Carbon nanotube/polyetherimide/thermosetting resin dielectric composite material and preparation method thereof

A polyetherimide, carbon nanotube technology, applied in plastic/resin/wax insulators, circuits, electrical components, etc., can solve the problems of reducing dielectric loss, complex structure design, ineffectiveness, etc., to avoid direct contact , The effect of increasing the dielectric constant and reducing the leakage and conduction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of carbon nanotube / polyetherimide composites

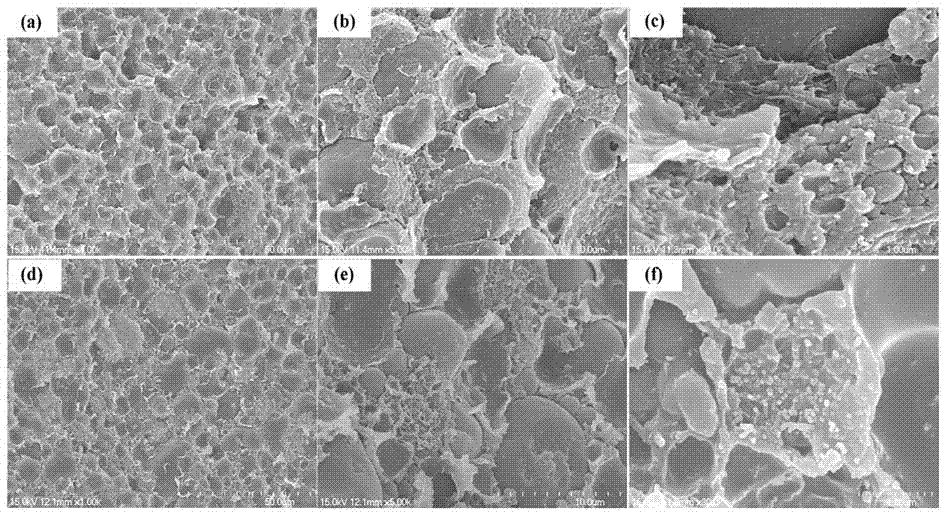

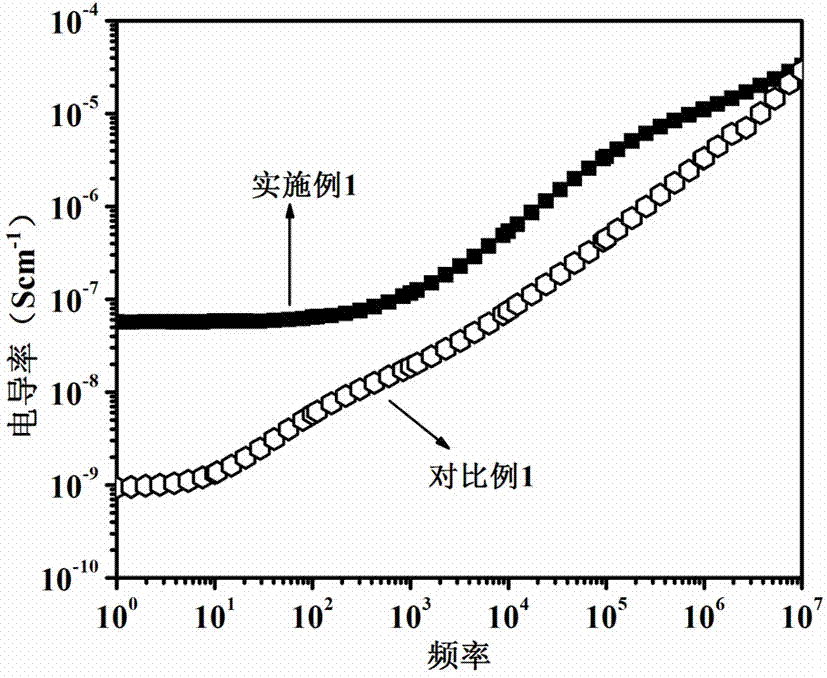

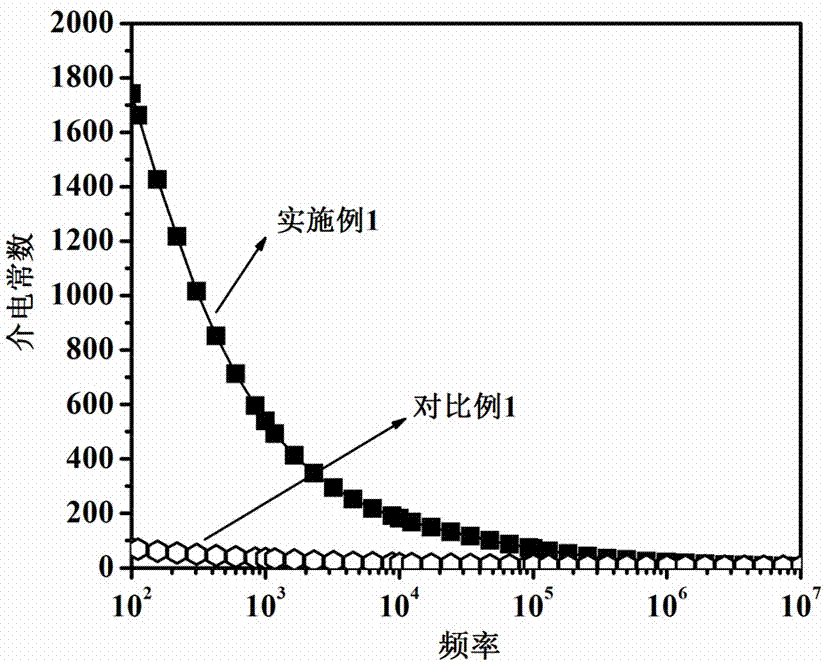

[0026] 3.0 g of multi-walled carbon nanotubes and 60 g of polyetherimide were mixed and stirred uniformly, and the mixture was added to the Haake melting chamber, and melted and banburyed for blending (blending conditions were 15 min at 330 °C). After the banburying is completed, the carbon nanotube / polyetherimide composite is obtained by cooling.

[0027] 2. Preparation of carbon nanotube / polyetherimide / bismaleimide resin dielectric composites

[0028] Dissolve 10.5 g of carbon nanotube / polyetherimide composite in 100 mL of dichloromethane to form a homogeneous solution A; add 37 g of 2.2'-diallyl bisphenol A to solution A, stir and heat up to 150 ° C ; Slowly add 50g of N,N'-(4,4'-methylenediphenyl)bismaleimide, keep stirring for 40min to obtain a prepolymer. Pour the prepolymer into the preheated mold, vacuum defoaming at 145°C for 30min, and perform curing and post-treatment at 165°C / 2h+185°C / 2h+220°C / 2...

Embodiment 2

[0040] 1. Preparation of carbon nanotube / polyetherimide composites

