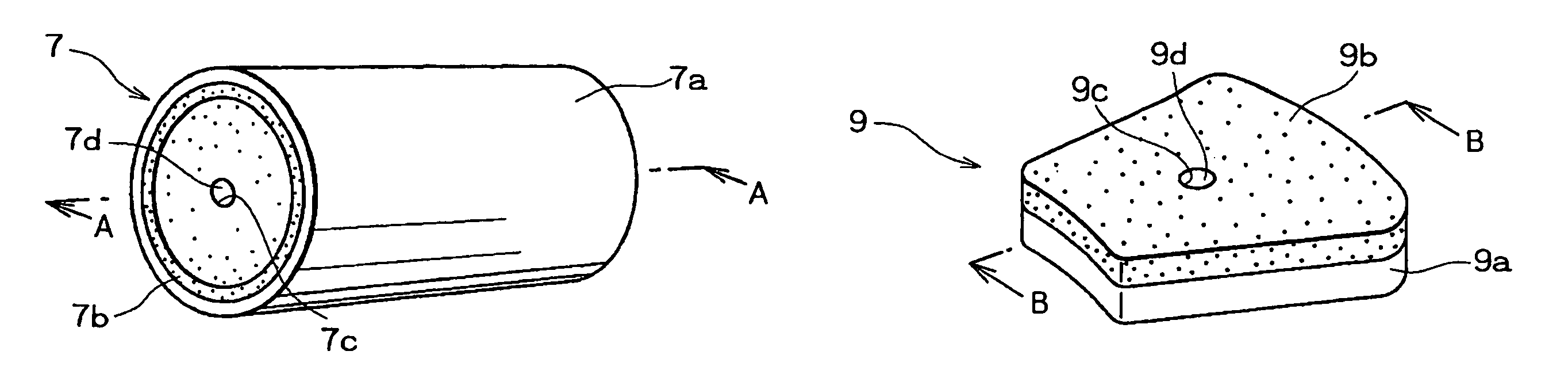

Bearing and screw compressor

ActiveUS20060165335A1Accurately detect temperatureSuperior thermal conductivityThermometer detailsBearing assemblyPolytetrafluoroethyleneTemperature measurement

In a bearing constituted by a plural-layer slide member, the plural-layer slide member comprises a resin layer of polytetrafluoroethylene as a slide member and a backing strip to which the resin layer is bonded. A fitting hole having a depth exceeding the thickness of the resin layer is formed from the resin layer side. A temperature measuring metallic member formed of a white metal is fitted in the fitting hole. A temperature sensor is positioned within the temperature measuring metallic member. This bearing permits an accurate detection of its temperature. Further, in an oil cooled screw compressor having a bearing lubricating oil supply pipe, a slide surface of the bearing is covered with polyether ether ketone. Even if foaming occurs in the oil, it is possible to prevent the occurrence of a mechanical trouble such as galling.

Owner:KOBE STEEL LTD

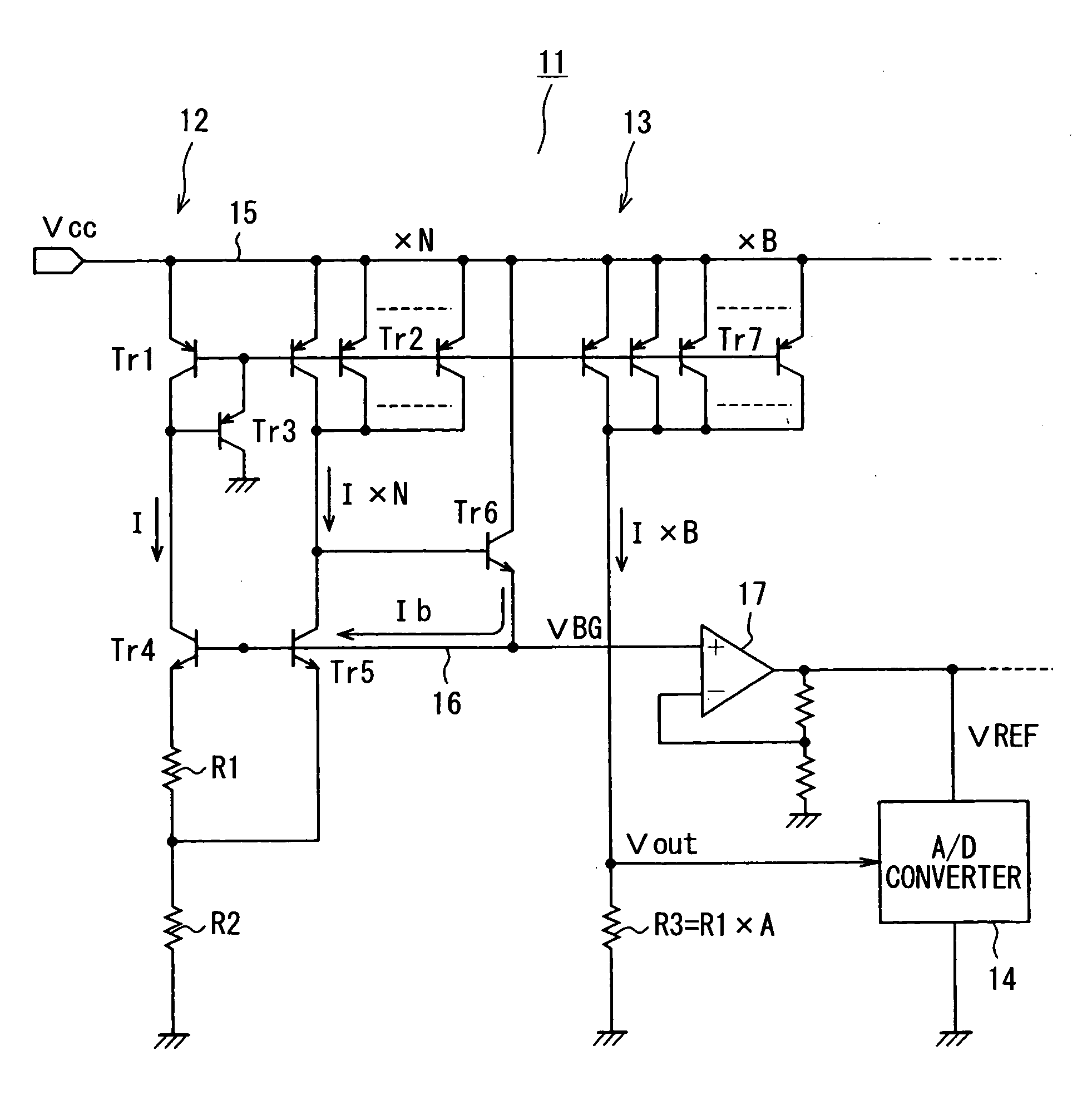

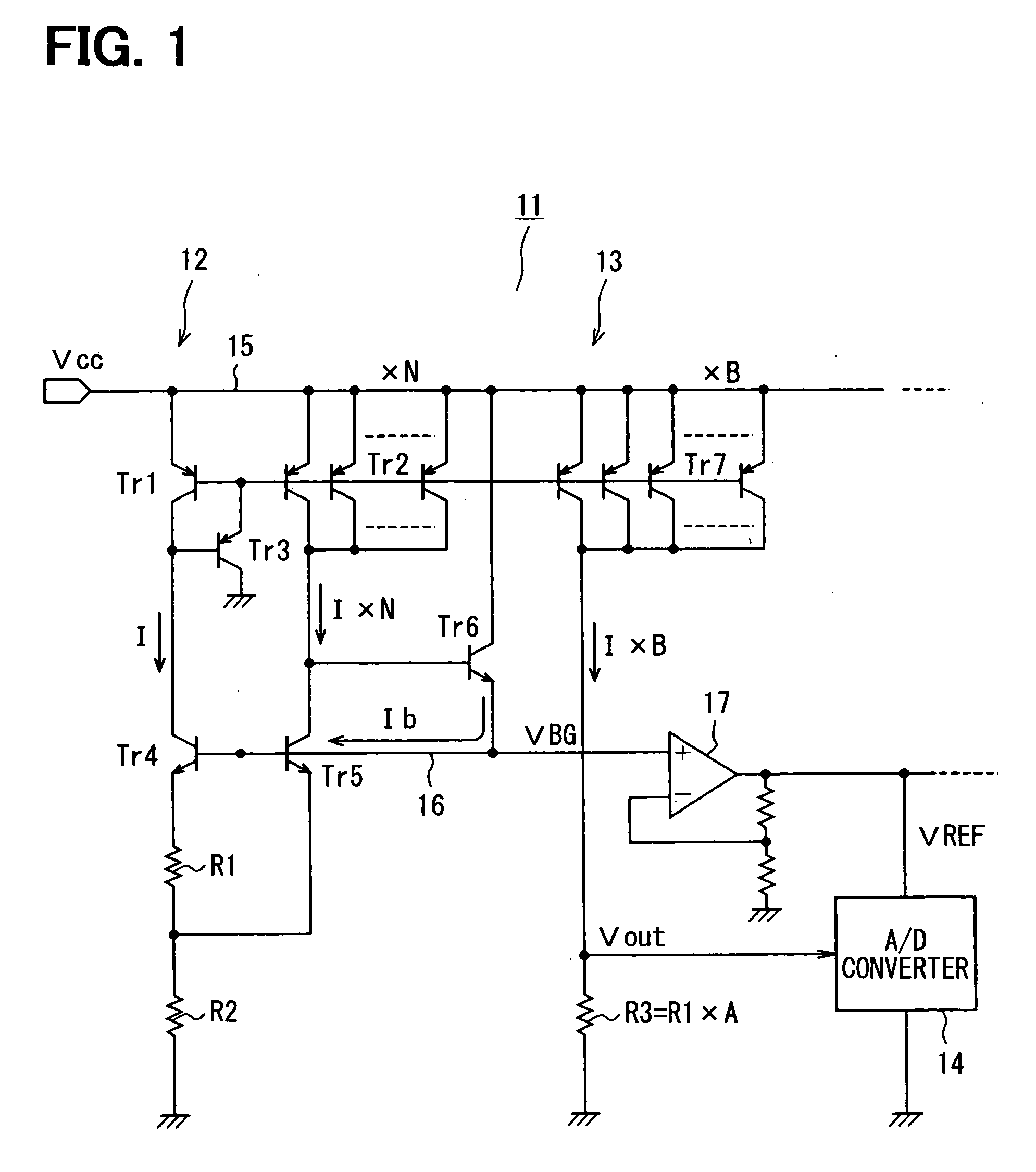

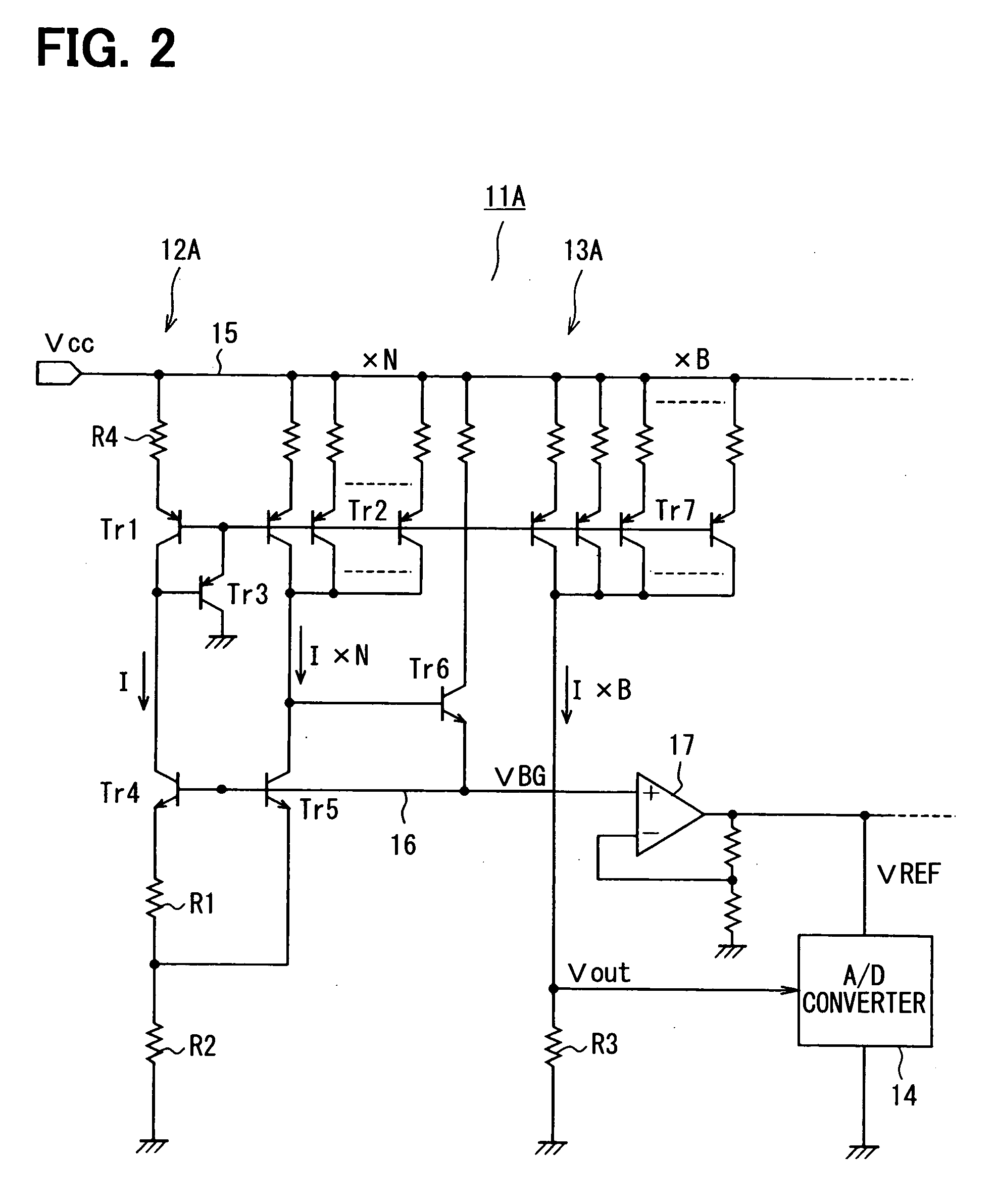

Temperature detection circuit

InactiveUS20080187026A1Accurate temperature detectionMultiple input and output pulse circuitsInstant pulse delivery arrangementsVoltage dropEngineering

A temperature detection circuit includes a bandgap reference voltage generation circuit, a detection output circuit, and an output conversion circuit. The bandgap reference voltage generation circuit generates a first reference voltage and causes a bias current to flow through a current path to produce a thermal voltage. The current path has a first resistor. The detection output circuit has a second resistor and causes a mirror current of the bias current to flow through the second resistor. The output conversion circuit uses a second reference voltage to convert a voltage drop across the second resistor to a predetermined output form to detect a temperature. The first and second resistors are substantially identical in temperature dependence. The second reference voltage is generated from the first reference voltage.

