Passion fruit seed oil and preparation method thereof

A technology of passion fruit seed oil and passion fruit, which is applied in the production of edible oil/fat, fat oil/fat, and fat production, etc. It can solve the problems of low extraction efficiency of fruit oil, single extraction process, and lack of flavor, and achieve a wide variety of products , clear and bright color, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

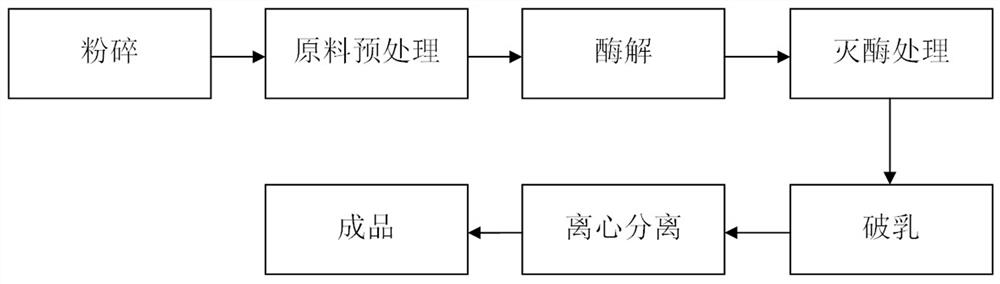

[0028] A preparation method of passion fruit seed oil, comprising the steps of:

[0029] (1) Crushing: Freshly picked passion fruit with no damage on the outside is used as raw material, and passion fruit seeds are obtained after separation and drying. The weight water content of raw passion fruit seeds is 1.50-3.00%, and the total sugar content is 1.16-2.24g / 100g. Fat content 21.00-25.30g / 100g, protein content 10.10-11.60g / 100g, linoleic acid content 15.00-16.50g / 100g, oleic acid content 2.80-3.70g / 100g, total phenol content 6.50-7.80g / 100g. Passion fruit seed powder is obtained after crushing and sieving (the sieve is 20-40 mesh);

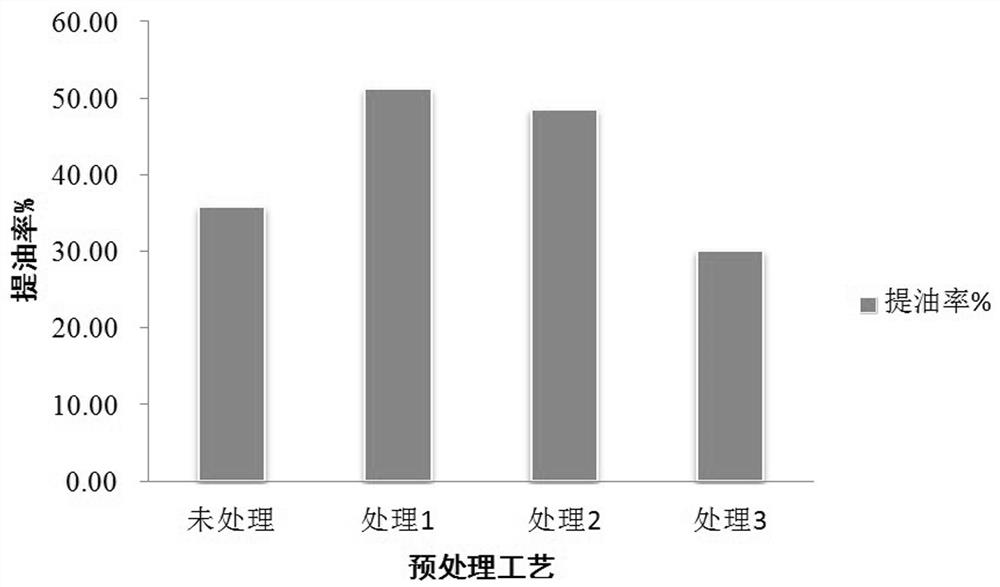

[0030] (2) Raw material pretreatment: steam the passion fruit seed powder at 120°C for 5-10 minutes, and the tile thickness is less than 1cm;