[0041] Mix 0.6 g of multi-walled carbon nanotubes and 60 g of polyetherimide, add the mixture into the Haake melt chamber, and melt banbury and blend (the blending condition is 15 min at 330 °C). After the banburying is completed, the carbon nanotube / polyetherimide composite is obtained by cooling.

[0042] 2. Preparation of carbon nanotube / polyetherimide / bismaleimide resin dielectric composites

[0043] Dissolve 10.1 g of carbon nanotube / polyetherimide composite in 75 mL of dichloromethane to form a homogeneous solution A; add 30 g of 2.2'-diallyl bisphenol A to solution A, stir and heat up to 150 ° C ; Slowly add 50g of N,N'-(4,4'-methylenediphenyl)bismaleimide, keep stirring for 40min to obtain a prepolymer. Pour the prepolymer into the preheated mold, vacuum defoaming at 145°C for 30min, and perform curing and post-treatment at 165°C / 2h+185°C / 2h+220°C / 2h+240°C / 4h, that is, A carbon nanotube / polyetherim...

Embodiment 3

[0045] 1. Preparation of carbon nanotube / polyetherimide Haake composites

[0046] 4.2 g of multi-walled carbon nanotubes and 60 g of polyetherimide were mixed and stirred uniformly, and the mixture was added to the Haake melt chamber for melting and banburying (blending conditions were 10 min at 340 °C). After the banburying is completed, the carbon nanotube / polyetherimide composite is obtained by cooling.

[0047] 2. Preparation of carbon nanotube / polyetherimide / bismaleimide resin dielectric composites

[0048] Dissolve 10.0 g of carbon nanotube / polyetherimide composite in 100 mL of dichloromethane to form a homogeneous solution A, add 45 g of 2,2'-diallyl bisphenol A to solution A, stir and heat up to 150°C; slowly add 50g of N,N'-(4,4'-methylenediphenyl)bismaleimide, keep stirring for 40min, pour it into the preheated mold after the prepolymerization, at 145 Vacuum defoaming for 30min at ℃, curing and post-treatment according to 165℃ / 2h+185℃ / 2h+220℃ / 2h+240℃ / 4h to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com