Owner:DENSO CORP

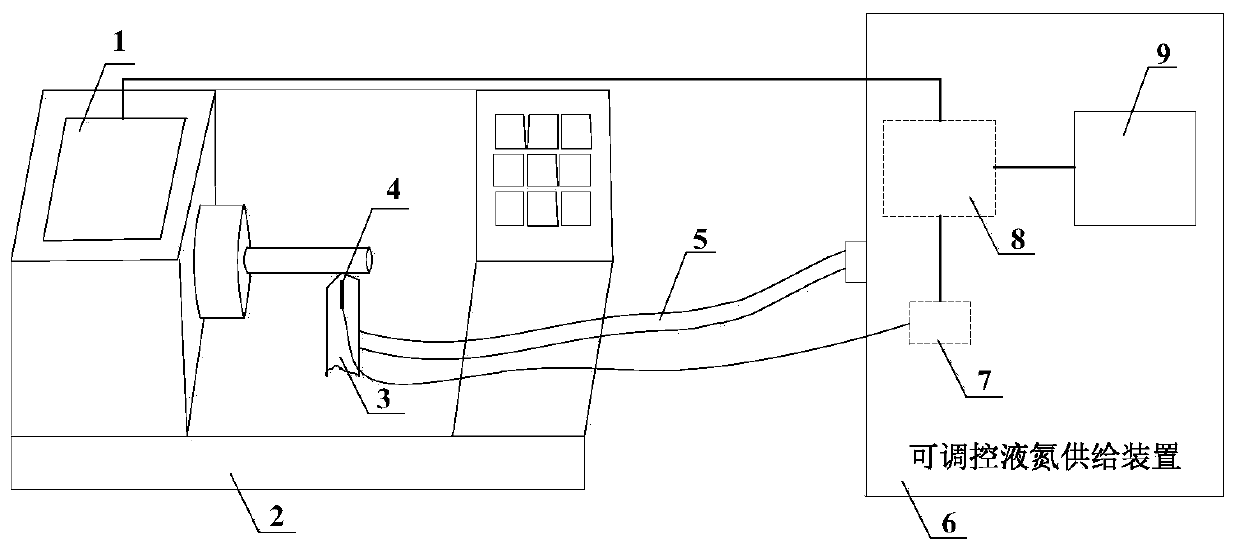

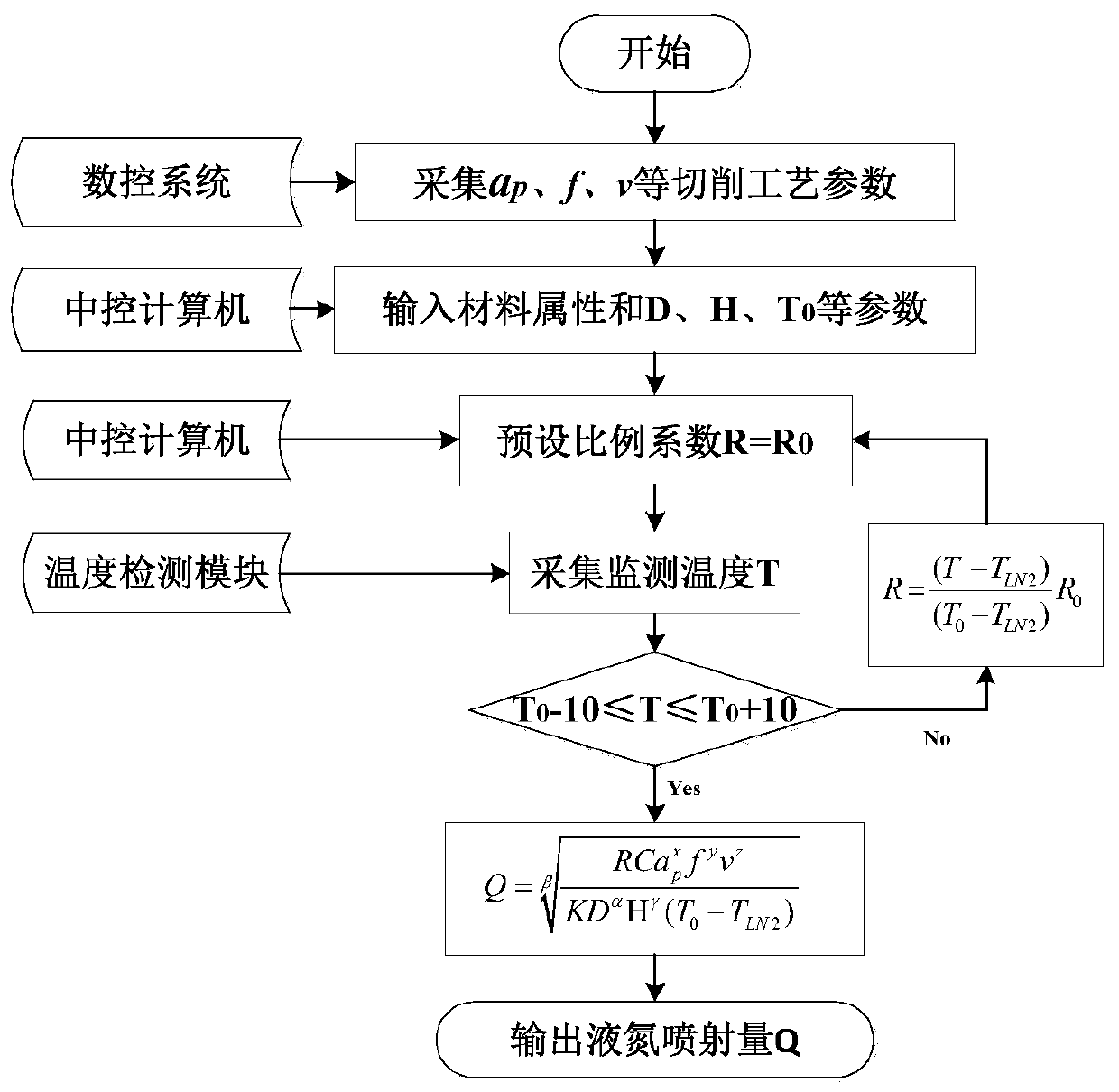

On-line control method of liquid nitrogen injection quantity for ultra-low temperature cooling processing

ActiveCN110058621AAvoid inaccurate temperature detectionGuaranteed accuracyTemperatue controlNumerical controlRelational model

The invention relates to an on-line control method of liquid nitrogen injection quantity for ultra-low temperature cooling processing. The on-line control method of the liquid nitrogen injection quantity for ultra-low temperature cooling processing comprises the following steps that firstly, a relation model between cutting process parameters and the liquid nitrogen injection quantity is constructed, and the model is placed into an on-line controller for ultra-low temperature processing liquid nitrogen injection. The controller can regulate and control material characteristics, tool parameters, an optimal cutting temperature and heat dissipation ratio coefficients input by a central control computer of a liquid nitrogen supply device based on the collected cutting process parameters of a machine tool numerical control processing system, and expected liquid nitrogen injection quantity is determined by calling the relational model and a parameter database; and meanwhile, the controller collects the temperature of a cutting area online through a thermocouple fixed in an internal jet type cutting tool to feedback and adjust actual liquid nitrogen injection quantity to change within a certain range, so that the cutting area is in an optimal cutting temperature range, the processing quality of parts is ensured, and the service life of the cutting tool is prolonged. The on-line control of the liquid nitrogen injection on-line quantity is achieved according to the heating condition of cutting processing, optimization iteration time is short, and accurate control over the temperature of the cutting area can be quickly realized.

Owner:DALIAN UNIV OF TECH

Apparatus for fixing toner on transferred material

InactiveUS20060062586A1Accurate temperature detectionStably fixing a tonerElectrographic process apparatusObject basedElectric power

The present invention relates to a fixing apparatus which radiates rays to a detection object and which detects the rays returned from the detection object to obtain a temperature signal. The apparatus specifies a radiant ratio of the surface of the detection object using at least one of accumulated image forming times, detection position, and radiation deterioration, corrects the detected temperature signal based on the specified radiant ratio of the surface of the detection object to produce temperature data, and controls a power to be supplied to a heating mechanism which raises temperature of the detection object based on the produced temperature data.

Owner:KK TOSHIBA +1

Bearing and screw compressor

ActiveUS20050013521A1Improve thermal conductivityAccurate temperature detectionBearing assemblyShaftsPolytetrafluoroethyleneTemperature measurement

In a bearing constituted by a plural-layer slide member, the plural-layer slide member comprises a resin layer of polytetrafluoroethylene as a slide member and a backing strip to which the resin layer is bonded. A fitting hole having a depth exceeding the thickness of the resin layer is formed from the resin layer side. A temperature measuring metallic member formed of a white metal is fitted in the fitting hole. A temperature sensor is positioned within the temperature measuring metallic member. This bearing permits an accurate detection of its temperature. Further, in an oil cooled screw compressor having a bearing lubricating oil supply pipe, a slide surface of the bearing is covered with polyether ether ketone. Even if foaming occurs in the oil, it is possible to prevent the occurrence of a mechanical trouble such as galling.

