Efficient distillation equipment suitable for mass production of cinnamomum petrophilum oil

A distillation equipment and technology of cinnamon oil, applied in the directions of essential oil/spice, fat production, etc., can solve the problems of small amount of processing raw materials, large environmental pollution, cumbersome steps, etc., improve strength and stability, and avoid steam leakage , the effect of increasing the heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

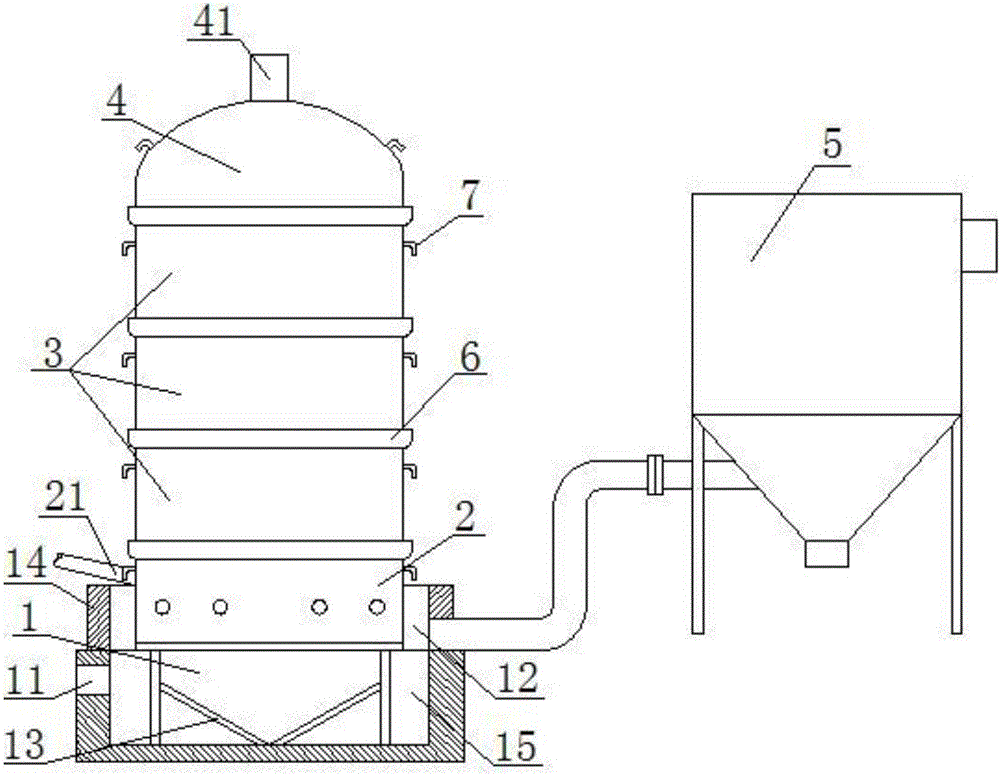

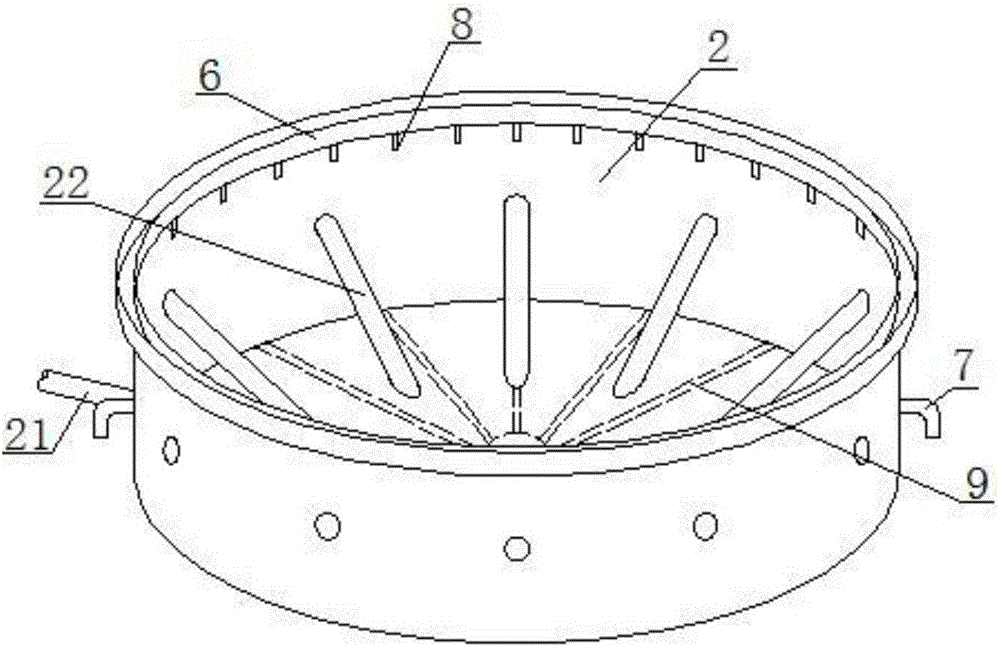

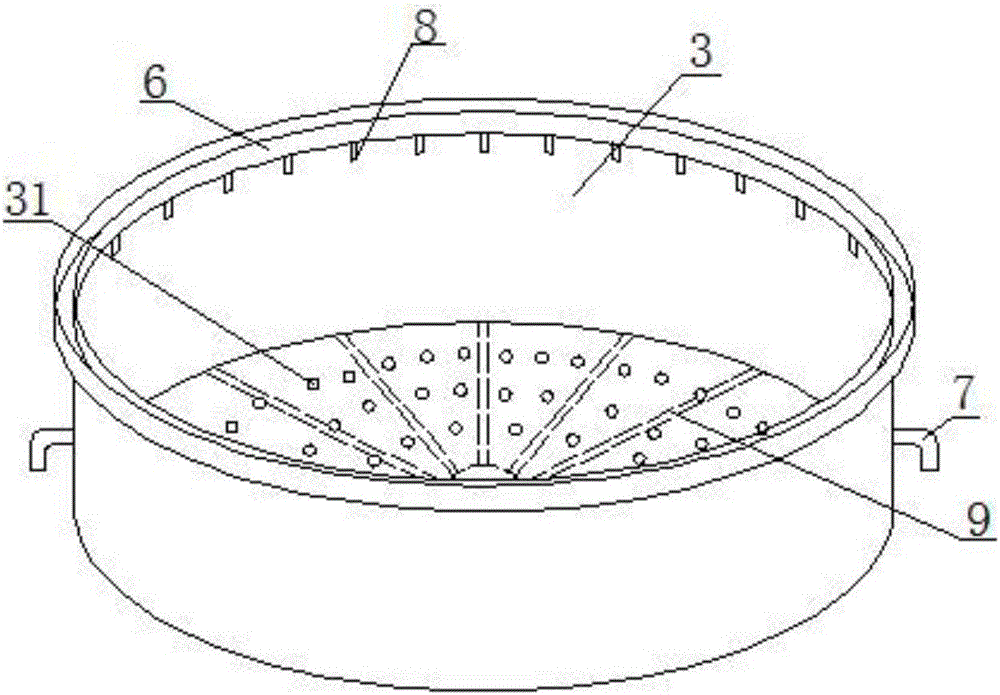

[0027] A high-efficiency distillation equipment for cinnamon oil suitable for mass production, comprising a furnace 1, a distillation pot 2 is placed on the furnace 1, a fuel inlet 11 is arranged on the side of the furnace 1, and an annular flue is arranged above the furnace 1 12. The annular flue 12 is connected with the soot treatment device 5 through the soot pipe, the still pot 2 is placed on the furnace 13, the side wall of the still pot 2 is provided with a return pipe 21, and a steamer 3 is placed above the still pot 2, The steaming drawer 3 has multiple layers, and the steaming drawer 3 on the top floor is provided with a steaming cover 4, the top of the steaming cover 4 is provided with an air collecting port 41, and the bottom of the steaming drawer 3 is evenly distributed with a number of ventilation holes 31, and the steaming drawer 3 Lifting lugs 7 are all arranged on the circumferential surfaces of the pot 2 , the steaming drawer 3 and the steaming cover 4 .

[0...

Embodiment 2

