Surf- or sail-board and method of producing the same

a technology of sailboards and surfboards, applied in the direction of skis, snowboards, sports apparatus, etc., can solve the problems of not allowing the position of the fin to be corrected, unable to mount the fins with sufficient strength, and unable to ensure a sufficiently secure attachment, so as to reduce the cost of manufacture, reduce the force exerted by the fin attachment on the surfboard, and reduce the strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

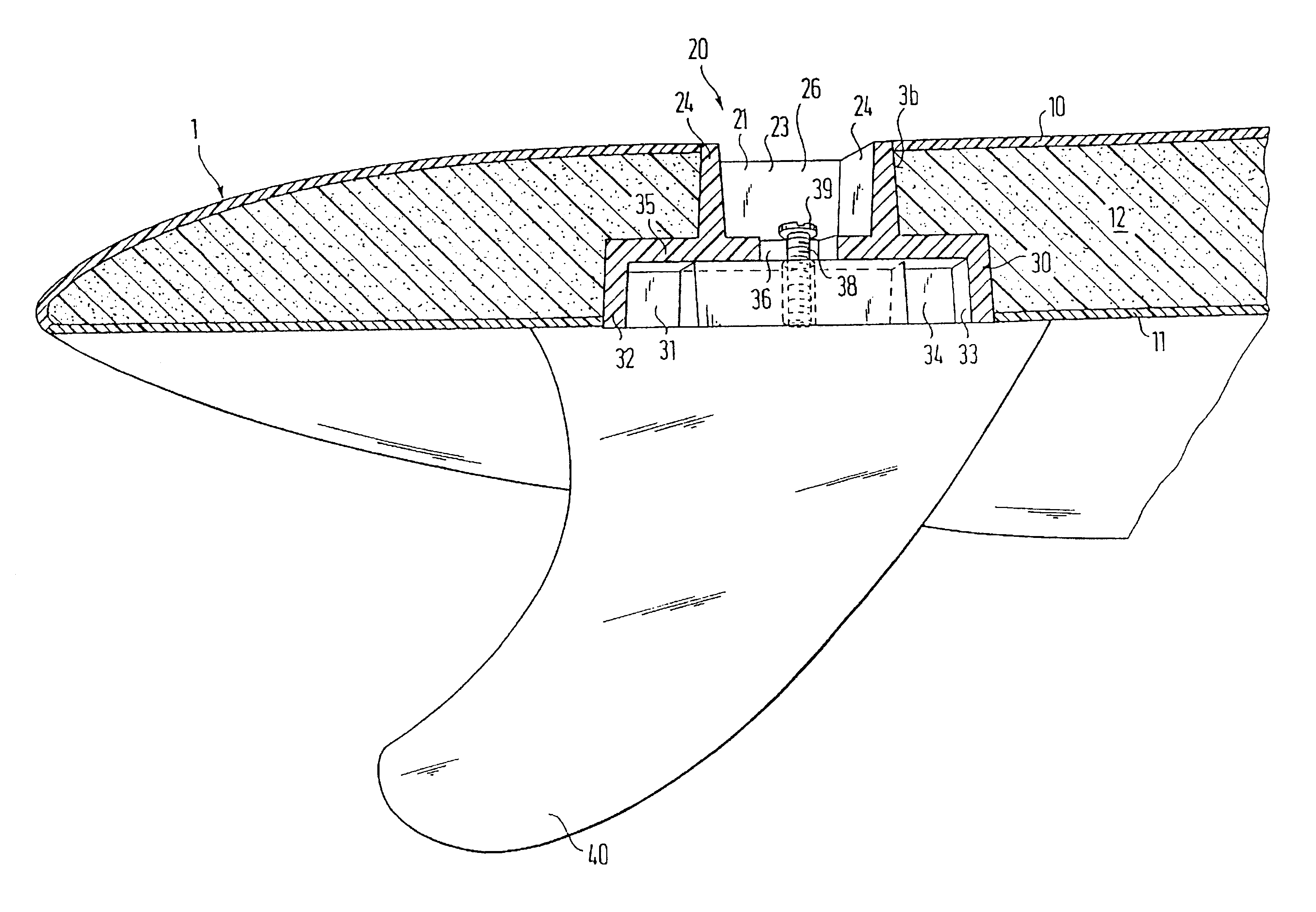

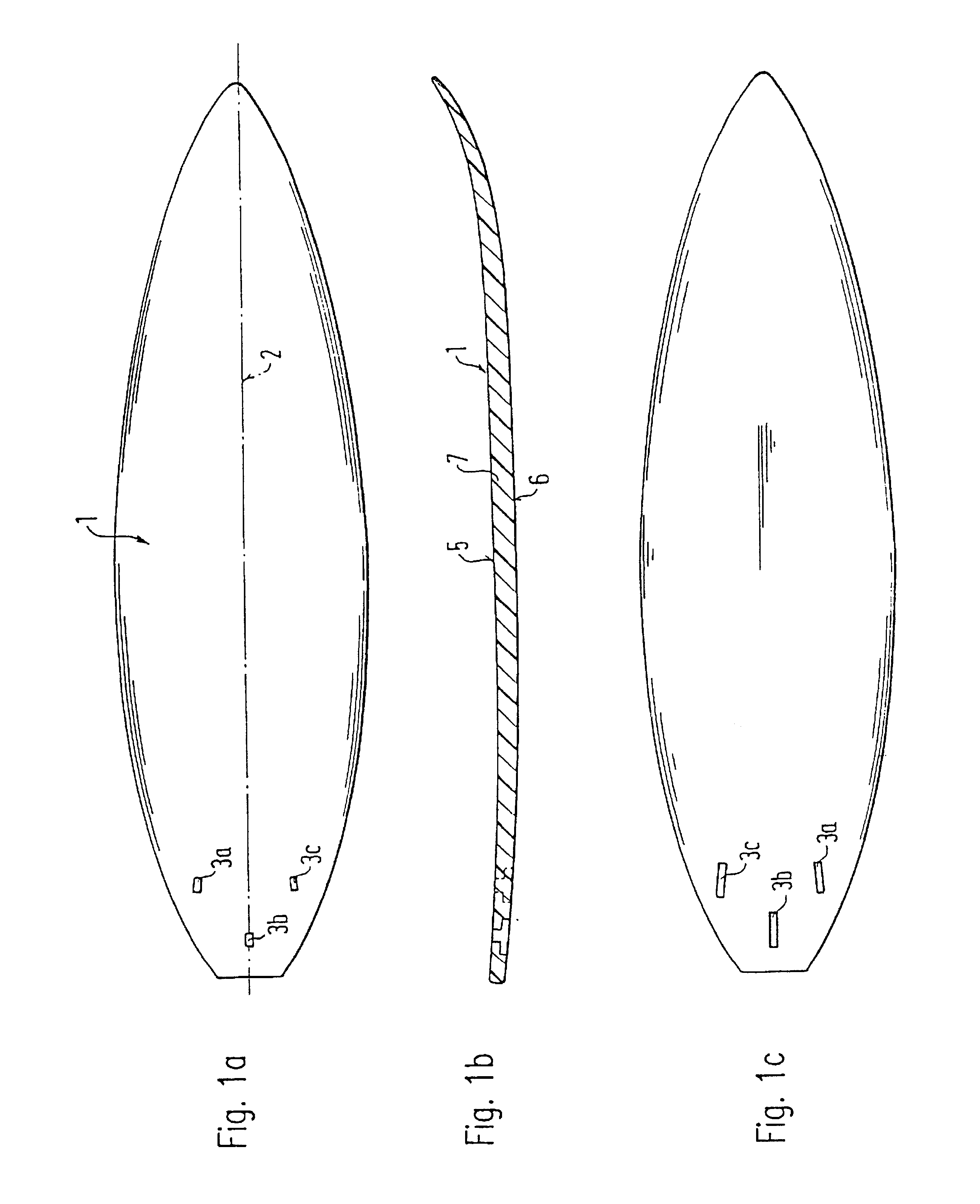

[0039]FIG. 1a shows the top view of a surfboard 1 which is arranged essentially symmetrically to an axis 2 running in the longitudinal direction.

[0040]In the rear region of the surfboard there are three slots 3a, 3b and 3c, the slots 3a and 3c enclosing with their longitudinal axes an acute angle relative to the longitudinal axis 2, while the slot 3b is arranged symmetrically to the longitudinal axis.

[0041]FIG. 1b shows a section through the surfboard according to FIG. 1a, 5 denoting the upper side of the surfboard on which the user stands and 6 denoting the underside which faces the water.