Owner:KOBE STEEL LTD

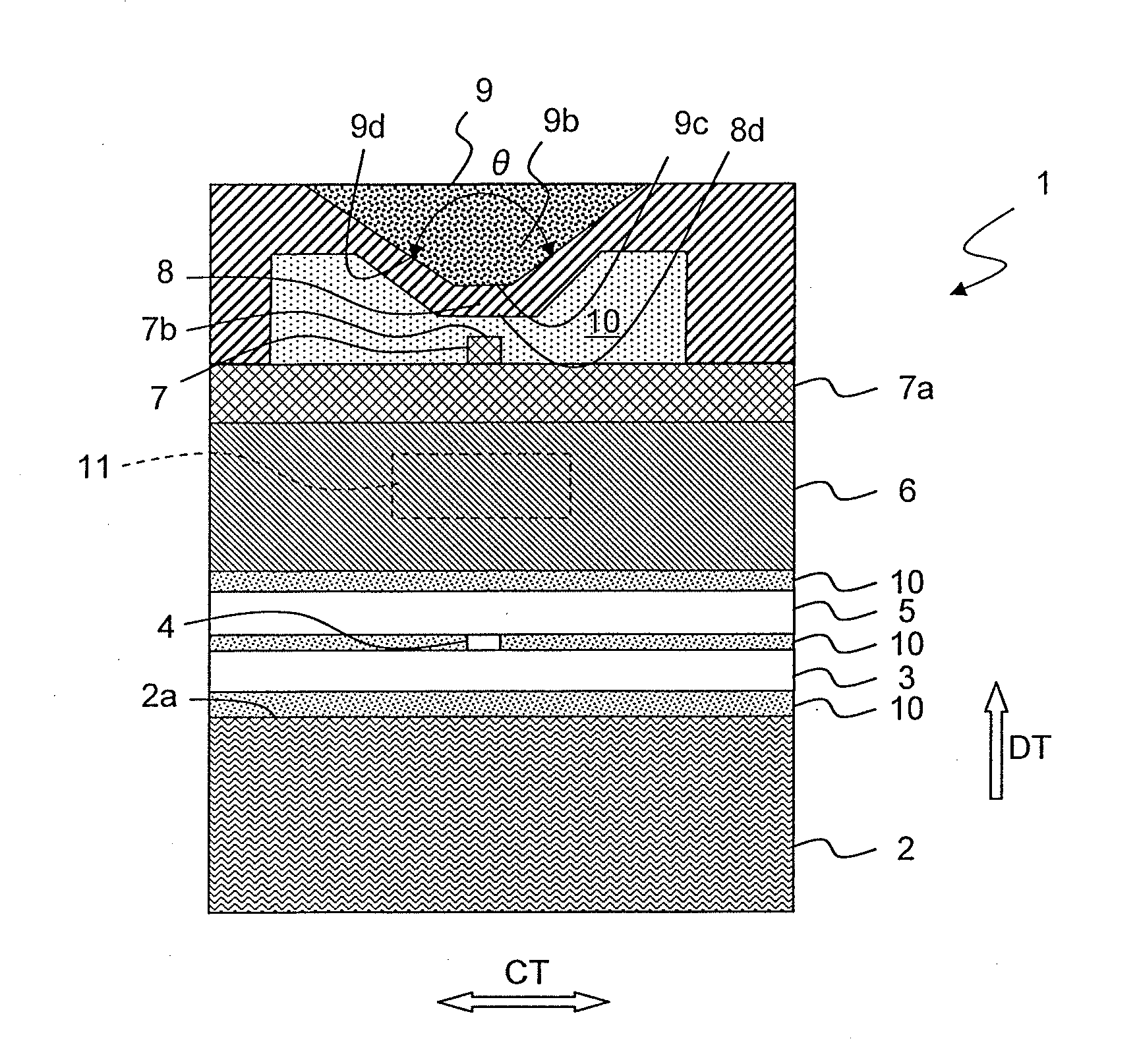

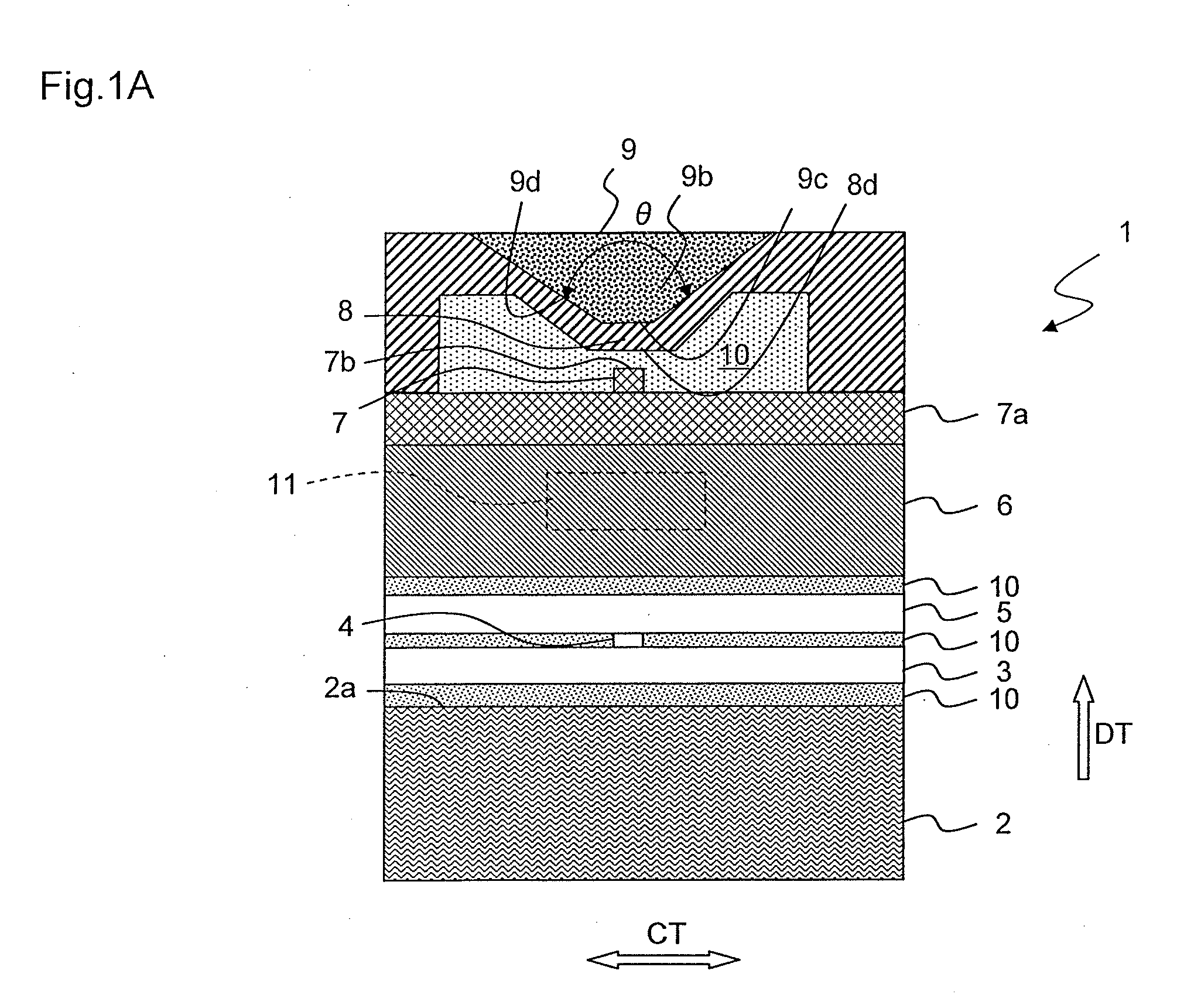

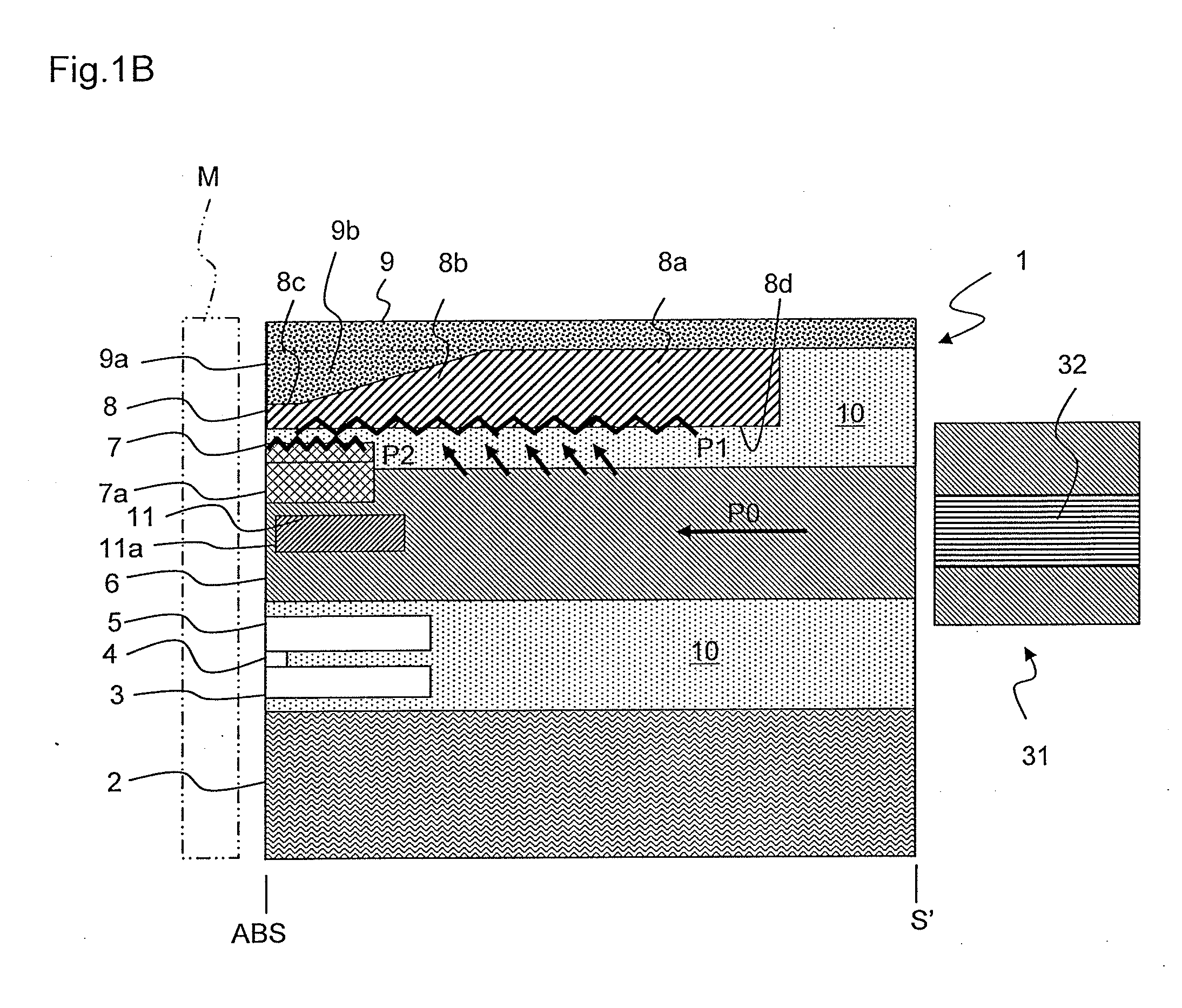

Thermally-assisted magnetic recording head having temperature sensor embedded on dielectric waveguide

ActiveUS20130258824A1Feel goodEfficient heatingRecord information storageMagnetic and optical recordingsHeat-assisted magnetic recordingSurface plasmon

A thermal assisted magnetic recording head includes a dielectric waveguide that is configured to propagate propagation light a metal waveguide that is provided facing the dielectric waveguide and that couples to the propagation light propagating through the dielectric waveguide in a surface plasmon mode, thereby generating and propagating surface plasmon, a near-field light generator that is exposed on an air bearing surface facing a magnetic recording medium either at an end part of the metal waveguide or at a position facing the end part of the metal waveguide, and that generates near-field light from the surface plasmon, a magnetic pole for magnetic recording that is exposed on the air bearing surface, and a temperature sensor that is arranged inside the dielectric waveguide.

