Device and method for carbon fiber precursor washing

A technology of carbon fiber precursor and washing device, which is applied in the direction of processing textile material equipment configuration, liquid/gas/steam yarn/filament processing, continuous processing of textile materials, etc., which can solve the problem of short washing tank length, reduced washing effect, dead Area and other problems, to achieve the effect of increasing the effective stroke, reducing sodium ions, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

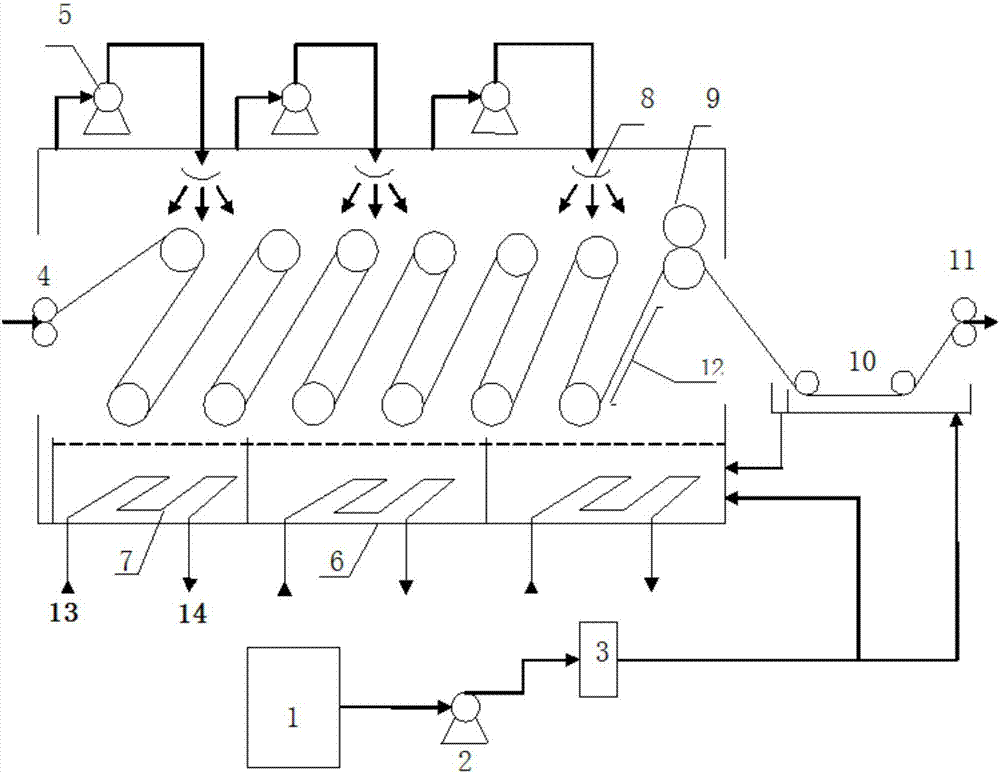

[0042] Such as figure 1 Shown is a device for washing carbon fiber precursors.

[0043] The device is arranged after the pickling treatment in the spinning process.

[0044] The devices include:

[0045] Washing machine godet roller group 9, circulating water tank 6, serpentine heating coil 7, spray water pump 5, spray nozzle 8, rinsing water tank 10, water retaining plate 12;

[0046] The serpentine heating coil 7 is laid on the bottom of the circulating water tank 6 to heat the washing water in the circulating water tank of the washing machine.

[0047] The washing machine godet roller group 9 is arranged above the circulating water tank 6, and the tow coming out of the pickling drawing roller group 4 is drawn through the washing machine by the washing machine godet roller group 9, enters the rinsing tank 10, and then is drawn by the washing drawing roller group 9. Group 11 is pulled to the next procedure.

[0048] The washing water in the circulating water tank 6 is tra...

Embodiment 2

[0055] One-step preparation of carbon fiber using sodium thiocyanate is usually using sodium thiocyanate as a solvent, acrylonitrile, the second monomer methyl acrylate, the third monomer itaconic acid as raw materials, and azobisisobutyronitrile as an initiator. Ternary polymerization reaction, polyacrylonitrile polymerization liquid is obtained after single removal and defoaming. The primary fiber tow is formed by wet spinning, and after the tow is washed with water and pickled, it is used figure 1 The device carries out the washing treatment of the second water washing. The concentration of the pickling solution is 1%, the temperature is 75°C, the tow passes through the pickling solution, and enters the washing machine for secondary washing, the temperature of the secondary washing water is 55°C, and the tow stays in the washing machine for 60 seconds. After washing, enter the rinsing tank, the desalinated water temperature in the rinsing tank is 50°C, the tow and the desa...

Embodiment 3

[0057] One-step preparation of carbon fiber using sodium thiocyanate is usually using sodium thiocyanate as a solvent, acrylonitrile, the second monomer methyl acrylate, the third monomer itaconic acid as raw materials, and azobisisobutyronitrile as an initiator. Ternary polymerization reaction, polyacrylonitrile polymerization liquid is obtained after single removal and defoaming. The primary fiber tow is formed by wet spinning, and after the tow is washed with water and pickled, it is used figure 1 The device carries out the washing treatment of the second water washing. The concentration of the pickling solution is 1%, the temperature is 75°C, the tow passes through the pickling solution, and enters the washing machine for secondary washing, the temperature of the secondary washing water is 60°C, and the tow stays in the washing machine for 120 seconds. After washing, enter the rinsing tank, the desalinated water temperature in the rinsing tank is 50°C, the tow and the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com