Intermittent efficient roller seed frying machine

A kind of drum frying machine, intermittent technology, applied in the direction of producing fat, fat oil/fat production, etc., can solve problems such as unfavorable feed usage, large residue of harmful substances in oil cake, affecting oil yield and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

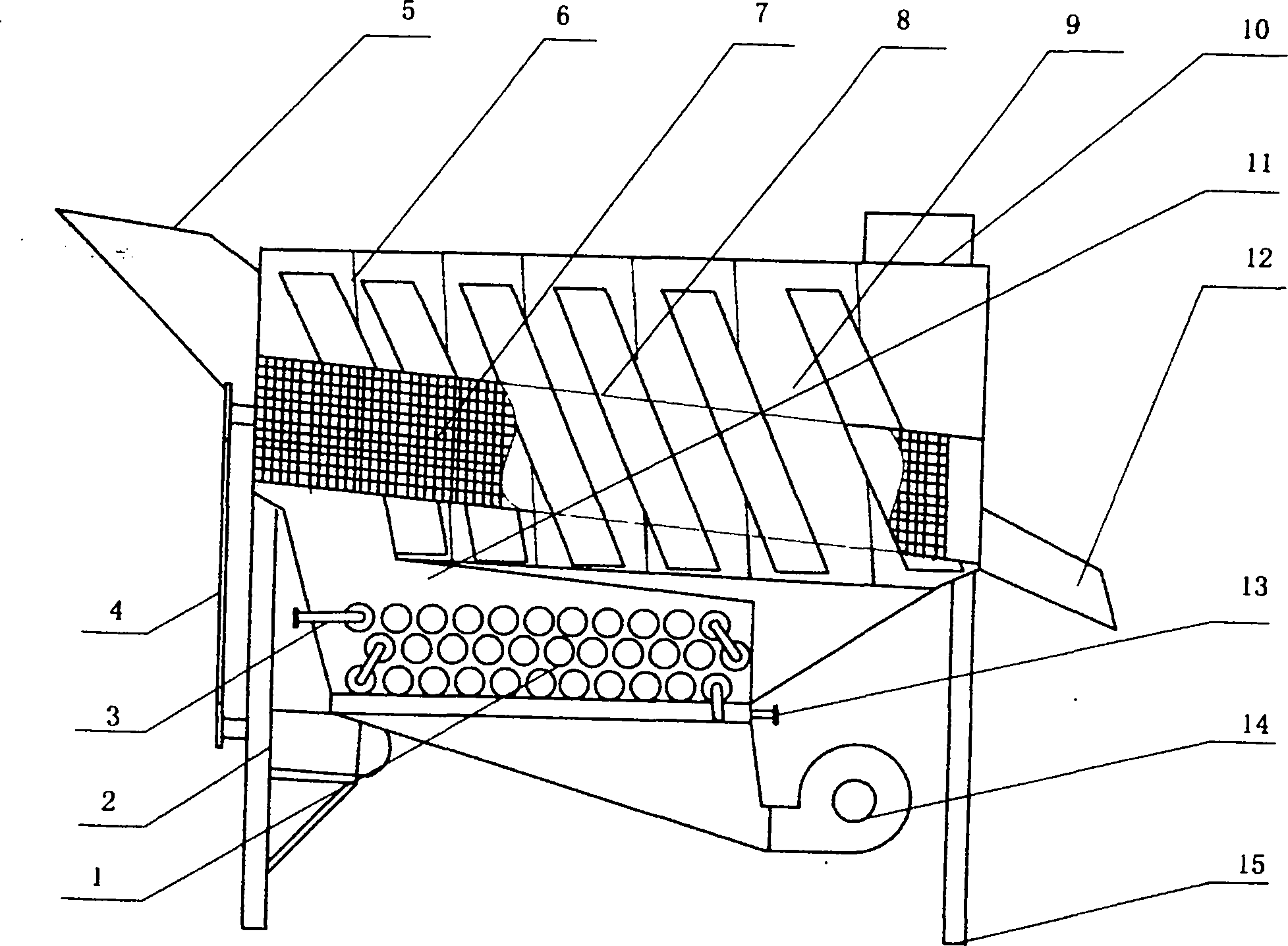

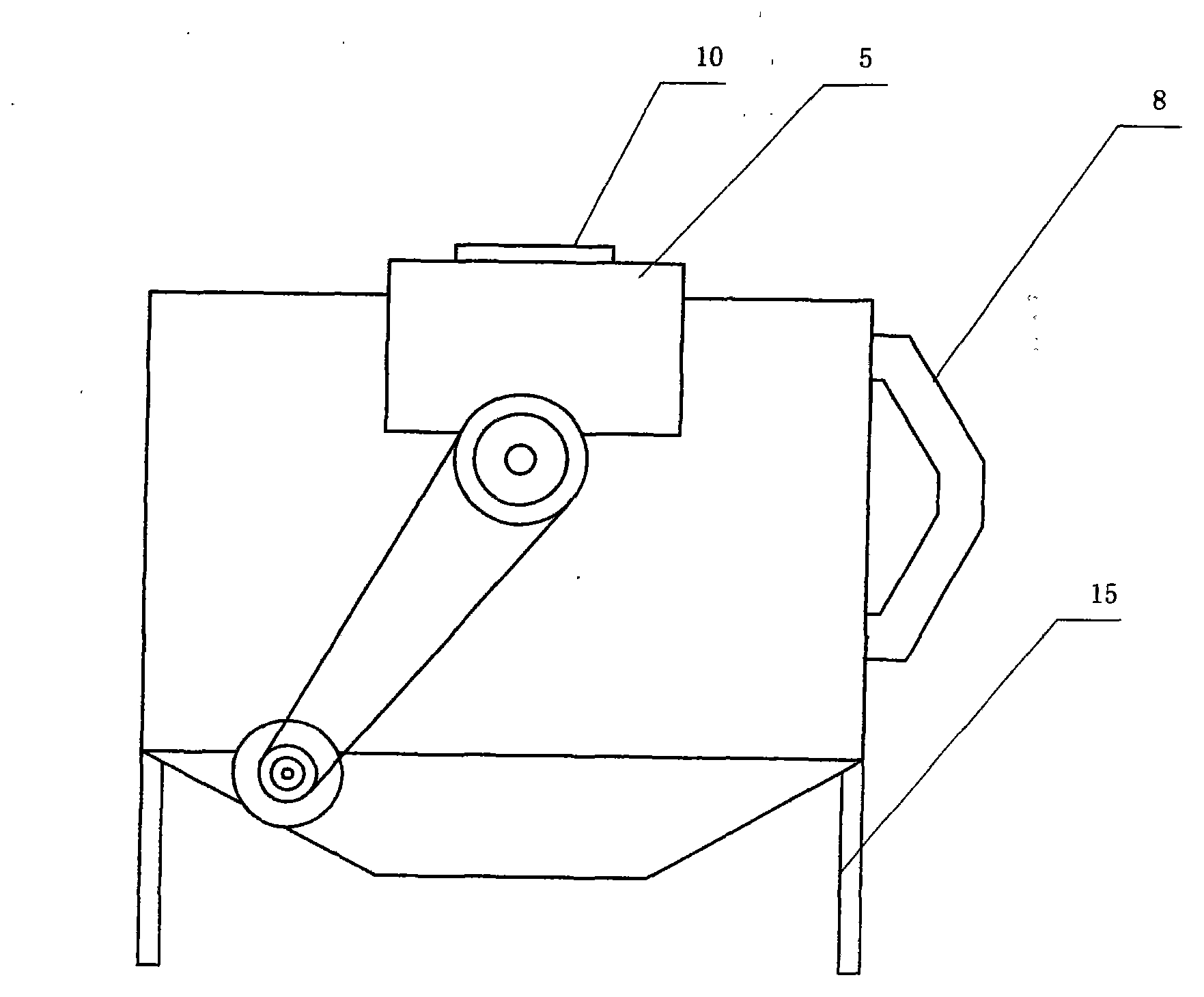

[0007] Depend on figure 1 , 2 As shown, the intermittent high-efficiency drum seed frying machine includes: heat transfer oil heat exchanger 1, motor reducer 2, transmission chain 4, feed hopper 5, screen drum 7, gas pulse chamber 11, discharge hopper 12, high pressure Fan 14, frame 15 form. The motor reducer 2 drives the screen-type drum 7 through the transmission chain 4, and the heat transfer oil inlet flange 13 and the heat transfer oil outlet flange 3 form a circulation channel with the output and oil return pipes respectively connected to the heat transfer oil furnace; the high-pressure fan 14 is connected to the gas pulse At the entrance of the chamber 11, the gas pulse chamber 11 is provided with a plurality of partitions 6 in the chamber, which divide it into a plurality of heating chambers 9; the high-temperature gas running channel is extended, thereby improving the heat utilization rate. When the motor reducer 2 drives the screen drum 7 through the transmission c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com