Patents

Literature

56results about How to "Guaranteed oil yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

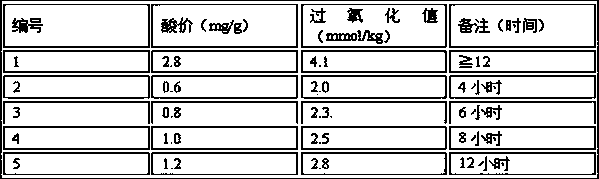

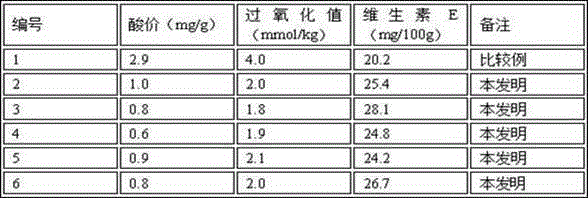

Camellia seed coldly-pressed tea-seed oil and processing process

ActiveCN104212628APrevent acidity riseQuality assuranceFatty-oils/fats refiningFatty-oils/fats productionChemistryFiltration

The invention provides camellia seed coldly-pressed tea-seed oil and a processing process. The processing process comprises the following steps: 1, pre-processing camellia seeds: selecting fresh camellia fruits; peeling and separating to obtain fresh camellia seeds; drying the camellia seeds at a low temperature; and storing; and 2, coldly pressing: cleaning the camellia seeds; shelling and removing shells; grinding; adding water and homogenizing; pressing to obtain primary oil; filtering; and finely filtering to obtain pure natural tea-seed oil. The fresh camellia seeds are dried at the low temperature within four hours and the drying temperature is controlled to be lower than 70 DEG C; the water is controlled to be 6%-10% and the camellia seeds are stored in a low-temperature warehouse to be processed; in the step of shelling and removing shells, the camellia seed shells with the weight percent of 15%-25% are remained in the camellia seeds; and the temperature of the water in the step of adding the water and homogenizing is 40-60 DEG C. By adopting the process to press the camellia seed oil, the quality of an obtained finished product is stable and the efficiency is improved; and the oil yield is guaranteed to the great extent.

Owner:HUBEI HUANGPAOSHAN GREEN PROD

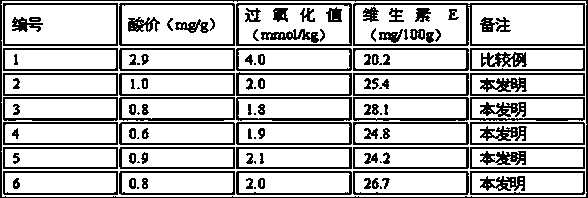

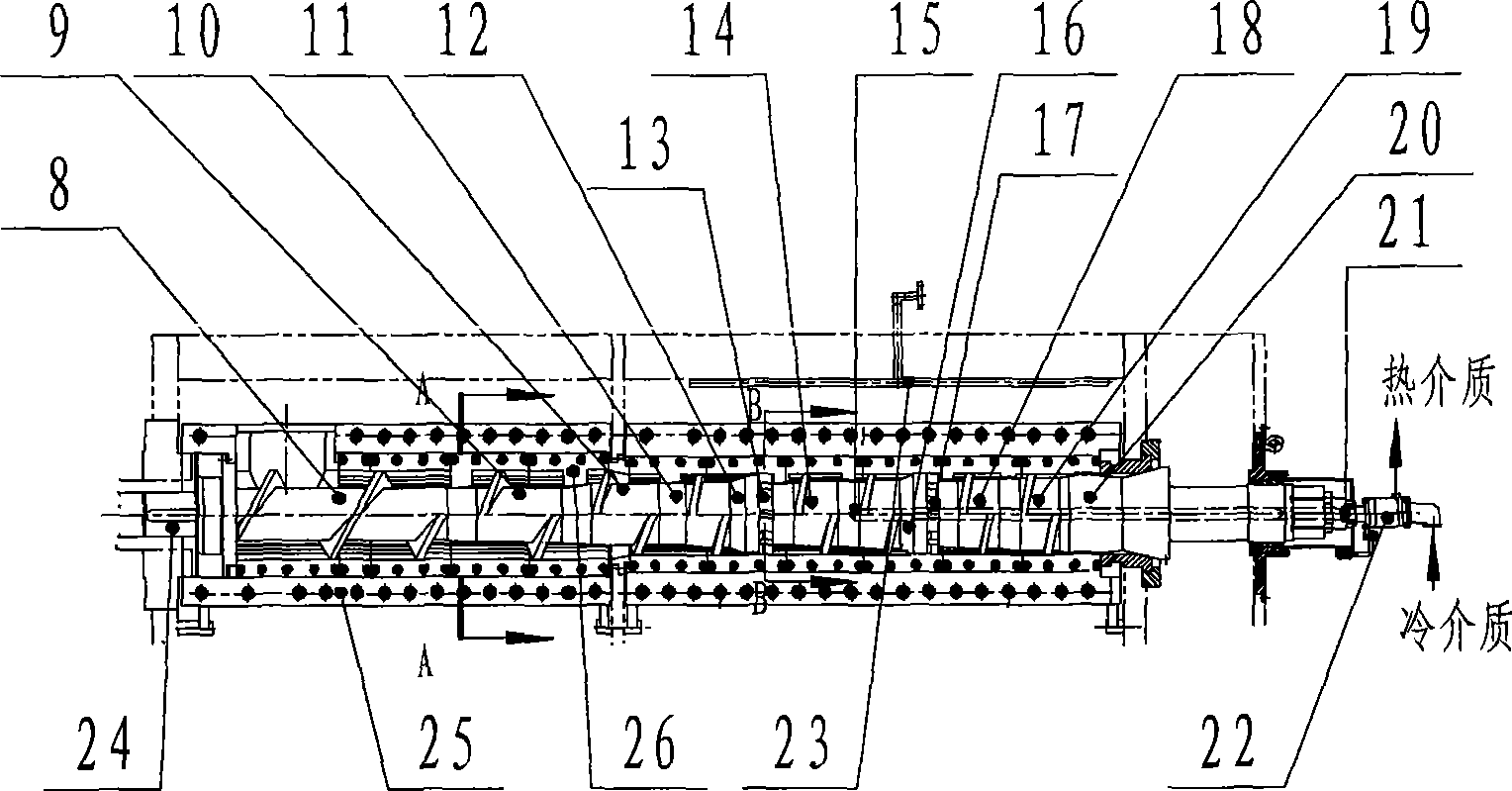

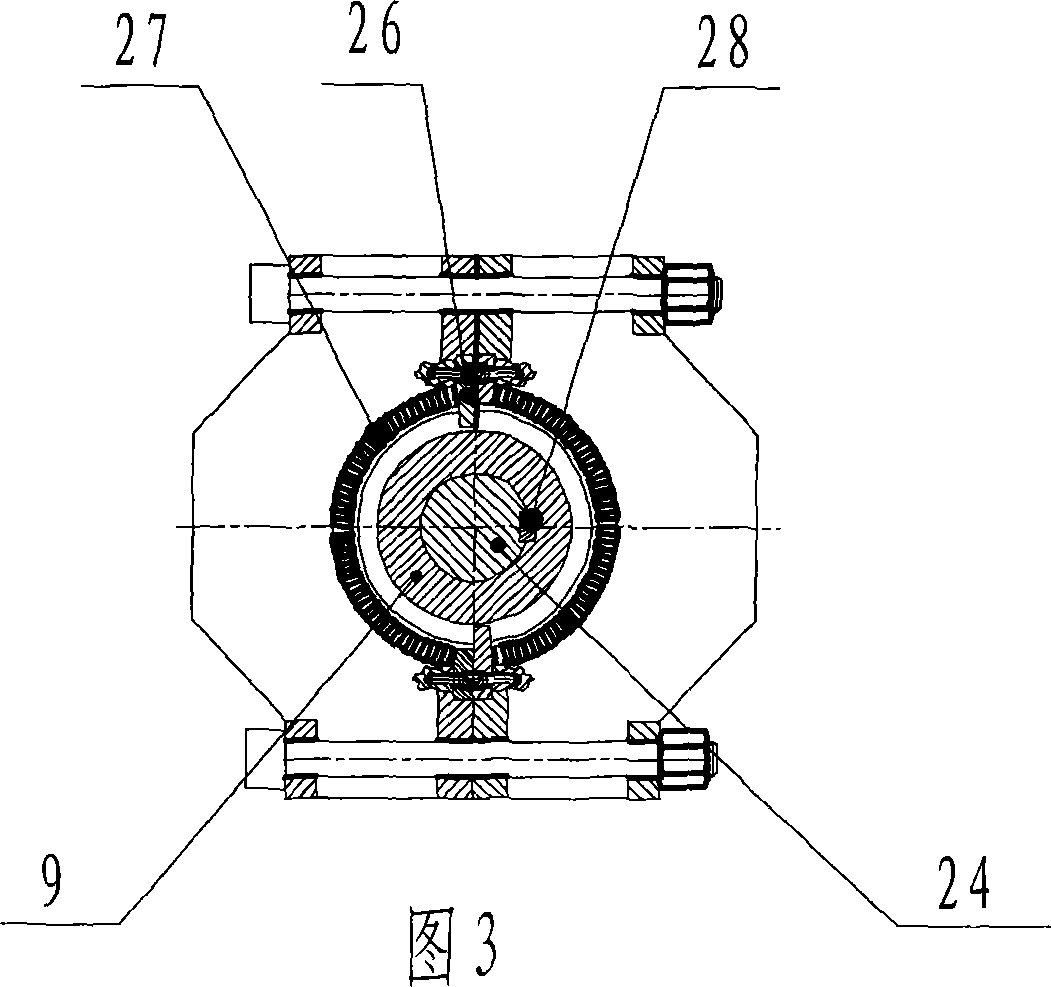

Single screw rod oilseed cold pressing expeller

The invention relates to a single-screw oil material cold squeezer which comprises a squeezing cage and shaft component, which consists of a squeezing cage part and squeezing shafts; and the squeezing shaft is positioned in the squeezing cage part. The cold squeezer is characterized in that the squeezing shaft comprises a squeezing screw mainshaft, a squeezing screw, a cake forming ring and a cake pulverization ring; and the squeezing screw, the caking forming ring and the cake pulverization ring are sleeved and fixed on the outside of the squeezing screw mainshaft. Spiral of the squeezing screw is broken. The squeezing cage part comprises a squeezing cage and a scraper; the scraper is arranged on the squeezing cage; and the scraper is centripetally inserted into a disconnection part of the spiral of the squeezing screw. The squeezing shaft comprises a first squeezing section, a second squeezing section and a third squeezing section. Under the condition of low temperature, the cold squeezer can squeeze an oil material, squeezes out most lipin of the oil material, ensures low denaturing performance of protein in the oil material, is suitable for single squeezing process and is also suitable for presqueezing and leaching process.