Owner:TDK CORPARATION

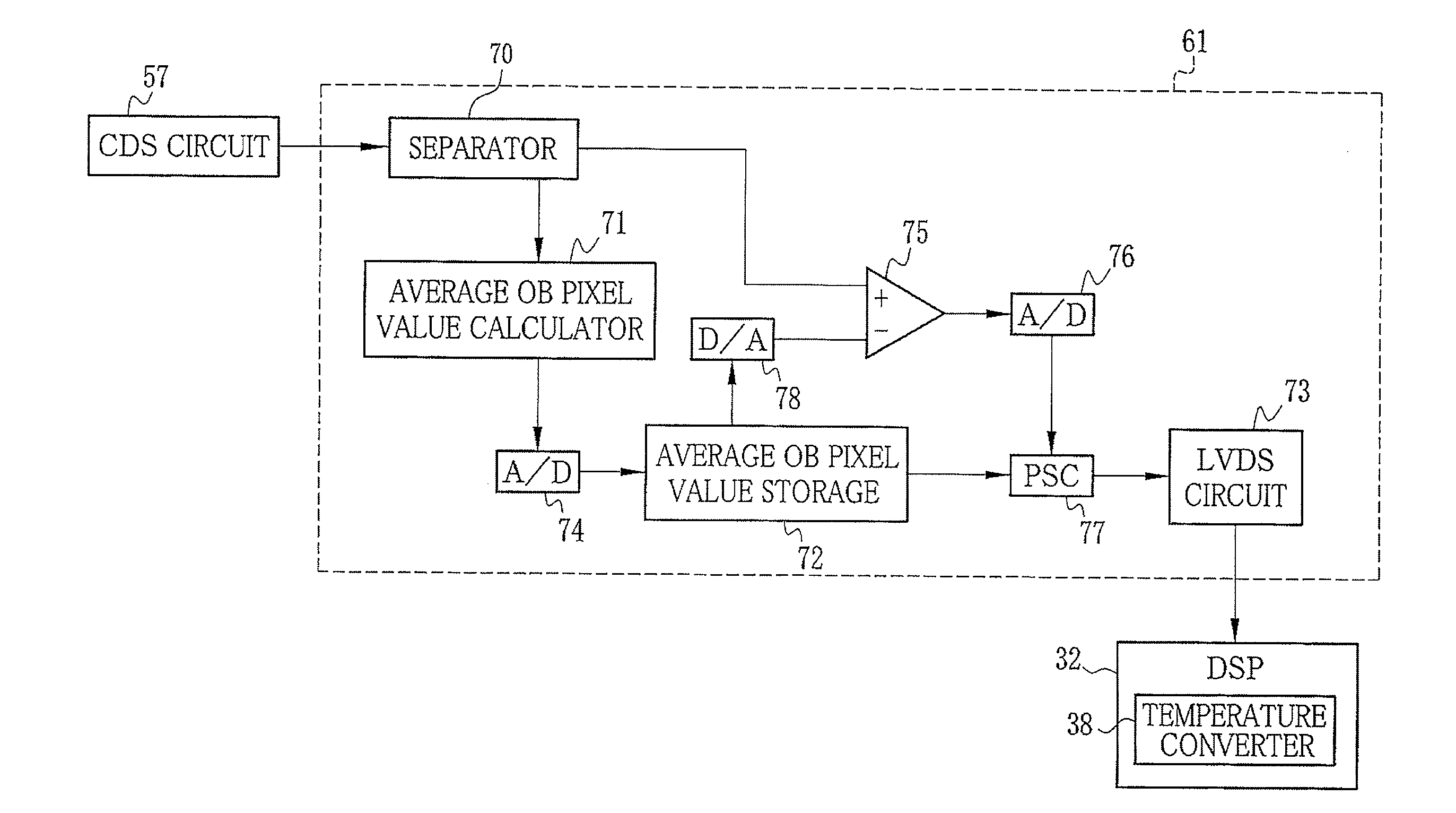

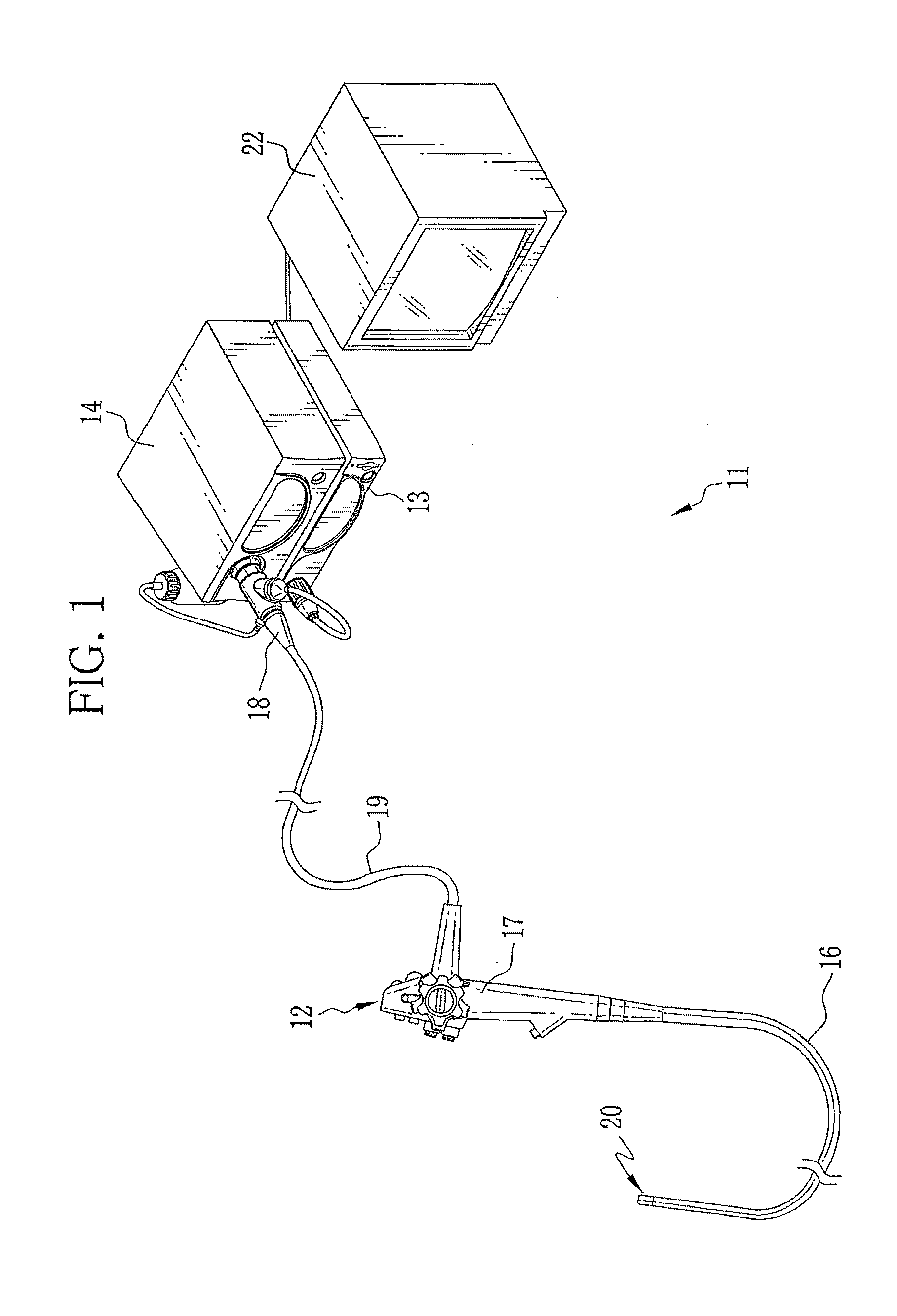

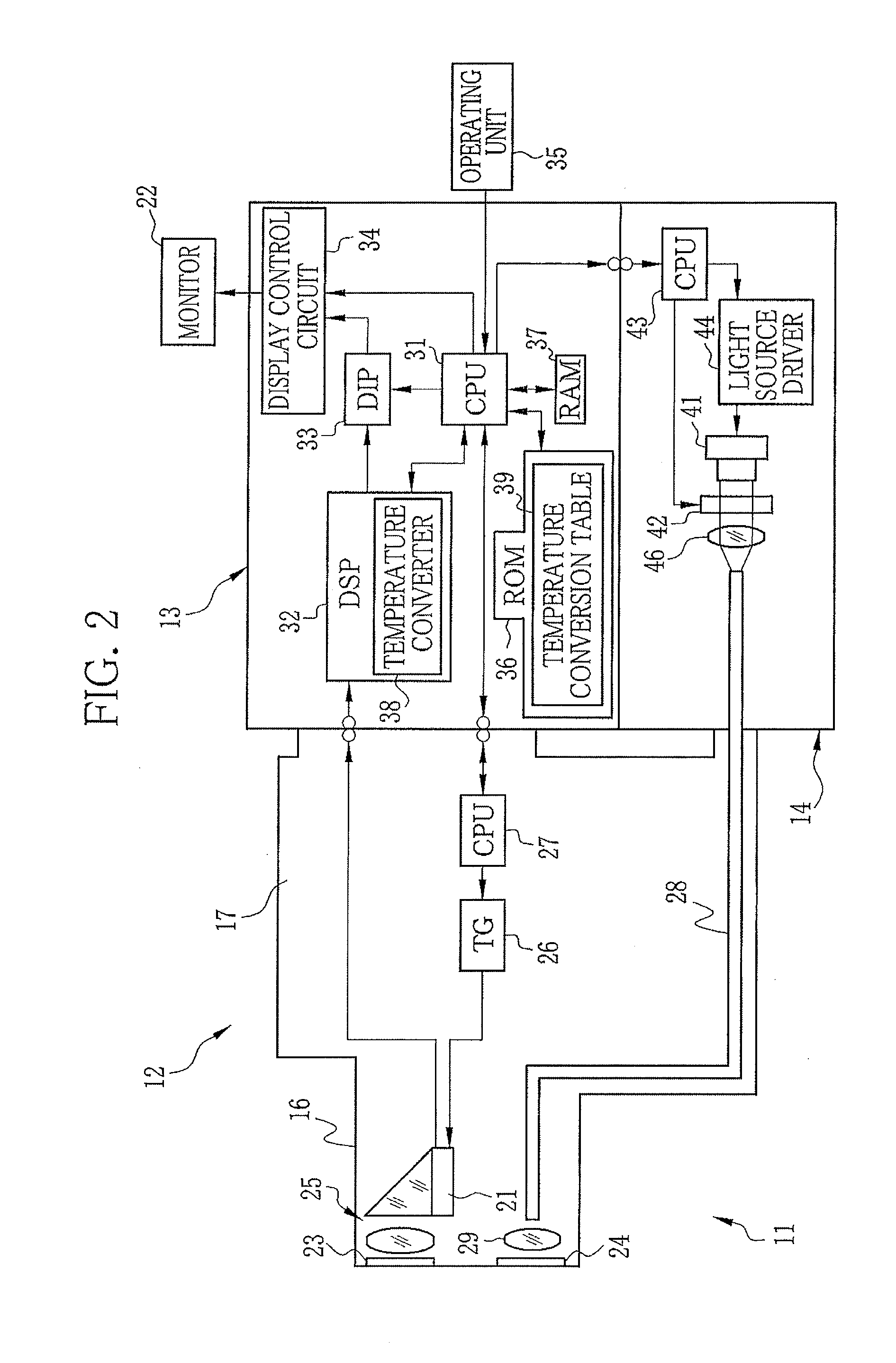

Electronic endoscope system

InactiveUS20140228638A1Increase the diameterSimplify the electronic structureTelevision system detailsSurgeryCMOS sensorDistal portion

An electronic endoscope system is composed of an electronic endoscope, a light source apparatus, and a temperature converter. The electronic endoscope has a CMOS sensor in a distal portion of an insert section to be inserted into a patient's body cavity. Illumination light from the light source apparatus is applied to the body cavity through the distal portion. The temperature converter obtains an average pixel value of