Super-stable Y zeolite, preparation method and application thereof

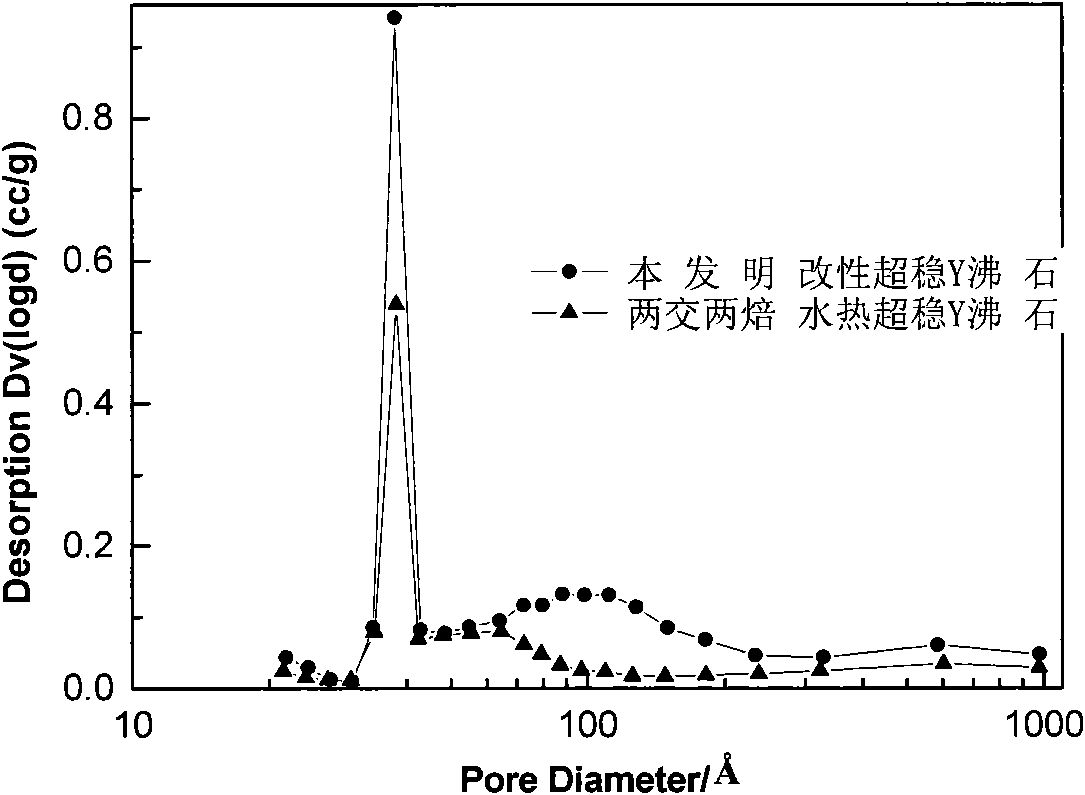

A technology of zeolite and secondary pores, which is applied in the field of ultra-stable Y zeolite and its preparation and application, which can solve the problems of easily destroyed crystal structure, low acid center density, and decreased crystallinity, and achieve dry gas and coke selectivity Good, heavy oil conversion ability, high crystallinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