Owner:中机康元粮油装备(北京)有限公司 +2

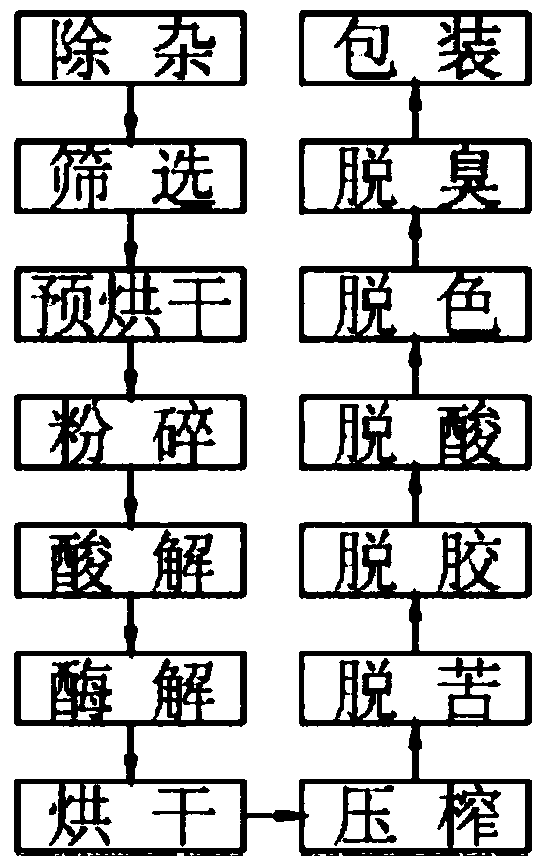

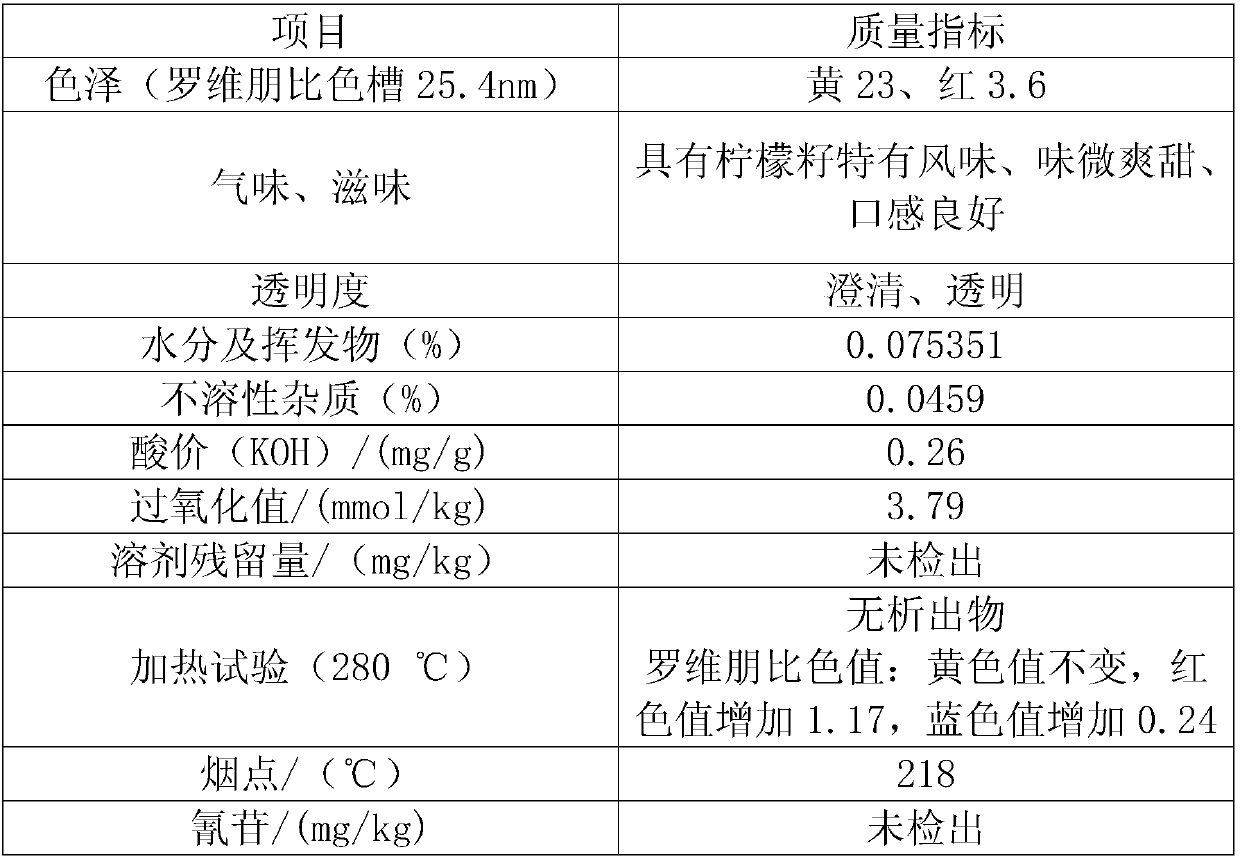

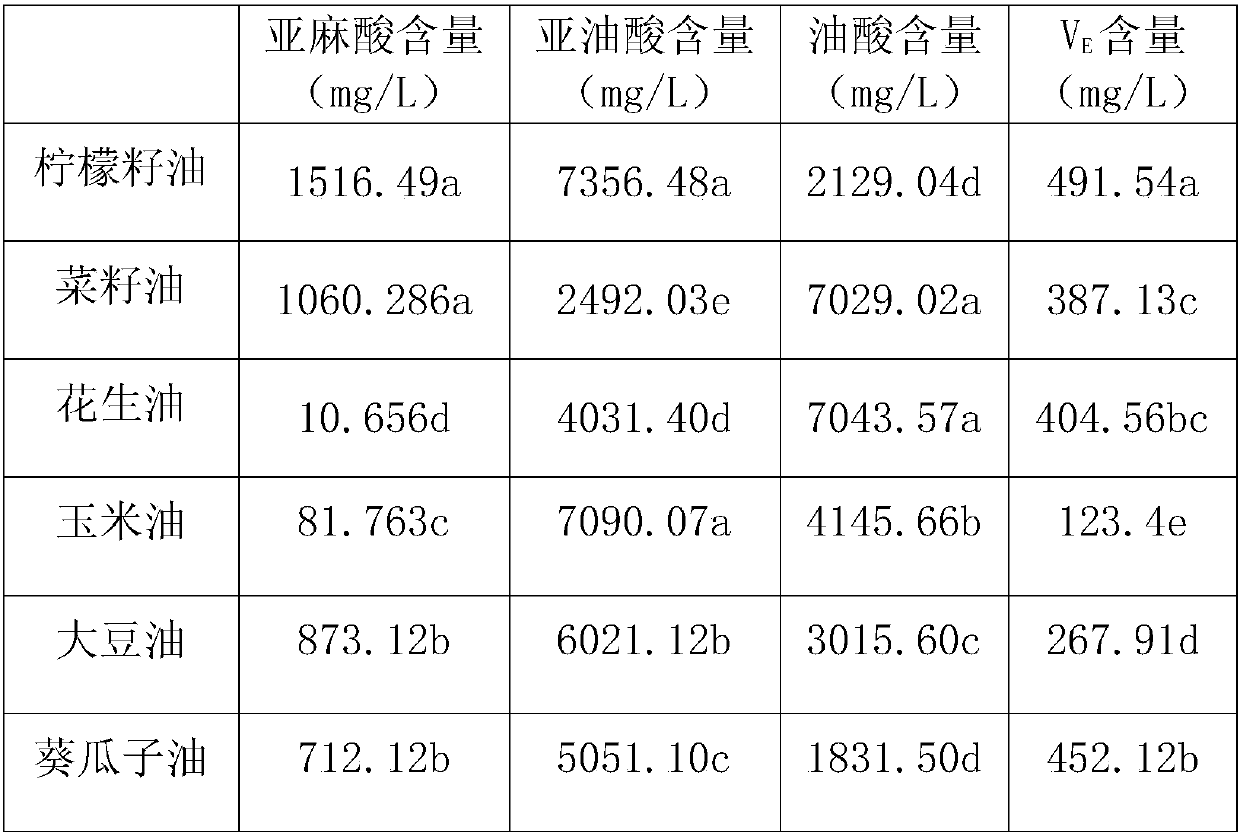

Processing technique for preparing debitterized lemon seed oil by cold pressing

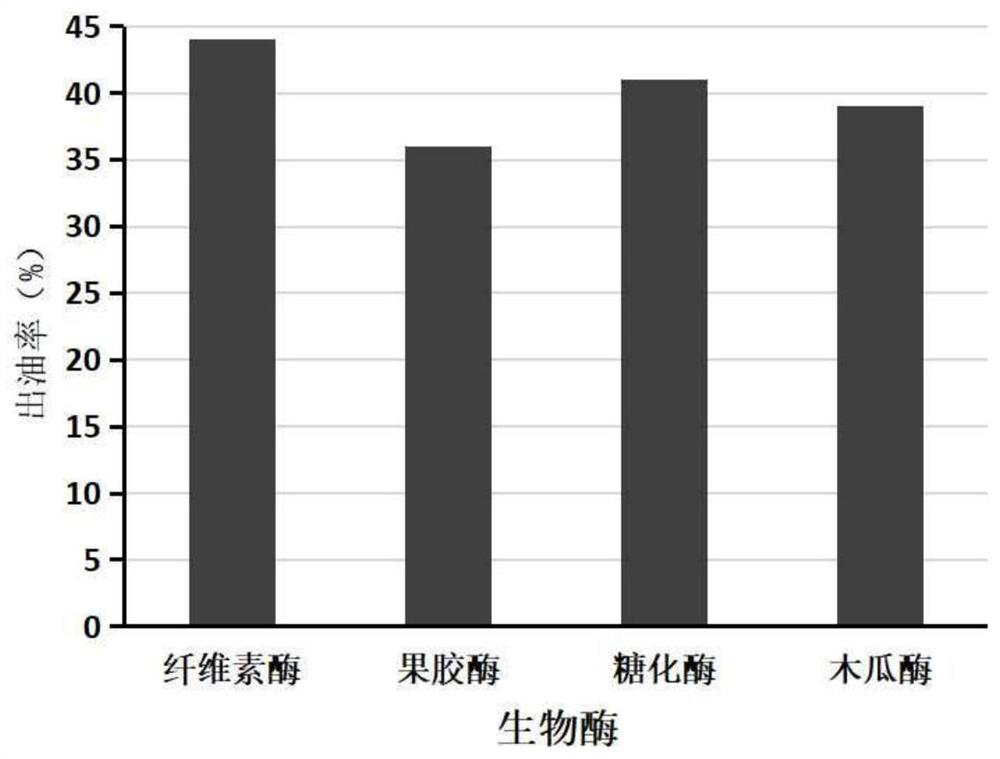

InactiveCN107794114AAvoid lostGuaranteed oil yieldFatty-oils/fats refiningFatty-oils/fats productionNutrientEnzyme

The invention relates to a processing technique for preparing debitterized lemon seed oil by cold pressing. The processing technique comprises the following steps of 1), screening, performing acidolysis and enzymolysis on a lemon seed: enabling the lemon seed to be suitable for oil pressing; 2), three-stage low-temperature oil pressing of the lemon seed; (3), debitterizing of coldly-pressed lemonseed oil: firstly carrying out enzymolysis on a bitter substance by using a debitterizing compound enzyme, then carrying out adsorptive debitterization by using a solid debitterizing agent, and finally, adding sucrose and beta-cyclodextrin; 4), refining operation of degumming, deacidifying, deodorization, decolorization and the like of the debitterized lemon seed oil. A raw material, to which theprocessing technique relates, is the intact or crushed lemon seed; the processing technique belongs to the reutilization of agricultural waste; the raw material is extremely low in cost and is used for developing edible oil; not only can the pollution by the agricultural waste be avoided, but also the downstream industrial chain of a lemon fruit can be completed. The method for producing the oil from the lemon seed by the cold pressing and a debittering technique thereof, to which the invention relates, are low in consumable-material price, simple in device and technical process and easy to popularize and a developed edible oil product is up to the standard of second-grade edible oil and high in nutrient value and has a wide commercial application prospect.

Owner:重庆汇达柠檬科技集团有限公司

Method for extracting peony oil from peony seeds

A method for extracting peony oil from peony seeds comprises the following steps: after peony seed stock is rinsed and cleaned, water is drained off, and the drained peony seed stock is placed into a drying cabinet for drying; peony seeds are placed into a shucking machine for shucking, and peony seed kernels are screened out; the peony seed kernels are placed into a frying-pan for roasting; peony oil is extracted from the peony seeds; the drying temperature in the drying step is 60 DEG C, after drying, the water content of the peony seeds is 15 wt percent, the roasting time in the roasting step lasts is 40 to 70 min, the roasting temperature is 70 to 110 DEG C, the method for extracting peony oil from peony seeds further comprises the steps of grinding to be thick liquid, water adding, alkali refining, centrifugal separation, raw oil mixing and the like. The method has the advantages that the process is simple, the operation is convenient, the promotion is easy, resolvent residue is avoided, the manufacturing cost is reduced, and original nutritional quality of the peony oil can be further kept.

Owner:北京同仁堂安徽中药材有限公司

Preparation method of tea oil

InactiveCN105754713ALow costDark colorFatty-oils/fats refiningFatty-oils/fats productionBiotechnologyMonoglyceride

The invention discloses a preparation method of tea oil. The preparation method has the beneficial effects that the operation of a cold pressing process is simple, the oil extraction rate of tea seeds is guaranteed, and the quality of the tea oil is not influenced; preparations required to be added in a refining process are common substances in the daily life and are low in cost, silicone oil and fatty acid monoglyceride succinate or citric acid monoglyceride succinate are added, so that a grease composition for heating and cooking in oil content remained in cooking objects can be efficiently reduced; by virtue of a method for treating tea oil through ultrahigh magnetism and ultrahigh pressure techniques, polyunsaturated fatty acid in the tea oil can be converted into monounsaturated fatty acid, the color is relatively deep, the fragrance is relatively strong, and the guarantee period is relatively long; natural plant polysaccharide and a biological enzyme regent are utilized as raw materials for removing a trace plasticizer in the tea oil, and organic solvents are not used, so that the residual solvent is avoided, and the safety of the tea oil is greatly improved.

Owner:江西阁皂山天然食品有限公司

Flavor-improved salted chicken egg yolk

InactiveCN107439997AKeep the flavorReduce oxidation rateFood thermal treatmentFood ingredient as taste affecting agentYolkAcetic acid

The invention discloses flavor-improved salted chicken egg yolk. The flavor-improved salted chicken egg yolk is prepared from raw materials including chicken egg yolk, food-grade ethyl acetate, a food-grade osmotic pressure regulator, food-grade acetic acid, food-grade ethanol, a food-grade antioxidant and table salt. Chicken eggs with the freshness higher than or equal to 72 Ha are subjected to separation of egg white and egg yolk, a flavor substance is added to the egg yolk, ultrasonic pretreatment and heat-cold pretreatment are performed sequentially, the egg yolk is added to an isotonic salting solution to be completely immersed, table salt is added multiple times, so that the salting solution has certain concentration gradients, the egg yolk is salted for a period of time and cooked at 70 DEG C, and the flavor-improved salted chicken egg yolk can be obtained. The flavor-improved salted chicken egg yolk has the characteristics of being refreshing in flavor, fine, moderate in saline taste and high oil yield, the process is simple, a little salt is used, and industrial production is easy to realize.

Owner:马述腾

Refining-free natural tea seed skincare oil and preparation method thereof

InactiveCN102885753AScavenging oxygen free radicalsInhibit lipid peroxidationCosmetic preparationsToilet preparationsNutritional compositionMoisturizer

The invention provides a refining-free natural tea seed skincare oil and a preparation method thereof. The refining-free natural tea seed skincare oil is prepared from the following components in parts by mass: 80-98 parts of tea oil, 1.0-19 parts of plant essential oil, 15-30 parts of linolenic acid, 2.5-5 parts of tea polyphenol, 5-10 parts of vitamin E and 1-2 parts of lamb placenta extract. The preparation method comprises the steps of: based on the proportions, stirring the tea oil, the plant essential oil, the linolenic acid, the tea polyphenol, the vitamin E, the lamb placenta extract, emulsifier, emollient, moisturizer and stabilizer, and heating to 50-55 DEG C; and then uniformly mixing the components in proportion to obtain the product. The skincare oil disclosed by the invention has the functions of whitening and skincare, strong anti-oxidation property and radiation resistance. The main raw material tea oil of the product refining-free natural tea seed skincare oil provided by the invention is extracted by a refining-free method, thus maintaining the natural activity and nutritional ingredients of the tea oil and improving the skincare function of the skincare oil.

Owner:广西三江源源茶业有限公司

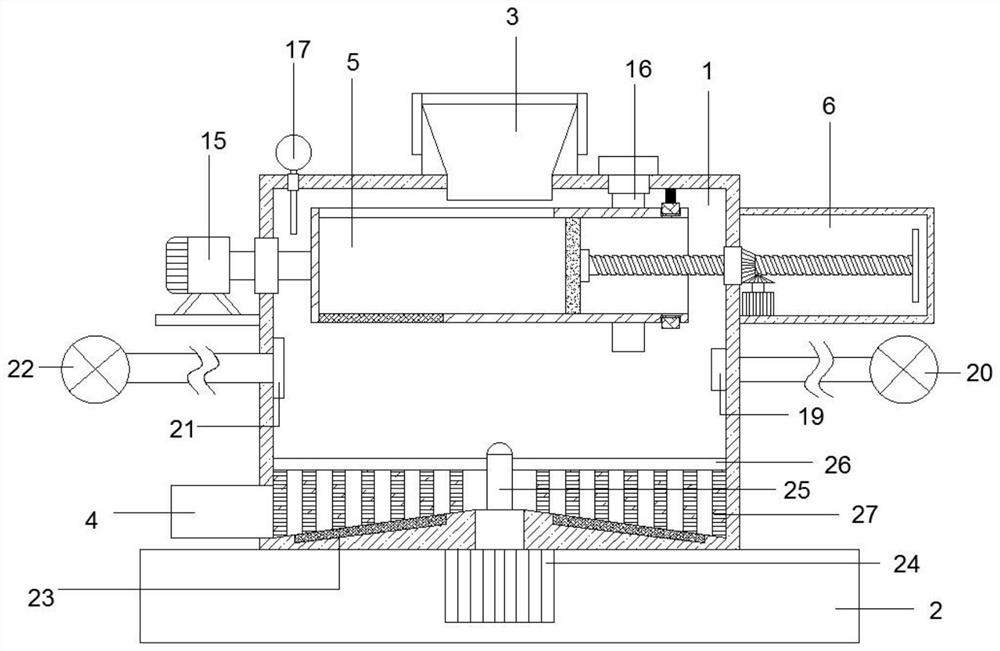

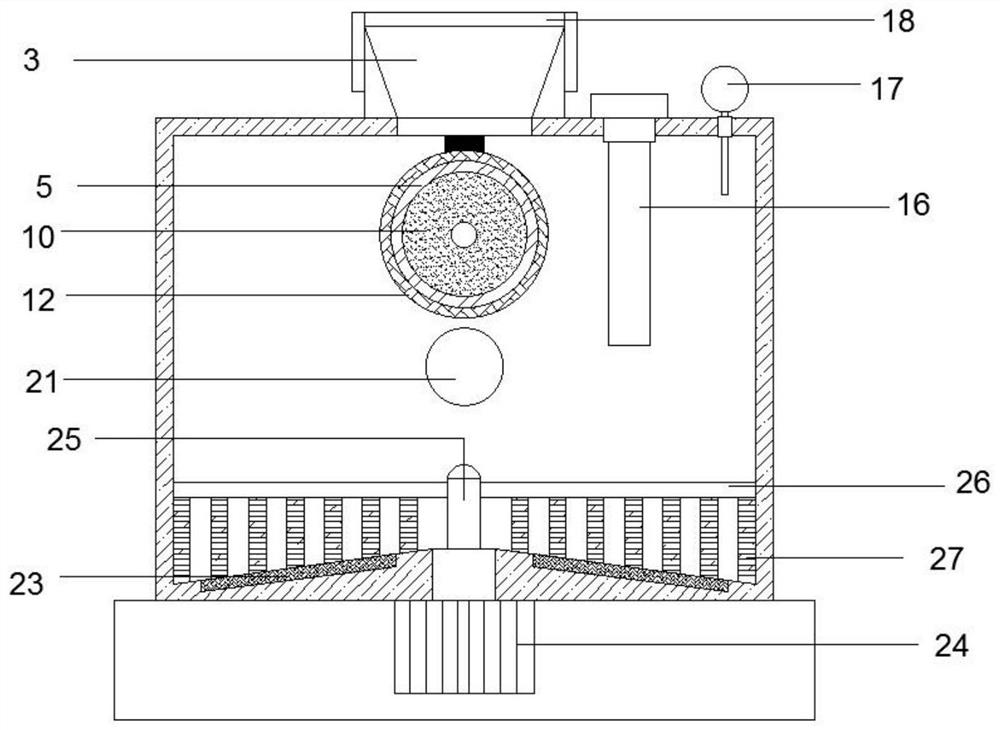

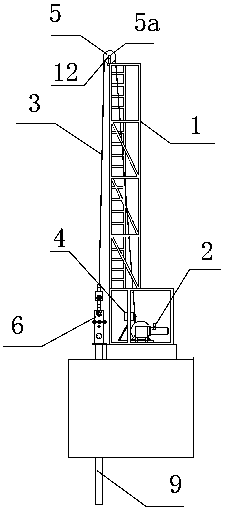

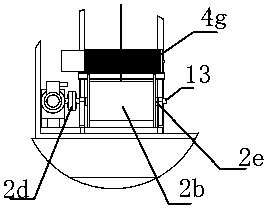

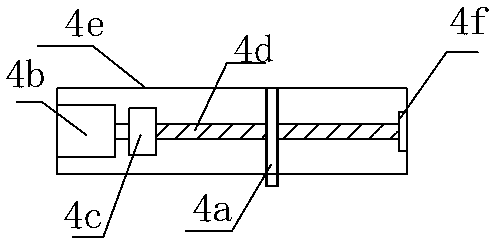

Process and device for processing tea oil with rich fragrance

ActiveCN113308294AIncrease contentAdd flavorClimate change adaptationFatty-oils/fats refiningOil processingProcess engineering

The invention provides a process and a device for processing tea oil with rich fragrance, and relates to the technical field of tea oil processing. The processing technology mainly comprises the steps of raw material selection, shelling treatment, tea seed shell treatment, crushing and uniform wetting, low-temperature puffing, curing preparation, squeezing extraction, refining and impurity removal and the like. The oil yield of tea seeds is effectively improved, meanwhile, aromatic substances in the tea oil are greatly reserved, and the flavor of the tea oil is improved; the tea oil seeds can be effectively squeezed and then extracted by using the tea oil squeezing and extracting combined device, two-step operation is realized by using a single device, waste of manpower is effectively reduced, and squeezing and extracting are used in the same device, so that the dissipation of flavor substances is prevented, and the fragrance of the tea oil in the later stage is improved.