an optical black (OB) region out of an imaging signal from the CMOS sensor, and converts the average OB pixel value into a temperature of the CMOS sensor on a frame-by-frame basis with the use of data in a temperature conversion table. The table represents a relationship between the average OB pixel value and the temperature of the CMOS sensor. Light quantity of the illumination light is adjusted in accordance with the temperature of the CMOS sensor to prevent deterioration of image quality.

Owner:FUJIFILM CORP

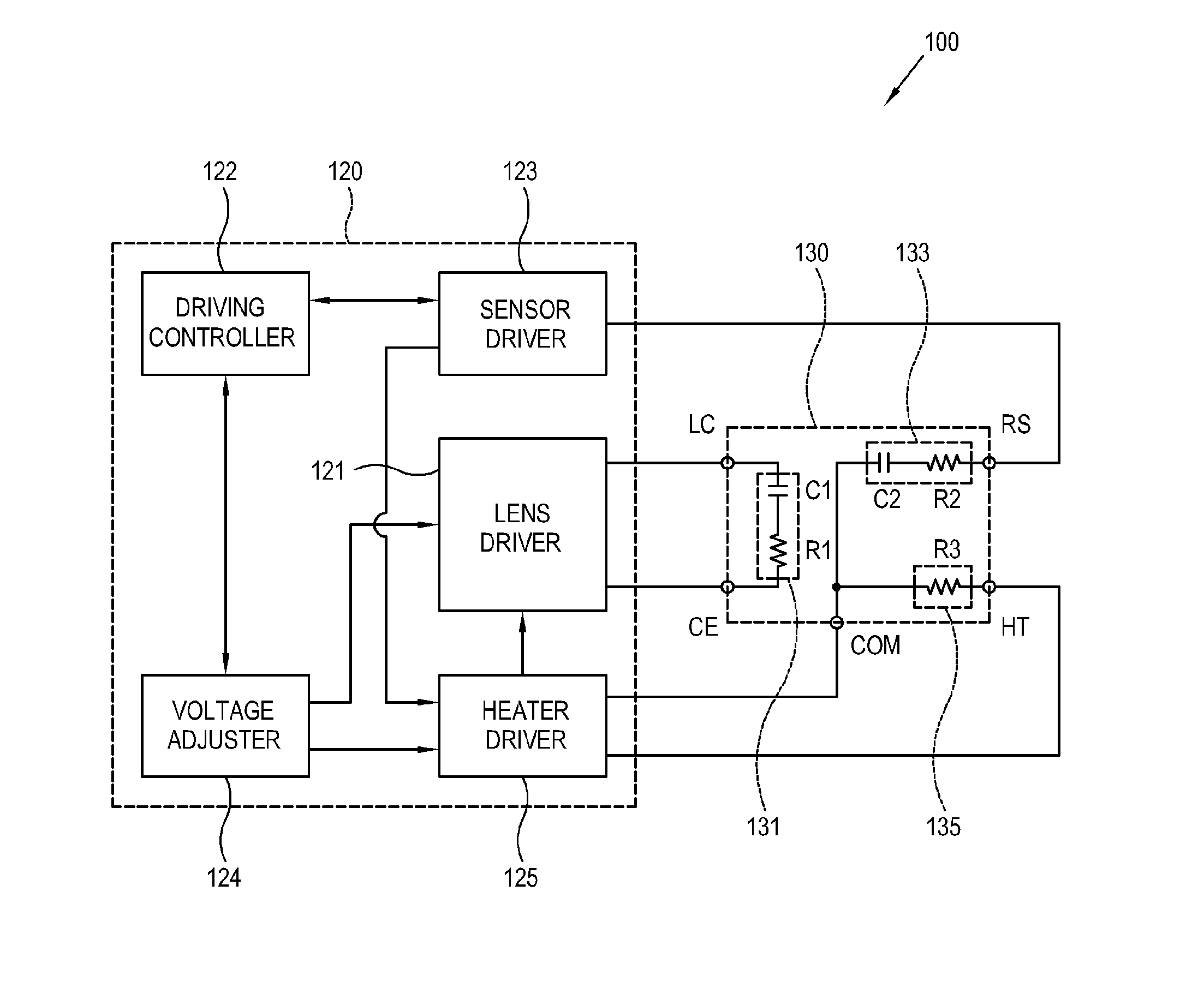

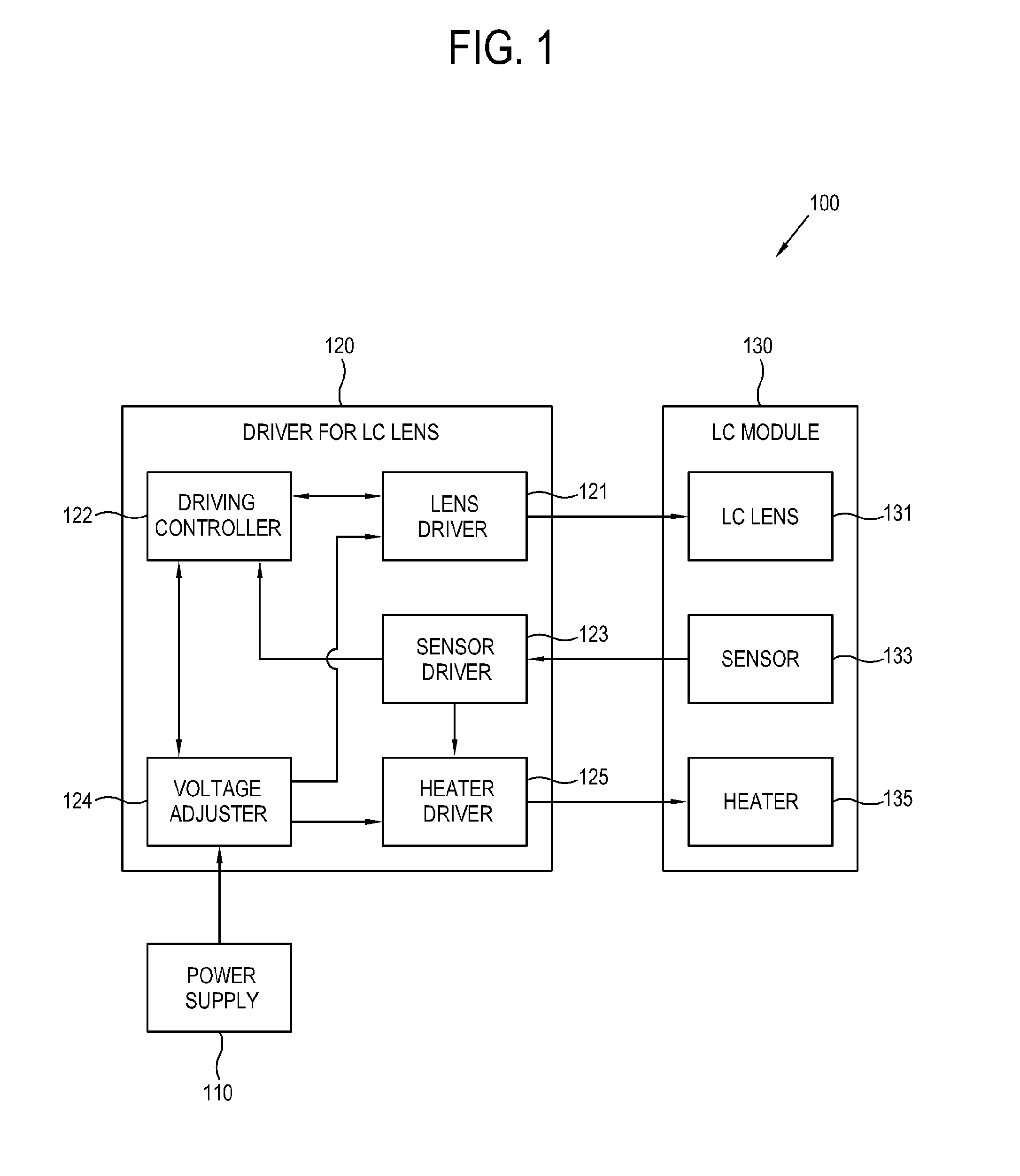

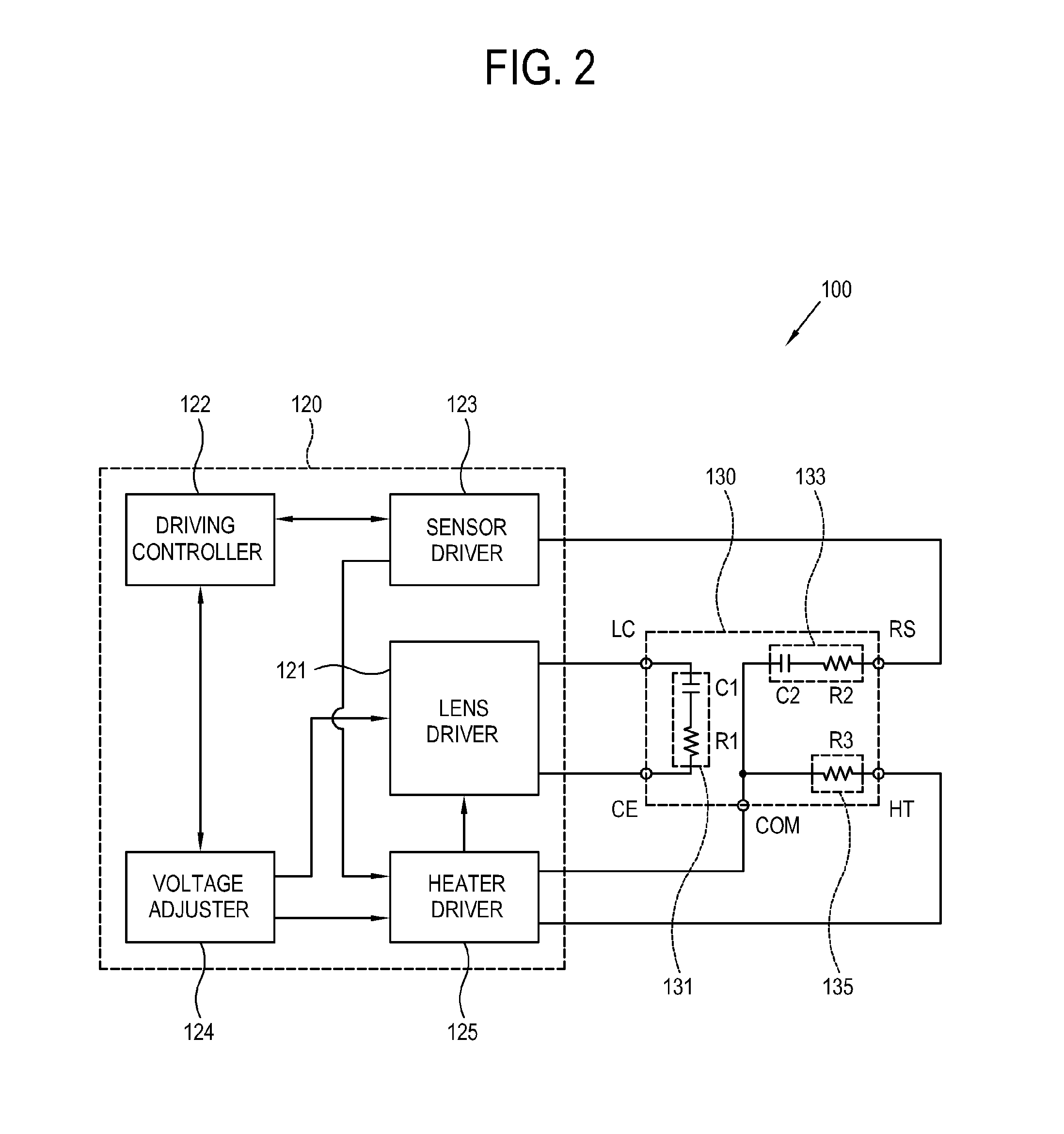

Driver for liquid crystal lens, imaging apparatus and temperature controlling method thereof

