Process and device for processing tea oil with rich fragrance

A tea oil and aroma type technology, which is applied in the directions of fat oil/fat production, fat oil/fat refining, climate change adaptation, etc., can solve the problems of time-consuming and labor-intensive production of tea oil, trouble in actual production, and no pressing and extraction, etc. The effect of convenient pressing and extraction, improving retention rate and reducing extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

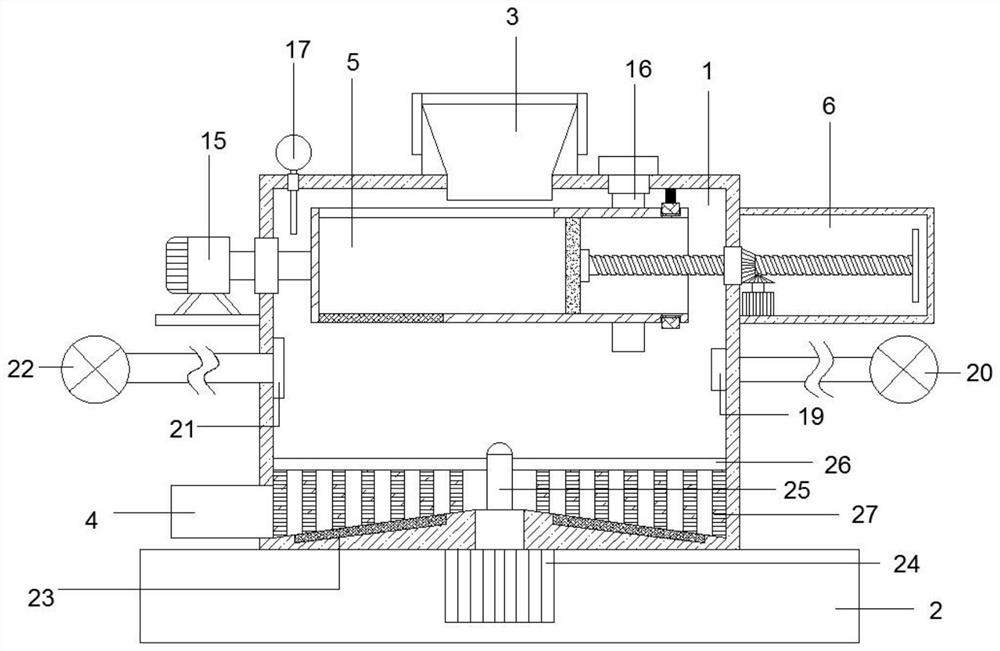

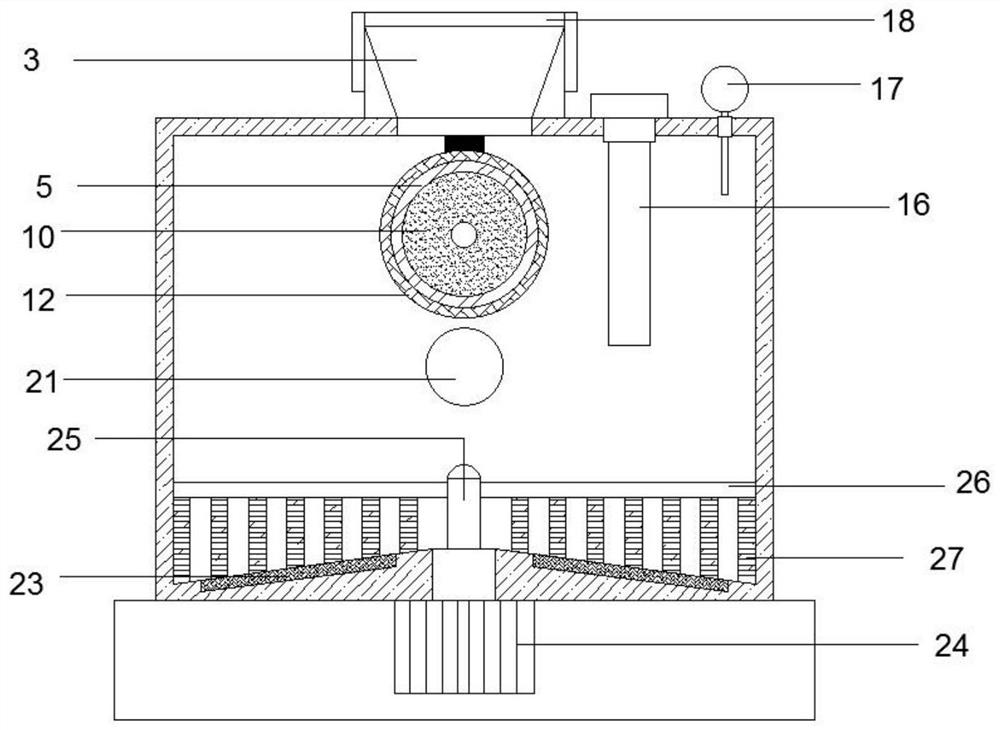

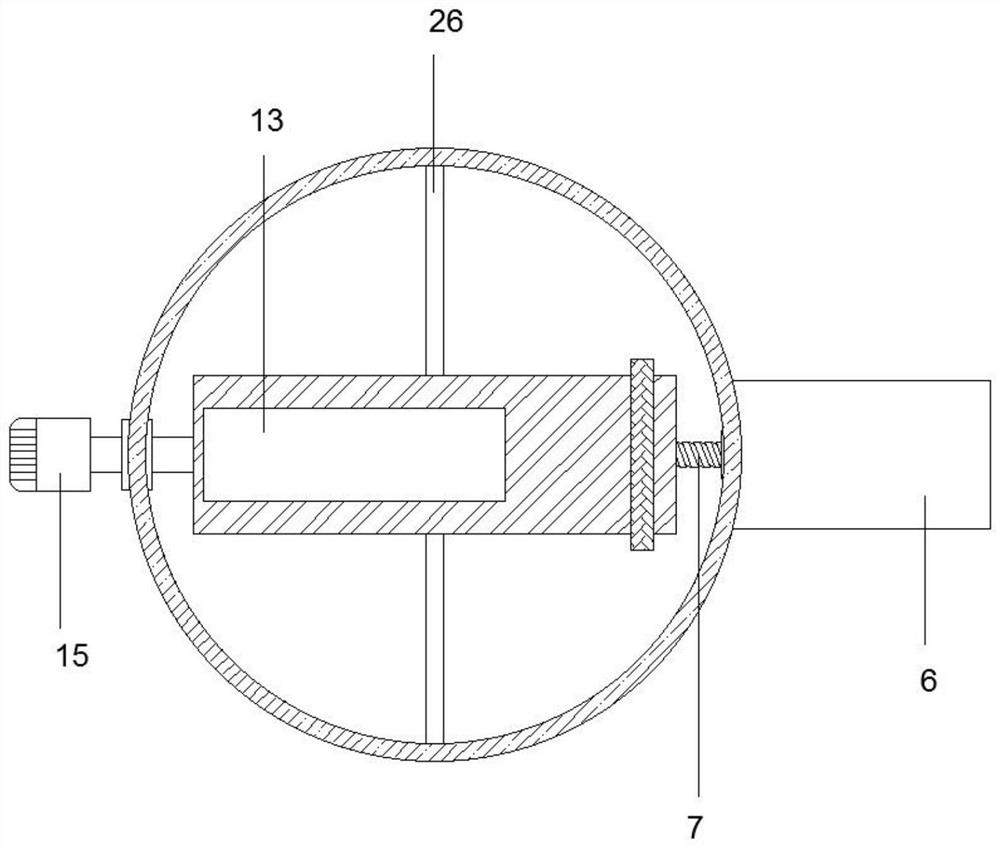

Image

Examples

Embodiment 1

[0037] A process for processing rich and fragrant camellia oil, the process for processing rich and fragrant camellia oil comprises the following steps:

[0038] (1) Raw material selection: pick mature Camellia oleifera seeds, select Camellia oleifera seeds with a complete surface and no mildew and shriveled, place them in the outdoor sun to dry until the moisture content is lower than 25%, and then place them at 45°C for hot air drying to reduce the moisture content less than 10%, and the shell of camellia oleifera seeds is cracked, the dried camellia oleifera seeds are ready for use;

[0039] (2) Shelling treatment: the above-mentioned dry camellia oleifera seeds are placed in a shelling machine for shelling treatment, and the tea seed shell, tea seed kernel and tea seed shell are sieved for subsequent use;

[0040] (3) Tea seed husk treatment: add the above-mentioned separated tea seed husk to boil and filter to obtain the boiled filtrate for subsequent use;

[0041] (4) C...

Embodiment 2

[0047] A process for processing rich and fragrant camellia oil, the process for processing rich and fragrant camellia oil comprises the following steps:

