Cyclohexane oxidation decomposition liquid refinement apparatus

A refining device and decomposition liquid technology, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of increased by-product X oil, reduced catalyst activity, increased bed resistance, etc., to avoid emulsification and reduce sodium ions Content, the effect of reducing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention is not limited to the scope described in the embodiments.

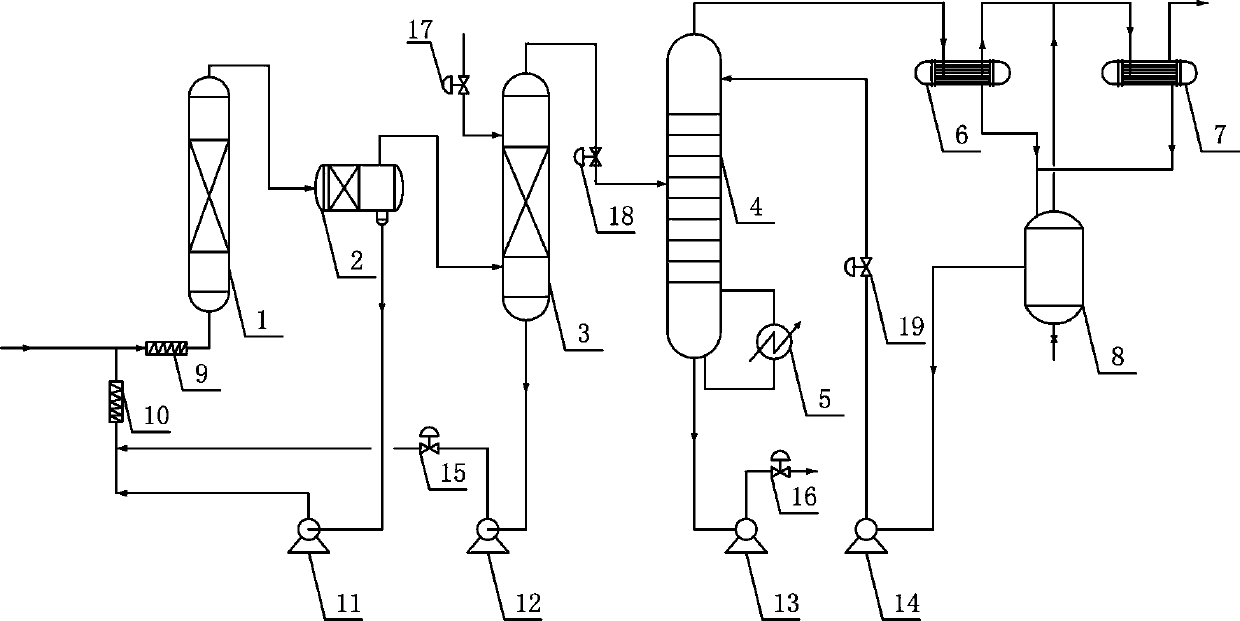

[0019] Such as figure 1 As shown, a refining device for cyclohexane oxidative decomposition liquid includes a feed mixer 9, a saponification tower 1, a separator 2, a washing tower 3, a pretreatment tower 4, and a reflux tank 8 connected in sequence through pipelines; Including the lye mixer 10, the circulation pump 11 is connected to the separator 2 and the lye mixer 10 respectively through pipelines; the washing water pump 12 is connected to the washing tower 3 and the lye mixer 10 through pipelines;

[0020] Further, a reboiler 5 is provided outside the pretreatment tower 4 , and a closed loop is formed between the pretreatment tower 4 and the reboiler 5 .

[0021] Further, the device is also provided with a condenser 6, the top of the pretrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com