ActiveUS20130148059A1Accurate temperature detectionStable maintenanceStatic indicating devicesProjector focusing arrangementTemperature controlEngineering

A driver for a liquid crystal lens, an imaging apparatus and a temperature controlling method thereof, include: a liquid crystal lens which adjusts a focal length according to a voltage applied thereto; a lens driver which applies the voltage to the liquid crystal lens; a sensor driver which detects a temperature of the liquid crystal lens, compensates for the detected temperature, and determines whether the compensated temperatures maintains a preset range for the driver for the liquid crystal lens to perform a control operation; and a heater driver which, according to the determination by the sensor driver, controls heat generation of the liquid crystal lens to maintain a temperature of the liquid crystal lens in the preset range. Thus, the driver detects a temperature of the liquid crystal lens accurately by compensating for a resistance value from the liquid crystal lens to thereby maintain stability of the imaging apparatus.

Owner:DONG WOON ANATECH CO LTD

Bearing and screw compressor

ActiveUS7682084B2Accurate temperature detectionAccurate detectionThermometer detailsBearing assemblyWhite metalEngineering

Owner:KOBE STEEL LTD

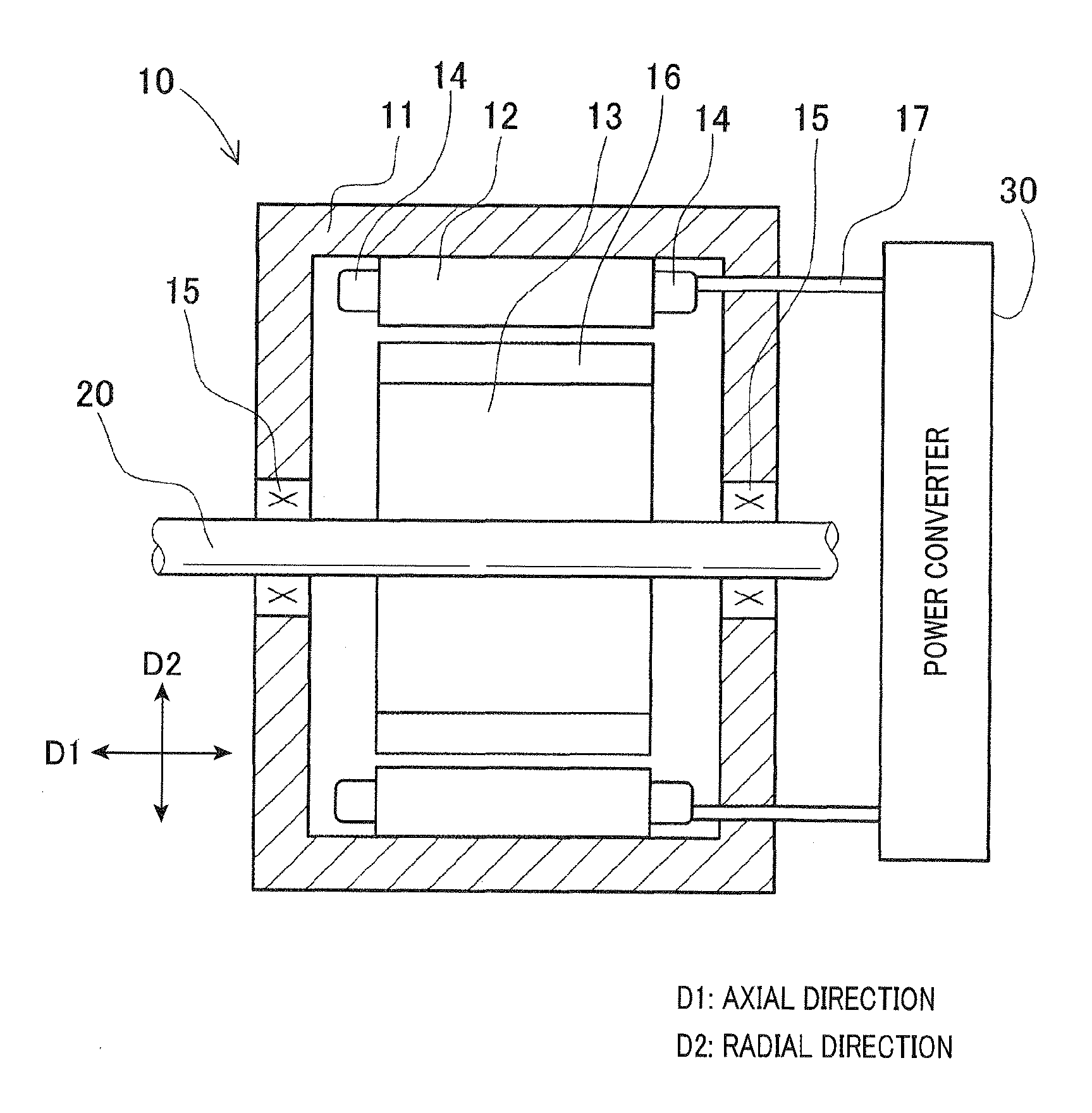

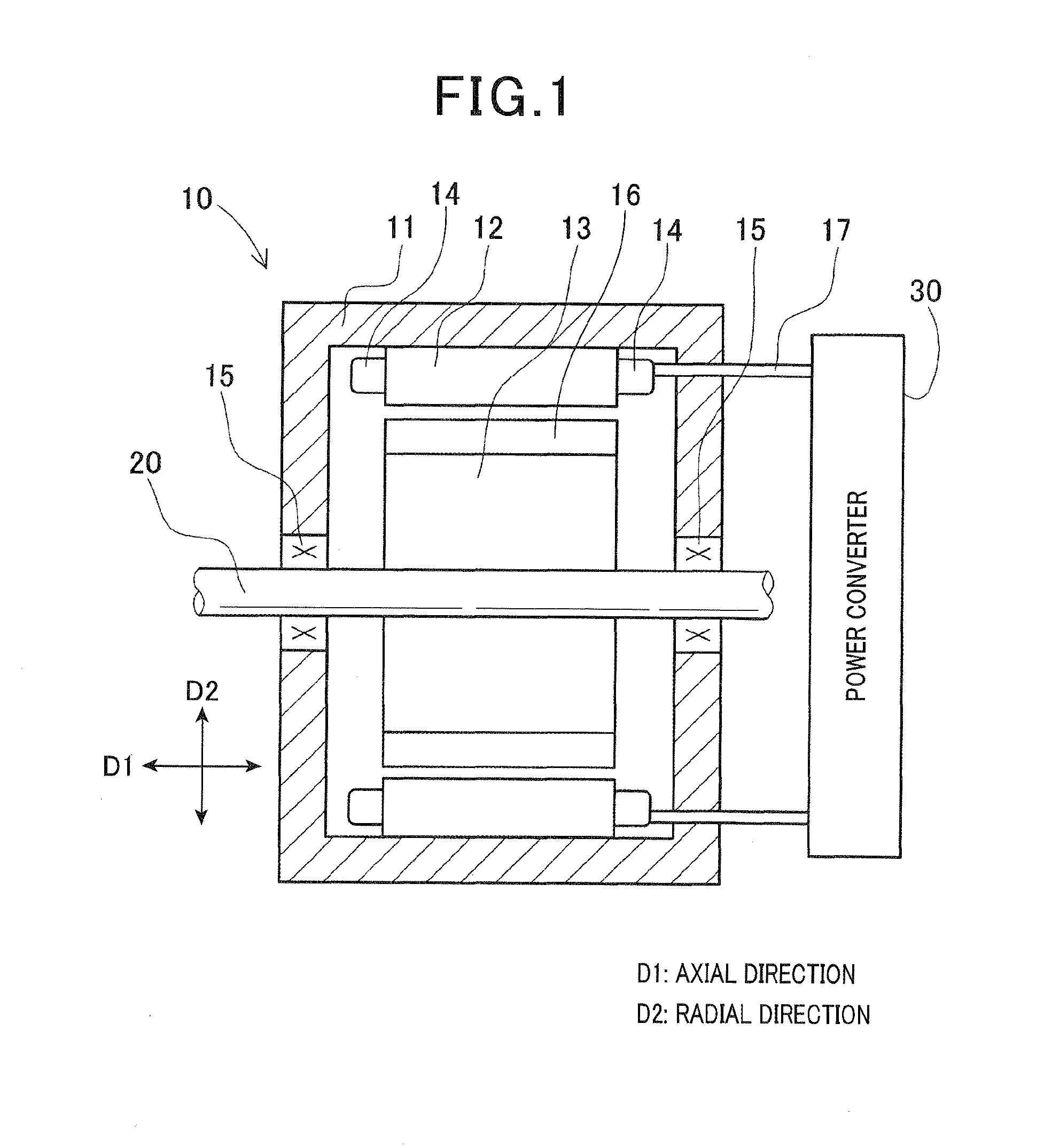

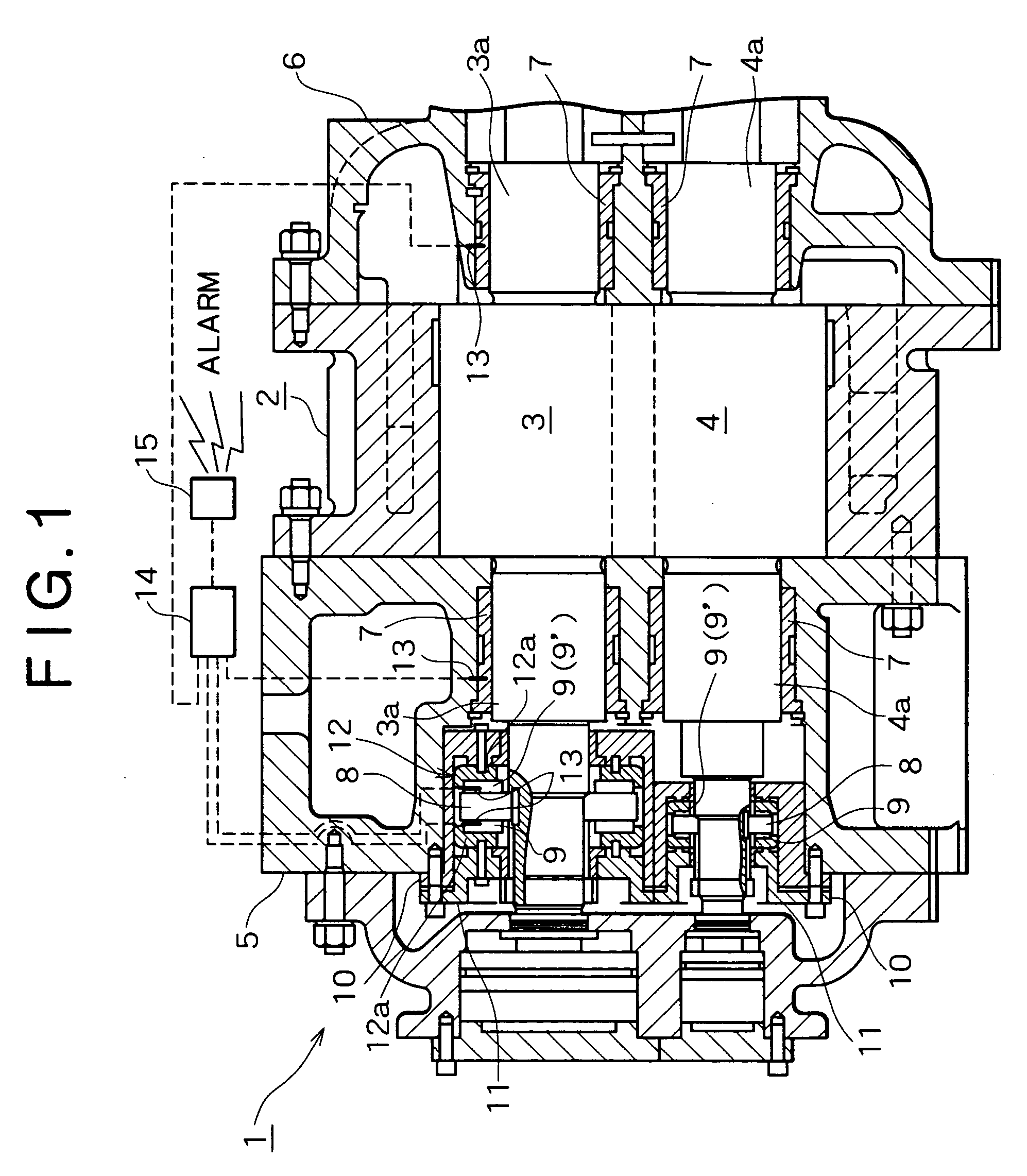

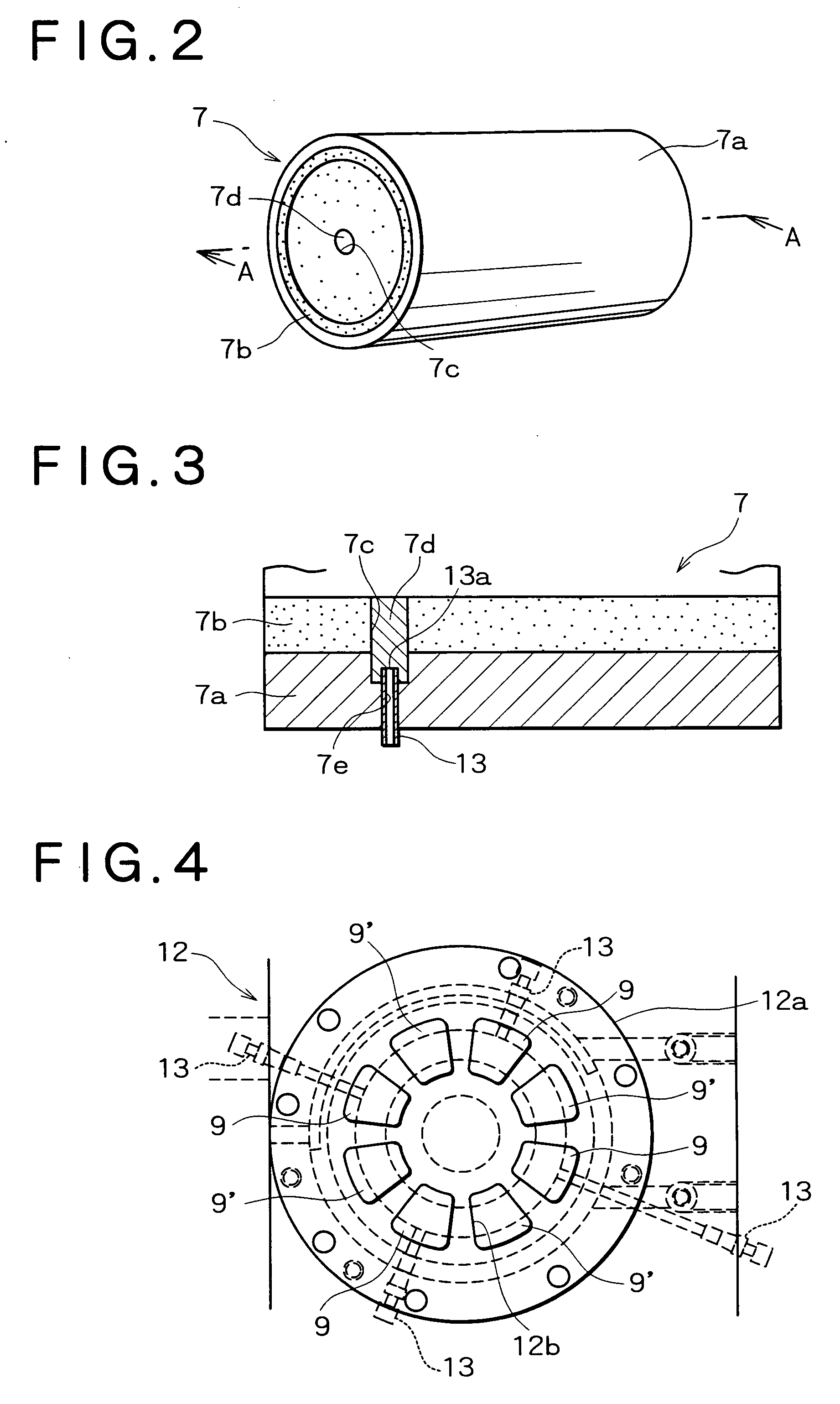

Dynamoelectric machine

ActiveUS7633197B2Easy to assembleImprove precisionSynchronous generatorsElectric motor controlEngineeringConductor Coil

A dynamoelectric machine enabling stator winding temperature detecting precision of a temperature measuring means to be improved while also improving assembly of the dynamoelectric machine is provided.The dynamoelectric machine according to the present invention includes: a stator winding disposed in a stator; a temperature sensor for estimating a stator winding temperature of the stator winding; and a thermally-conductive bracket disposed between the stator winding and the temperature sensor. An estimated value of the stator winding temperature is calculated using a sum of a measured temperature measured by the temperature measuring means and a correcting value for correcting the measured temperature.

