Method for removing sodium ions from nanometer rare earth oxide prepared through sodium salt depositing process

A nano rare earth and rare earth oxidation technology, applied in rare earth metal oxides/hydroxides, rare earth metal compounds, chemical instruments and methods, etc., can solve problems such as high sodium ion content affecting the quality of applied products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of nanometer yttrium oxide

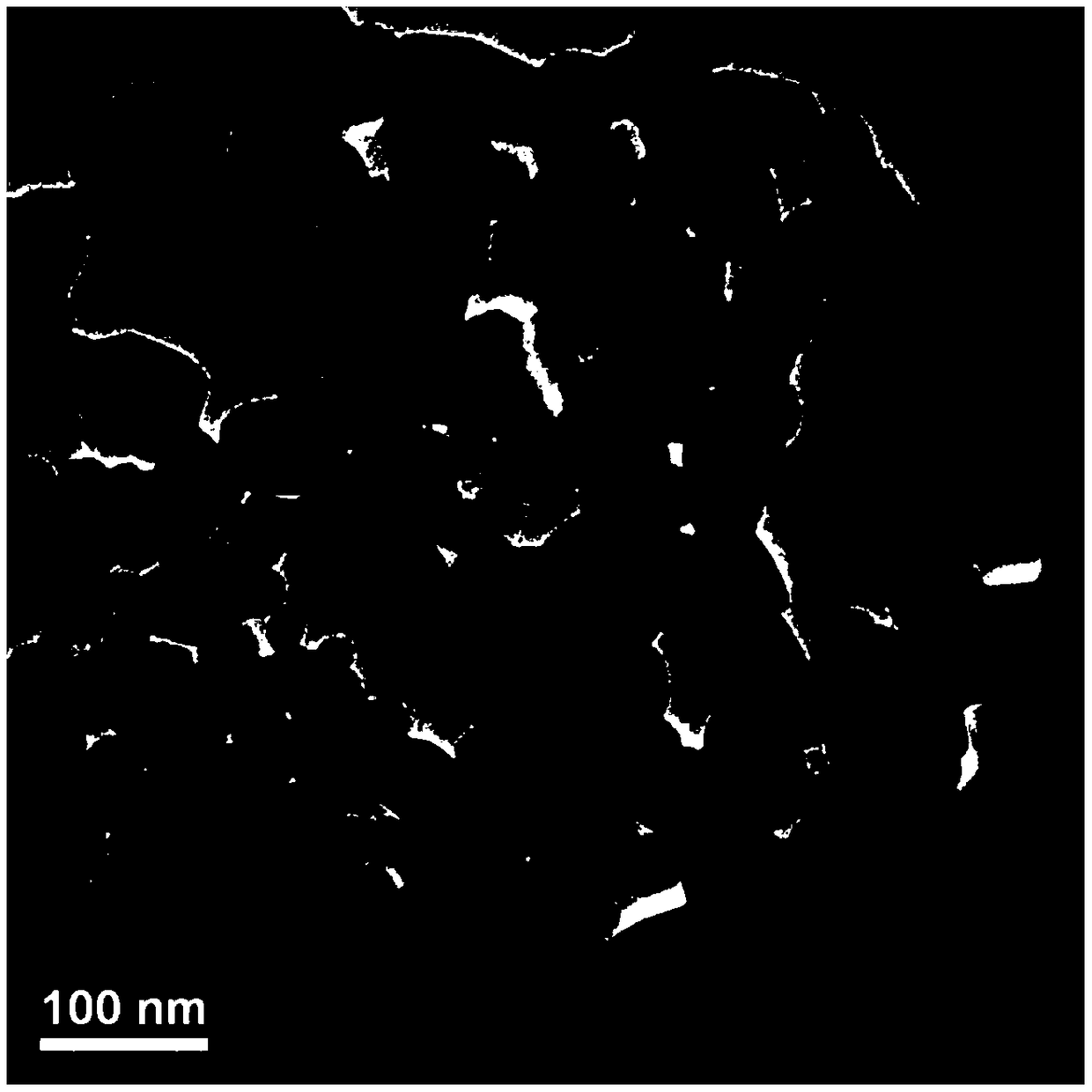

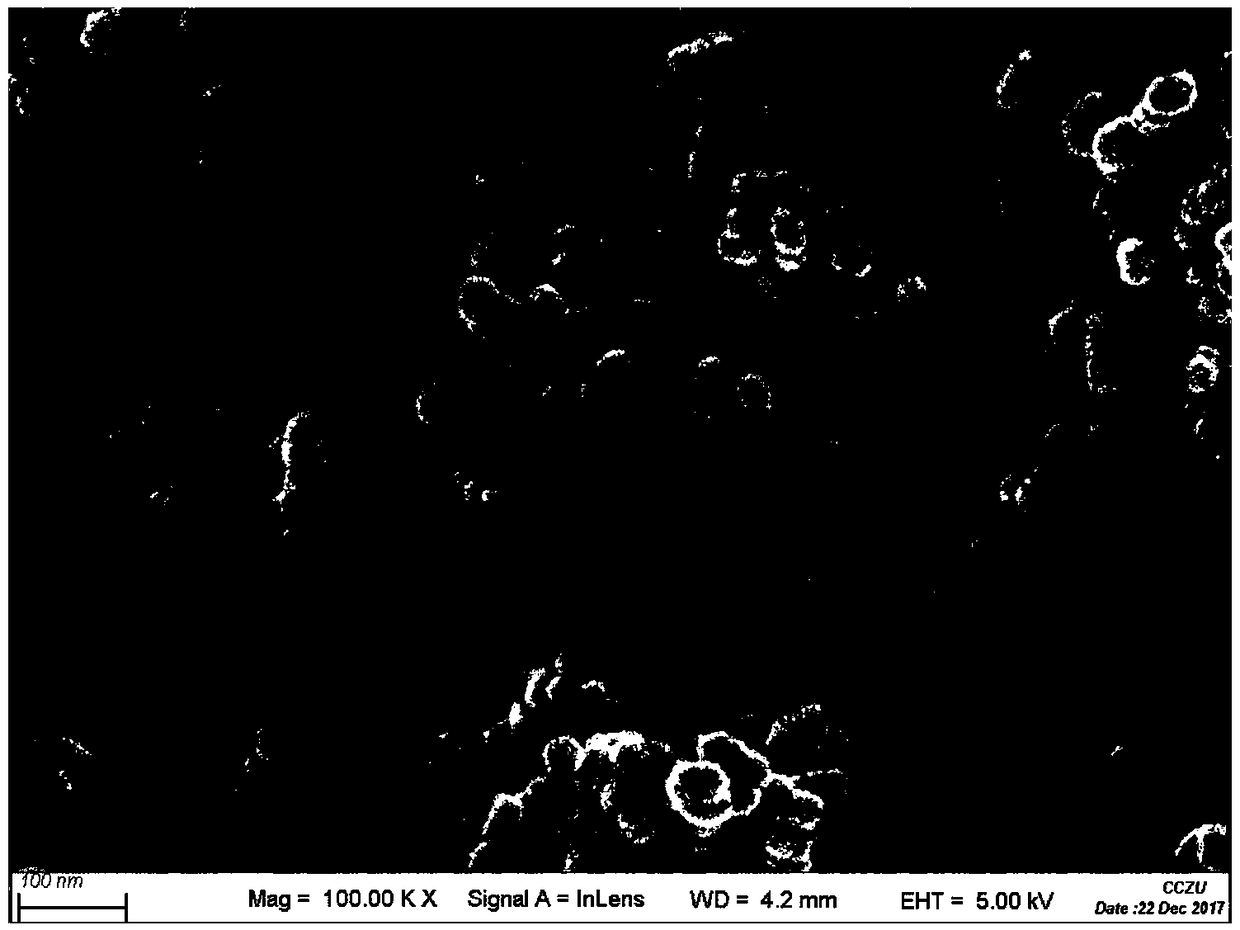

[0030] Prepare the yttrium oxide feed liquid with a concentration of 0.4mol / l, add sodium carbonate according to the molar ratio of yttrium oxide to precipitant: 1:1.6, then add 2% dispersant PEG2000, add positive precipitation dropwise, after the dropwise addition Stir for 1 hour, turn off the stirring and age for 2 hours, then filter with suction, wash until the pH of the washing water is 7, then burn at 850-900°C, keep warm for 1-3 hours, and finally sieve to obtain nanometer rare earth oxides. Tested: Na + : 3178ppm, the scanning electron microscope photo of nano rare earth oxide is as image 3 : Primary particle size: 30-70nm, good particle distribution.

[0031] 2. Washing nano-yttrium oxide to remove sodium ions

[0032] Step 1: Take pure water, heat it to 60°C, and adjust the pH to 0.5-1 with dilute nitric acid to obtain a washing solution;

[0033] Step 2: In the washing solution prepared in step (1), add the nano...

Embodiment 2

[0040] The preparation method of nanometer yttrium oxide is the same as embodiment 1.

[0041] Washing nanometer yttrium oxide to remove sodium ions

[0042] Step 1: Take pure water, heat it to 80°C, and adjust the pH to 1-2 with dilute nitric acid to obtain a washing solution;

[0043] Step 2: In the washing solution prepared in step (1), add the nano-rare earth oxide obtained after precipitation and burning and stir for 0.5h to wash, and filter with suction until it is drained, wherein the ratio of the oxide mass to the washing solution It is 1Kg: 20L.

[0044] Step 3: Repeat step (2) to step (3) for a total of 5 times;

[0045] Step 4: drying the washed and suction-filtered nano-rare earth oxide obtained in step (3) at 120° C., and sieving to obtain the nano-rare earth oxide after removing sodium ions.

[0046] Sodium ions dropped from 3178ppm to 90ppm. The effect is very obvious.