[0033] A high-efficiency distillation equipment for cinnamon oil suitable for mass production, comprising a furnace 1, a distillation pot 2 is placed on the furnace 1, a fuel inlet 11 is arranged on the side of the furnace 1, and a hollow interlayer 15 is arranged inside the furnace 1 , an annular flue 12 is arranged above the hollow interlayer 15, a stepped furnace bridge 13 is arranged in the furnace 1, the annular flue 12 is connected with a soot treatment device 5 through a smoke pipe, and the distillation pot 2 is placed in the furnace 13 Above, a return pipe 21 is provided on the side wall of the distillation pot 2, and a steaming drawer 3 is placed above the distillation pot 2. The steaming drawer 3 has multiple layers, and a steaming cover 4 is placed on the steaming drawer 3, and a steaming cover 4 is arranged on the top of the steaming cover 4. The air collecting port 41, the bottom of the steaming drawer 3 are evenly distributed with some ventilation holes 31, and th...

Embodiment 3

[0039] A high-efficiency distillation equipment for cinnamon oil suitable for mass production, comprising a furnace 1, a distillation pot 2 is placed on the furnace 1, a fuel inlet 11 is arranged on the side of the furnace 1, and a hollow interlayer 15 is arranged inside the furnace 1 , an annular flue 12 is arranged above the hollow interlayer 15, a stepped furnace bridge 13 is arranged in the furnace 1, the annular flue 12 is connected with a soot treatment device 5 through a smoke pipe, and the distillation pot 2 is placed in the furnace 13 Above, a return pipe 21 is provided on the side wall of the distillation pot 2, and a steaming drawer 3 is placed above the distillation pot 2. The steaming drawer 3 has multiple layers, and a steaming cover 4 is placed on the steaming drawer 3, and a steaming cover 4 is arranged on the top of the steaming cover 4. The air collecting port 41, the bottom of the steaming drawer 3 are evenly distributed with some ventilation holes 31, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com