Owner:MITSUBISHI ELECTRIC CORP

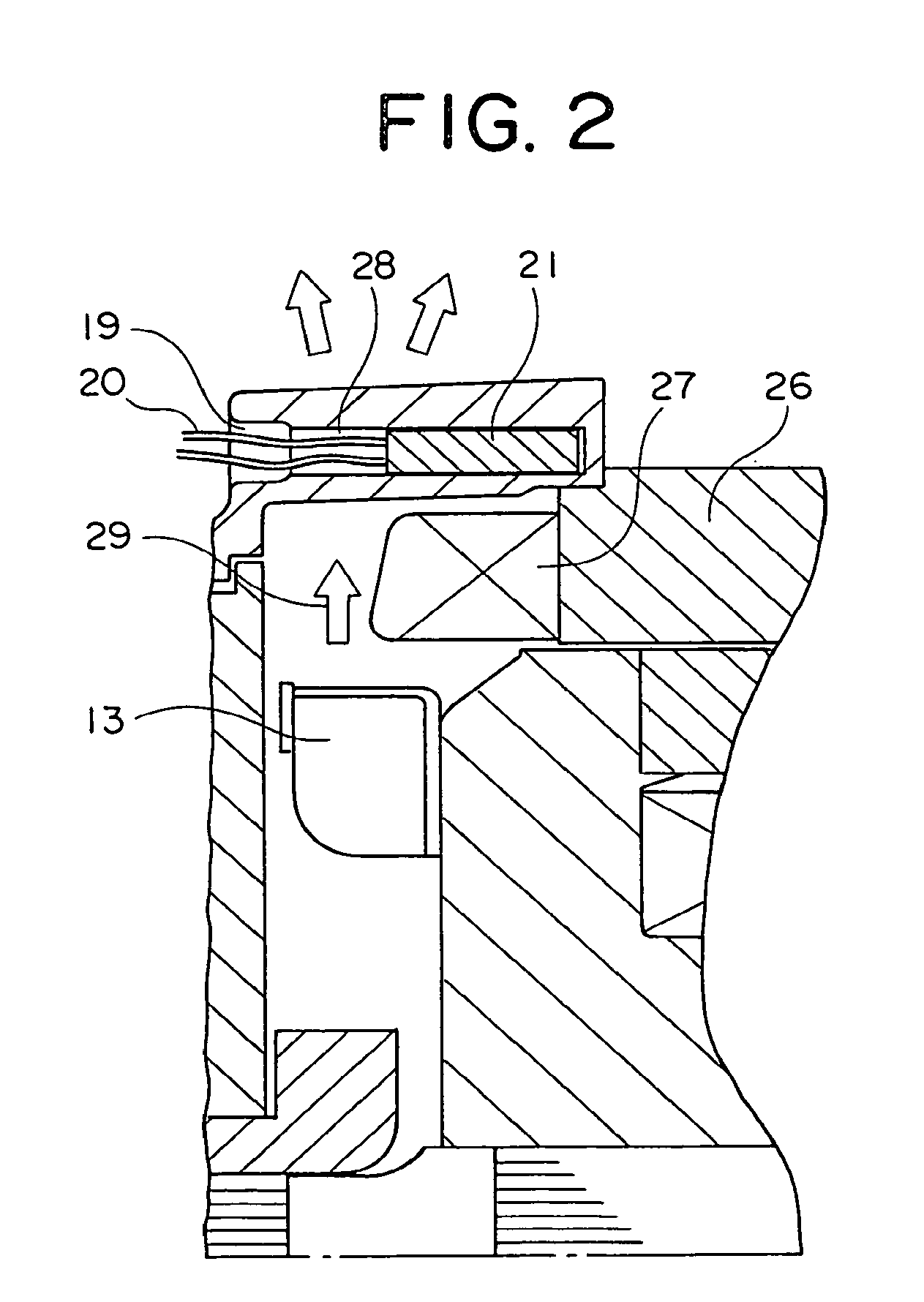

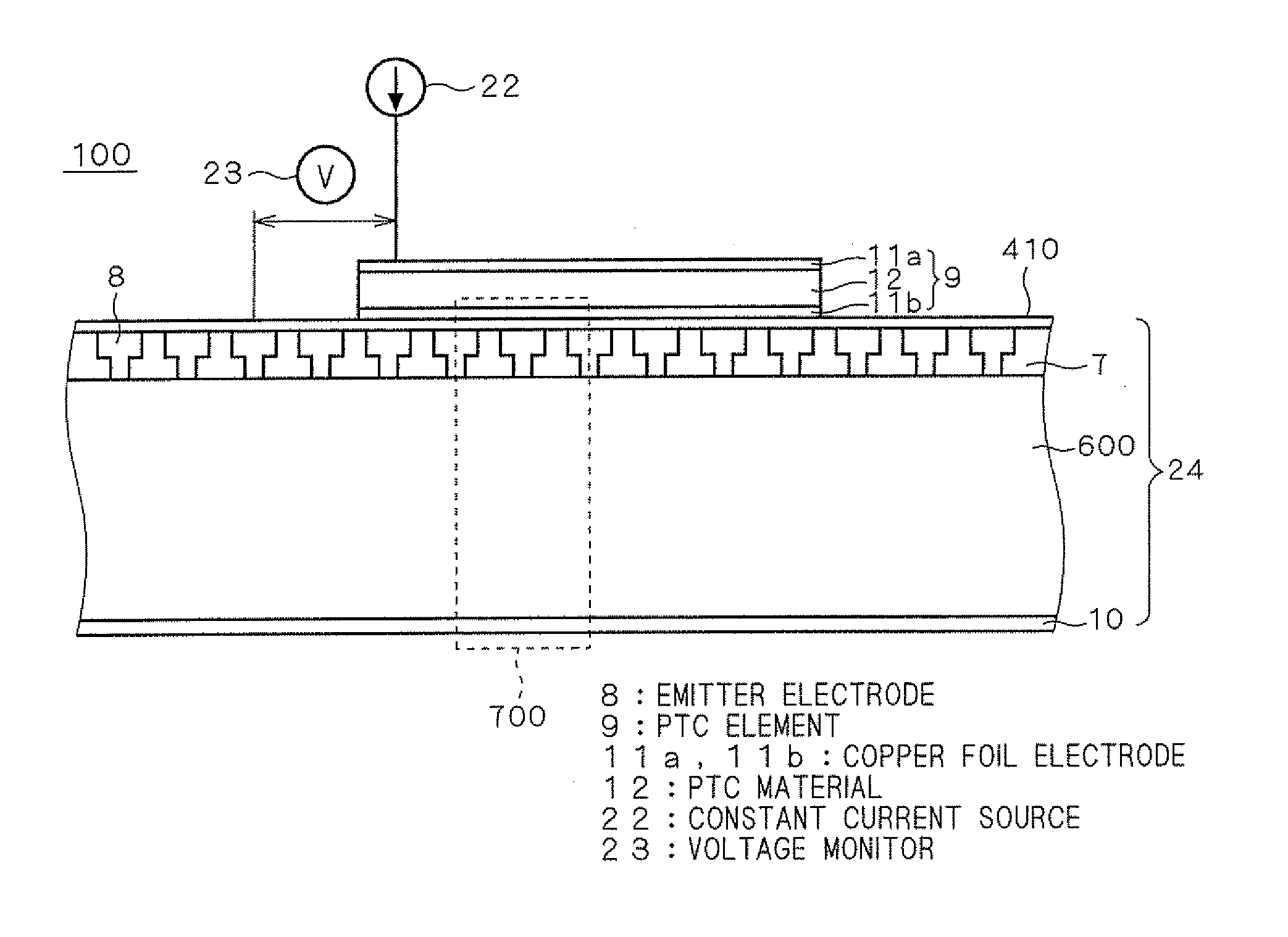

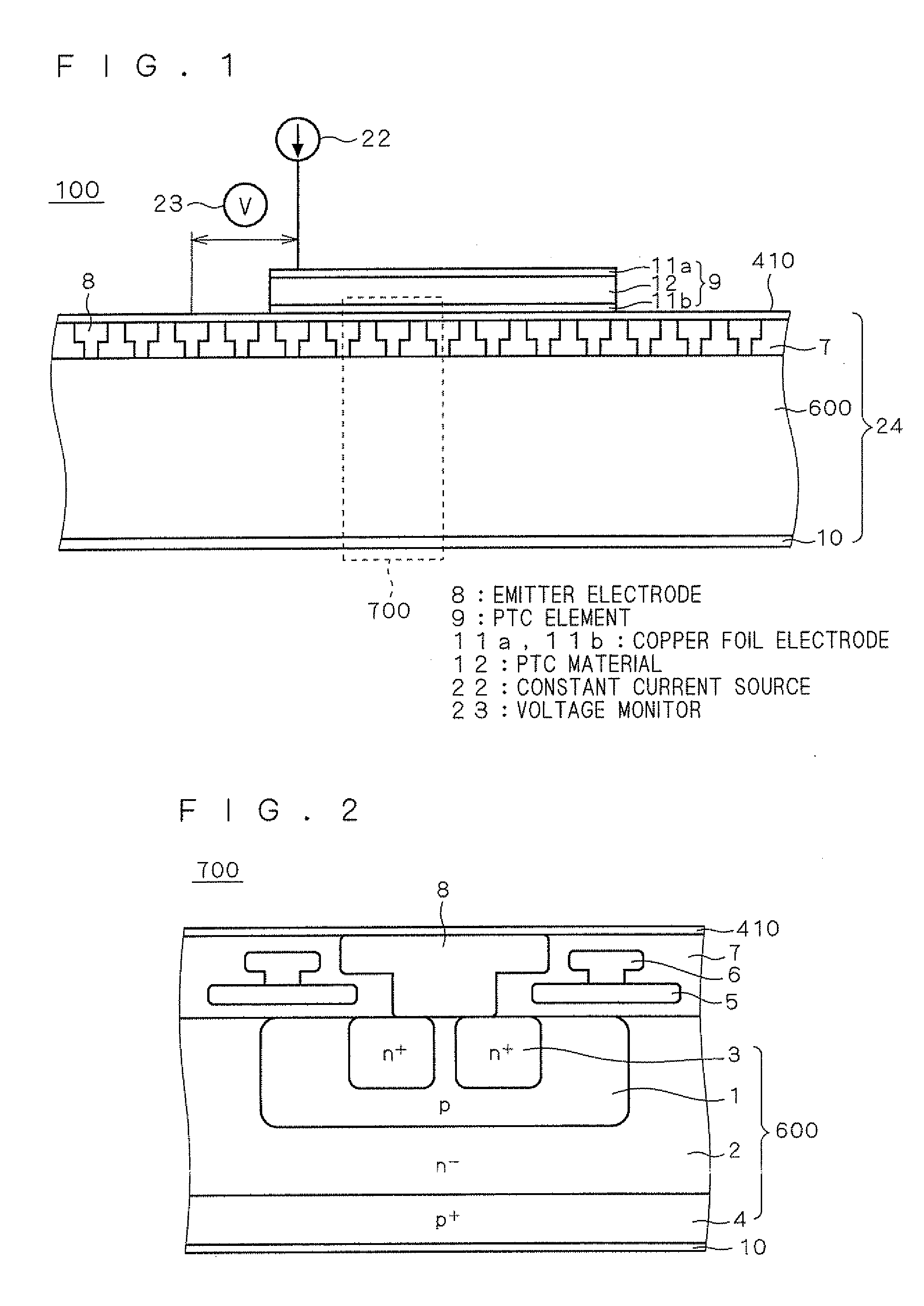

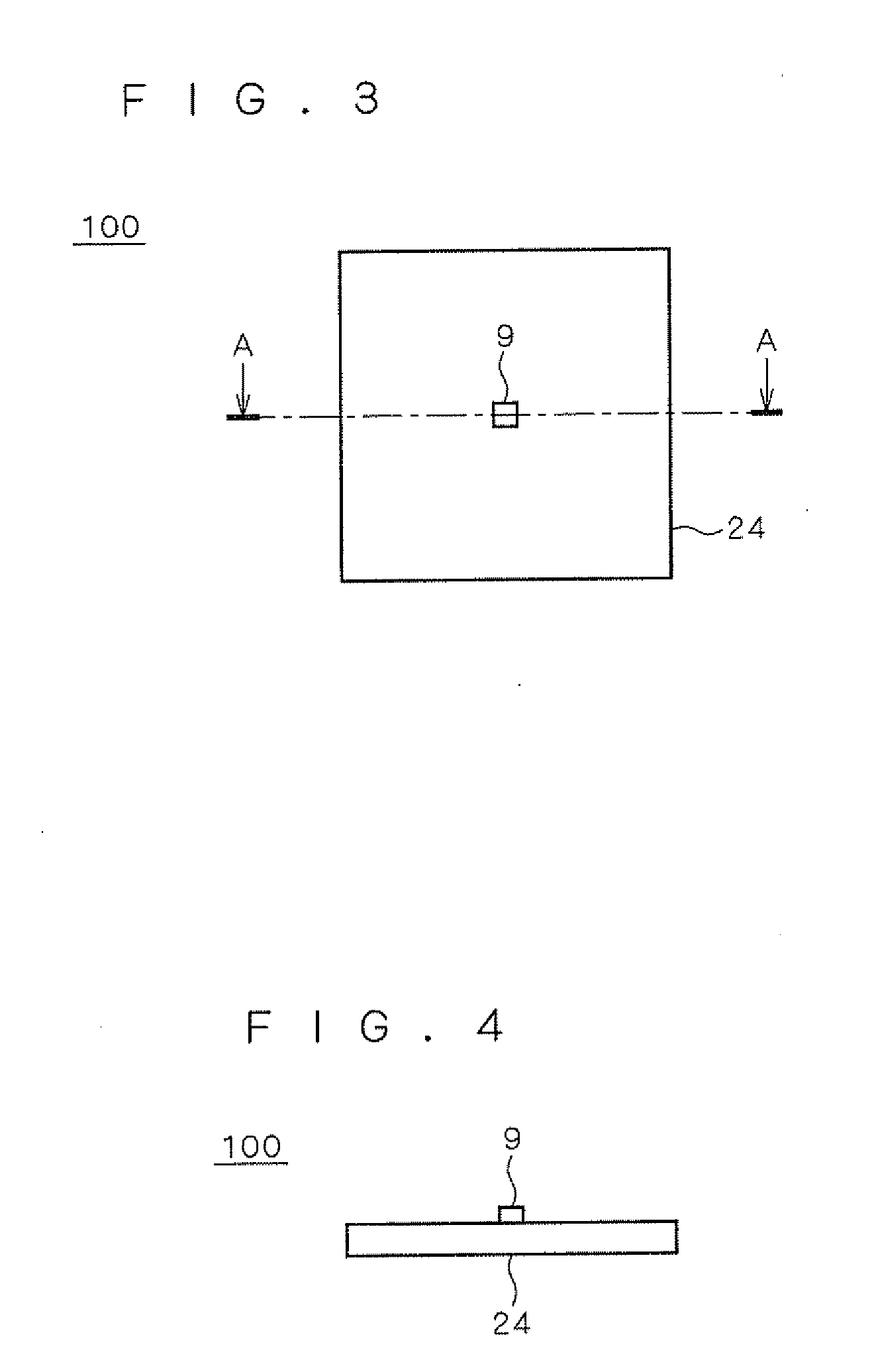

Semiconductor Device

ActiveUS20080006897A1Accurately monitoring temperature of semiconductor chipHighly accurate detection circuitSemiconductor/solid-state device detailsThermometers using electric/magnetic elementsMonitoring temperatureDevice material

A semiconductor device accurately monitoring temperature of a semiconductor chip even in a noisy environment, while not requiring a highly accurate detection circuit. A PTC element is bonded onto an IGBT chip. Then, a constant current flows from a constant current source through the PTC element, and an output voltage of the PTC element is detected by a voltage monitor. When output voltage increases, a voltage applied to a gate electrode by a detection circuit is decreased. Since the PTC element is directly arranged on the IGBT chip, the temperature of the IGBT chip can be monitored with high accuracy. Further, since the change in output voltage of the PTC element per 1° C. is large, a highly accurate detection circuit is not necessary, thereby allowing accurate monitoring of the temperature of the IGBT chip even in a noisy environment.

Owner:MITSUBISHI ELECTRIC CORP

Whole-temperature-range thermoelectric-field transmission electron microscope in-situ sample rod

InactiveCN105823908ARapid cooling and coolingReduce thermal contactScanning probe techniquesElectrical resistance and conductanceConventional transmission electron microscope

The invention discloses a whole-temperature-range thermoelectric-field transmission electron microscope in-situ sample rod which comprises a DEWAR fixing ring, a DEWAR outer tank upper portion, a DEWAR outer tank lower portion, guide pins, a sample rod shell, sealing rings, a fixing piece and a sample rod head, a DEWAR inner tank upper portion, a DEWAR inner tank lower portion, a heating module, a fixing plate, a vacuum electrical connector, a wire hole, a sample rod inner rod body, a PCB adapter plate and an in-situ test chip. Based on big-temperature-range design, electric signals can be directly added to a sample for conducting thermoelectric performance research in the sample material. The low-temperature and high-temperature cooling functions are achieved with liquid nitrogen, and refrigerating and cooling are achieved rapidly; a detachable mode is adopted for the sample rod head, the function of replacement and expansion is achieved, and single low temperature or high temperature is achieved or the whole-temperature-range is achieved at the same time; a chip microcell heating mode is adopted for a heating module, heat contact is lowered, and heat drift is reduced; design of enlarging the work microcell is utilized, a temperature measurement element is detected through resistance signal change, and real-time and accurate temperature detection can be achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