[0048] (1) Raw material selection: pick mature Camellia oleifera seeds, select Camellia oleifera seeds with a complete surface and no mildew and shriveled, place them in the outdoor sun to dry until the water content is less than 25%, and then place them at 60°C for hot air drying to the water content less than 10%, and the shell of camellia oleifera seeds is cracked, the dried camellia oleifera seeds are ready for use;

[0049] (2) Shelling treatment: the above-mentioned dry camellia oleifera seeds are placed in a shelling machine for shelling treatment, and the tea seed shell, tea seed kernel and tea seed shell are sieved for subsequent use;

[0050] (3) Tea seed husk treatment: add the above-mentioned separated tea seed husk to boil and filter to obtain the boiled filtrate for subsequent use;

[0051] (4) Crushing and eq...

Embodiment 3

[0057] A process for processing rich and fragrant camellia oil, the process for processing rich and fragrant camellia oil comprises the following steps:

[0058] (1) Raw material selection: pick mature Camellia oleifera seeds, select Camellia oleifera seeds with a complete surface and no mildew and shriveled, place them in the outdoor sun to dry until the water content is lower than 25%, and then place them at 55°C for hot air drying to the water content less than 10%, and the shell of camellia oleifera seeds is cracked, the dried camellia oleifera seeds are ready for use;

[0059] (2) Shelling treatment: the above-mentioned dry camellia oleifera seeds are placed in a shelling machine for shelling treatment, and the tea seed shell, tea seed kernel and tea seed shell are sieved for subsequent use;

[0060] (3) Tea seed husk treatment: add the above-mentioned separated tea seed husk to boil and filter to obtain the boiled filtrate for subsequent use;

[0061] (4) Crushing and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com