Owner:湖南天沃科技有限公司 +1

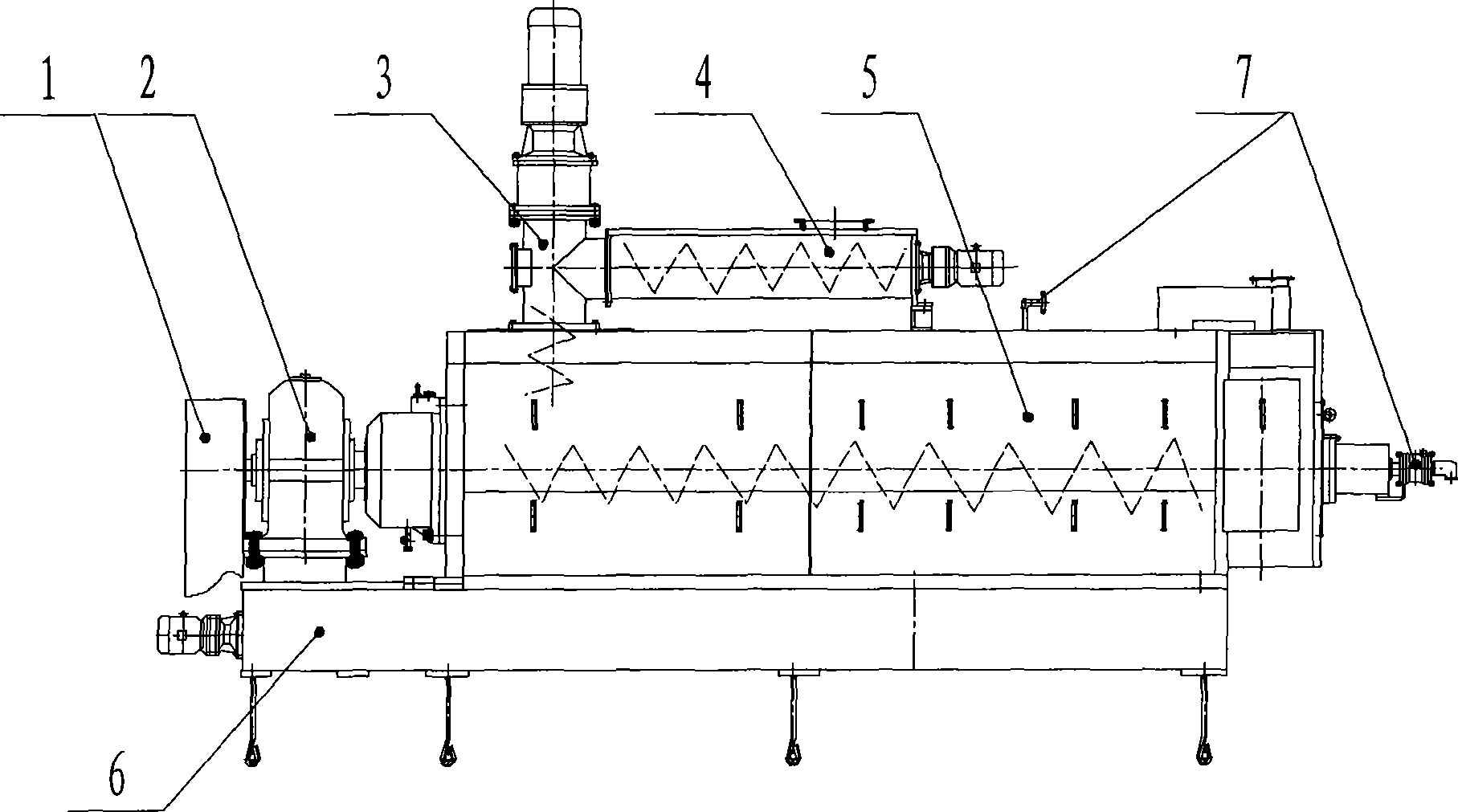

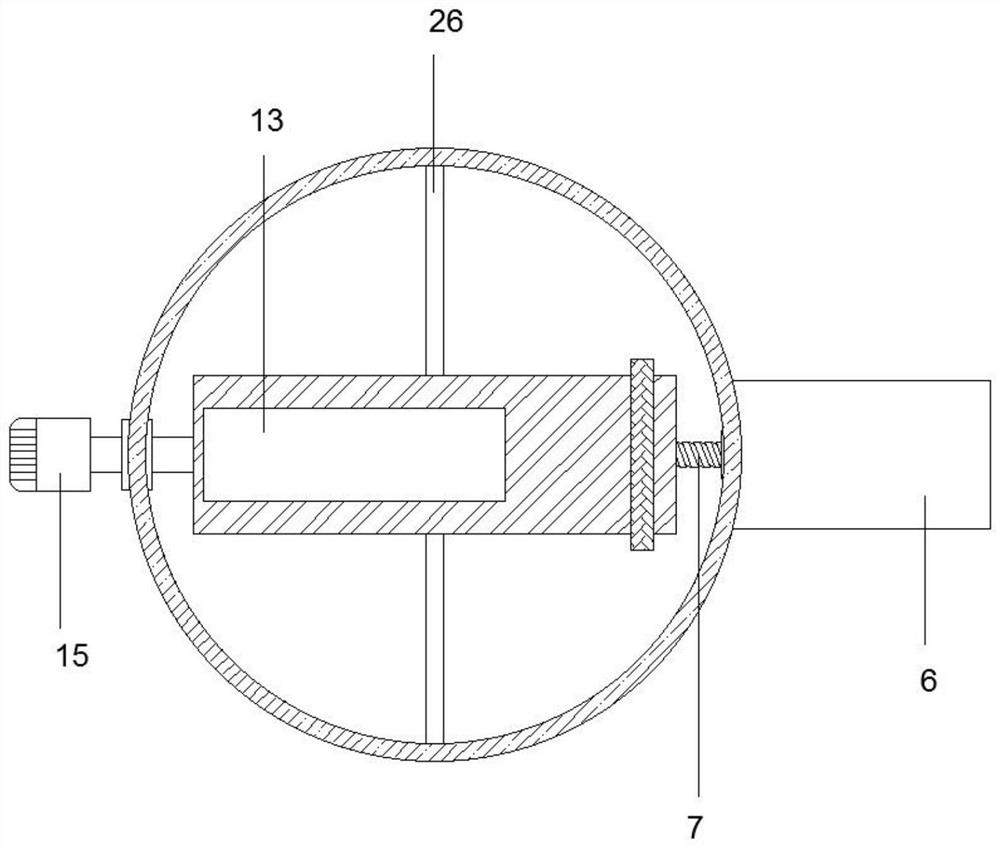

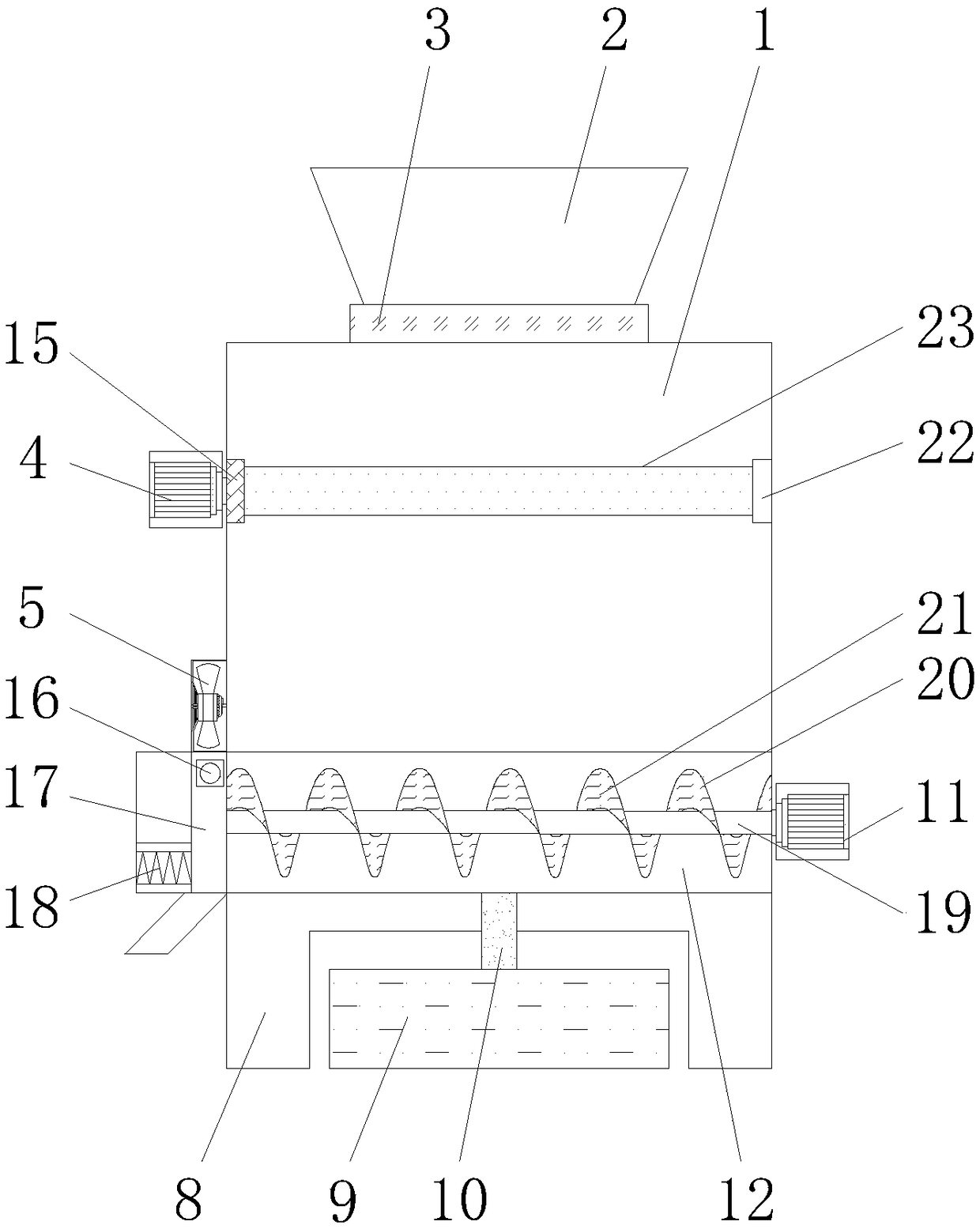

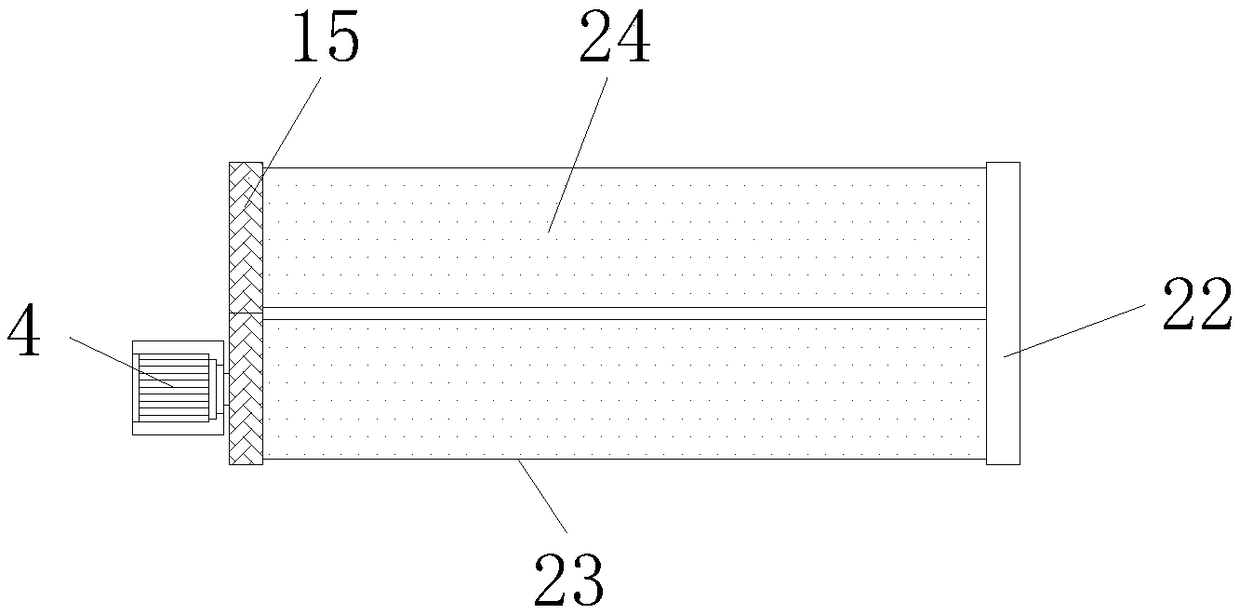

Spiral oil press with circular cooling system

The invention discloses a spiral oil press with a circular cooling system. The spiral oil press comprises a press unit used for containing a material to be pressed and finishing press operation, a base used for supporting the press unit and an air cooling circulation unit, the base is internally provided with an electric heating temperature control unit and a water cooling circular cooling unit which are matched with the press unit, the air cooling circulation unit is arranged above the press unit and communicates with the interior of a press cage of the press unit, at least one wall breakingcutting mechanism is detachably arranged on a feeding press screw segment, a ventilation hole is formed in the matching position of a shell and an air inlet pipe, and a ventilation assembly matched with the end of the air inlet pipe is arranged on the ventilation hole. The spiral oil press with the circular cooling system is provided, equipment cost controllability and stability of a product can be ensured, meanwhile, the temperature of the press unit is controlled, the work state is stable, product oil outlet is improved, and the nutrition component is higher.