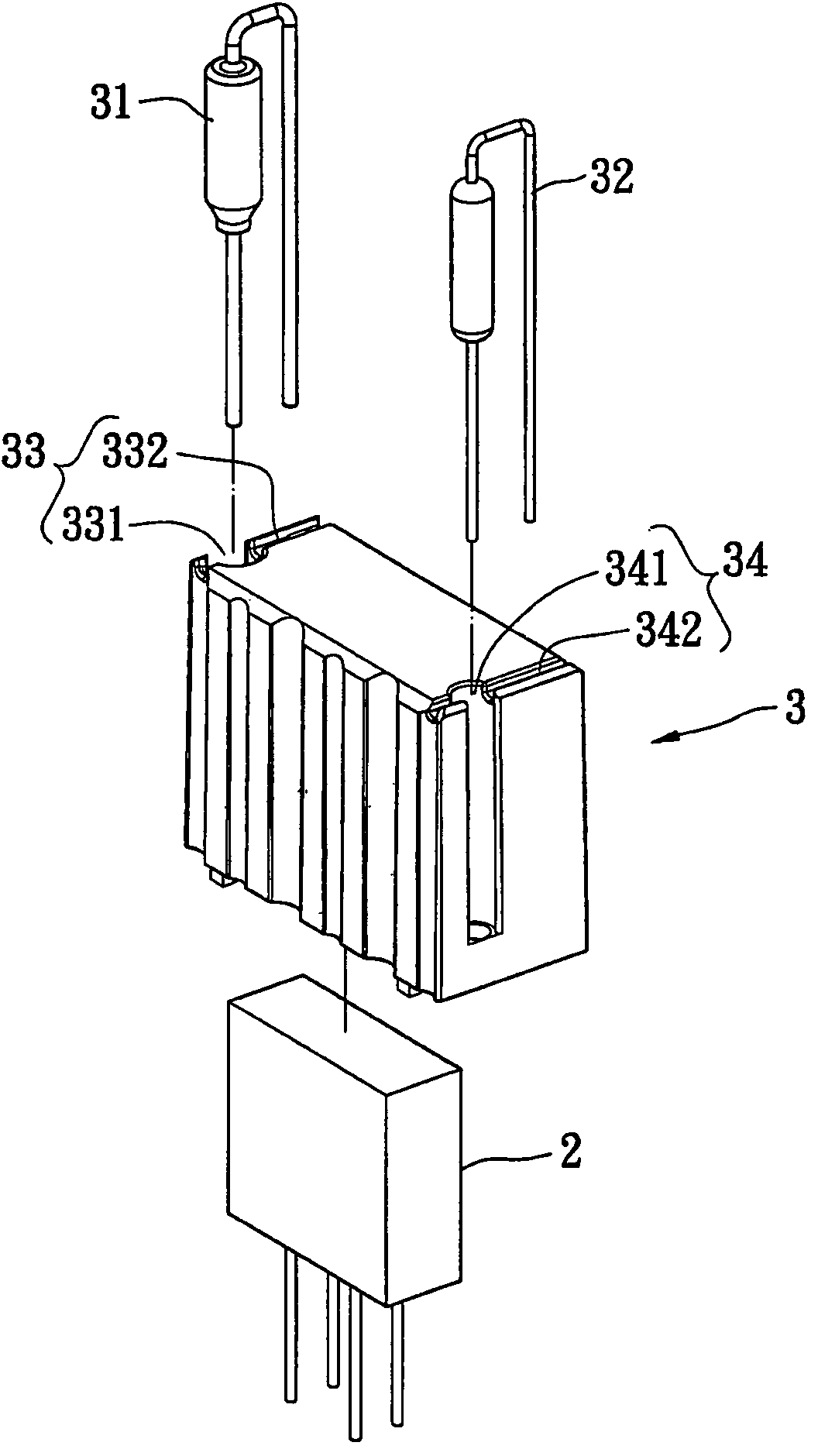

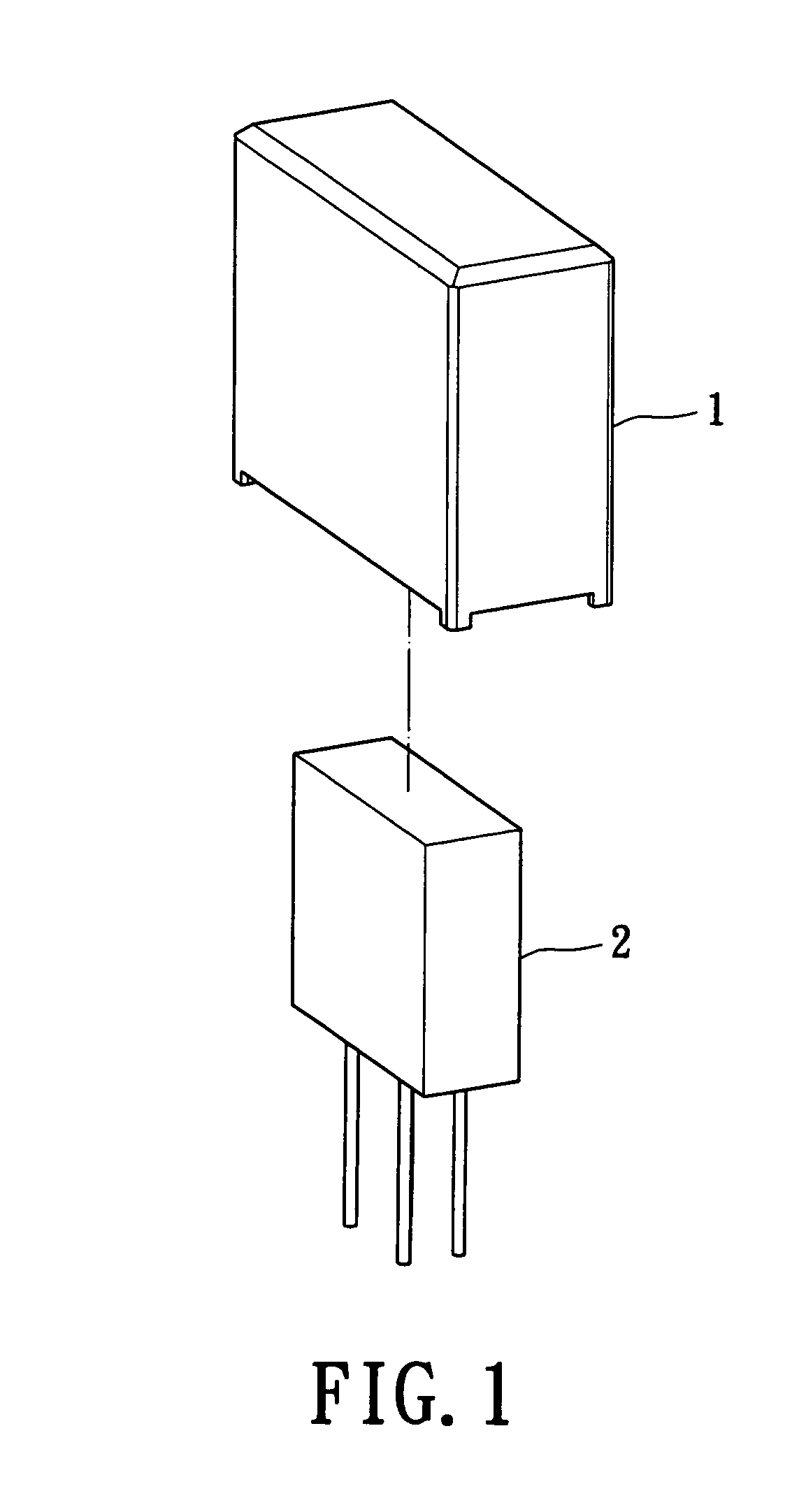

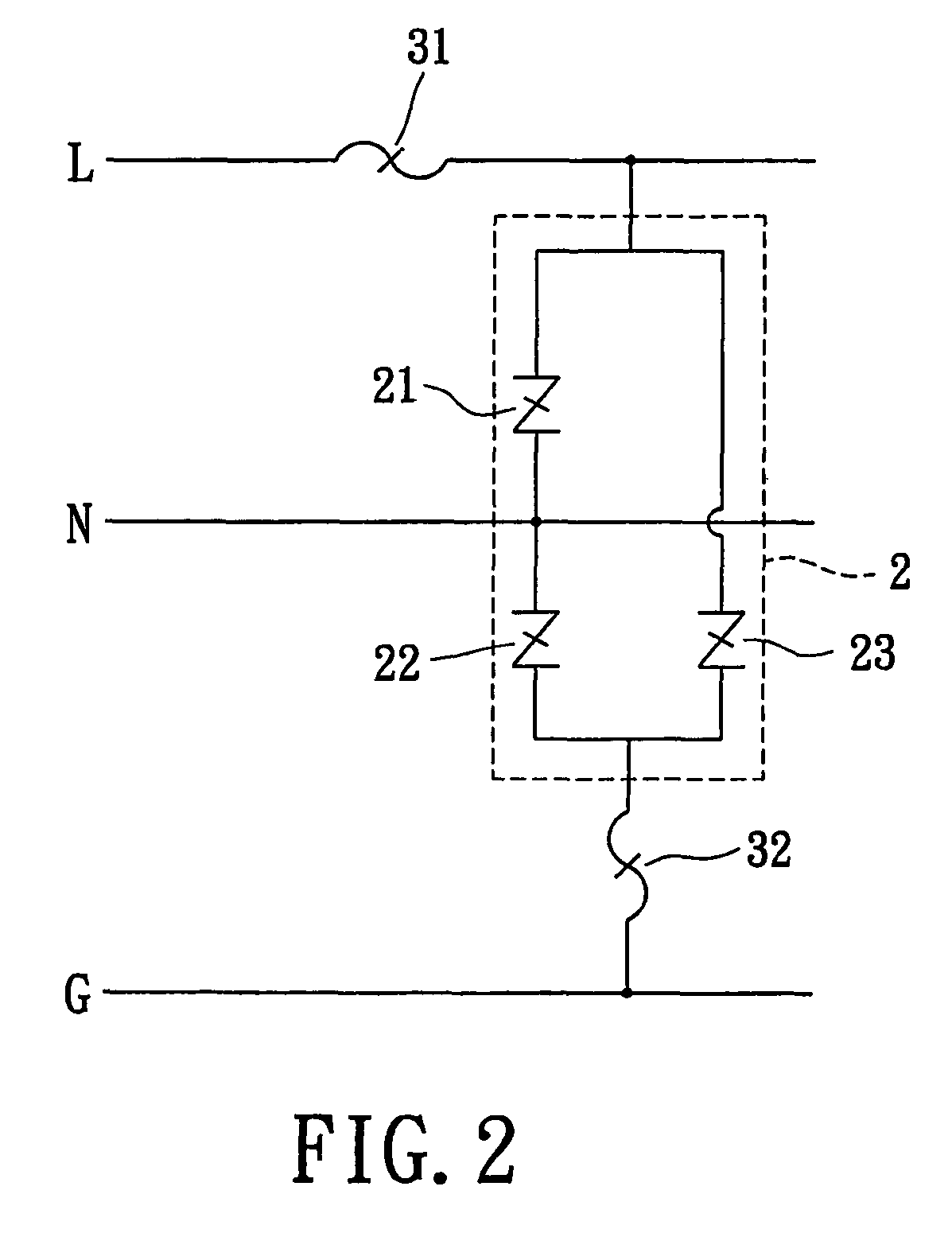

Varistor protection cover and varistor device

InactiveUS7808364B2Accurate temperature detectionReduce generationCurrent responsive resistorsEmergency protective arrangement detailsElectrical resistance and conductanceRefractory

A protection cover used for avoiding the influence brought about by the temperature effect of a varistor is proposed. The protection cover is made of ceramic or refractory material, and is used to bear high temperature generated when a metal oxide varistor breaks down to catch fire and to further cover the fire therein, thereby preventing the fire from burning out application components around the metal oxide varistor. Moreover, accommodation portions and grooves for receiving temperature breakers are disposed on the protection cover to provide a better contact surface between the protection cover and the temperature breakers so that the temperature breakers can more accurately detect the temperature on the protection cover, hence reducing the occurrence of the situation of erroneous actions.

Owner:POWERTECH INDAL

Heater with temperature detecting device and battery structure with the heater

ActiveUS20080093353A1Little changeMinimize uneven heatingCell temperature controlHeater elementsEngineeringMetal sheet

An object of the present invention is to provide a heater with temperature detecting device, arranged to accurately detect the temperature of a laminated sheet heater by use of a temperature detecting device over long periods, and a battery structure including the heater with temperature detecting device. A first heater with temperature detecting device includes a first laminated sheet heater and a temperature sensor having a temperature measuring portion. The first laminated heater is constituted of first and second insulating resin films, a heater element, a first metal sheet, and a second metal sheet and includes a heater metallic section in which, of the first insulating resin film, the second insulating resin film, the heater element, the first metal sheet, and the second metal sheet, any one of only the first metal sheet and only a combination of the first metal sheet and the second metal sheet is arranged in a lamination direction of the laminated heater. The temperature sensor is fastened to the heater metallic section of the first laminated heater with a flat rivet and fixed to an outer surface of the first metal sheet with the temperature measuring portion is in contact with the first metal sheet.

Owner:PANASONIC EV ENERGY CO LTD

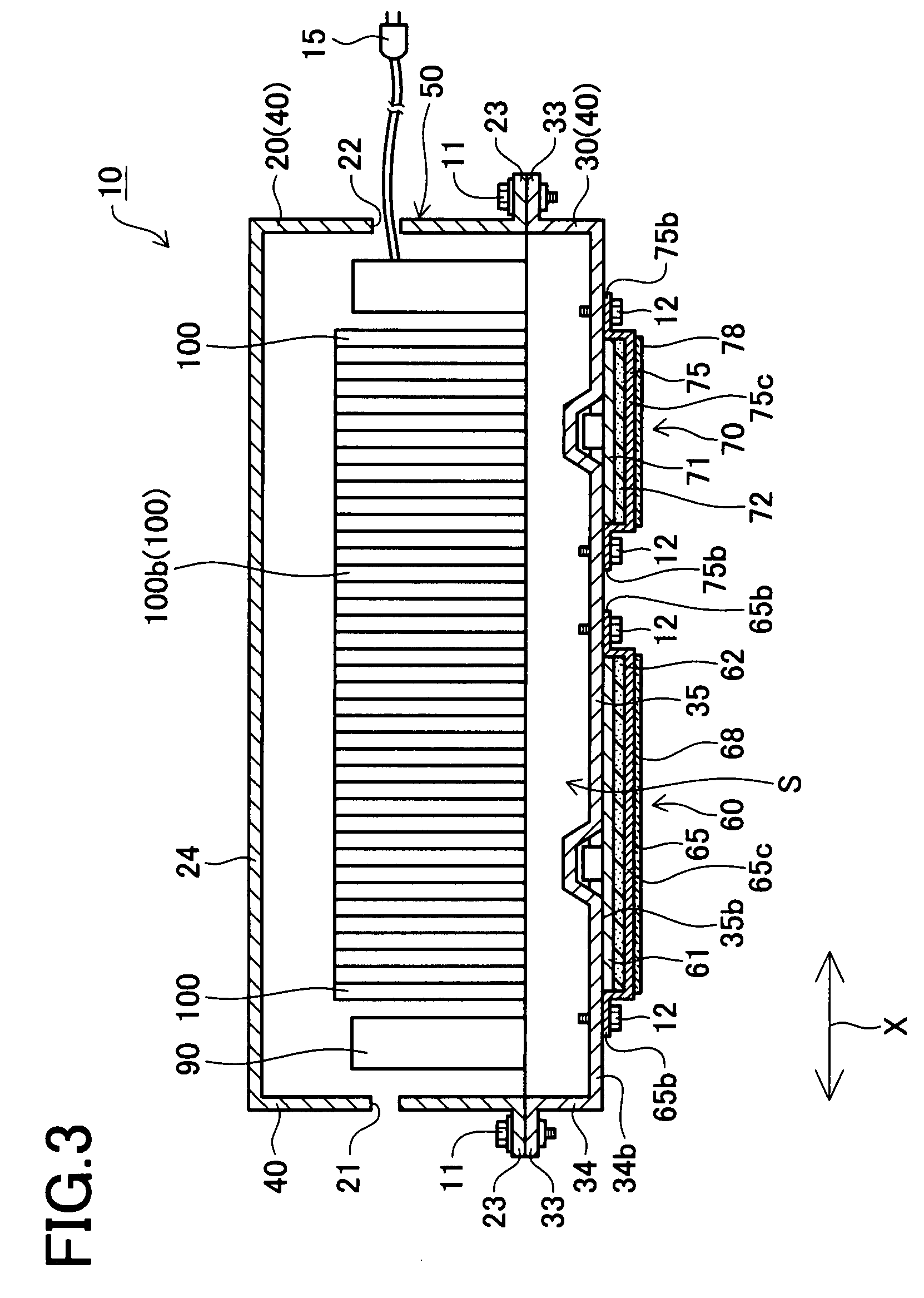

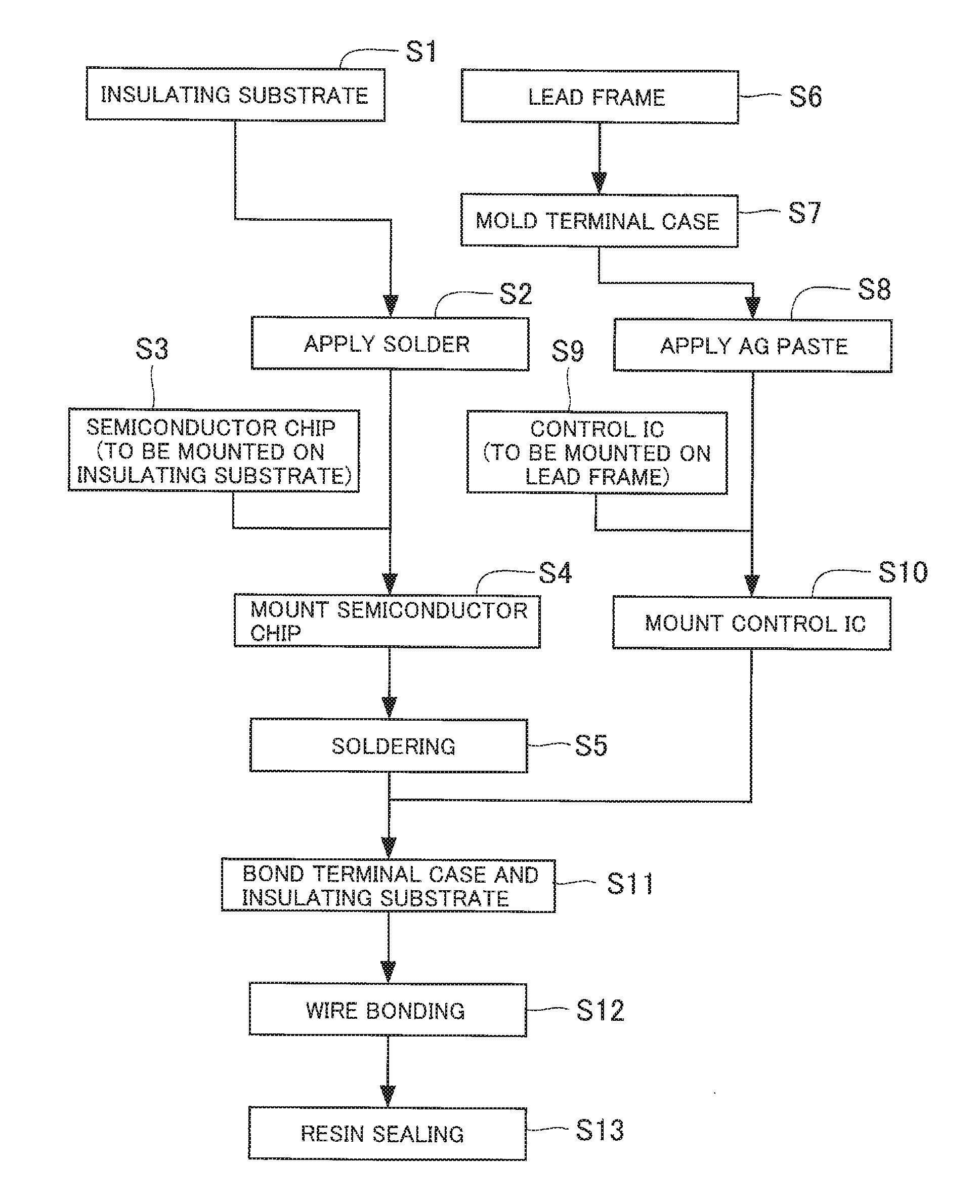

Semiconductor module and method for manufacturing the same

ActiveUS20160254215A1Improve productivityAccurate temperature detectionSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor chip

A terminal case formed by integrally molding a lead frame and a case that has internally an inner face on which the lead frame is mounted and has externally a step portion fixed to a circuit block having an insulating substrate and semiconductor chips formed on the insulating substrate. An opening portion is formed between the step portion and the inner face so as to extend through them, and the opening portion is filled with an adhesive to bond the insulating substrate to the step portion. Since a connecting area to which a bonding wire of the lead frame is ultrasonically bonded is fixed, it is possible to reduce the bonding failures of the lead frames.

Owner:FUJI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com