Method for preparing cured fish by ultrasonic-assisted low-temperature heating

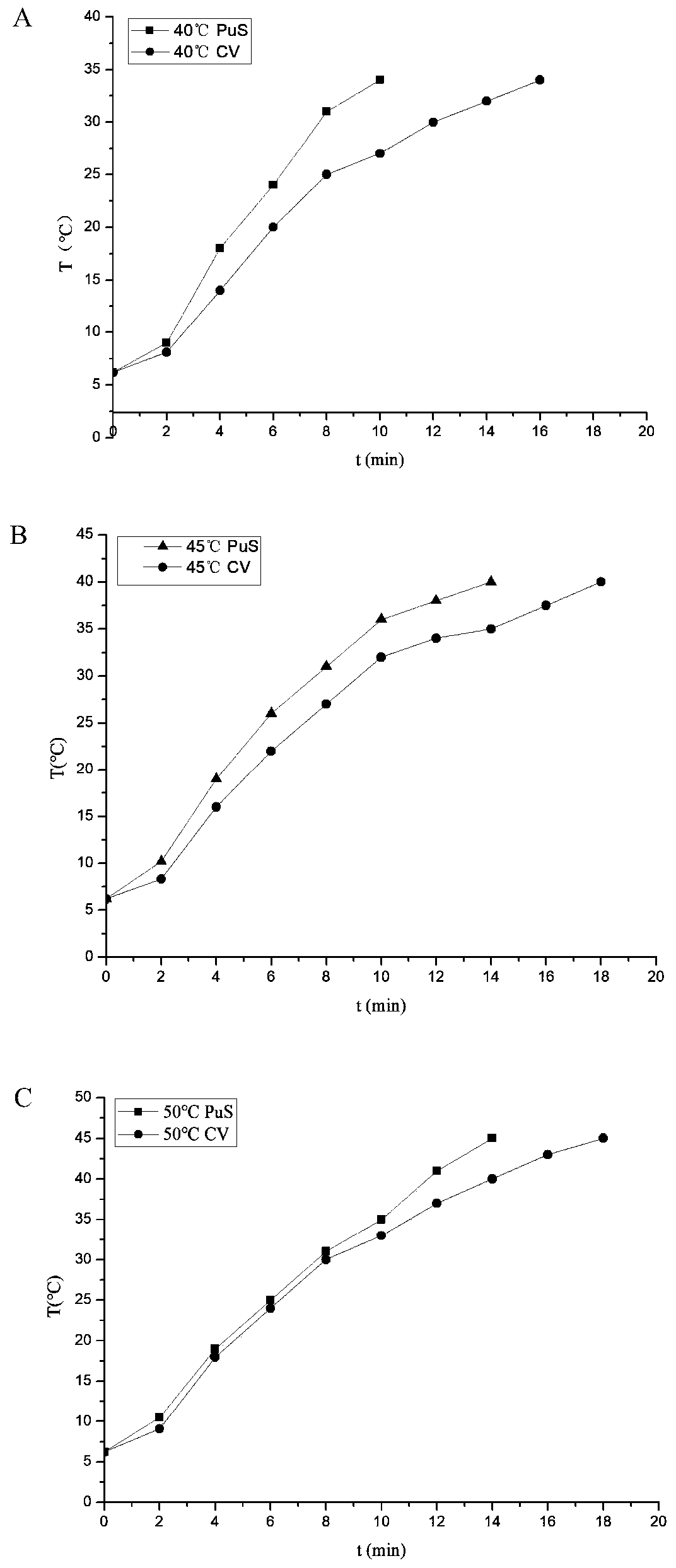

An ultrasonic-assisted, low-temperature technology is applied in food processing, preservation of meat/fish with chemicals, preservation of meat/fish through radiation/electrical treatment, etc. Long curing time and other problems, to achieve the effect of solving uneven water distribution, reducing sodium salt content, and shortening curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