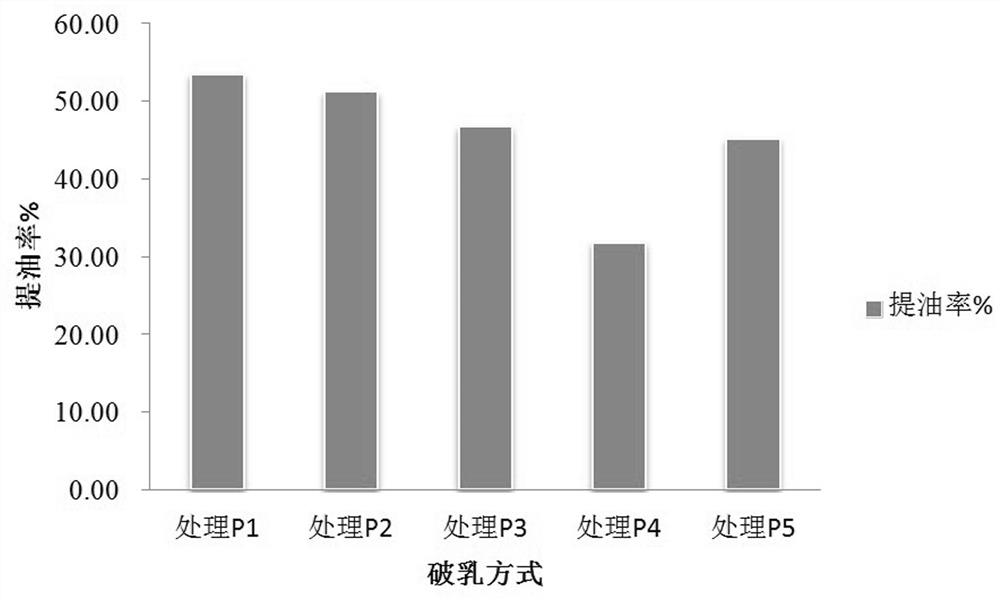

[0031] (3) Enzymolysis: add an appropriate amount of distilled water to the pretreated passion fruit seed powder to make a homogenate, and enzymolyze it for a certain period of time under the action of a...

Embodiment 1

[0051] A preparation method of passion fruit seed oil, comprising the steps of:

[0052] (1) Crushing: Freshly picked passion fruit with no damage on the outside is used as raw material. The raw material comes from Guangxi Guiping Huixin Passion Fruit Planting Cooperative. Passion fruit seeds are obtained after separation and drying. The weight water content of raw passion fruit seeds is 1.80%, the total sugar content is 1.16g / 100g, the fat content is 22.80g / 100g, the protein content is 11.40g / 100g, the linoleic acid content is 15.50g / 100g, and the oleic acid content is 3.70g / 100g , with a total phenol content of 7.40g / 100g, which was crushed and sieved (with a screen of 20 meshes) to obtain passion fruit seed powder;

[0053] (2) Raw material pretreatment: Weigh 100g of crushed passion fruit seed powder, steam treat the passion fruit seed powder at 120°C for 5 minutes, and spread it with a thickness of less than 1cm;

[0054] (3) Enzymolysis: add an appropriate amount of dis...

Embodiment 2

[0059] A preparation method of passion fruit seed oil, comprising the steps of:

[0060] (1) Crushing: Freshly picked passion fruit with no damage on the outside is used as raw material. The raw material comes from Guangxi Guiping Huixin Passion Fruit Planting Cooperative. Passion fruit seeds are obtained after separation and drying. The weight water content of raw passion fruit seeds is 1.50%, the total sugar content is 2.24g / 100g, the fat content is 23.60g / 100g, the protein content is 10.60g / 100g, the linoleic acid content is 16.50g / 100g, and the oleic acid content is 3.15g / 100g , with a total phenol content of 6.7g / 100g, which was crushed and sieved (with a screen of 20 meshes) to obtain passion fruit seed powder;

[0061] (2) Raw material pretreatment: Weigh 100g of crushed passion fruit seed powder, steam treat the passion fruit seed powder at 120°C for 10 minutes, and spread it with a thickness of less than 1cm;

[0062] (3) Enzymolysis: add an appropriate amount of dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com