Mixing, stirring and oil discharging equipment and oil discharging process method of ground sesame oil

A technology of small grinding sesame oil and equipment, which is applied in the direction of fat oil/fat production and fat production, and can solve the problems of mechanization, labor intensity, production efficiency, economic benefits, disadvantages of large scale, high labor intensity of auxiliary stirring, high labor intensity, etc. problems, to achieve the effects of mechanized production, reducing material sticking to the wall, and reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

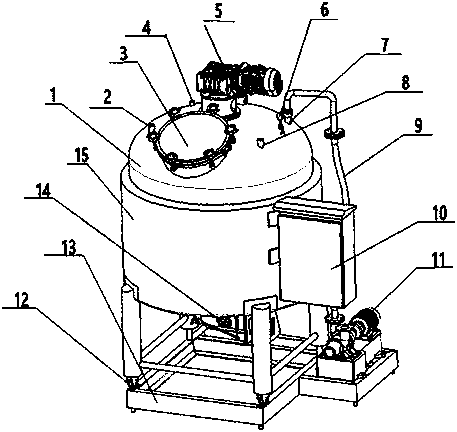

[0027] A kind of mill sesame oil blending slurry stirring oil extraction equipment and its oil output process method, its composition comprises: bracket 13, described bracket is connected with weighing sensor 12, and described bracket is connected with tank body jacket 15, and described The bottom of the tank jacket is connected to the discharge port 14, the tank jacket is connected to the tank body 1, the tank body is connected to the suction port 7, the gas suction port is connected to the metal hose 9, and the metal flexible The pipe is connected to the vacuum pump 11, the vacuum pump is connected to the control box 10, the tank body is connected to the feed port 2, the manhole 3, the pressure gauge 6, and the water inlet 8, the tank body is connected to the intake valve 4, and the tank body is connected to the intake valve 4. The fixed frequency conversion motor 5 of the tank body.

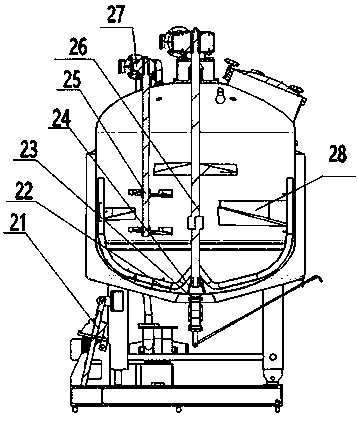

[0028] The support is connected to the hydraulic tilting system 21, and the polytetrafluor...

Embodiment 2

[0031] In the small grinding sesame oil blending and stirring oil extraction equipment described in Example 1, the tank body is in a sealed state, and the tank body is vacuumed by a vacuum pump, and the vacuum degree is 0--0.1 MPa.

Embodiment 3

[0033] A kind of small ground sesame oil blending and stirring oil extraction equipment described in Example 1, the hydraulic system controls the inclination of the tank body, and through the action of the hydraulic system, the tank body is at an angle of 0-30° Tilt freely within the range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com