Owner:四川广鑫粮油机械制造有限公司

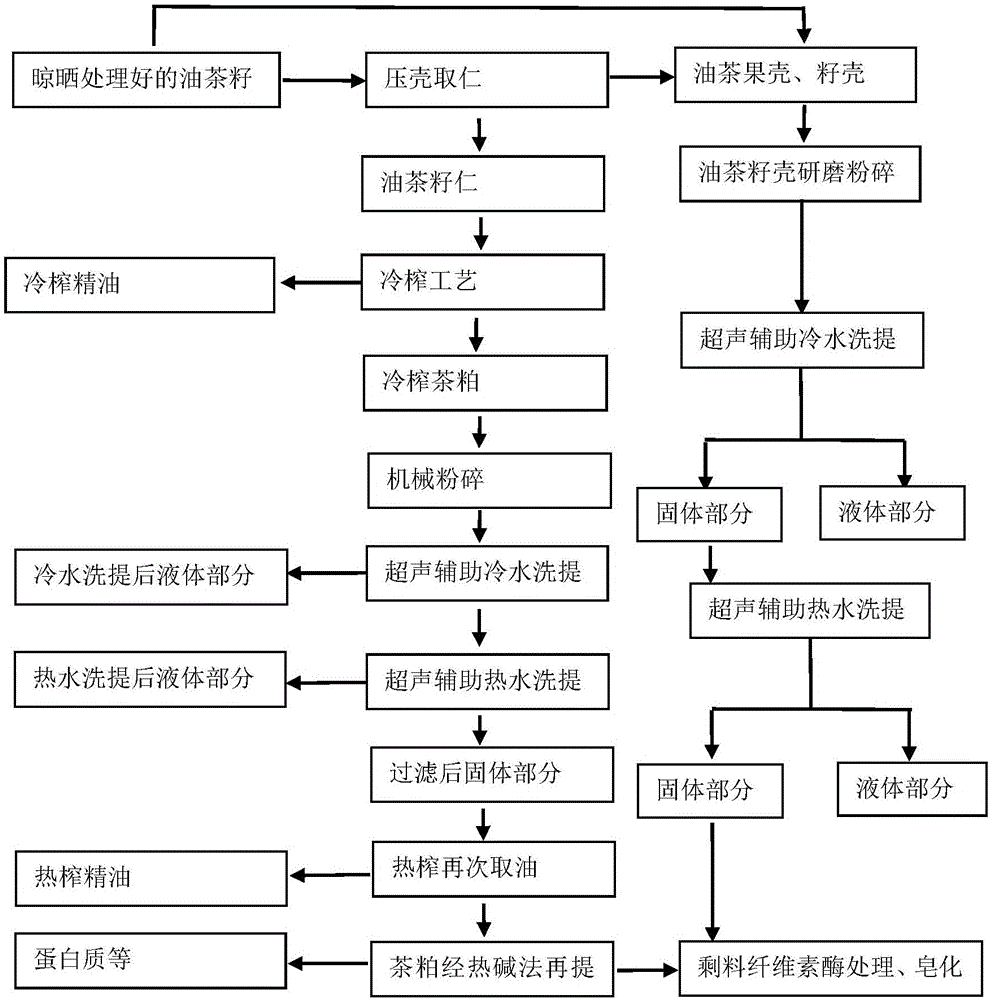

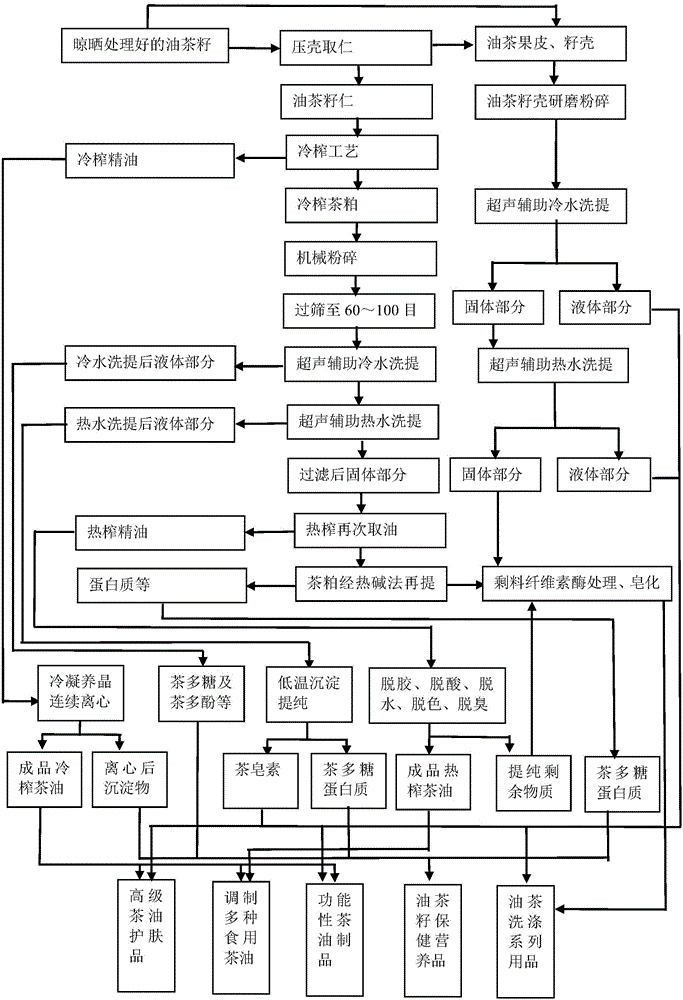

Processing technology for camellia seeds

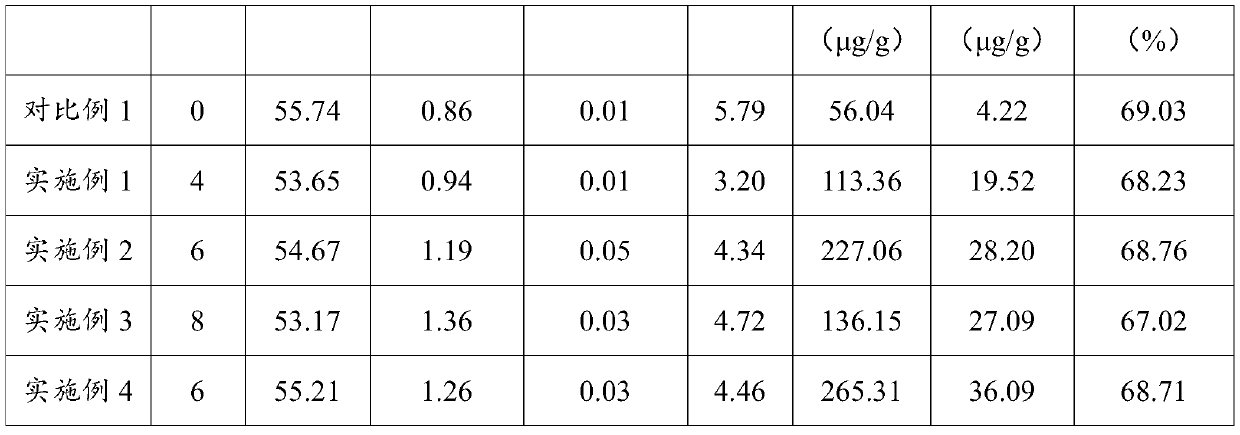

InactiveCN105132138AGuaranteed oil yieldImprove oil qualityFatty-oils/fats productionEdible oils/fatsZero emissionHot press

The invention is applicable to the processing of camellia seeds, and provides a processing technology for camellia seeds. The processing technology comprises the following steps: firstly, processing harvested camellia seeds, dividing the processed camellia seeds into camellia seed kernels, shells and seed husks, performing continuous processes of one-time cold-pressing, two-time cold water elution, two-time hot water elution and one-time hot-pressing on camellia seed kernels, and respectively utilizing various products in the processes; performing two-time cold extraction and two-time hot extraction on shells and seed husks, and respectively utilizing various products in the processes. According to the invention, all the components of camellia seeds are fully utilized, and the shells and seed husks of camellia seeds, usually abandoned, are converted into products with higher economic value; grease, protein, tea saponin, tea polyphenol, tea polysaccharide and cellulose in camellia seeds are extracted respectively, a low-cost and environment-friendly extraction technology meeting the requirements of camellia seeds is designed according to the technological requirements of follow-up products, the zero contamination and zero emission of the production process are realized through the follow-up product preparation, and camellia seeds are comprehensively utilized.

Owner:SHENZHEN UNIV +1

Flavor-improved salted goose egg yolk

The invention discloses flavor-improved salted goose egg yolk which comprises the following raw materials: goose egg yolk, food-grade ethyl acetate, a food-grade osmotic pressure regulator, food-grade acetic acid, food-grade ethanol, a food-grade antioxidant and edible salt. The flavor-improved salted goose egg yolk is prepared by the following steps: separating egg white from egg yolk of a goose egg of which the production time is within 2d; adding flavor substances to the egg yolk, carrying out ultrasonic pretreatment, and then carrying out heating-cooling pretreatment; adding and completely soaking the egg yolk into an isotonic pickling liquid; adding the edible salt many times to enable the pickling liquid to have certain gradient concentration; pickling the egg yolk for a certain time; and after curing at 70 DEG C, removing the flavor in vacuum so as to obtain the flavor-improved salted goose egg yolk. The flavor-improved salted goose egg yolk disclosed by the invention has the characteristics of large size, fresh flavor, small smell, fineness, moderate salty taste and more egg yolk oil; and the production process is simple and convenient in technology, low in usage amount of table salt, low in energy consumption, more friendly to the environment, and more likely to realize industrial production.

Owner:马述腾

Raspberry seed oil product and extraction method

InactiveCN101411363AGuaranteed oil yieldFast oilFood preparationEdible oils/fats production/working-upNutritive valuesUltrasonic assisted

The invention relates to a plant seed oil product and a method for extracting the same, in particular to a red raspberry seed oil product and a method for extracting the same. The red raspberry seed oil is the plant fat product extracting from seeds of red raspberry fruits, thereby having extremely high nutritive value and better health care function, solving the problem of utilizing the seed separated when the product such as fruit juice and fruit jam is prepared by the red raspberry, changing waste into valuable and having great significance for the development of the red raspberry industry and the comprehensive utilization of byproducts. The extraction and preparation method for the red raspberry seed oil is as follows: seeds separated by pulping the red raspberry fruit is dried, crushed by a crusher and soaked in a solvent with a certain ratio for extraction, by the cooling or ultrasonic auxiliary extraction, the working efficiency and the oil yield are improved, and the seed soaked in the solvent is filtered to separate the solvent and then packaged to obtain the red raspberry seed oil product.

Owner:LIAONING TODAY AGRI

Blueberry seed oil as well as preparation method and application thereof

InactiveCN104560378AGuaranteed oil yieldResidue reductionSenses disorderMetabolism disorderAdjuvantOrganic solvent

The invention discloses blueberry seed oil and as well as a preparation method and an application thereof. The blueberry seed oil is prepared by the following one or more extraction methods: an organic solvent leaching method, a supercritical extraction method and a physical squeezing method; a blueberry seed oil preparation is prepared from blueberry seed oil described above as an active ingredient, and substances having healthy function and / or acceptable adjuvants of health food; and the invention discloses an application of the blueberry seed oil and the blueberry seed oil preparation in preparing health foods having the effects of improving eyesight and reducing blood lipid. Since three methods, namely, the physical squeezing method, the organic solvent leaching method and the CO2 supercritical extraction method are used alone or in combination, the yield of the blueberry seed oil is ensured; the method is high in production efficiency and oil yield, low in cost and is economic and feasible and the technology is reliable; and the method has wide applicable range and is used in large-sized, medium-sized and small-sized businesses.

Owner:GUANGZHOU INST OF BIOMEDICINE & HEALTH CHINESE ACAD OF SCI

Method for extracting oat oil through microwave pretreatment

InactiveCN103122273AChanges in seed coat structureIncrease leaching rateFatty-oils/fats productionAgricultural engineeringAgronomy

The invention discloses a method for extracting oat oil through microwave pretreatment. The method comprises the following steps: cleaning oat raw materials, draining the cleaned oat, and drying the oat in a drying oven; hulling the oat in a huller, and separating oat bran; crushing the oat bran in a crusher; and extracting the oat oil from the crushed oat bran, and performing microwave treatment after the oat is dried and before the dried oat is hulled in the huller, wherein the microwave treatment method comprises the following step of: putting the dried oat particles into a microwave dryer, wherein the power is regulated to be 180-900W, the treatment time is 60-150 seconds, the drying temperature in the drying step is 60 DEG C, and the moisture content of the dried oat is 15wt%. The method provided by the invention is simple and reliable, convenient to operate, low in cost, high in speed and high in leaching efficiency and has a high economic value.