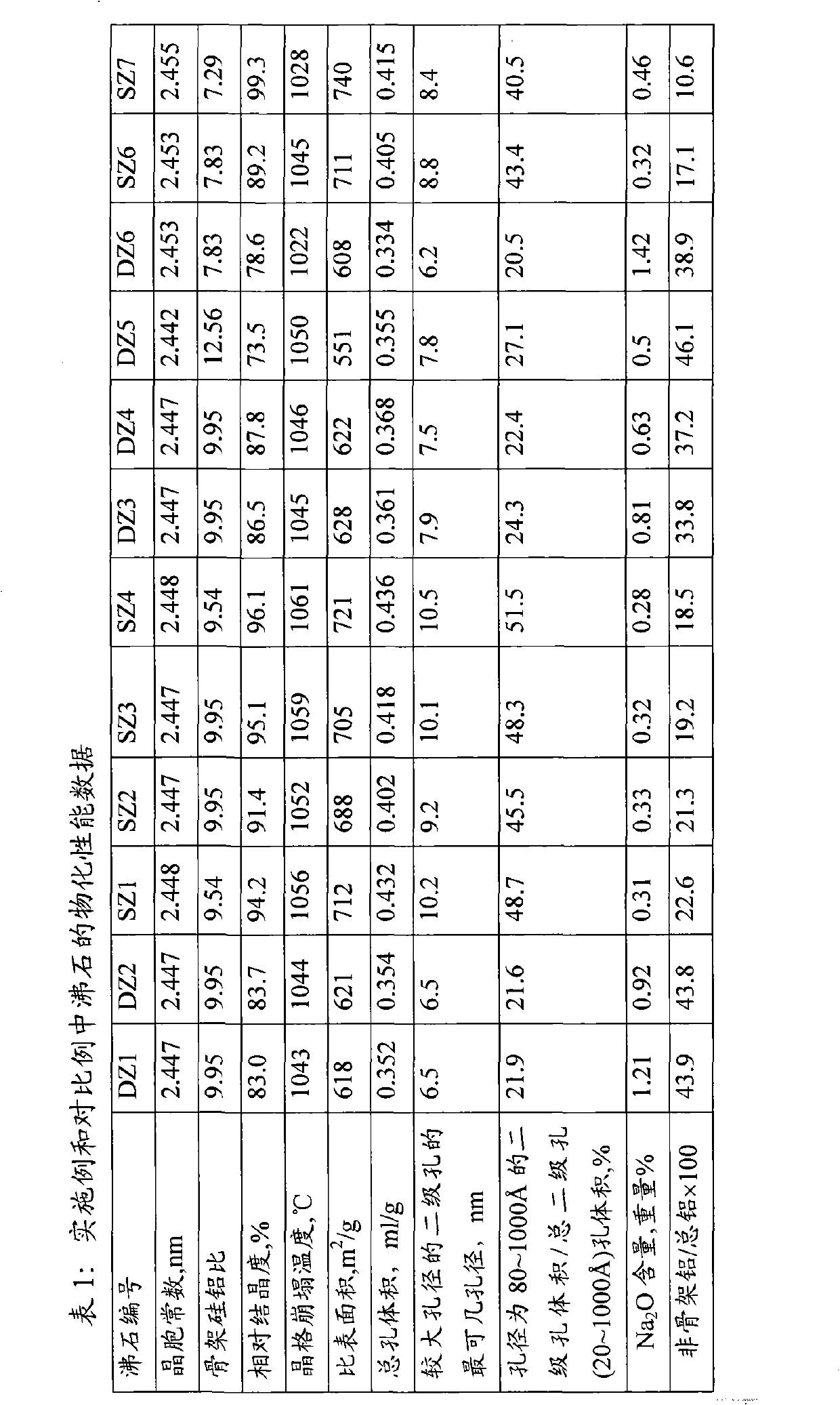

[0035] At room temperature, take 1000 grams (dry basis) of DZ1, add it to 10 liters of mixed acid aqueous solution with a concentration of 0.2N oxalic acid and a concentration of 0.1N hydrochloric acid, stir to make it evenly mixed, put it into a reaction kettle, seal it, and fill it with N 2 , keep the pressure of the system at 0.15MPa (gauge pressure), raise the temperature to 100°C at a rate of 10°C / min, keep at this temperature and pressure for 1 hour, filter, wash, and dry at 120°C for 5 hours to obtain the modification The ultra-stable Y-type zeolite sample, denoted as SZ1, table 1 has provided the composition of SZ1, unit cell constant, relative crystallinity, structure collapse temperature, specific surface area and larger pore diameter (pore diameter is ) of secondary pores accounted for the total secondary pores percentage.

Embodiment 2

[0037] At room temperature, take 2000 grams (dry basis) of DZ1, add it to 20 liters of mixed acid aqueous solution with a concentration of acetic acid of 0.1N and a concentration of hydrochloric acid of 0.15N, stir to make it evenly mixed, put it into a closed pressure reactor, and fill it with N 2 , control the pressure of the reactor to 0.3MPa (gauge pressure), raise the temperature to 115°C at a heating rate of 10°C / min, and keep it at this temperature and pressure for 30 minutes, then filter, wash, and dry the filter cake at 120°C for 5 hours , to get the modified ultrastable Y-type zeolite sample, denoted as SZ2, table 1 has provided the composition of SZ2, unit cell constant, relative crystallinity, structure collapse temperature, specific surface area and larger pore diameter (pore diameter is ) of secondary pores accounted for the total secondary pores percentage.

Embodiment 3

[0039] At room temperature, take 1500 grams (dry basis) of DZ1, add it to 20 liters of mixed acid aqueous solution with a citric acid concentration of 0.1N and a nitric acid concentration of 0.05N, stir to make it evenly mixed, put it into a closed pressure reactor, and fill it with He Gas, the control system pressure is 0.5MPa, the temperature is raised to 130°C at a rate of 10°C / min, and kept at this temperature and pressure for 10 minutes, then filtered, washed, and the filter cake is dried at 120°C for 5 hours, and the modified The ultra-stable Y-type zeolite sample is denoted as SZ3. Table 1 shows the composition of SZ3, unit cell constant, relative crystallinity, structure collapse temperature, specific surface area and larger pore size (pore size is ) of secondary pores accounted for the total secondary pores percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com