Method for detecting impurity F and impurity G of omeprazole sodium

A technology of omeprazole sodium and a detection method, applied in the field of pharmaceutical preparations, can solve the problems of multiple impurities, inaccurate impurities, easy changes in chemical structure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

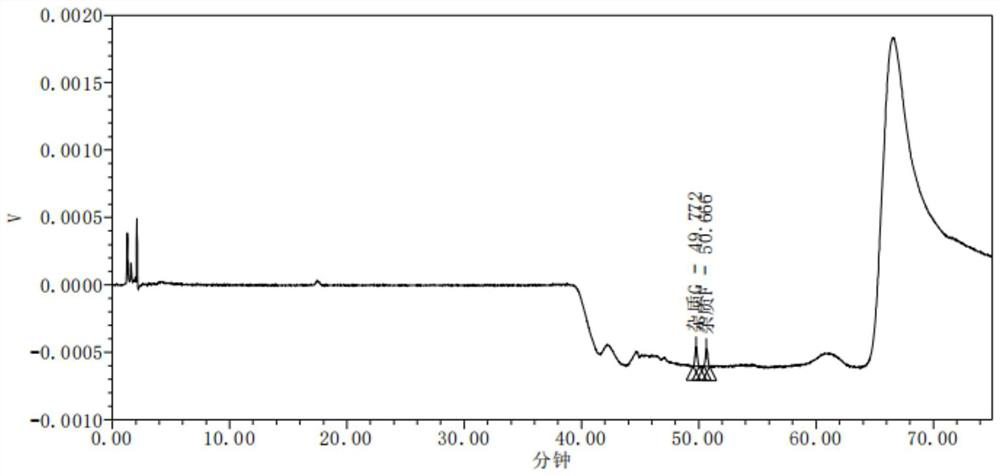

Image

Examples

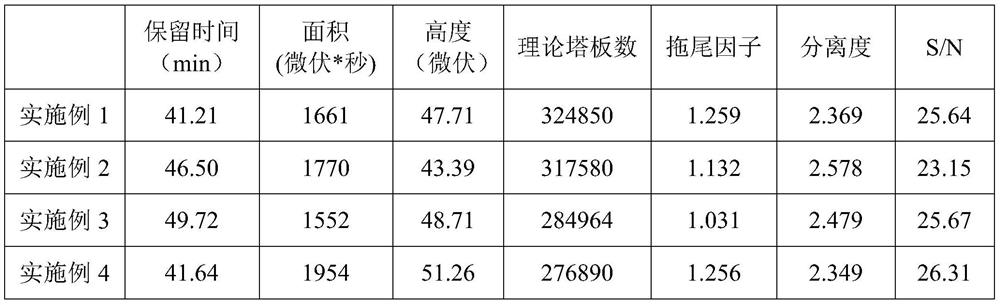

Embodiment 1

[0029] A detection method of omeprazole sodium impurity F and impurity G, comprising the steps of: adopting high performance liquid chromatography to detect omeprazole sodium impurity F and impurity G,

[0030] (1) HPLC detection conditions are as follows:

[0031] Chromatographic column: Octylsilane bonded silica gel as filler

[0032] Mobile phase A: 0.003mol / L disodium hydrogen phosphate solution-acetonitrile, adjust the pH to 7.8, the volume ratio of disodium hydrogen phosphate and acetonitrile is 73:27

[0033] Mobile Phase B: Acetonitrile

[0034] The detection wavelength is 200nm

[0035] Column temperature is 22°C

[0036] Injection volume 15μl

[0037] Flow rate 0.8ml / min

[0038] Gradient elution was carried out with mobile phase, and the elution procedure was as follows:

[0039] From 0 to 35 minutes, the volume ratio of mobile phase A to mobile phase B is 88:12;

[0040] From 35.01 to 60 minutes, the volume ratio of mobile phase A to mobile phase B is 50:50;...

Embodiment 2

[0045] A detection method of omeprazole sodium impurity F and impurity G, comprising the steps of: adopting high performance liquid chromatography to detect omeprazole sodium impurity F and impurity G,

[0046] (1) HPLC detection conditions are as follows:

[0047] Chromatographic column: Octylsilane bonded silica gel as filler

[0048] Mobile phase A: 0.012mol / L disodium hydrogen phosphate solution-acetonitrile, adjust the pH to 7.8, the volume ratio of disodium hydrogen phosphate and acetonitrile is 73:27

[0049] Mobile phase B: acetonitrile aqueous solution with a mass fraction of 0.5-1.3%

[0050] The detection wavelength is 300nm

[0051] Column temperature is 28°C

[0052] Injection volume 25μl

[0053] Flow rate 1.2ml / min

[0054] Gradient elution was carried out with mobile phase, and the elution procedure was as follows:

[0055] From 0 to 35 minutes, the volume ratio of mobile phase A to mobile phase B is 99:1;

[0056] From 35.01 to 60 minutes, the volume ra...

Embodiment 3

[0061] A detection method of omeprazole sodium impurity F and impurity G, comprising the steps of: adopting high performance liquid chromatography to detect omeprazole sodium impurity F and impurity G,

[0062] (1) HPLC detection conditions are as follows:

[0063] Chromatographic column: Octylsilane bonded silica gel as filler

[0064] Mobile phase A: 0.01mol / L disodium hydrogen phosphate solution-acetonitrile, adjust the pH to 7.8, the volume ratio of disodium hydrogen phosphate and acetonitrile is 73:27

[0065] Mobile phase B: acetonitrile aqueous solution with a mass fraction of 0.5-1.3%

[0066] The detection wavelength is 280nm

[0067] Column temperature is 25°C

[0068] Injection volume 20μl

[0069] Flow rate 1.0ml / min

[0070] Gradient elution was carried out with mobile phase, and the elution procedure was as follows:

[0071] From 0 to 35 minutes, the volume ratio of mobile phase A to mobile phase B is 90:10;

[0072] From 35.01 to 60 minutes, the volume ra...

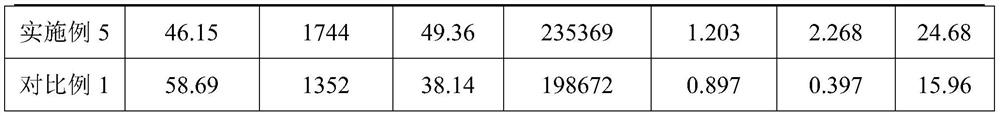

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com