Owner:HENAN UNIV OF SCI & TECH

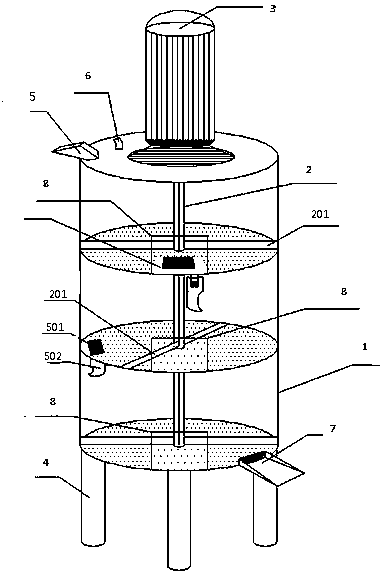

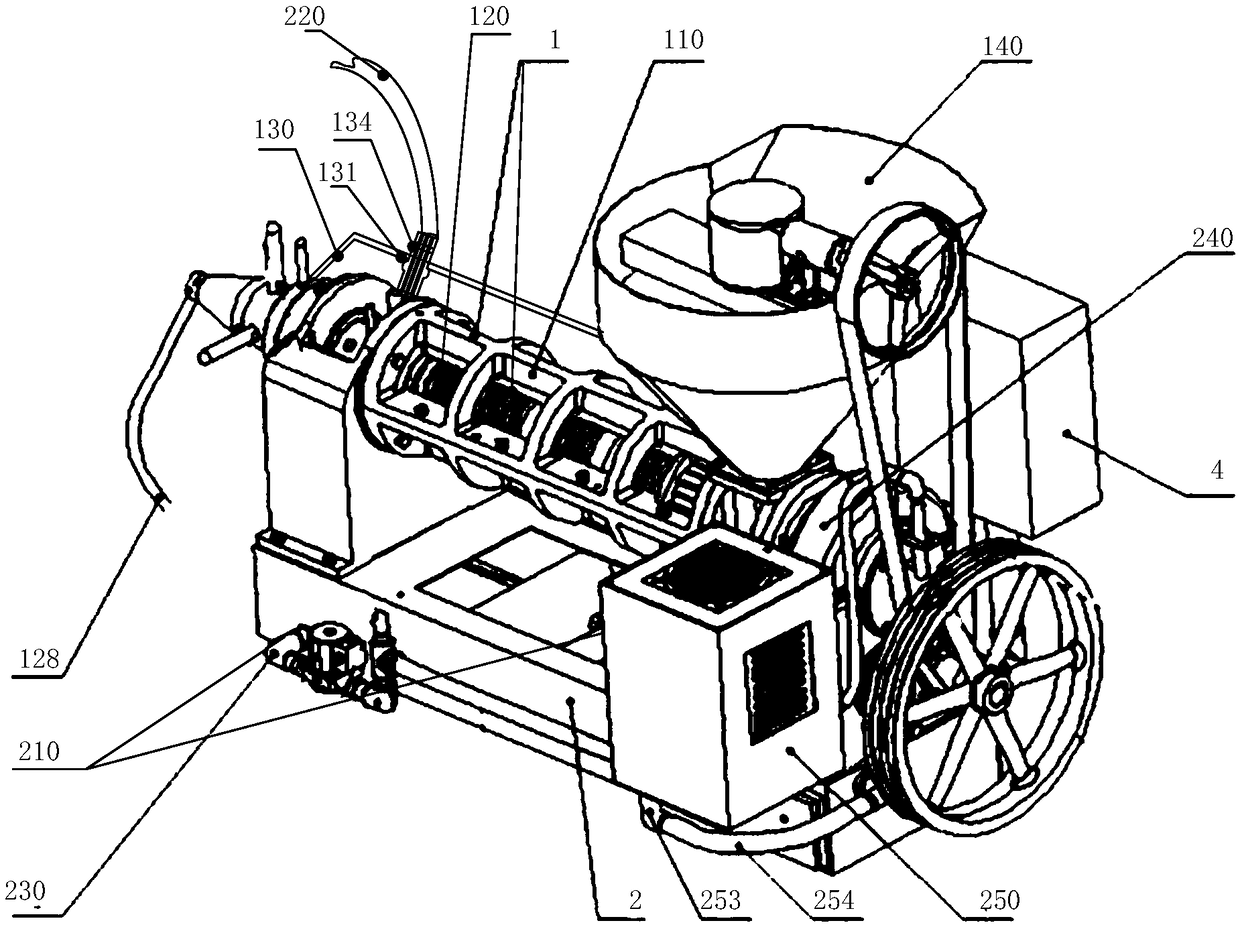

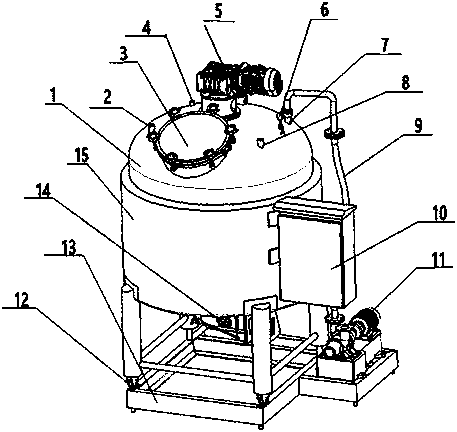

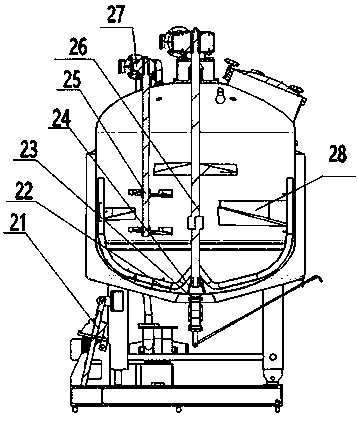

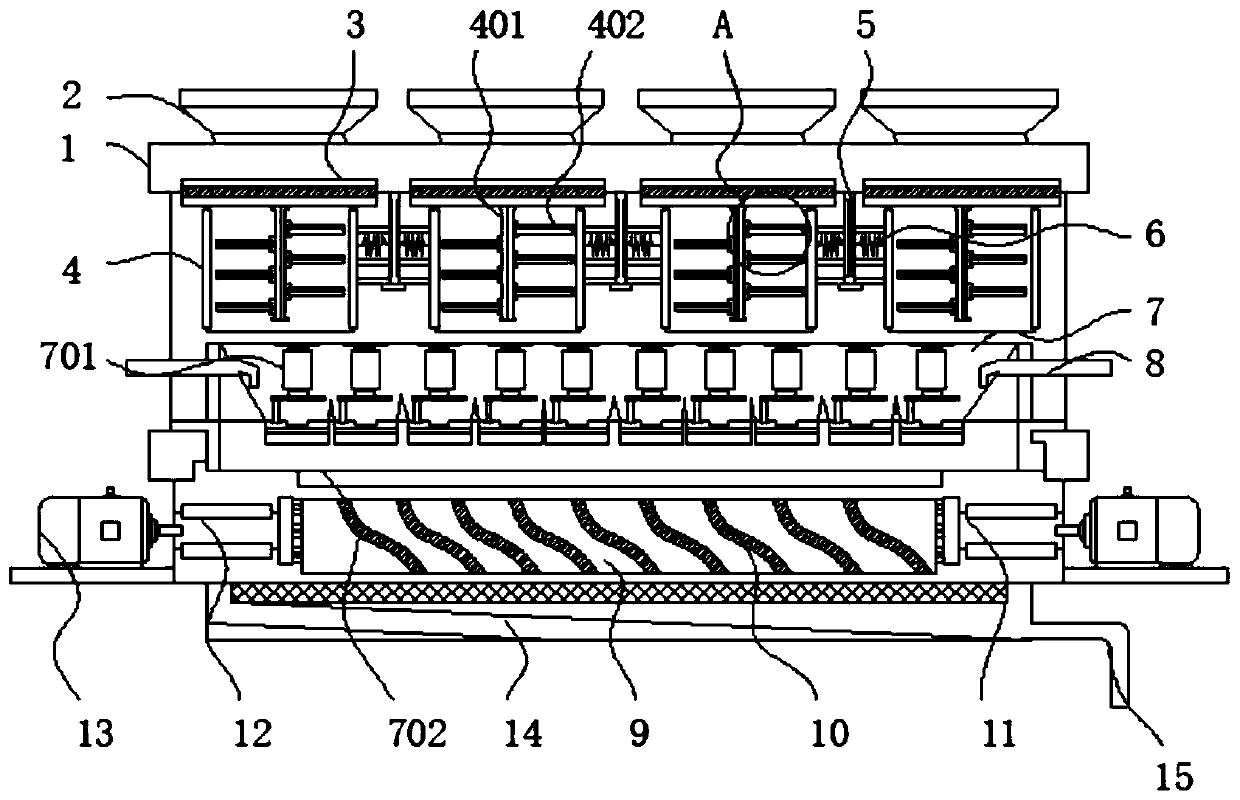

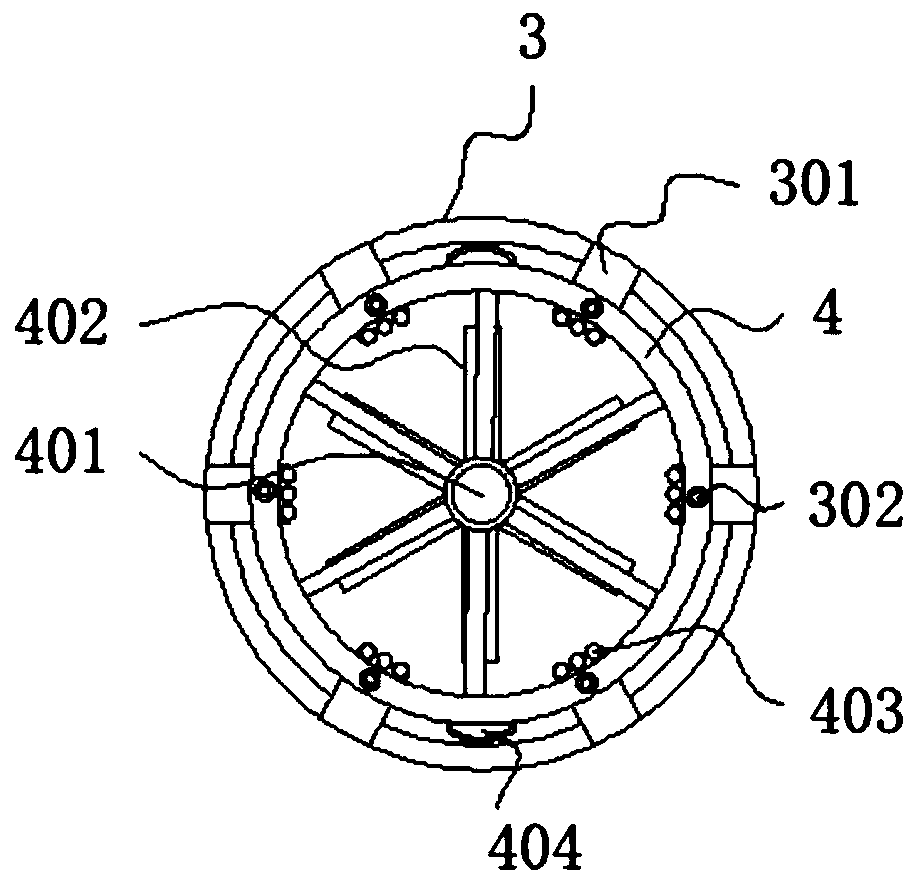

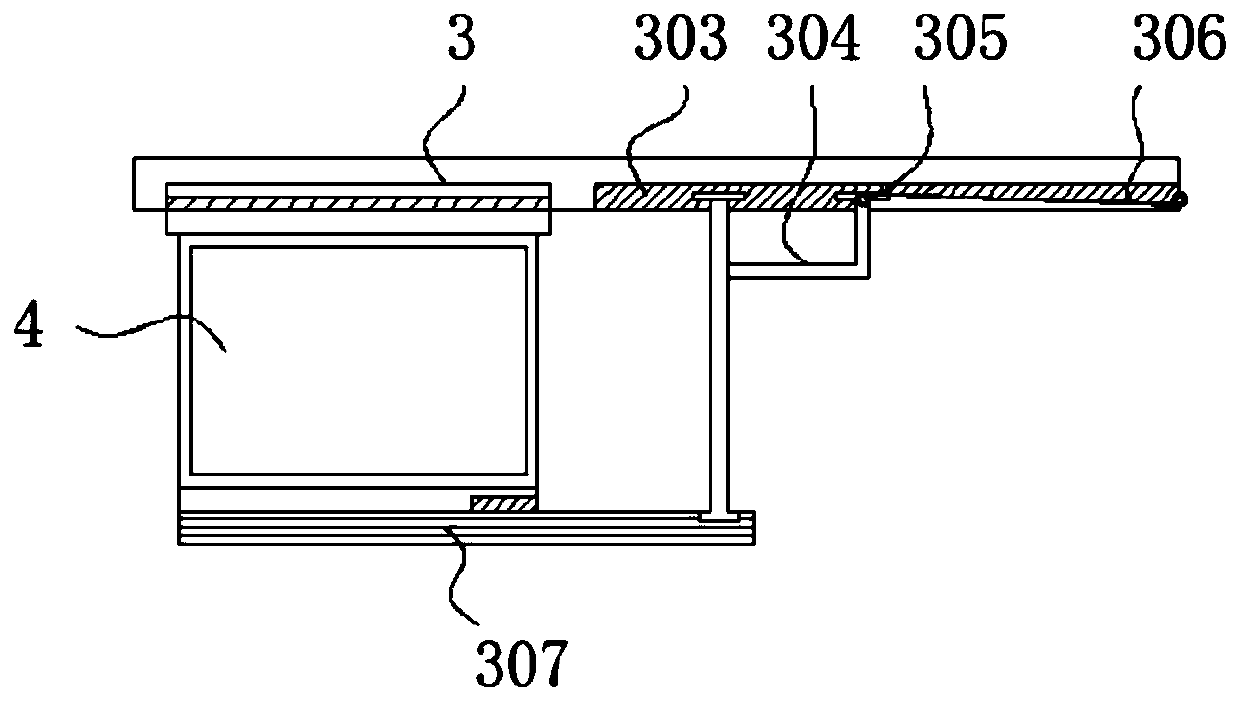

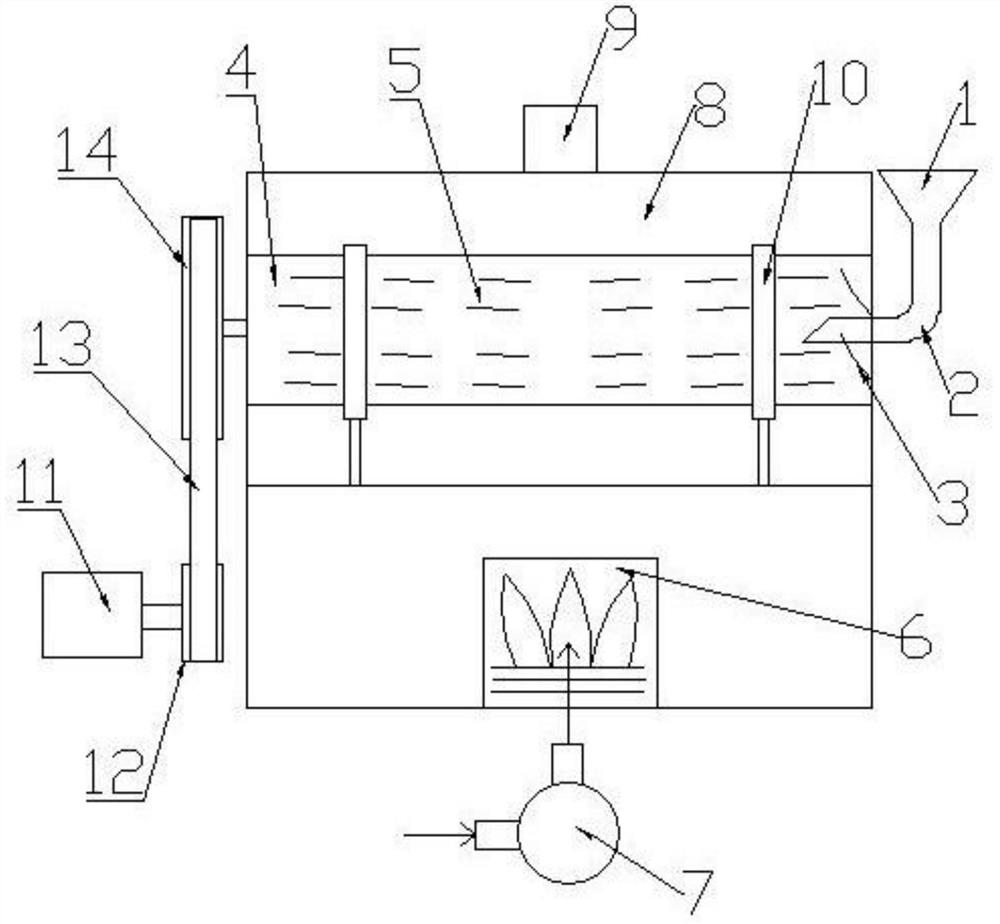

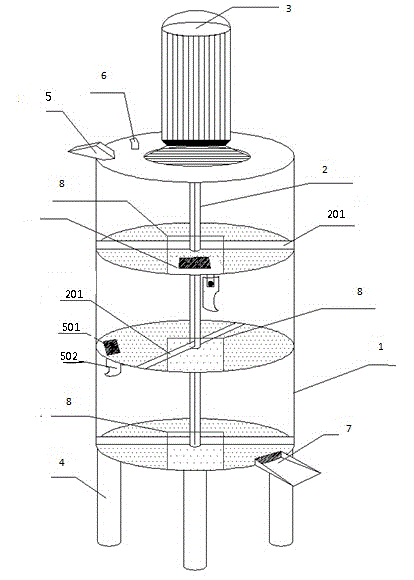

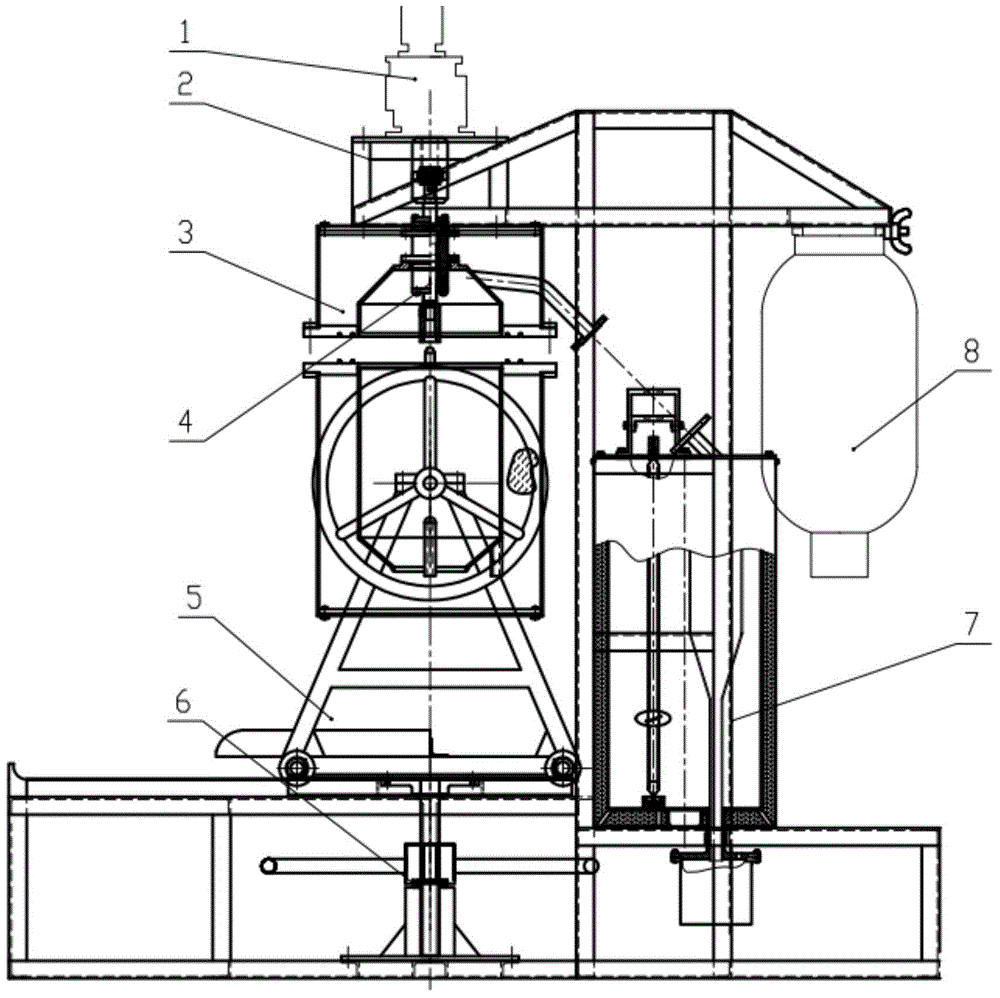

Mixing, stirring and oil discharging equipment and oil discharging process method of ground sesame oil

PendingCN111040864AHigh degree of mechanizationReduce the amount of solutionFatty-oils/fats productionInlet valveElectric machinery

The invention discloses mixing, stirring and oil discharging equipment and an oil discharging process method of ground sesame oil. The equipment comprises a bracket, which is connected with a weighingsensor and is connected with a tank body jacket, wherein the bottom of the tank body jacket is connected with a material outlet, the tank body jacket is connected with a tank body, the tank body is connected with a gas sucking port, the gas sucking port is connected with a metal hose, the metal hose is connected with a vacuum pump, the vacuum pump is connected with a control box, the tank body isconnected with a material inlet, a manhole, a pressure gauge and a water inlet, the tank body is connected with a gas inlet valve, and the tank body is fixedly provided with a variable frequency motor. The equipment and the method are used for mixing, stirring and oil discharging equipment of ground sesame oil.

