Method of manufacturing energy absorption device

An energy-absorbing device and a manufacturing method technology, applied in the field of manufacturing safety protection devices, to achieve good energy-absorbing effect, stable deformation mode, and long effective stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

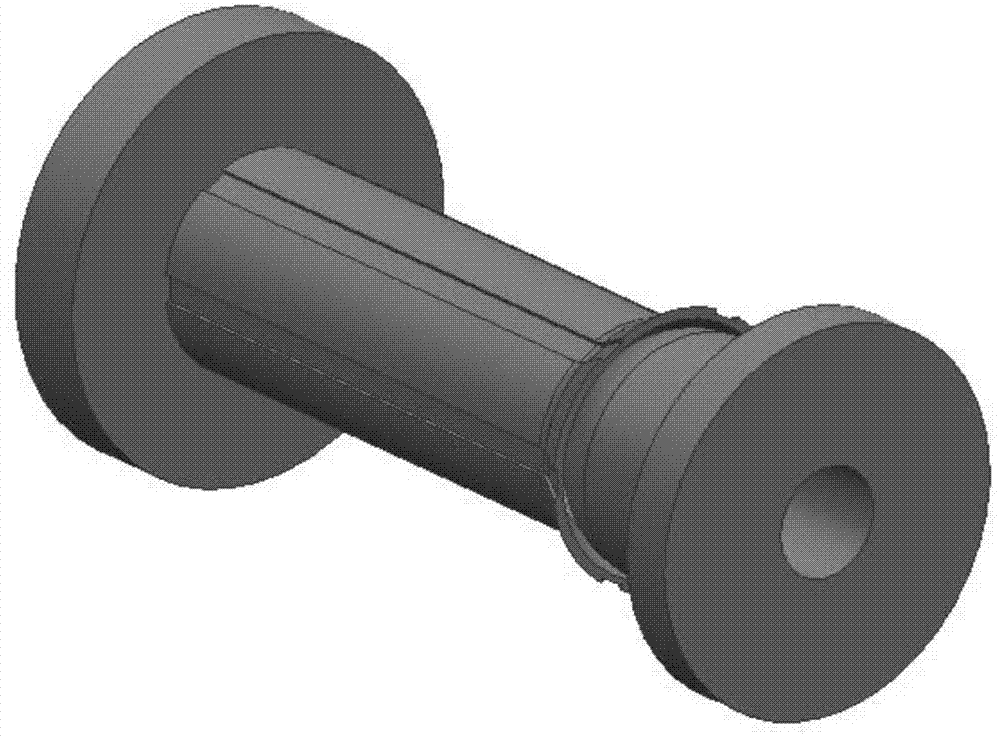

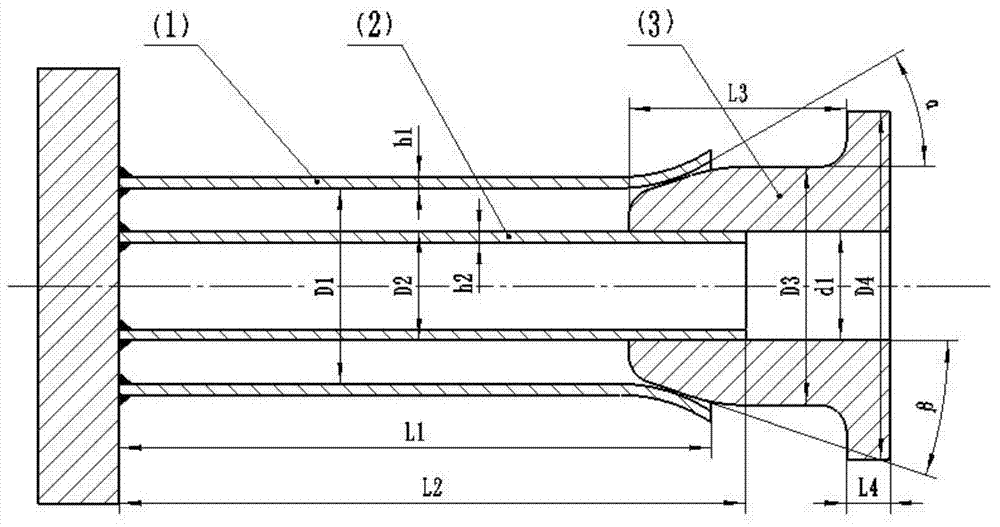

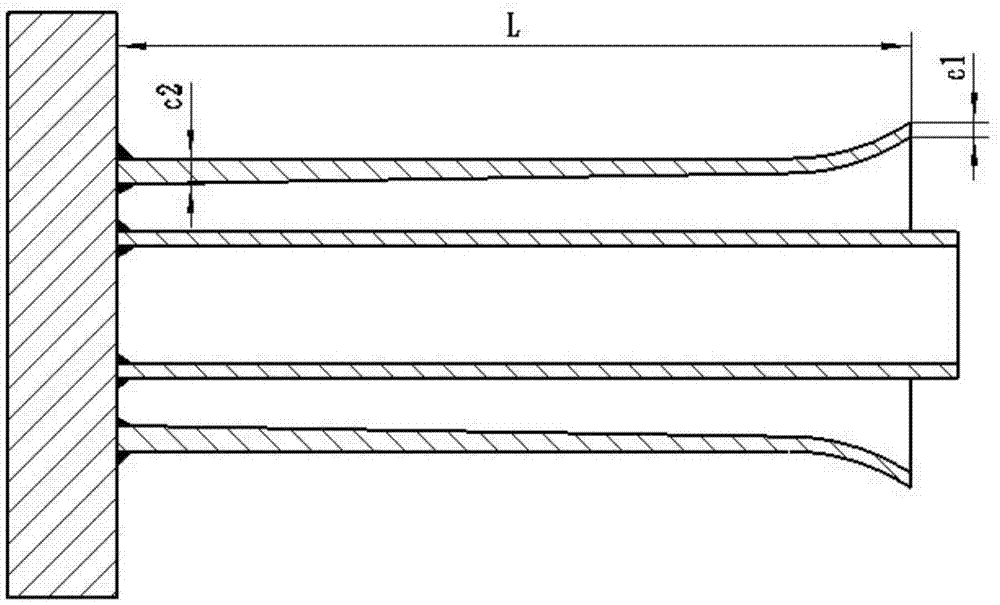

[0033] The inner diameter D1 of the pre-tearing circular tube 1 is 40mm, the wall thickness h1 is 3mm, the length L1 is 90mm, the cone angle α is 20°, the outer diameter D2 of the guide friction circular tube 2 is 22mm, and the wall thickness h2 is 2mm, Length L2=L1+0.4×D1=106mm, the outer diameter of the punch 3 D3=D1×(1+λ)=60mm, where λ is the pre-expansion percentage, the value is 50%, the cone angle β is 17°, and the inner The hole diameter d1=D2=22mm, the outer diameter of the shoulder D4=D3+10=70mm, the matching size of the punch 3 and the guide friction tube in the initial state p=(L2-L1)×112.5%=18mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com