Edible oil processing oil press capable of preventing oil leakage and convenient to clean

A technology of edible oil and oil press, which is applied to mixers, mixers, presses, etc. with rotating stirring devices, and can solve the problems of affecting the service life of the oil press, inconvenient internal cleaning of the main body, and oil output from the oil press. Drip and other problems, to achieve the effect of ensuring purity, improving quality and ensuring oil yield

Active Publication Date: 2019-06-21

山东矬草峪农业科技有限公司

View PDF14 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the deficiencies of the prior art, the present invention provides an oil press for edible oil processing to prevent oil leakage and easy to clean, which solves the problem that the current oil press proposed in the background technology is inconvenient to carry out the main body in the later stage when it is in use. The internal cleaning work will cause improper cleaning inside the main body, which will affect the service life of the oil press. In addition, the oil press will leak when the oil is discharged.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

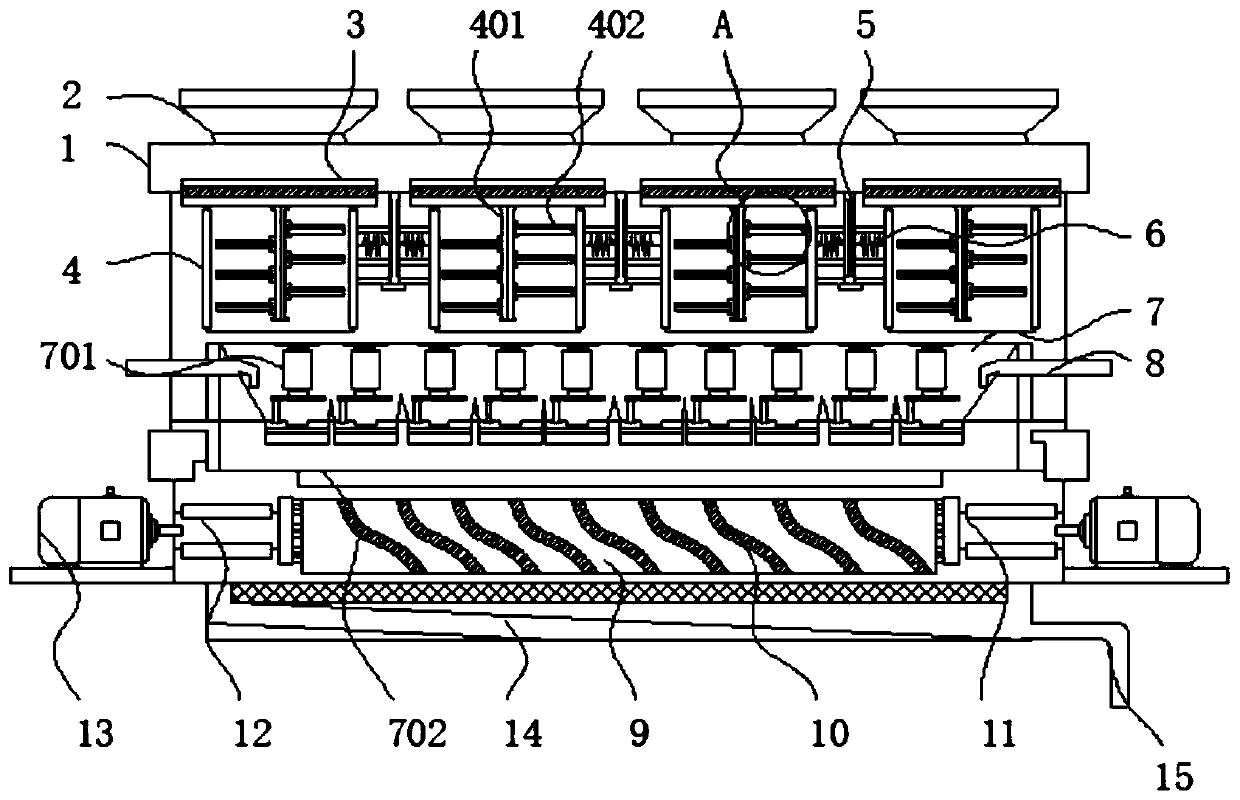

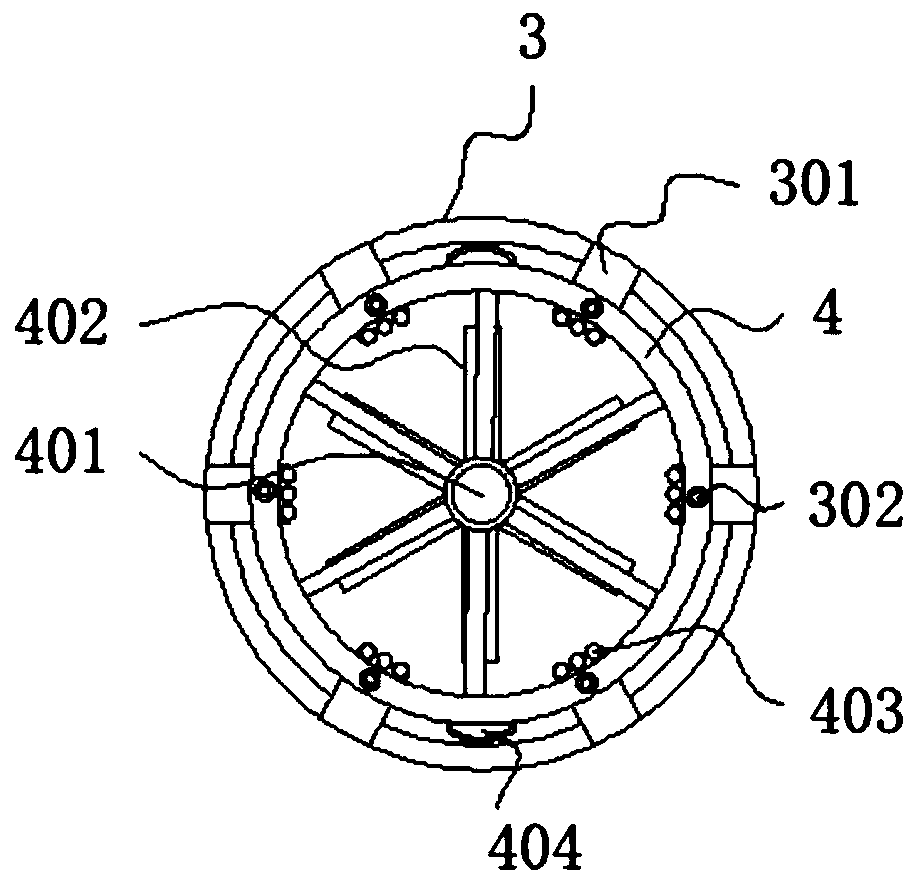

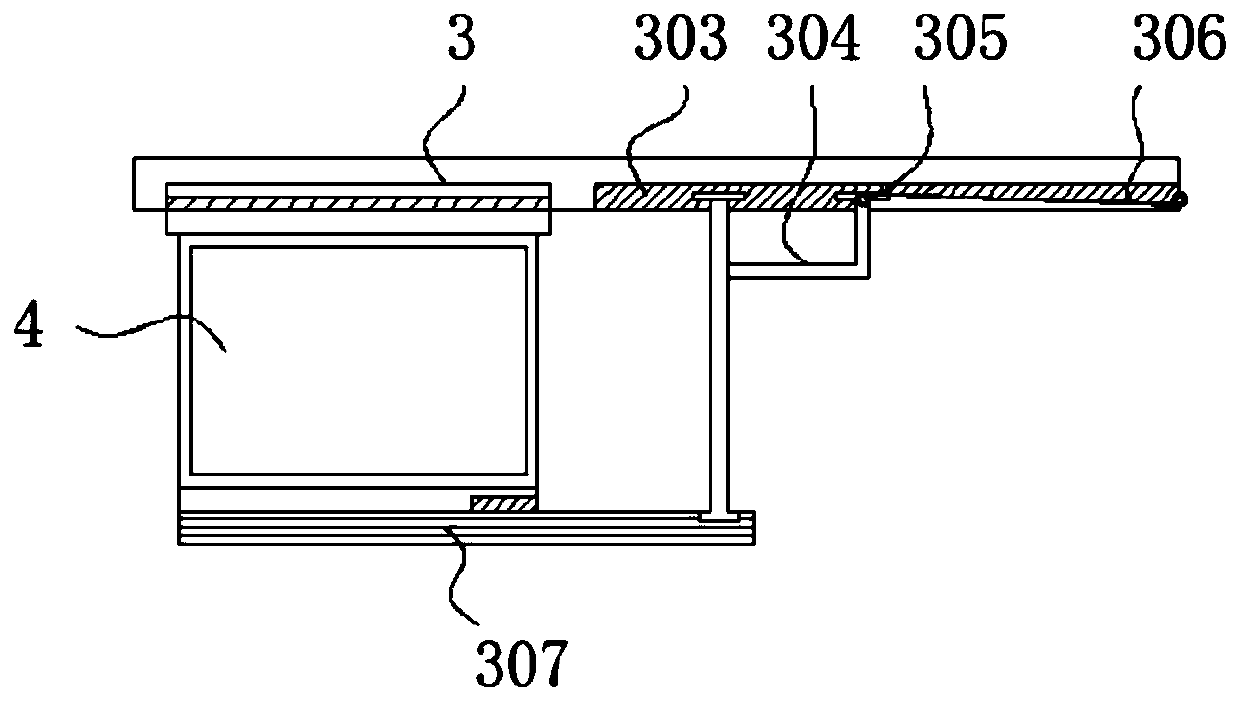

The invention discloses an edible oil processing oil press capable of preventing oil leakage and convenient to clean and relates to the technical field of oil press equipment. The edible oil processing oil press specifically comprises a main body and a woven cloth bag. Hoppers are welded above the main body, and a locating frame is mounted at the bottom of each hopper. An agitating vessel is put below each locating frame. A fixing rod is mounted on the surface of each agitating vessel. Treatment boxes are mounted below the agitating