Owner:HEZE BRANCH QILU UNIV OF TECH(SHANDONG ACAD OF SCI

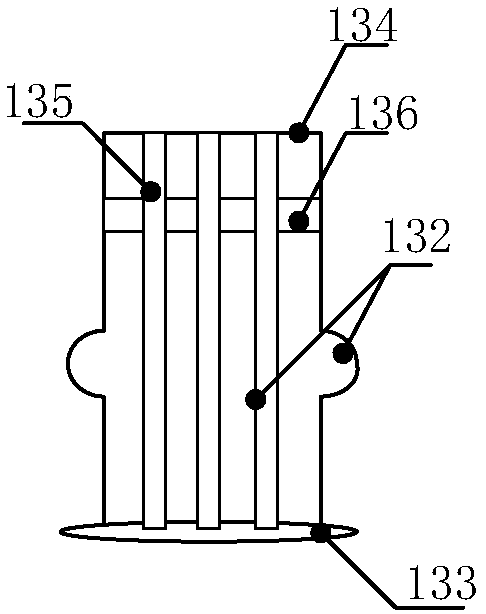

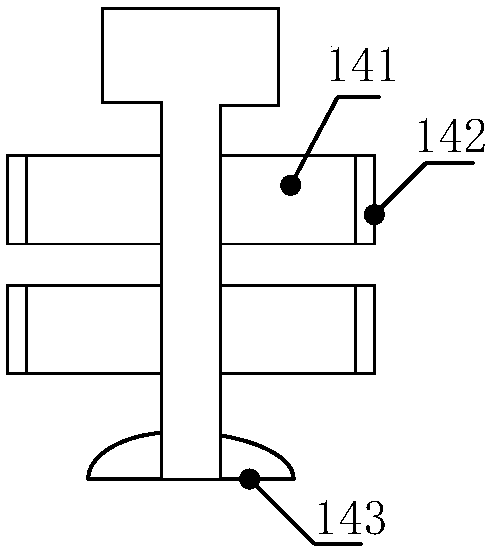

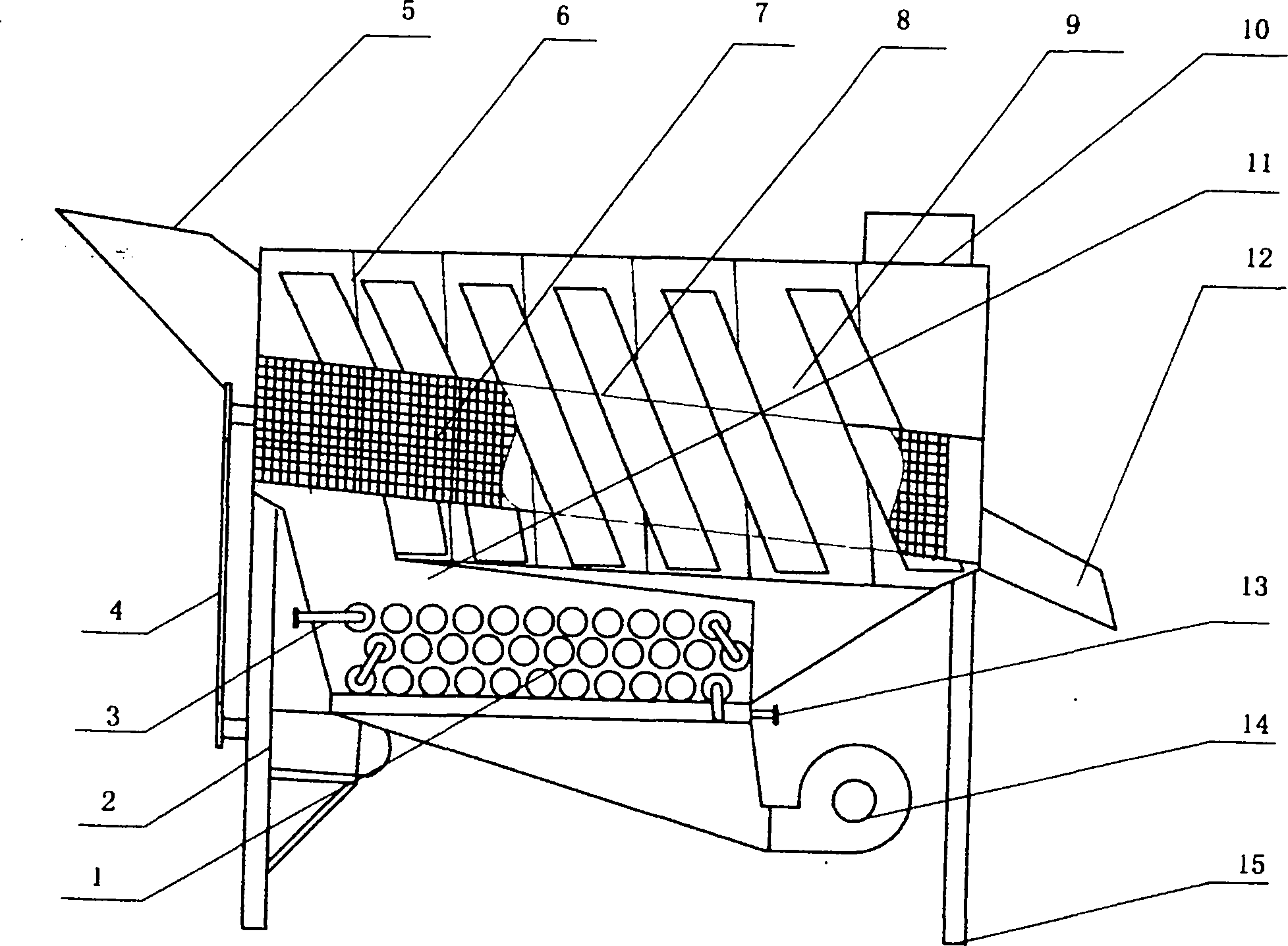

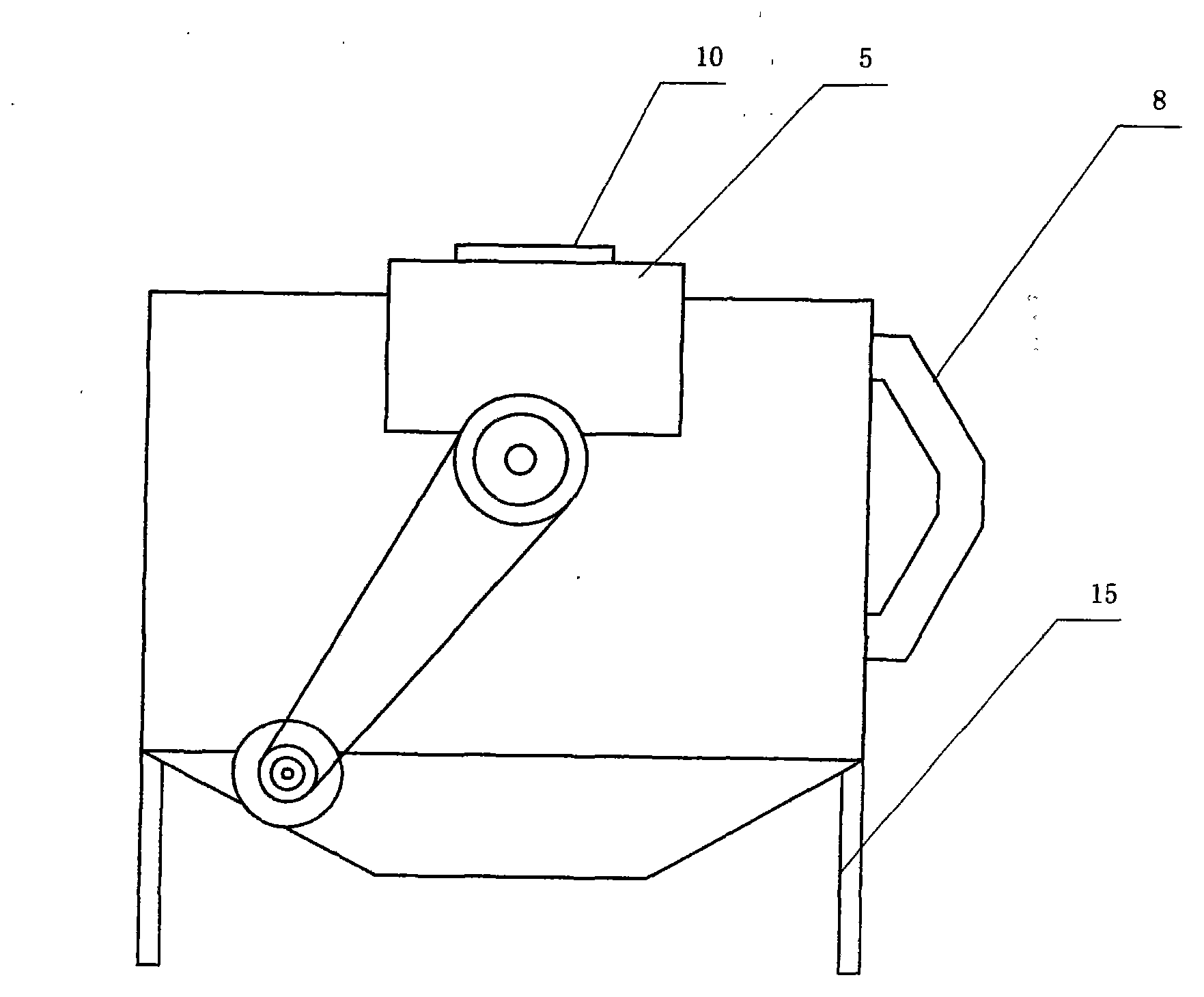

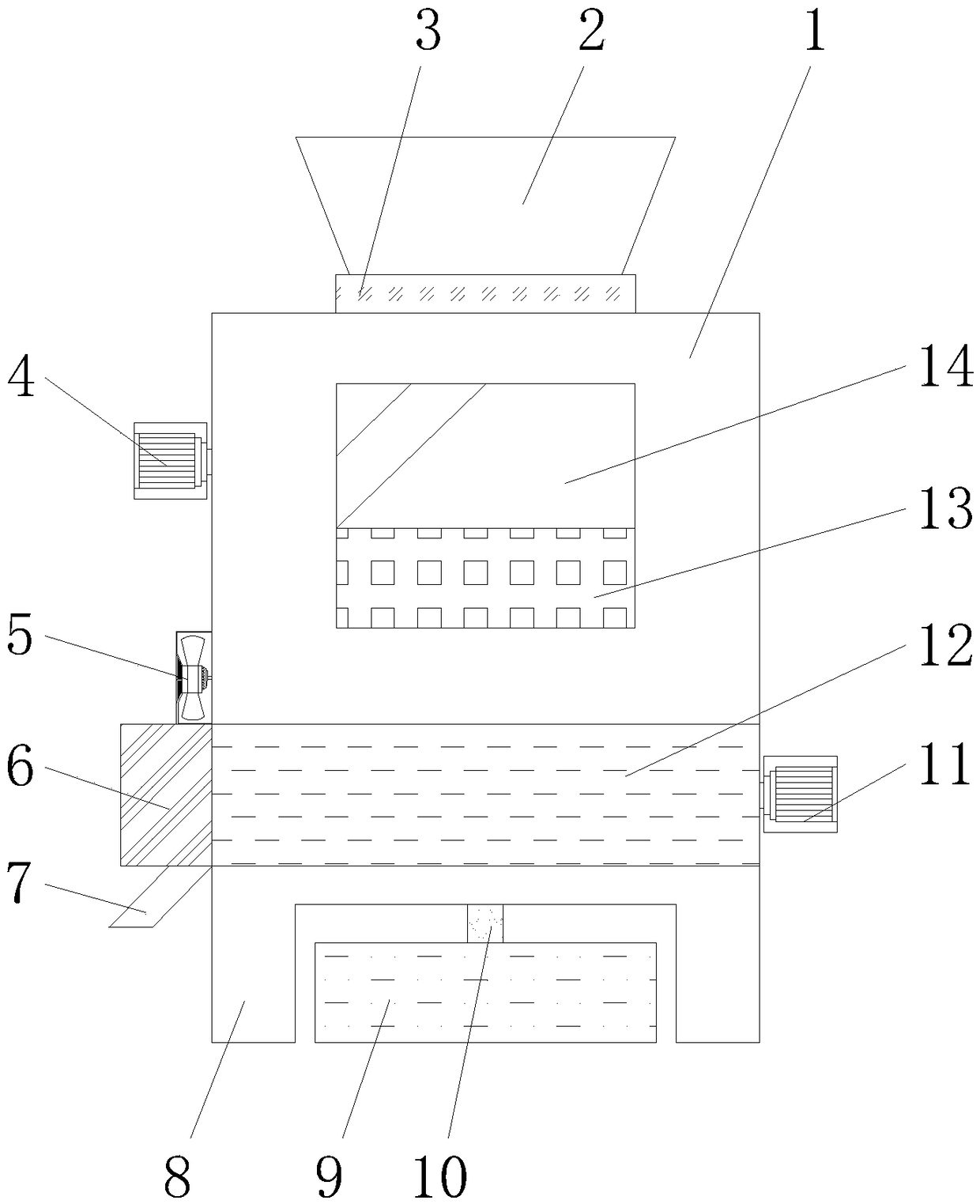

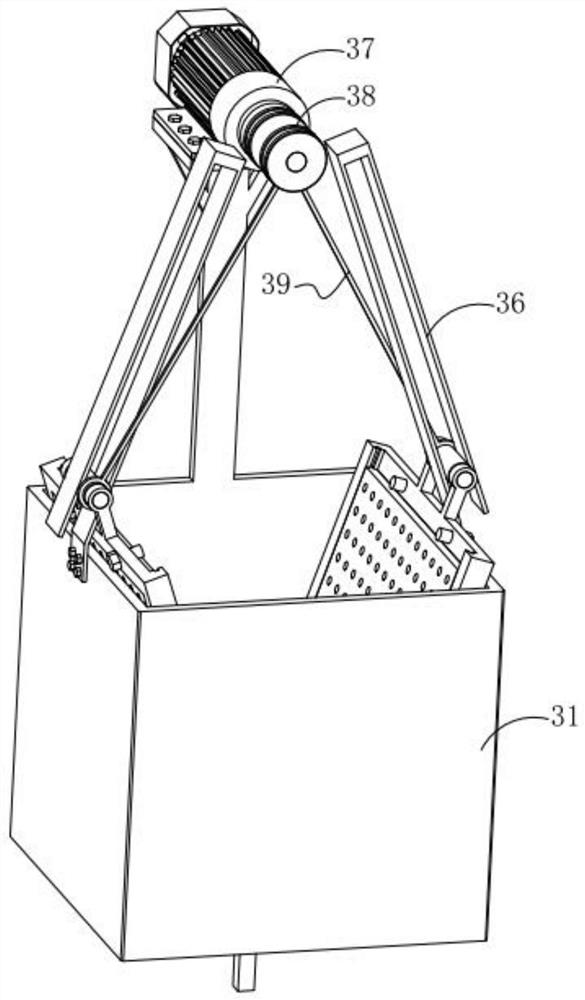

Intermittent efficient roller seed frying machine

InactiveCN104046507AGuaranteed oil yieldEasy to control the steaming effectFatty-oils/fats productionQuality levelHeat conducting

The invention discloses an intermittent efficient roller seed frying machine which is equipment capable of realizing easy quality level control of oil products. The intermittent efficient roller seed frying machine is characterized in that: an integrated-type motor reducer is arranged below a frame, a sieve-type roller is driven by a chain; the roller casing is provided with a sieve, and the specification of the sieve can replaced according to an oil material fruit; a gas pulse cavity of the frame is provided with baffles for diving the gas pulse cavity into a plurality of heating chambers; each pulse channel connects two adjacent heating chambers. The bottom of the gas pulse cavity is provided with s heat conducting oil heat exchanger, and a gas inlet is connected with a high pressure fan. A high temperature gas is directly used for heating the oil material fruit, because the high temperature gas enters into from the bottom and the sieve-type roller rotates, and the oil material fruit in the sieve-type roller is in the suspended state, and may not be burnt by the roller body; steaming and stir frying effects of the oil material fruit is easy to control, oil yield of the oil material can be well ensured, and the equipment has the advantages of simple structure and easy operation.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

Edible oil processing oil press capable of preventing oil leakage and convenient to clean

ActiveCN109910346AEasy to cleanPrevent oil spillsRotary stirring mixersHollow article cleaningSurface mountingEdible oil

The invention discloses an edible oil processing oil press capable of preventing oil leakage and convenient to clean and relates to the technical field of oil press equipment. The edible oil processing oil press specifically comprises a main body and a woven cloth bag. Hoppers are welded above the main body, and a locating frame is mounted at the bottom of each hopper. An agitating vessel is put below each locating frame. A fixing rod is mounted on the surface of each agitating vessel. Treatment boxes are mounted below the agitating vessels. A first clamping rod is connected to the right sideof the woven cloth bag, and a second clamping rod is connected to the left side of the woven cloth bag. A first motor is mounted at the outer side of the second clamping rod. An oil chute is mounted below the woven cloth bag. According to the edible oil processing oil press capable of preventing oil leakage and convenient to clean, the locating frames are located below the hoppers and meanwhile fixed to the main body, and the number of the locating frames is the same as that of the agitating vessels; and the locating frames are mainly arranged for fixedly storing the agitating vessels.

