Microspheric ionomer having crosslinking structure, and preparation method and application thereof

A technology of cross-linked structure and ionomer, applied in the field of microspherical ionomer and its preparation, to achieve the effect of comprehensive utilization and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

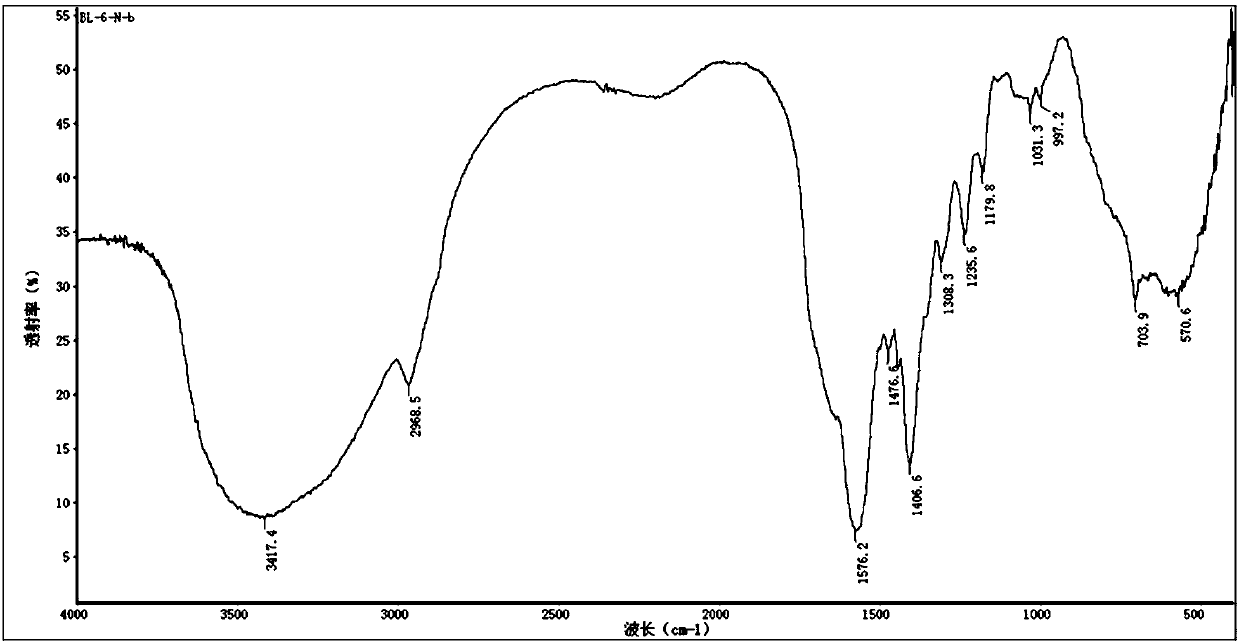

[0023] The method for preparing the microspherical ionomer with cross-linked structure provided by the invention comprises:

[0024] (1) In an organic solvent, in the presence of the first part of the initiator, the maleic anhydride and the first part of the monomer M are contacted to react, and then the solution containing the cross-linking agent is introduced to continue the reaction, wherein the cross-linking agent-containing The solution contains crosslinking agent, optional second part of monomer M and optional second part of initiator, monomer M is provided by carbon four and / or carbon five;

[0025] (2) In the presence of water, the product obtained in step (1) is contacted with an alkali for salinization (or hydrolysis).

[0026] The amount ratio of maleic anhydride to monomer M (mixed olefins, carbon four and / or carbon five) can be a conventional choice, but in a preferred embodiment of the present invention, relative to the maleic anhydride of 100mol, the first part ...

Embodiment 1

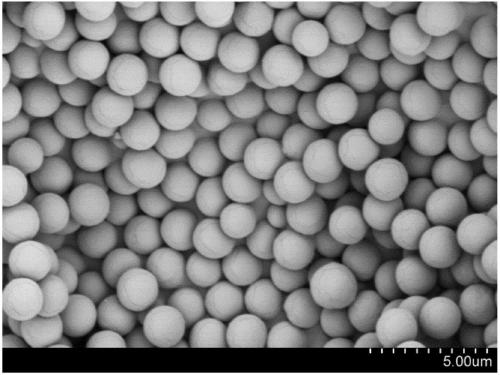

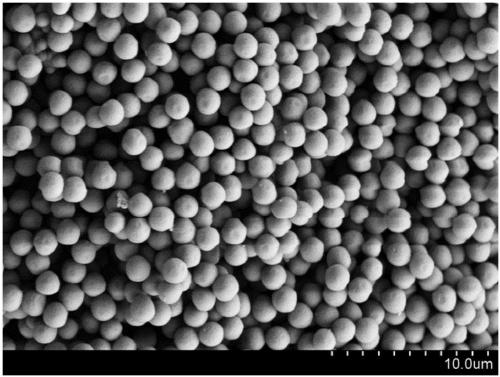

[0048] This example is used to illustrate the microspherical ionomer (or ionomer microsphere) with a cross-linked structure of the present invention and its preparation method.

[0049] (1) mixed butene gas is composed of: trans-2-butene, 40.83% by weight; cis-2-butene, 18.18% by weight; n-butane, 24.29% by weight; n-butene, 9.52% by weight; isobutene, 2.78% by weight %; others, 4.4% by weight. Maleic anhydride 100g and azobisisobutyronitrile 6g are dissolved in 800mL isoamyl acetate to form a solution one, and the mixed butenes (the moles of effective components (terminal olefins) in maleic anhydride and mixed olefins) that pass into metered The ratio is 1:1), under nitrogen atmosphere, react at 70°C and 0.5MPa for 1 hour;

[0050] (2) 25 g of divinylbenzene was dissolved in 200 mL of isoamyl acetate to form solution 2. Solution 2 was added to the reaction system by a plunger pump and added dropwise for 2 hours. After the addition was completed, the reaction system was kept ...

Embodiment 2

[0054] This example is used to illustrate the ionomer microspheres of the present invention and its preparation method.

[0055](1) Maleic anhydride 100g and azobisisobutyronitrile 5g are dissolved in 800mL isoamyl acetate to form solution one, and the mixed butenes (composition is the same as in Example 1, maleic anhydride and mixed olefins) The molar ratio of effective components (terminal olefins) is 1:1), under nitrogen atmosphere, react at 70°C and 0.4MPa for 2 hours;

[0056] (2) 15 g of divinylbenzene was dissolved in 200 mL of isoamyl acetate to form solution 2. Solution 2 was added to the reaction system by a plunger pump and added dropwise for 2 hours. After the addition was completed, the reaction system was kept warm for 3 hours.

[0057] (3) Release the pressure after the reaction, add 200 mL (15 wt%) of sodium acetate aqueous solution, and react at 100° C. for 3 hours. After the reaction, the system is statically separated, the heavy phase is centrifuged at 5000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com