Single screw rod oilseed cold pressing expeller

A single-screw, oil-based technology, applied in presses, manufacturing tools, etc., can solve the problems of waste of high-quality protein resources, etc., and achieve the effects of improving use value, low denaturation, and ensuring oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

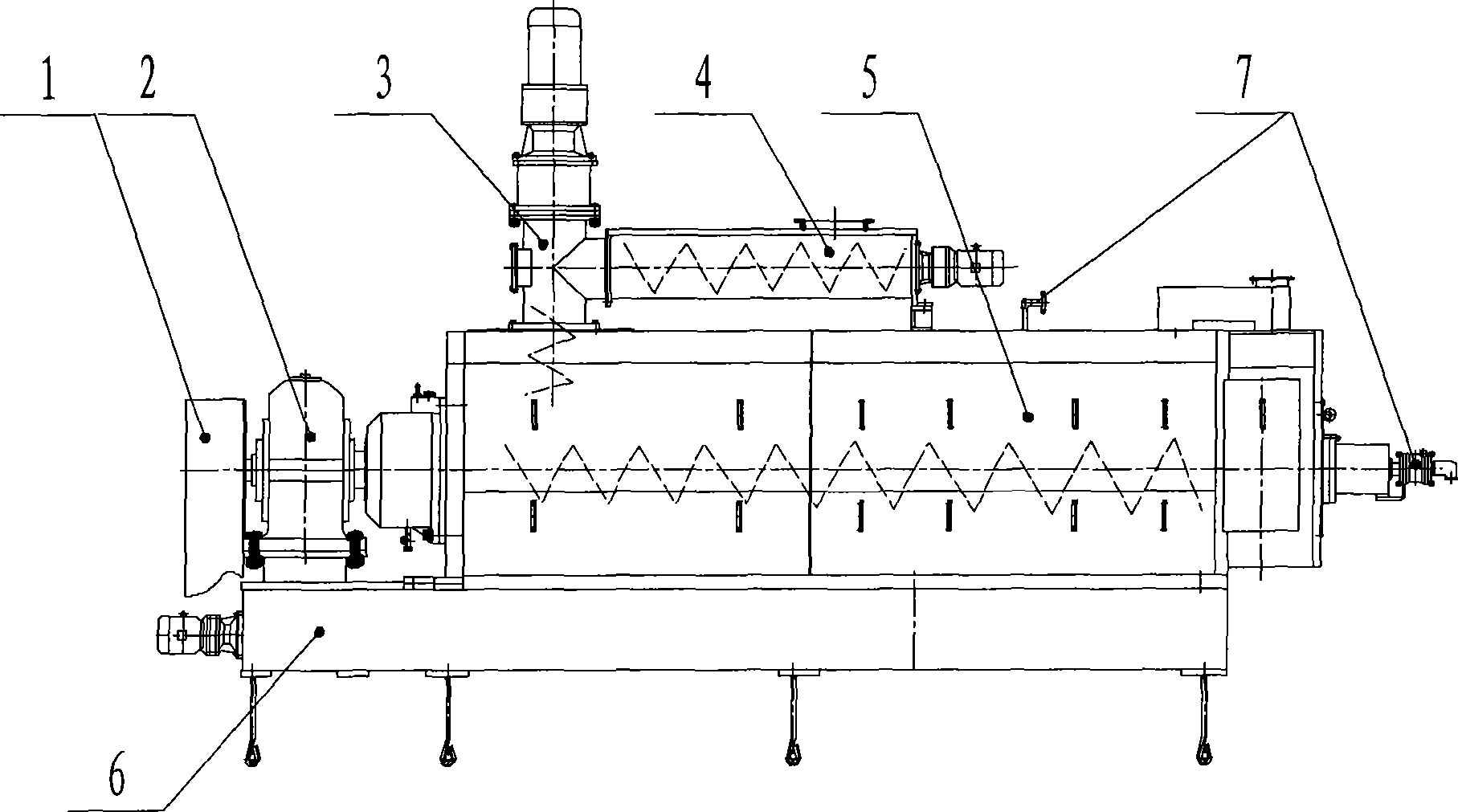

[0026] Such as figure 1 It is a schematic diagram of the appearance of a cold press, including an outer transmission part 1, a reducer 2, a feeding mechanism 3, a feeding mechanism 4, a press shaft assembly 5, a base 6, and a cooling part 7. The outer transmission part is composed of a pulley and a belt, which is used to transmit the power transmitted by the motor. The feeding mechanism 4 is composed of a frequency-variable speed-regulating reducer and an auger. It is installed on the base 6 and connected with the feeding mechanism 3 as a whole. And accurately adjust the feeding amount of the material to make the operation of starting and stopping easier. The feeding mechanism 3 is composed of a pressing shaft with a spiral blade at the lower end and a blanking cylinder. The screw blade under the feeding shaft has the function of forced feeding to increase the feeding amount; there is an inspection hole on the blanking cylinder, which can be opened to clean the material when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com