Owner:山东矬草峪农业科技有限公司

Refining-free natural tea seed skincare oil and preparation method thereof

InactiveCN102885753BMaintain skin care and beauty effectsEnhance skin whitening effectCosmetic preparationsToilet preparationsBiotechnologyPhenolic content in tea

The invention provides a refining-free natural tea seed skincare oil and a preparation method thereof. The refining-free natural tea seed skincare oil is prepared from the following components in parts by mass: 80-98 parts of tea oil, 1.0-19 parts of plant essential oil, 15-30 parts of linolenic acid, 2.5-5 parts of tea polyphenol, 5-10 parts of vitamin E and 1-2 parts of lamb placenta extract. The preparation method comprises the steps of: based on the proportions, stirring the tea oil, the plant essential oil, the linolenic acid, the tea polyphenol, the vitamin E, the lamb placenta extract, emulsifier, emollient, moisturizer and stabilizer, and heating to 50-55 DEG C; and then uniformly mixing the components in proportion to obtain the product. The skincare oil disclosed by the invention has the functions of whitening and skincare, strong anti-oxidation property and radiation resistance. The main raw material tea oil of the product refining-free natural tea seed skincare oil provided by the invention is extracted by a refining-free method, thus maintaining the natural activity and nutritional ingredients of the tea oil and improving the skincare function of the skincare oil.

Owner:广西三江源源茶业有限公司

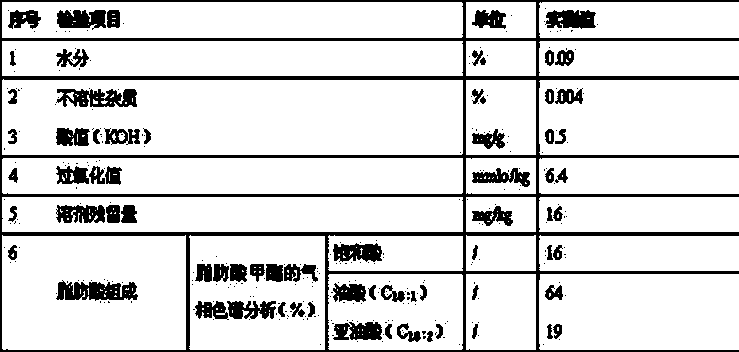

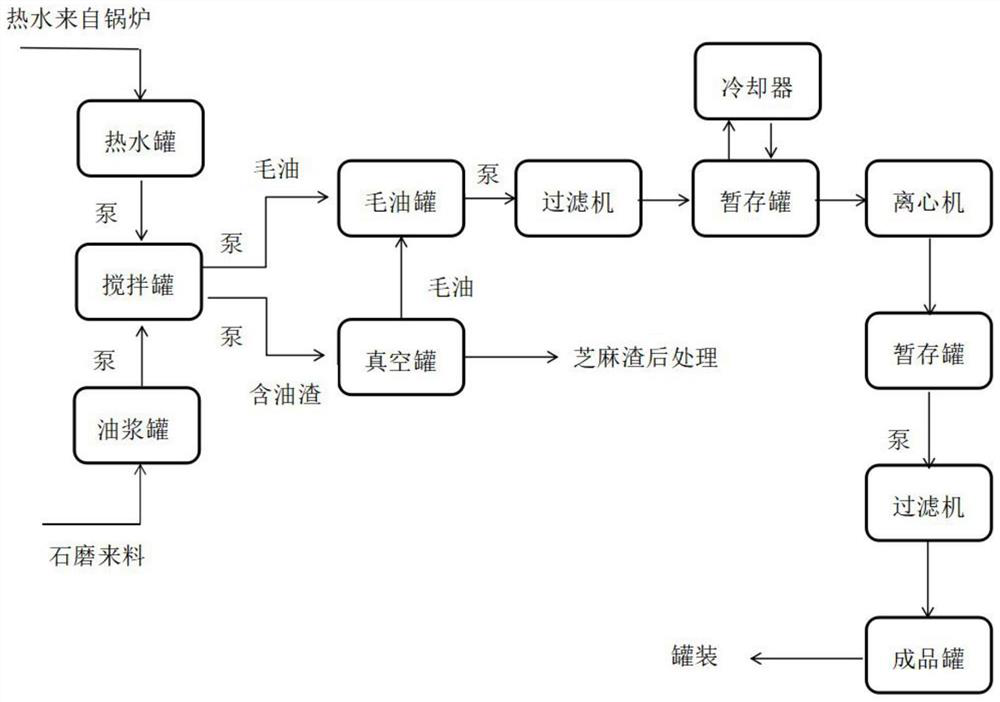

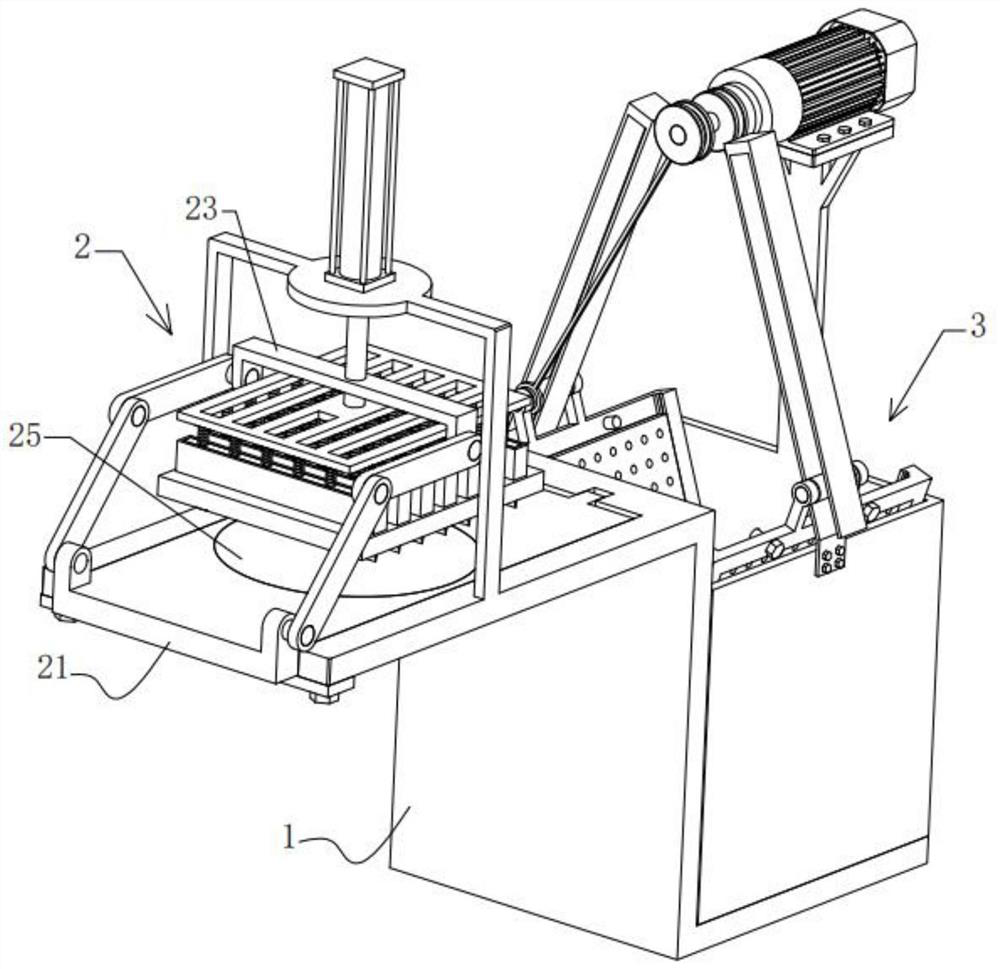

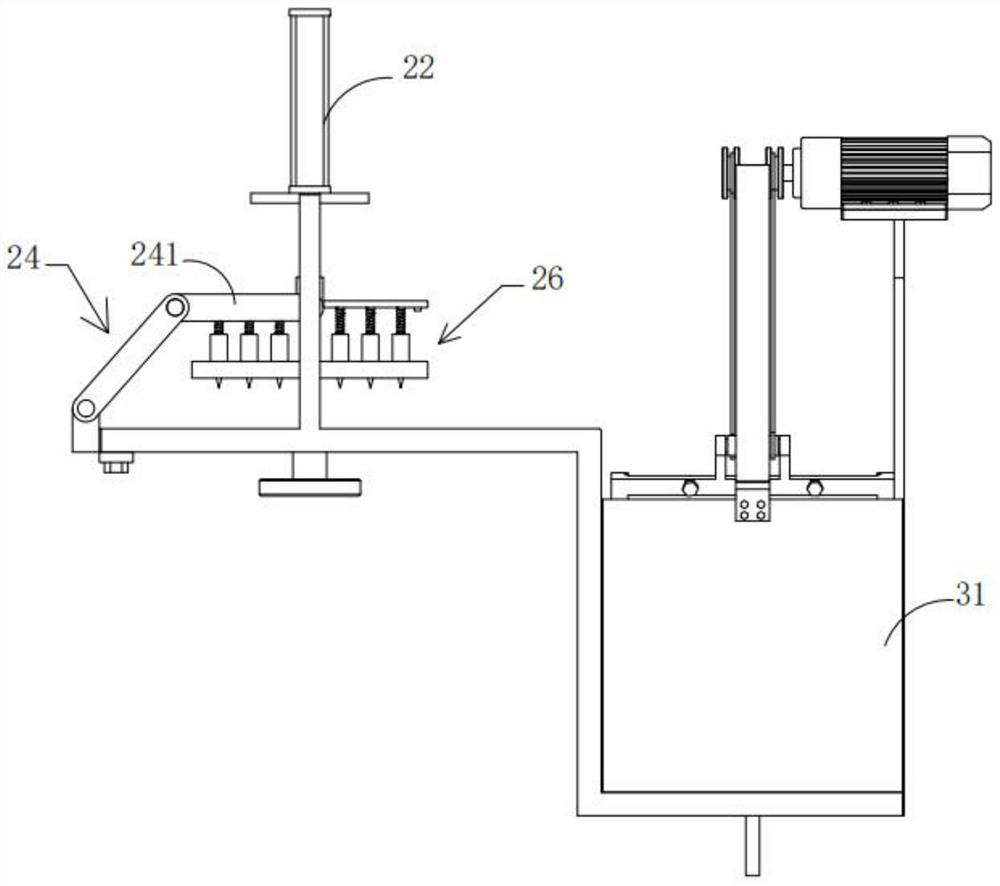

Process method for producing ground sesameseed oil by water extraction method

PendingCN114317108AReduce labor intensityIncrease production capacityFatty-oils/fats refiningProcess engineeringSesame Oils

The invention relates to a production process method of ground sesame seed oil by a water extraction method, which comprises the following steps: obtaining crude oil in a stirring oil outlet and vacuum oil outlet manner, carrying out hot filtration on the crude oil to obtain hot filtration oil, cooling, standing, crystallizing and centrifuging the hot filtration oil, and carrying out cold filtration to obtain clarified finished product oil. The production process method breaks through a traditional vibration oil outlet or hammering oil outlet process method, the whole process is completed under the closed condition, the sesame oil quality and the oil outlet rate are guaranteed, the sesame oil is clean and sanitary, the modern food production process requirements are met, the productivity is greatly improved, the production time is shortened, and the production efficiency is improved; and the effects of mechanization, automation, reduction of the labor intensity of workers and reduction of the production cost are remarkable, and the industrial application prospect is wide.

Owner:HEZE BRANCH QILU UNIV OF TECH(SHANDONG ACAD OF SCI +1

Efficient oil press

InactiveCN108859215AEasy to install and disassembleGood for dust removalCleaning using gasesFatty-oils/fats productionSlagSpiral blade

The invention discloses an efficient oil press which comprises a machine shell, an oil pressing chamber and a base. The upper end of the machine shell is provided with a feed inlet, grinding rollers are installed inside the machine shell, the left ends of the grinding rollers are sleeved with driving gears, the right ends of the grinding rollers are provided with bearing pedestals, the left end ofthe machine shell is provided with a grinding motor, the lower end of the machine shell is connected with the oil pressing chamber, a spiral rotating shaft is installed inside the oil pressing chamber, the surface of the spiral rotating shaft is sleeved with a spiral blade, the left end of the oil pressing chamber is provided with a slag outlet, the oil pressing chamber is located at the top endof the base, and an oil storage tank is arranged inside the base. The problems that an existing oil press is not high in oil pressing efficiency, incapable of removing impurities such as dust, moisture and oil slag waste and incapable of conveniently collecting drained oil are solved.

Owner:宿松县春江粮油有限公司

Production method of egg butter

InactiveCN107629864ABreak emulsion stabilityPrevent water fillingFatty-oils/fats refiningFatty-oils/fats productionYolkActivated carbon

The invention relates to a production method of egg butter, wherein the production method comprises the steps: separating egg white from egg yolk of eggs with the freshness of more than or equal to 72Ha, carrying out ultrasonic treatment and hot-cold treatment on the egg yolk, transferring to an isoosmotic pickling liquid, adding edible salt for multiple times, pickling under a condition that a pickling liquid has a certain gradient concentration, cleaning the pickled egg yolk, breaking, centrifuging with an industrial centrifugal machine, collecting an oil liquid, carrying out water washingdesalination, vacuum deodorization and activated carbon adsorptive decolorization, and thus obtaining the egg butter finish product. The method has the advantages of low requirements for equipment, simple process, low energy consumption, no use of organic solvents, and safe and reliable products, and can be used for industrialized production.

Owner:马述腾

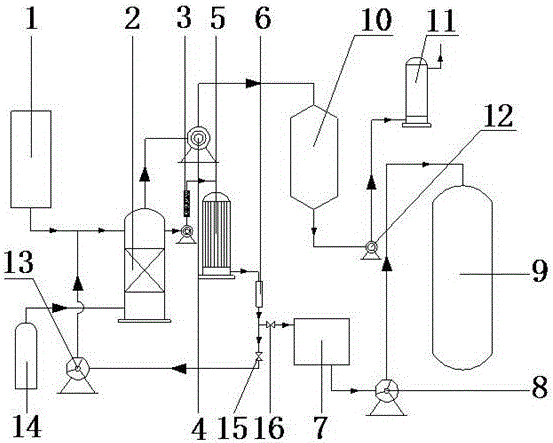

Animal fat refining device

PendingCN113372989AAchieve extrusionAvoid residual greaseFatty-oils/fats refiningFatty-oils/fats productionOil and greaseEngineering

The invention provides an animal fat oil refining device which comprises a rack, a fat dicing mechanism and an oil refining mechanism, the oil refining mechanism comprises an oil refining pot, a rotating shaft, a filter plate frame, a filter plate, a roller, a guide rail, a winch, a wire spool and a steel cable, and the oil refining pot is arranged on the rack and located below the fat dicing mechanism so as to receive small fat dices cut by the fat dicing mechanism. The two filter plate frames are obliquely arranged to form the oil refining area, the winch drives the filter plate frames to ascend after oil refining is completed, the filter plate frames are folded inwards under the action of the guide rails, then oil residues are squeezed, residual grease in the oil residues is avoided, the filter plate frames are separated from an oil pan in the oil residue squeezing process, and then the oil residues are directly taken out. The processing efficiency is improved on the premise of ensuring the oil yield.

