Pressure-sensitive adhesive layer, optical film provided with pressure-sensitive layer, optical laminate, and image display device

An adhesive layer and adhesive technology, applied in the directions of polymer adhesive additives, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as poor adhesion, reduce adhesion, Effects of high durability and good reoperability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0188] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples. In addition, the parts and % in each example are based on weight. Hereinafter, all room temperature storage conditions that are not particularly limited are 23° C. and 65% RH.

[0189]

[0190] The weight average molecular weight (Mw) of a (meth)acrylic-type polymer (A) was measured by GPC (gel permeation chromatography), and Mw / Mn was measured similarly.

[0191] ・Analyzer: HLC-8120GPC manufactured by Tosoh Corporation

[0192] ・Pillar: Tosoh Co., Ltd., G7000H XL +GMH XL +GMH XL

[0193] ・Column size: 7.8mmφ×30cm each, 90cm in total

[0194] ·Column temperature: 40℃

[0195] ·Flow rate: 0.8mL / min

[0196] ·Injection volume: 100μL

[0197] ·Eluent: tetrahydrofuran

[0198] Detector: Differential refractometer (RI)

[0199] ·Standard sample: polystyrene

[0200]

Synthetic example 1~2

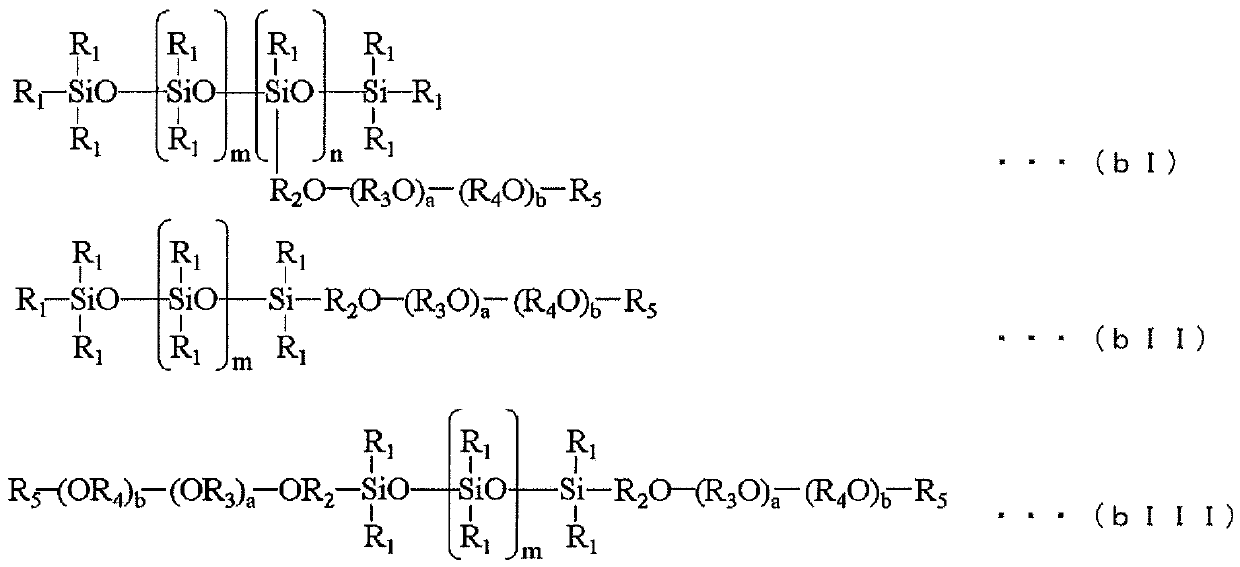

[0202] Organopolysiloxane compounds (B1) and (B2) having the compositions described in Table 1 can be synthesized according to Example 1 described in JP-A-2013-129809

[0203] [Table 1]

[0204]

[0205]

[0206] The composition of the organopolysiloxane compound passes the following conditions 1 Confirmed by H-NMR measurement.

[0207] ・Analyzer: AVANCEIII 600 with Cryo Probe, manufactured by Bruker Biospin

[0208] ·Observation frequency: 600MHz(1H)

[0209] ·Determination solvent: CDCl 3

[0210] ·Measuring temperature: 300K

[0211] ・Chemical shift reference: Measurement solvent [1H: 7.25ppm]

[0212]

[0213] The organopolysiloxane compound (B3) having the composition described in Table 2 can be synthesized according to Example 2 described in JP-A-2013-129809.

[0214] [Table 2]

[0215]

[0216]

[0217] A polyvinyl alcohol film having a thickness of 80 μm was stretched 3 times between rollers having different speed ratios while being dyed in a 0.3% i...

Embodiment 2~15、 comparative example 1~4

[0226] In Example 1, as shown in Table 3, the types of monomers used in the preparation of acrylic polymers and their usage ratios were changed, and the production conditions were controlled to prepare the polymer properties (weight average molecular weight) recorded in Table 3. , Mw / Mn) acrylic polymer solution.

[0227] In addition, for each obtained solution of acrylic polymer, as shown in Table 3, the type or amount of the silicon compound (B), the type or amount of the silane coupling agent containing a reactive functional group (or not used), Except the usage-amount of a crosslinking agent, it carried out similarly to Example 1, and prepared the solution of the acrylic adhesive composition. Moreover, the polarizing film with an adhesive layer was produced similarly to Example 1 using the solution of this acrylic adhesive composition.

[0228] The following evaluation was performed about the polarizing film with an adhesive layer obtained in the said Example and the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com