Refining-free natural tea seed skincare oil and preparation method thereof

A production method and tea seed technology are applied in the production field of tea seed skin care oil and skin care oil, which can solve the problems of skin care oil safety hazards, loss of natural vitamin E, etc., achieve good bactericidal ability, delay aging, and reduce lipofuscin. effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

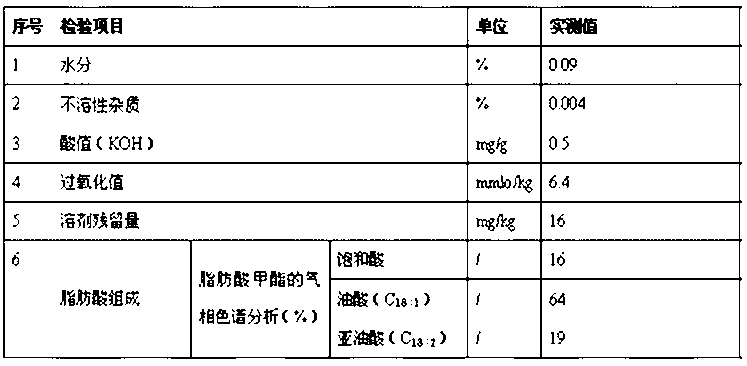

Image

Examples

Embodiment 1

[0053] A kind of non-refining natural tea seed skin care oil, made of components with the following mass ratio:

[0054] Seed oil 80kg

[0055] Rose essential oil 1.0kg

[0056] Linolenic acid 15kg

[0057] Tea polyphenols 2.5kg

[0058] Vitamin E 5kg

[0059] Sheep placenta 1kg.

[0060] The production method of the present embodiment free refining natural tea seed skin care oil comprises the following steps:

[0061] (1) Fruit selection: select tea fruits with normal color, no mildew, no impurities and plumpness, and dry them naturally until the water content of the tea fruits reaches 20%;

[0062] (2) Dehulling: Dehull the tea fruit, separate the shell and kernel to obtain the tea kernel, dry it naturally until the water content of the tea kernel is 8%, and store it in an environment at 0°C;

[0063] (3) Low-temperature drying: bake the tea kernels at 80°C for 50 minutes;

[0064] (4) Pressing: Put the dried tea kernels into an air pressure tank and press for 20 minu...

Embodiment 2

[0069] A kind of non-refining natural tea seed skin care oil, made of components with the following mass ratio:

[0070] Tea seed oil 90kg

[0071] Jasmine essential oil 10kg

[0072] Linolenic acid 20kg

[0073] Tea polyphenols 4kg

[0074] Vitamin E 8kg

[0075] Sheep Placenta 1.5kg

[0076] Emulsifier 10kg, one of the non-ionic emulsifiers with hydrophilic-lipophilic HLB value between 8-15

[0077] vegetable oil 10kg

[0078] Polyol 10kg, that is, one of glycerin, butylene glycol, polyethylene glycol, propylene glycol, hexylene glycol, xylitol, polypropylene glycol and sorbitol.

[0079] The production method of above-mentioned non-refining natural tea seed skin care oil comprises the steps:

[0080] (1) Fruit selection: select tea fruits with normal color, no mildew, no impurities and plumpness, and dry them naturally until the water content of the tea fruits reaches 20%;

[0081] (2) Dehulling: Dehull the tea fruit, separate the shell and kernel to obtain the tea ...

Embodiment 3

[0088] A kind of non-refining natural tea seed skin care oil, made of components with the following mass ratio:

[0089] Tea seed oil 95kg

[0090] Osmanthus essential oil 15kg

[0091] Linolenic acid 25kg

[0092] Tea polyphenols 4.5kg

[0093] Vitamin E 8kg

[0094] Sheep Placenta 2kg

[0095] Emulsifier 12kg, one of the anionic emulsifiers with hydrophilic-lipophilic HLB value between 8-15

[0096] Hydrogenated vegetable oil 12kg

[0097] Hyaluronic Acid 12kg

[0098] The production method of above-mentioned non-refining natural tea seed skin care oil comprises the steps:

[0099] (1) Fruit selection: select tea fruits with normal color, no mildew, no impurities and plumpness, and dry them naturally until the water content of the tea fruits reaches 20%;

[0100] (2) Dehulling: Dehull the tea fruit, separate the shell and kernel to obtain the tea kernel, dry it naturally until the water content of the tea kernel is 9%, and store it in an environment at 7°C;

[0101]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com