[0042]FIG. 1c shows a bottom view, the slots 3a, 3b and 3c also being visible here.

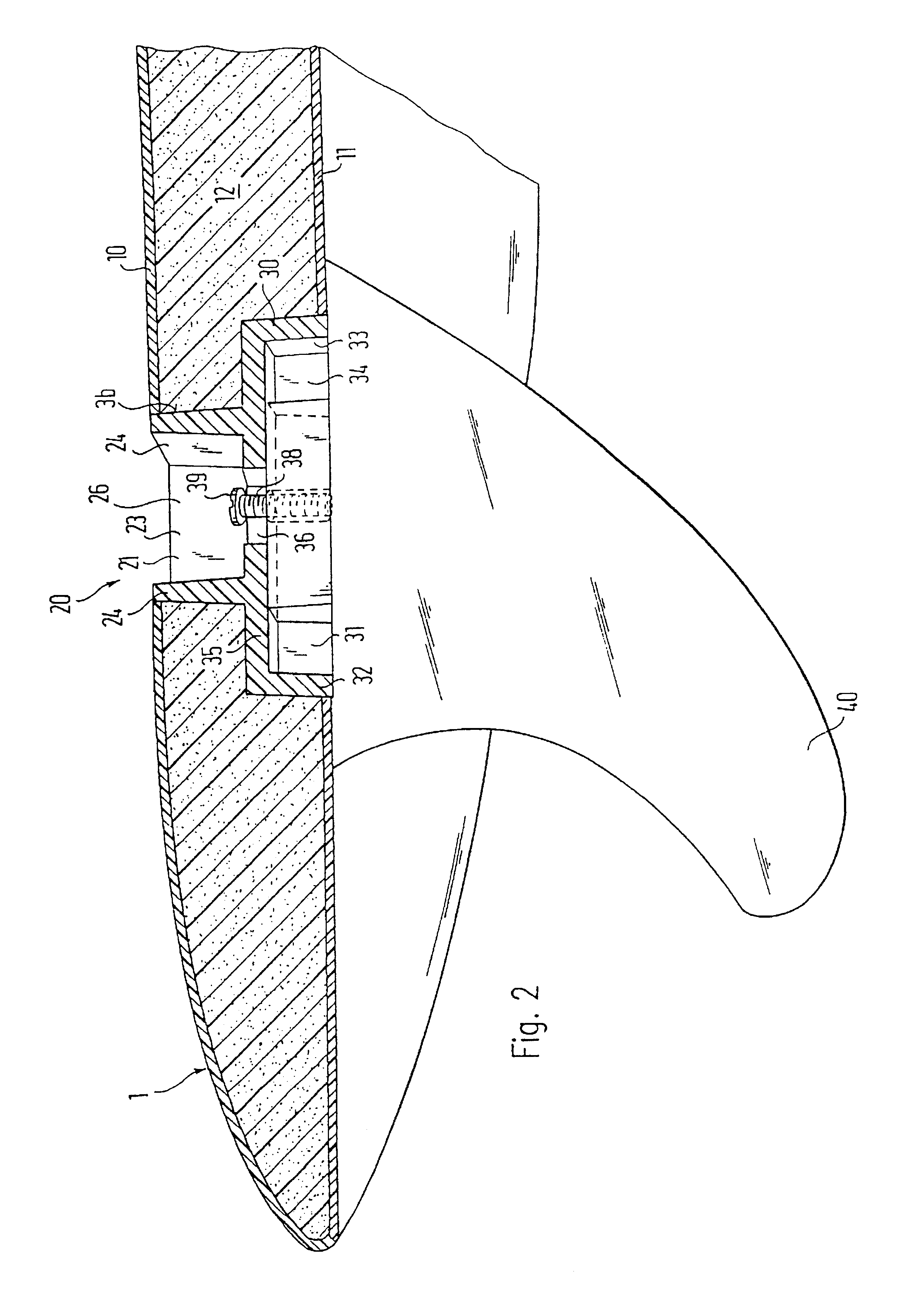

[0043]FIG. 2 shows a section through the surfboard along the axis of symmetry of the slot 3b running in longitudinal directions.

[0044]As can be seen in this section, the surfboard 1 consists of a plastic upper shell 10, a plastic lower shell 11 and a foamed body 12 arranged between them. In the exemplary embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com