Method for washing nickel-cobalt-manganese ternary precursor to remove impurity sodium

A nickel-cobalt-manganese ternary and precursor technology, applied in the manufacture of electrical components, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of corrosion of calcining equipment, performance degradation of ternary positive electrode materials, polluting gases, etc., to reduce sodium The effect of ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

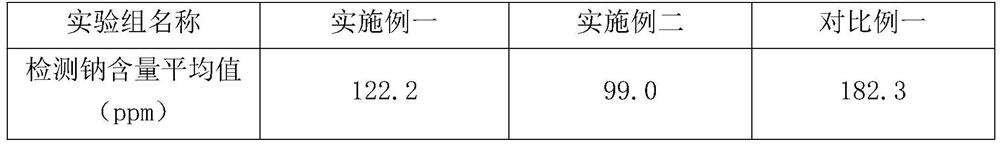

Embodiment 1

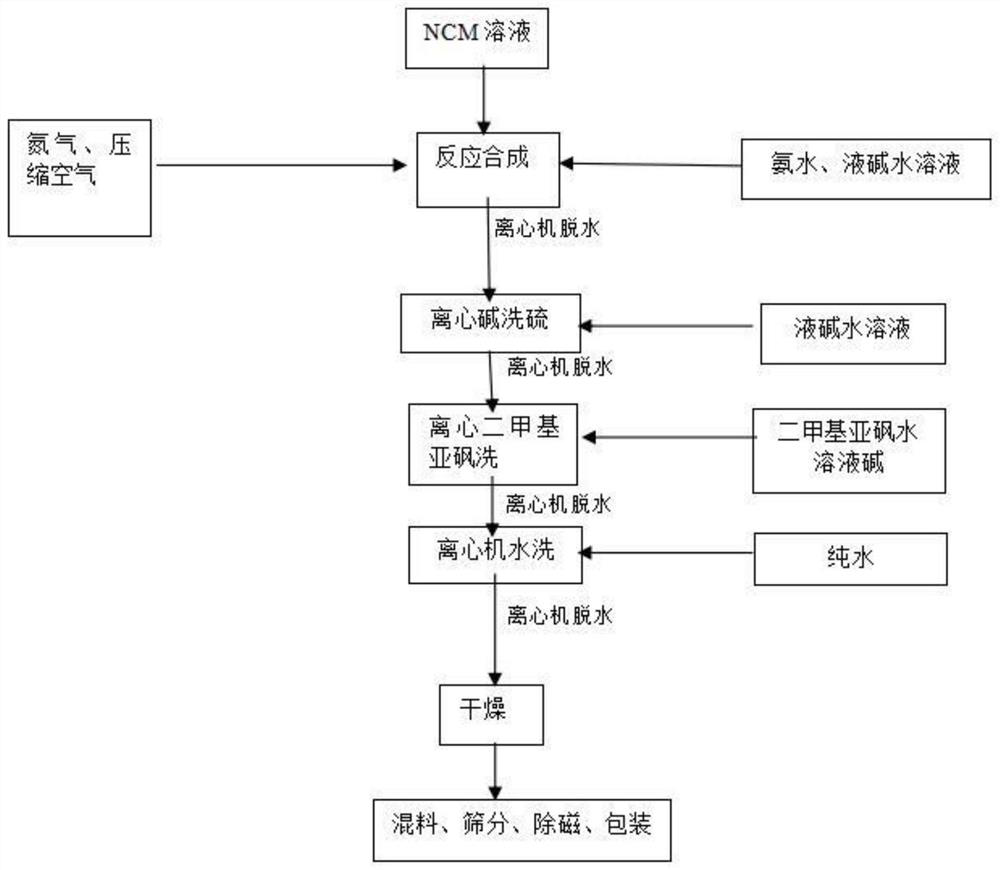

[0023] Wash the nickel-cobalt-manganese ternary precursor crude product as follows:

[0024] (1) will 1m 3 The solid-liquid mixture of the crude product of the nickel-cobalt-manganese ternary precursor (all the examples and comparative examples use the same batch of slurry, with a particle size of 3.5-3.8um) was dehydrated at a medium speed for 30 minutes with a centrifuge to obtain a solid ternary precursor crude product;

[0025] (2) use 1m 3 A sodium hydroxide solution with a concentration of 0.15 mol / L is used to spray and wash the crude solid ternary precursor to remove sulfate ions on the surface, and then use a centrifuge to dehydrate at a medium speed for 25 minutes to obtain a dehydrated solid phase;

[0026] (3) Use 0.5m 3 Spray and wash the dehydrated solid phase with an aqueous solution of dimethyl sulfoxide at a concentration of 0.15 mol / L, and then use a centrifuge to dehydrate at a medium speed for 30 minutes to obtain a solid material;

[0027] (4) Use 3m ...

Embodiment 2

[0029] Wash the nickel-cobalt-manganese ternary precursor crude product as follows:

[0030] (1) will 1m 3 The solid-liquid mixture of the crude product of the nickel-cobalt-manganese ternary precursor (all the examples and comparative examples use the same batch of slurry, with a particle size of 3.5-3.8um) was dehydrated at a medium speed for 30 minutes with a centrifuge to obtain a solid ternary precursor crude product;

[0031] (2) use 1m 3 A sodium hydroxide solution with a concentration of 0.15 mol / L is used to spray and wash the crude solid ternary precursor to remove sulfate ions on the surface, and then use a centrifuge to dehydrate at a medium speed for 25 minutes to obtain a dehydrated solid phase;

[0032] (3) Use 1m 3 Spray and wash the dehydrated solid phase with an aqueous solution of dimethyl sulfoxide at a concentration of 0.3 mol / L, and then use a centrifuge to dehydrate at a medium speed for 30 minutes to obtain a solid material;

[0033] (4) Use 3m 3 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com