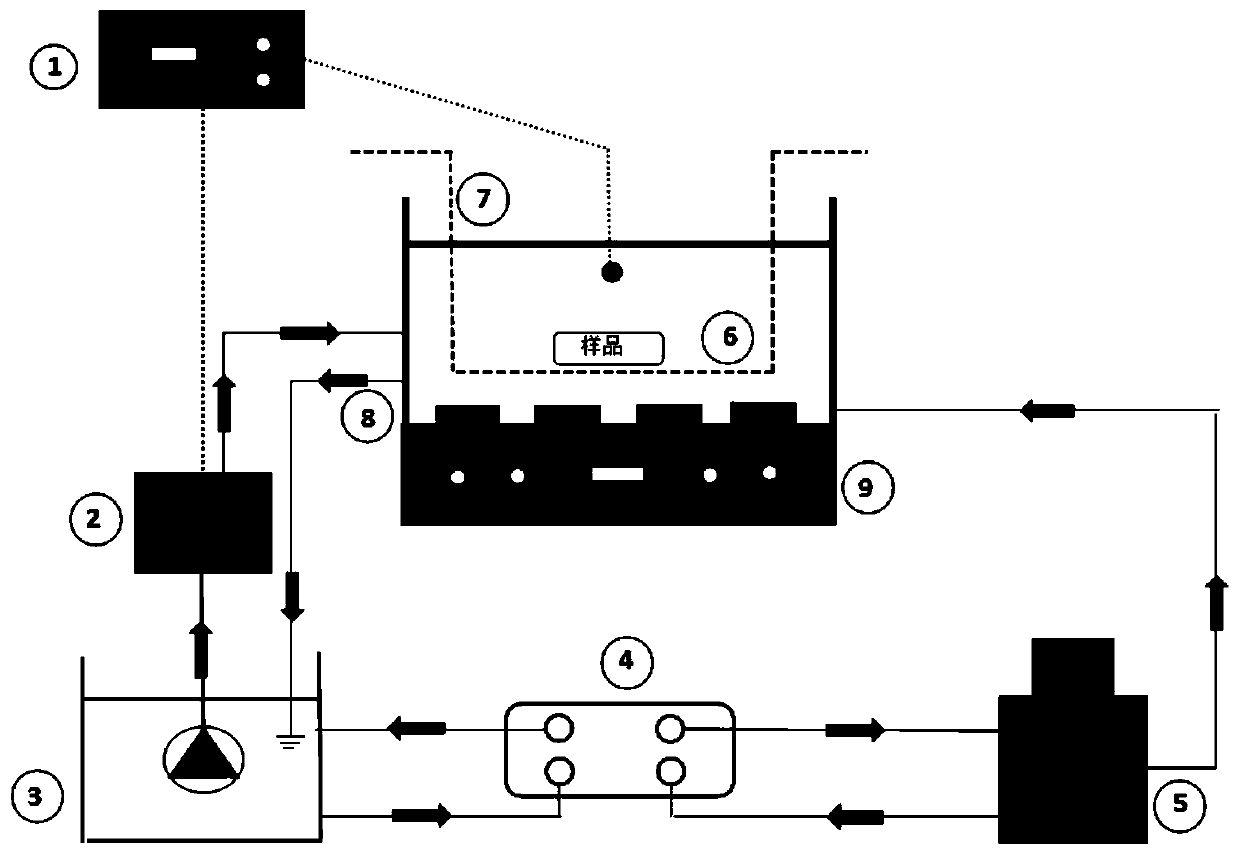

Method used

Image

Examples

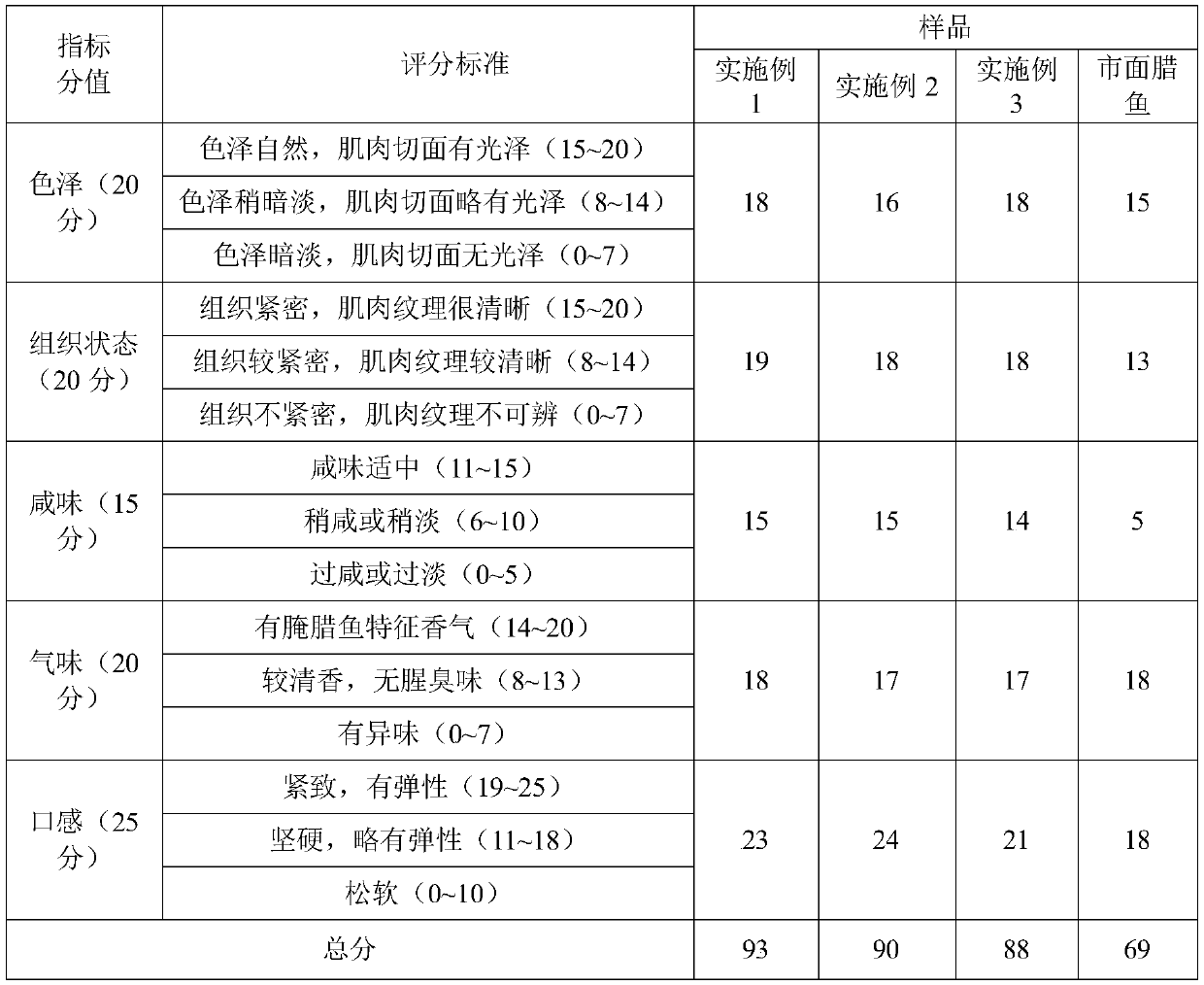

Embodiment 1

[0038] A method for preparing salted fish with power ultrasonic assisted low-temperature heating, comprising the following steps:

[0039] A. Pretreatment: Live grass carp is killed by beating the head, cut open the belly, remove the head, tail, viscera and black film, cut the fish fillets along the spine, and wash the surface of the fish fillets with 2% light salt water Blood stains, drain at room temperature.

[0040] B. pickling: the quality of the pickling liquid consists of 4% potassium chloride, 4% sodium chloride, 2% salty peptide (ornithine taurine, produced by Weikang Company in the United States), 2% mushroom powder, orange peel powder (Bozhou Deyongtang Biotechnology Co., Ltd.) 3%, sage powder (produced by Xi'an Baoyifeng Biotechnology Co., Ltd.) 0.5%, sodium ascorbate 2%, garlic powder 2%, monascus pigment 0.5%, the rest water, mixed evenly, to prepare a pickling liquid, put the drained fish into the pickling liquid to marinate, control the mass ratio of material ...

Embodiment 2

[0046] A method for preparing salted fish with power ultrasonic assisted low-temperature heating, comprising the following steps:

[0047] A. Pretreatment: Live grass carp is killed by beating the head, cut open the belly, remove the head, tail, viscera and black film, cut the fish fillets along the spine, and wash the surface of the fish fillets with 2% light salt water Blood stains, drain at room temperature.

