Destructive distillation testing device and destructive distillation method

A test device and dry distillation technology, used in special forms of dry distillation, petroleum industry, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of small processing capacity, low oil yield, imperfect process flow, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

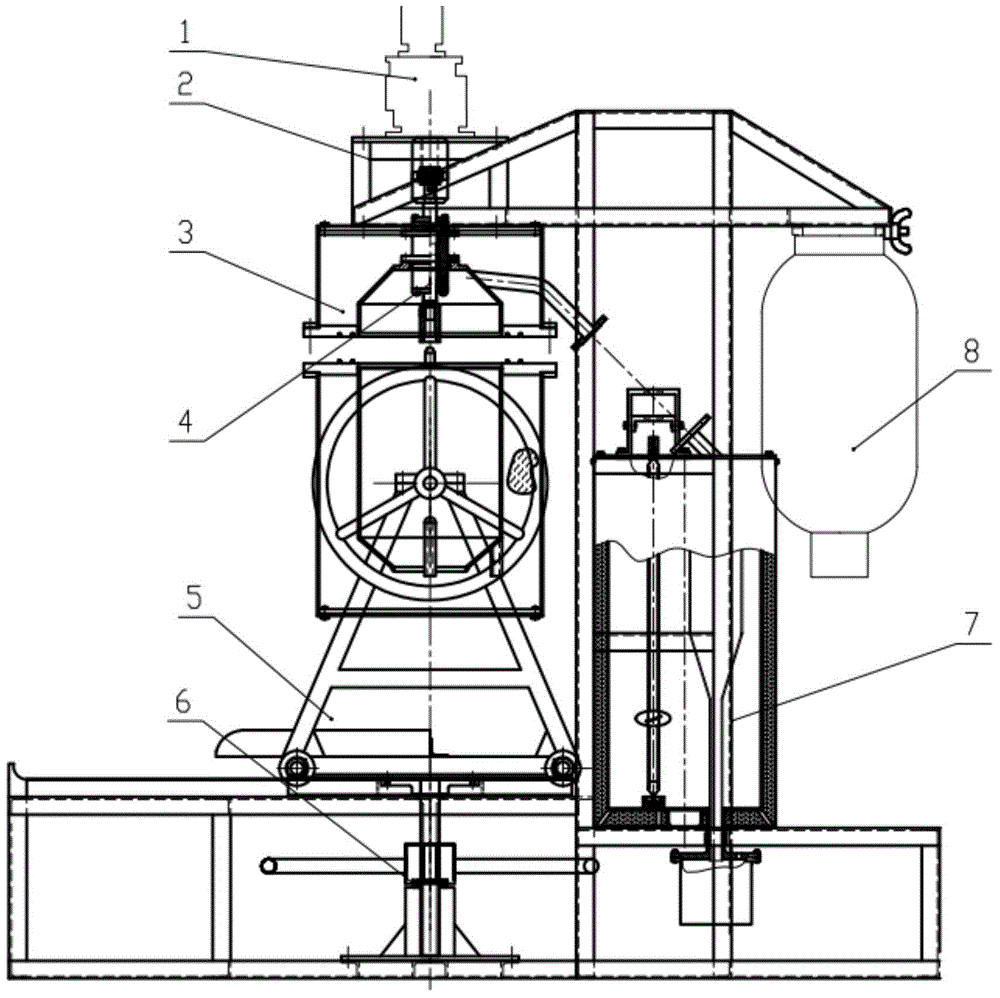

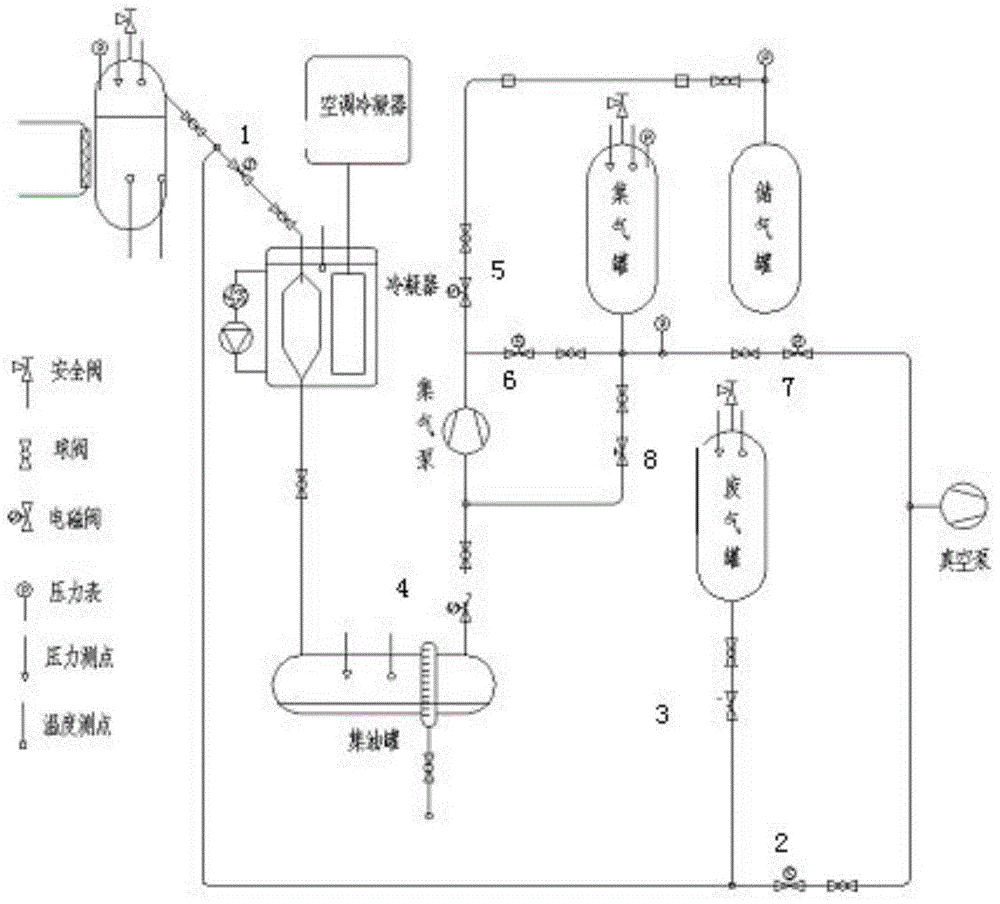

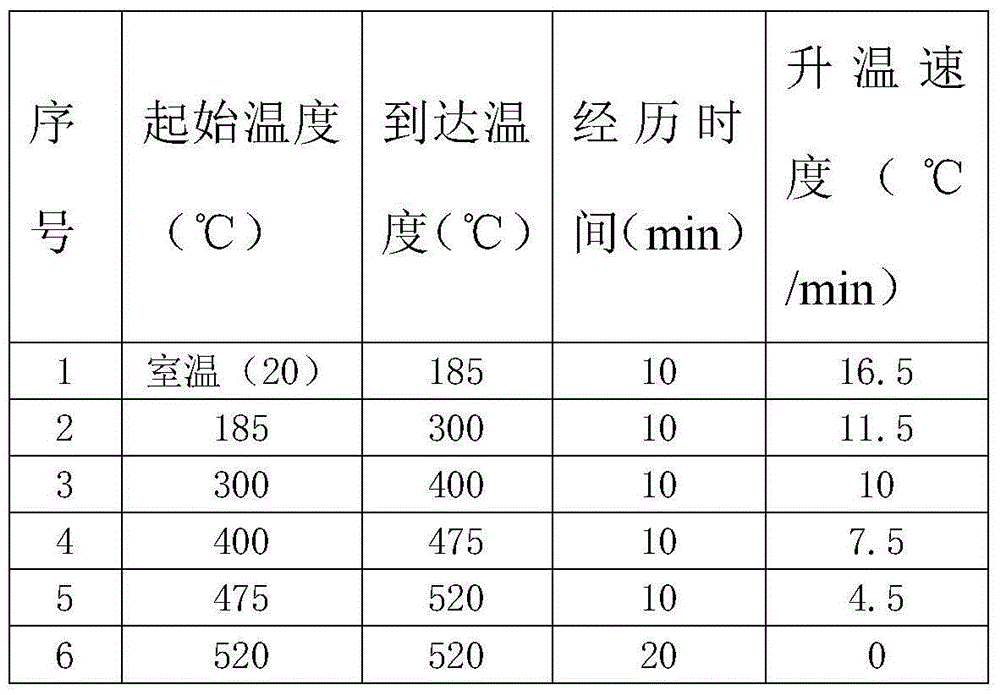

[0034] Step 1: Determine Design Parameters

[0035] This test device adopts the principle of "low temperature dry distillation method", which can satisfy the production of shale oil and dry distillation gas as the dry distillation product of 10kg oil shale sample and the determination of oil content, and can automatically collect shale oil, pyrolysis gas and waste gas . The heating rate of the sample can be adjusted within the specified range according to the setting.

[0036] The operation of the equipment adopts a programmable controller, which has a very reliable guarantee for intuitiveness and reliability;

[0037] The measured value is collected and processed by the computer and archived, the test report is automatically printed, and the test results and test data can be analyzed.

[0038] Installation location: Xi'an, Shaanxi

[0039] Device name: dry distillation test device

[0040] Mass of oil shale sample: ~10kg.

[0041] Reference standard: GB / T 212-2008 "Indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com