vessels. A first clamping rod is connected to the right sideof the woven cloth bag, and a second clamping rod is connected to the left side of the woven cloth bag. A first motor is mounted at the outer side of the second clamping rod. An oil chute is mounted below the woven cloth bag. According to the edible oil processing oil press capable of preventing oil leakage and convenient to clean, the locating frames are located below the hoppers and meanwhile fixed to the main body, and the number of the locating frames is the same as that of the agitating vessels; and the locating frames are mainly arranged for fixedly storing the agitating vessels.

Description

technical field [0001] The invention relates to the technical field of oil press equipment, in particular to an oil press used for edible oil processing to prevent oil leakage and facilitate cleaning. Background technique [0002] With the continuous improvement of people's living standards, edible oil has always been an essential kitchen material in residents' lives, and edible oil and other products are also one of the very important products in food. Now many technologies are constantly improving. The production technology of oil is also becoming more and more diversified. In order to pursue the demand in the market, many rapid production methods are used for production. Among them, the oil press is one of the indispensable equipment in the production of edible oil. [0003] With the continuous improvement of people's living standards, the demand for edible oil is also increasing, so manufacturers have more and more demand for oil presses. In the current production, oil p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B30B9/20B30B15/00B30B9/02C11B1/04B01F7/18B08B9/093

Inventor 余汉锡

Owner 山东矬草峪农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com