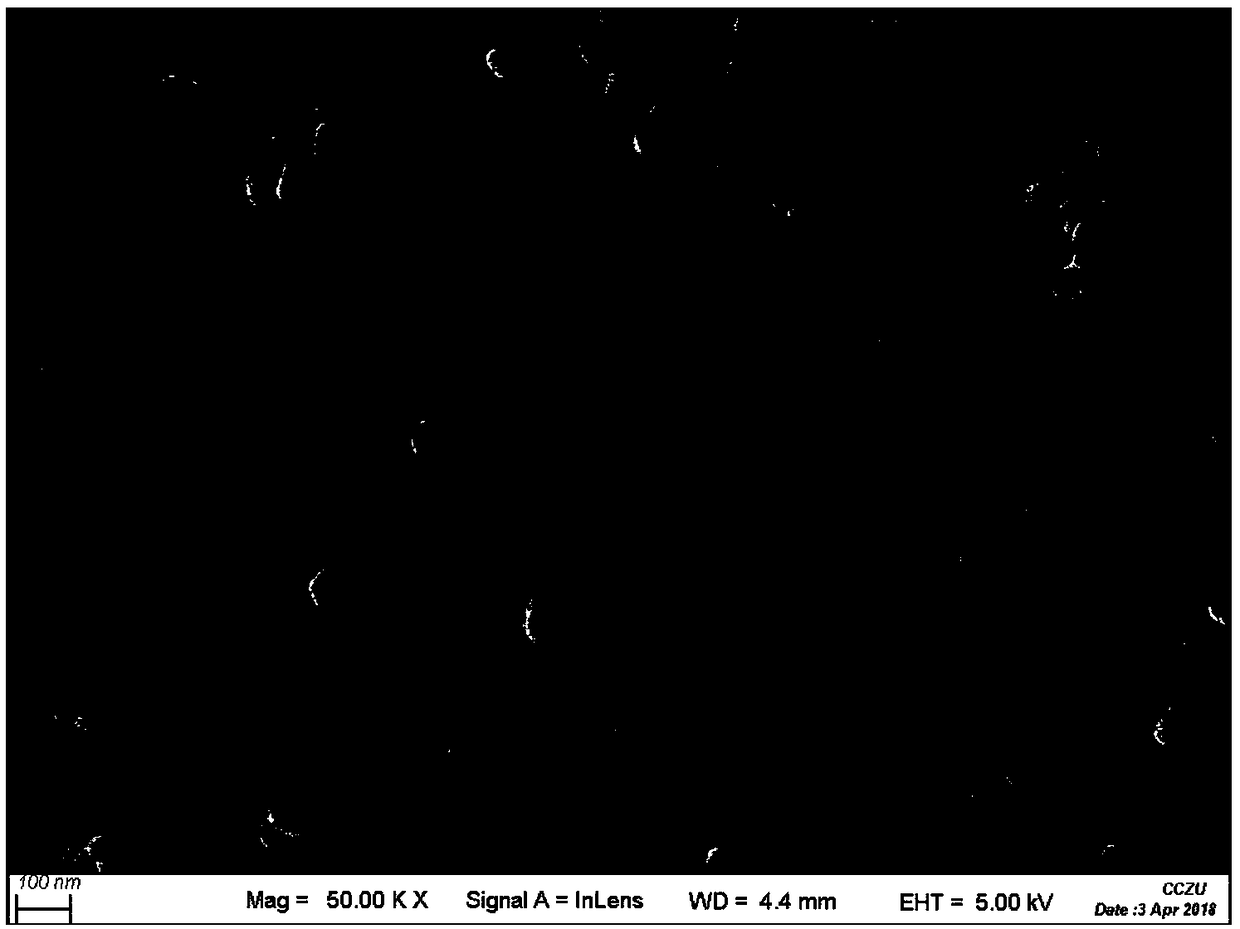

[0047] The primary particle size measured by the scanning electron microscope is 30-70n...

Embodiment 3

[0049] The preparation method of nanometer yttrium oxide is the same as embodiment 1.

[0050] Washing nanometer yttrium oxide to remove sodium ions

[0051] Step 1: Take pure water, heat it to 100°C, and adjust the pH to 2-3 with dilute nitric acid to obtain a washing solution;

[0052] Step 2: In the washing solution prepared in step (1), add the nano-rare earth oxide obtained after precipitation and burning and stir for 0.5h to wash, and filter with suction until it is drained, wherein the ratio of the oxide mass to the washing solution It is 1Kg: 20L.

[0053] Step 3: Repeat steps (2) to (3) for a total of 5 times;

[0054] Step 4: drying the washed and suction-filtered nano-rare earth oxide obtained in step (3) at 135° C., and sieving to obtain the nano-rare earth oxide after removing sodium ions.

[0055] Sodium ions dropped from 3178ppm to 92ppm. The effect is very obvious.

[0056]The primary particle size measured by the scanning electron microscope is 30-70nm, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com