Owner:ANHUI JIAYUAN GREASE

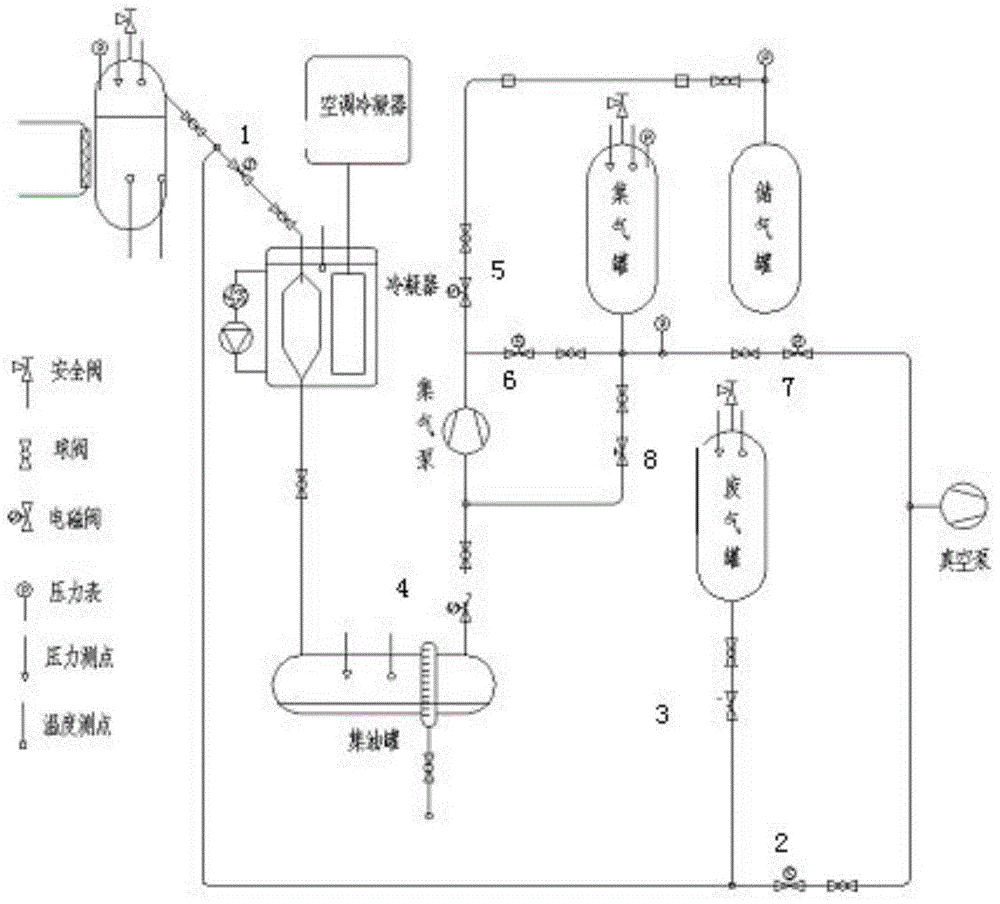

Waste tire pyrolysis recycling treatment system

The invention discloses a waste tire pyrolysis recycling treatment system which comprises pretreatment equipment, a pyrolysis furnace, a product treatment system and a waste gas purification system, wherein the pretreatment equipment is connected with an inlet of the pyrolysis furnace; outlets in the side surface and the top of the pyrolysis furnace are respectively connected with the product treatment system and the waste gas purification system; the waste gas purification system comprises a buffer tank and a purification tower. By using the buffer tank, the purification tower and other equipment, the waste tire pyrolysis recycling treatment system can effectively absorb and filter out sulfur and nitrogen gas pollutants, dust and other pollution components in waste gas produced by pyrolysis of a waste tire, so that secondary pollution to the environment is effectively avoided, and the current industrial development tendency is met; a controllable reflux pyrolysis branch pipeline is arranged at an outlet of a second-stage condensing pipe, so that the oil yield of rubber oil serving as a pyrolysis product can be effectively guaranteed, and the performance of the rubber oil can be improved; the waste tire pyrolysis recycling treatment system has a considerable practical significance.

Owner:玉门市云华再生资源有限责任公司

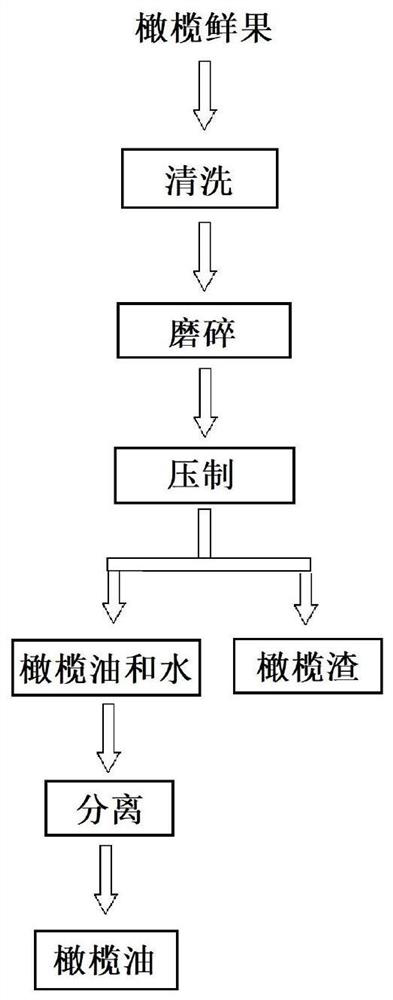

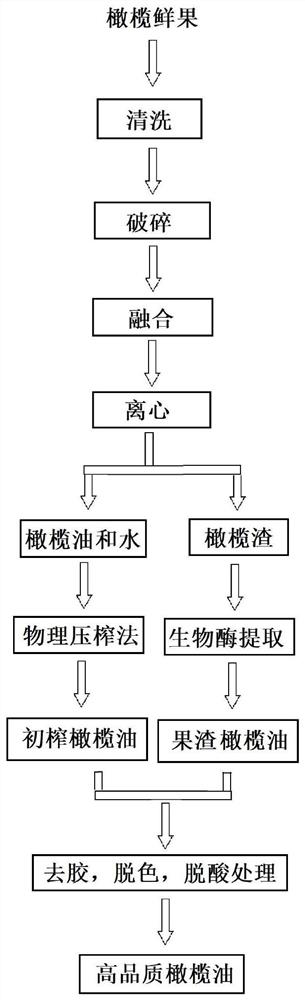

High-quality olive oil processing technology

InactiveCN113755232AIncrease oil productionRetain nutritional valueFatty-oils/fats refiningFatty-oils/fats productionCentrifugationEngineering

The invention discloses a high-quality olive oil processing technology which comprises the following steps: S1, cleaning, airing and crushing fresh olive fruits to obtain olive paste; s2, transferring the olive paste into a fusion pool for fusion treatment; s3, loading the olive paste subjected to fusion treatment into a closed centrifugal machine for centrifugal treatment, taking out an upper-layer mixture, extracting oil by a physical squeezing method, collecting the oil, and filtering to remove impurities so as to obtain virgin olive oil; s4, collecting pomace olive oil floating on the upper layer from the lower precipitate olive pomace obtained by centrifugation by adopting a biological enzyme extraction method, and filtering to remove impurities; s5, mixing the squeezed olive oil with the pomace olive oil, and performing degumming, decoloration and deacidification treatment to obtain the high-quality olive oil. According to the process, the oil yield of the olive oil can be improved, unsaturated fatty acid components in the fresh olive fruits are better reserved, and the prepared olive oil is long in preservation time.

Owner:心之源(上海)食品股份有限公司

Improved rapeseed oil ancient-method squeezing process

PendingCN111621358AGuaranteed frying effectGuaranteed oil yieldFatty-oils/fats refiningFatty-oils/fats productionSaline waterProcess engineering

The invention provides an improved rapeseed oil ancient-method squeezing process which comprises the following steps: step 1, stir-frying: putting rapeseeds into a rotary drum baking and stir-frying machine, stir-frying the rapeseeds with firewood, stir-frying the rapeseeds until hulls and kernels of the rapeseeds can be completely separated by sampling and crushing and the kernels are golden yellow, and pouring out the rapeseeds; step 2, oil pressing: pouring the fried rapeseeds into a rapeseed oil press for oil pressing to obtain crude oil; step 3, filtering, adding 50g of saline water intoevery 5 kg of the crude oil, wherein the temperature of the saline water is 85-95 DEG C, and the concentration of the saline water is 0.5-1%, pouring the crude oil mixed with the saline water into a rapeseed oil cleaning device for cleaning and filtering, removing erucic acid and precipitate; and step 4, refining, namely adding the filtered crude oil into rapeseed oil refining equipment, dephosphorizing, decolorizing and distilling to obtain the finished rapeseed oil. The rapeseeds are stir-fried with the firewood, the fragrance of the rapeseed oil squeezed by an ancient method is kept, and the rotary drum baking and stir-frying machine is improved to guarantee the stir-frying effect; and the saline water is added to remove the erucic acid during filtering.

Owner:谢国荣

Camellia seed coldly-pressed tea-seed oil and processing process

ActiveCN104212628BIncrease acidityQuality assuranceFatty-oils/fats refiningFatty-oils/fats productionCamellia oleiferaNatural oils

Owner:HUBEI HUANGPAOSHAN GREEN PROD

Natural plant extraction method

ActiveCN112608796AGuaranteed oil yieldImprove qualityEssential-oils/perfumesLavandulaProcess engineering

The invention discloses a natural plant extraction method. The method specifically comprises the following steps: step 1, collecting and treating raw materials; 2, distilling to obtain oil; 3, storing in batches; 4, performing thorough processing; and step 5, reprocessing. The invention relates to the technical field of plant extraction and processing. According to the natural plant extraction method, the whole lavender is decomposed, crushed and then placed on different screens respectively, distillation treatment is conducted in the mode that the lavender is directly placed in the same distillation tower, the purpose of separating essential oil of different qualities is achieved, high-quality essential oil can be obtained from obtained first-grade essential oil through secondary rectification, the whole process is simple in operation, separate distillation is not needed, the essential oil does not need to be blended in subsequent use, use is more convenient, finally, the distilled lavender is squeezed, thorough extraction of the essential oil can be guaranteed, and the oil yield of the lavender is effectively guaranteed.

Owner:湖北省金谷药业有限公司

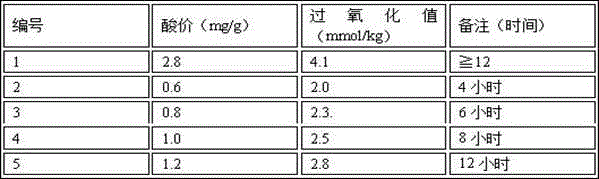

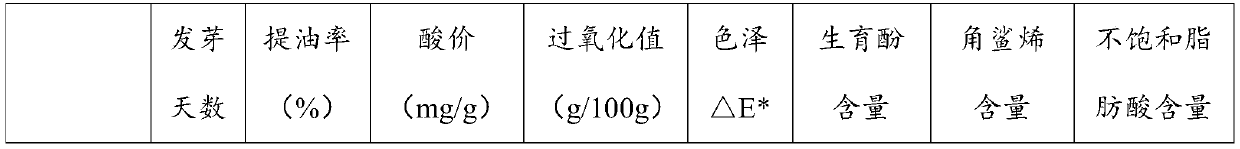

Shaddock seed oil rich in fat-soluble beneficial substances and preparation method thereof

PendingCN110257161ANo significant effect on oil yieldGuaranteed oil yieldFatty-oils/fats refiningFatty-oils/fats productionCitron melonSqualene

The invention belongs to the technical field of food, and discloses a shaddock seed oil rich in fat-soluble beneficial substances and a preparation method thereof. Wastes namely shaddock seeds of shaddock processing are taken as raw materials; then shaddock seeds are shelled, epidermis of shaddock seeds is removed (preprocessing), then shaddock seeds are cultured by water to carry out germination, and after germination, the shaddock seeds are processed to produce the shaddock seed oil rich in fat-soluble beneficial substances. The provided preparation method has the advantages of simple operation and low cost, guarantees the oil yield of shaddock seeds, effectively enhances the nutritional effect of the shaddock seed oil, and increases the value of shaddock seeds; the quality of obtained shaddock seed oil is high, and the content of fat-soluble beneficial substances (tocopherol and squalene) is high.

Owner:ZHONGKAI UNIV OF AGRI & ENG

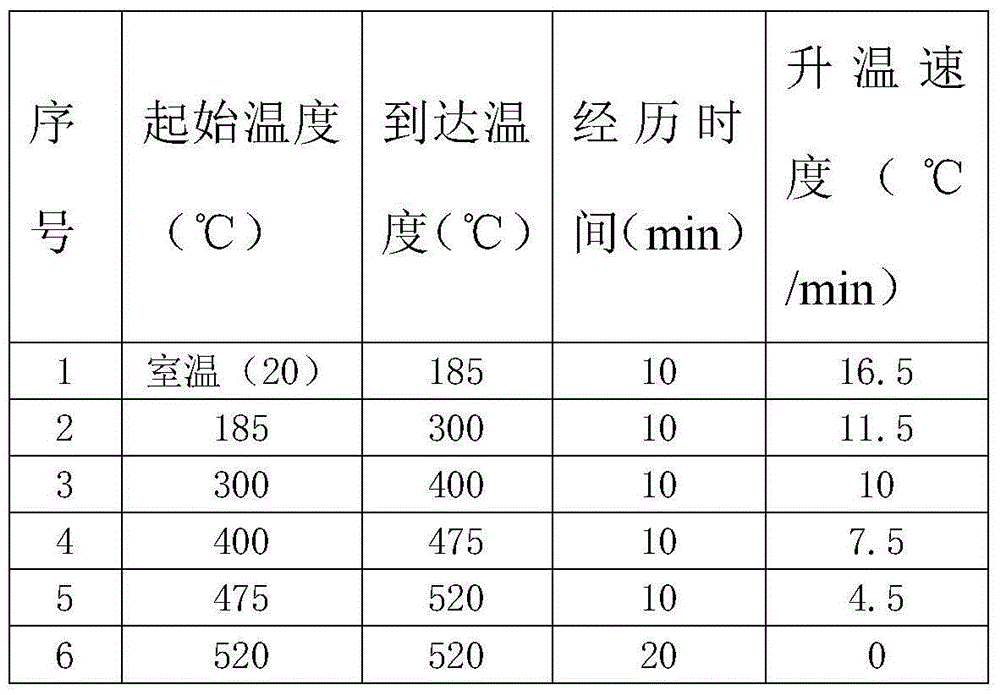

Destructive distillation testing device and destructive distillation method

InactiveCN104099115ASimplify manual operationsEvenly heatedLiquid hydrocarbon mixture productionSpecial form destructive distillationShale gasElectric heating

The invention discloses a destructive distillation testing device which comprises a steel frame, wherein a speed reducer is fixed above the steel frame; an electric heating furnace is fixed below one end the steel frame; a transmission stirring mechanism is arranged in the electric heating furnace; a trolley and a support device are arranged below the transmission stirring mechanism in sequence; a liquid gas storage tank is fixed below the other end of the steel frame; a condensing device is arranged on the air outlet side of the electric heating furnace. A destructive distillation method comprises the following steps: firstly drying collected oil shale, smashing till the particle diameter is 0-6 mm, then putting obtained oil shale particles into the electric heating furnace, and conducting destructive distillation on the oil shale so as to obtain coal gas and tar oil. According to the destructive distillation testing device and the method, the problems that the conventional oil shale destructive distillation testing table is small in treatment capacity, low in oil yield and incomplete in technological process, and cannot completely analyze components of shale oil and shale gas are solved.

Owner:陕西鼓风机集团西安锅炉有限责任公司(西安特种汽车厂)

An intelligent oil scooping machine

The invention relates to an intelligent oil fishing machine, comprising a bracket, a rope winding device, a steel rope, a rope guide, a pulley, a wellhead device, an oil guide, an oil collector, a guide pipe and an oil pipe, and the pulley is installed above the bracket , the rope reeling device and the rope guide are installed under the bracket, the oil pipe is sleeved in the guide pipe, the wellhead device is connected with the oil pipe, the oil collector is installed under the oil pipe, the guide The oiler is installed in the oil pipe, one end of the steel rope is wound on the rope winding device, and the other end of the steel rope is connected with the oil collector. The present invention realizes the effect of automatic oil extraction and automatic collection through the setting of the intelligent oil extraction machine, ensures the oil output rate, improves the oil extraction efficiency, realizes the automatic unblocking of the oil pipe at the same time, solves the problem of slow oil output, and further The oil yield is guaranteed.

Owner:福建双环能源科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com