A device and method for high-efficiency batch continuous production of collagen for industrial use

A collagen and continuous production technology, applied in the field of medicine, can solve the problems of slow concentration process, low collagen content, and difficulty in mass production, and achieve the effect of fast concentration process, high collagen content, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

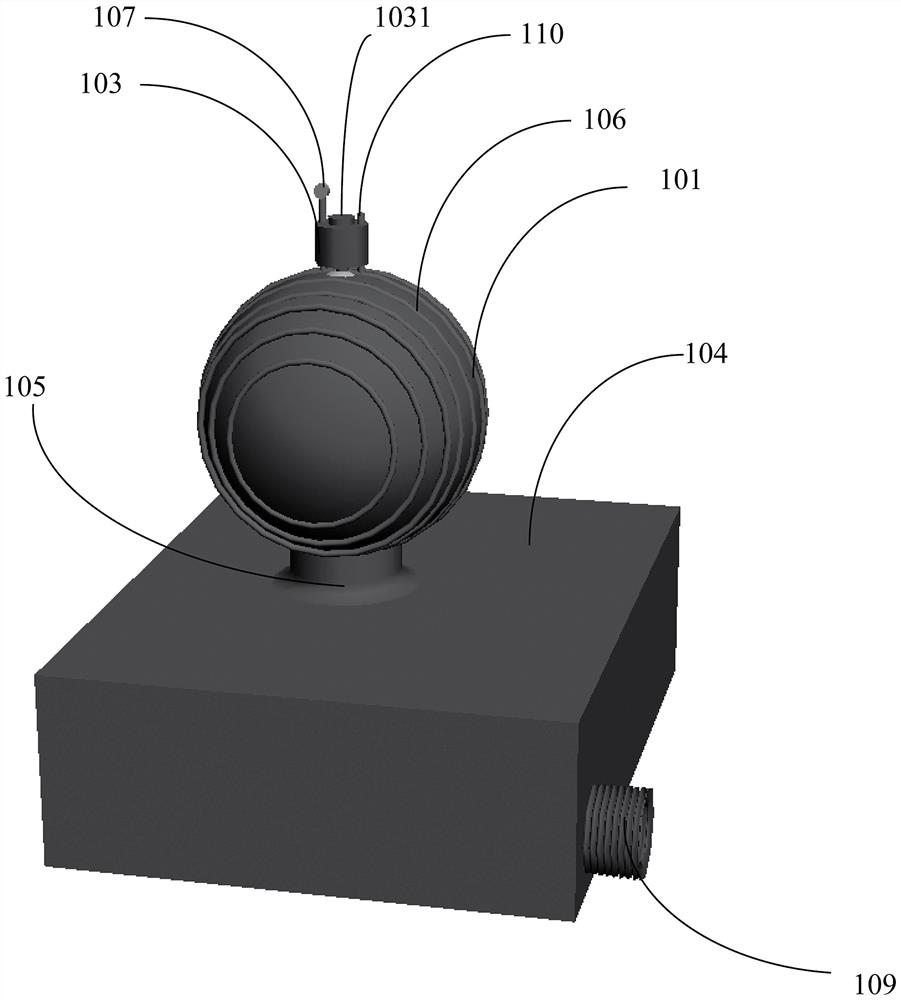

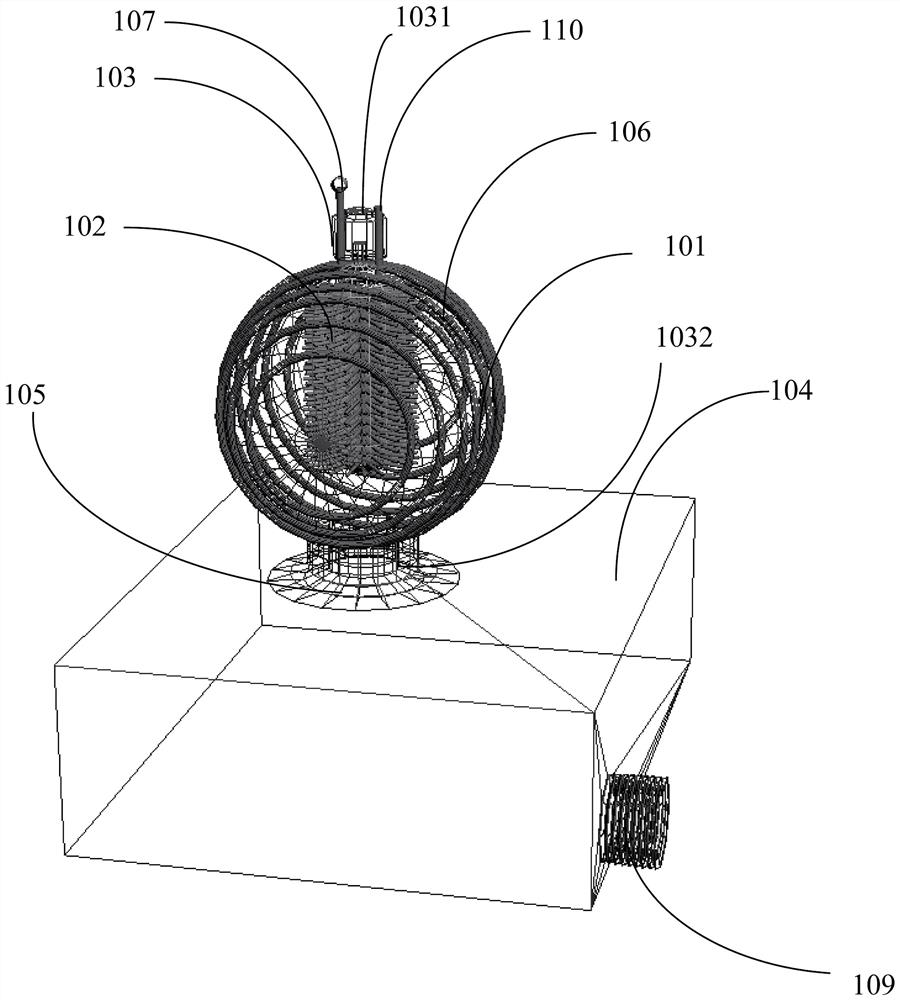

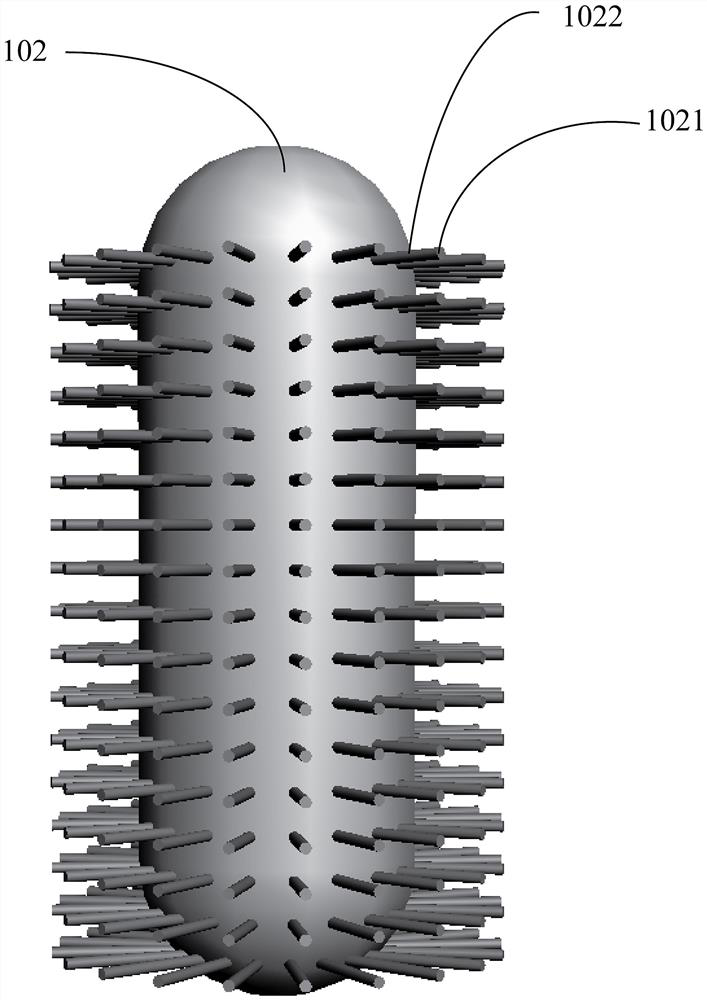

Image

Examples

Embodiment 1

[0061] After removing the fat and fascia from the fresh pork skin or tendon, cut it into slices under 5 mm, the smaller the better, the better for collagen extraction. Then remove the blood, degrease, rinse with distilled water, and dry for later use. During pretreatment, adipose tissue must be fully removed. Once lipids are mixed in collagen, it cannot be removed by neutral or acidic precipitation and dissolution, and finally only a milky collagen solution can be obtained.

[0062] The pretreated pig skin or tendon was weighed and put into a conical flask. A certain amount of enzyme and a certain concentration of acetic acid solution were added for hydrolysis, and the temperature was controlled at about 4 °C and slowly stirred for 12 hours. 8000r·min -1 Centrifuge and take the supernatant solution to obtain crude collagen solution.

[0063] Slowly add 6 mol·L to the crude collagen solution -1 The pH value of the sodium hydroxide solution is adjusted to 3.5, and the precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com