[0048] B. Pickling: the mass composition of the pickling solution is 3% potassium chloride, 3% sodium chloride, 3% salty peptide, 2% mushroom powder, 3% orange peel powder, 0.5% sage powder, and 2% sodium ascorbate. %, garlic powder 2%, monascus pigment 0.5%, and the rest is water, mix evenly to make a pickle solution, put the drained fish into the pickle solution to marinate, and control the mass ratio of material to liquid to be 1:4 , and then ultrasonically treated for 1h under 20KHz ultrasonic conditions.

[0049] C. Drying: temperature 15°C, wind speed 1.5m / s, ...

Embodiment 3

[0054] A method for preparing salted fish with power ultrasonic assisted low-temperature heating, comprising the following steps:

[0055] A. Pretreatment: Live grass carp is killed by beating the head, cut open the belly, remove the head, tail, viscera and black film, cut the fish fillets along the spine, and wash the surface of the fish fillets with 2% light salt water Blood stains, drain at room temperature.

[0056] B. Pickling: the mass composition of the pickling solution is 3% potassium chloride, 2% sodium chloride, 3% salty peptide, 2% mushroom powder, 3% orange peel powder, 0.5% sage powder, and 2% sodium ascorbate. %, garlic powder 2%, monascus pigment 0.5%, and the rest is water, mix evenly to make a pickle solution, put the drained fish into the pickle solution to marinate, and control the mass ratio of material to liquid to be 1:3 , and then ultrasonically treated for 1h under 20KHz ultrasonic conditions.

[0057] C. Drying: temperature 20°C, wind speed 1.5m / s, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com