Modified polypropylene resin and preparation method thereof

A polypropylene resin and modification technology, applied in the field of polypropylene, can solve the problems of high nucleating agent content and non-water-soluble nucleating agent, and achieve the effects of simple preparation process, low processing cost and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

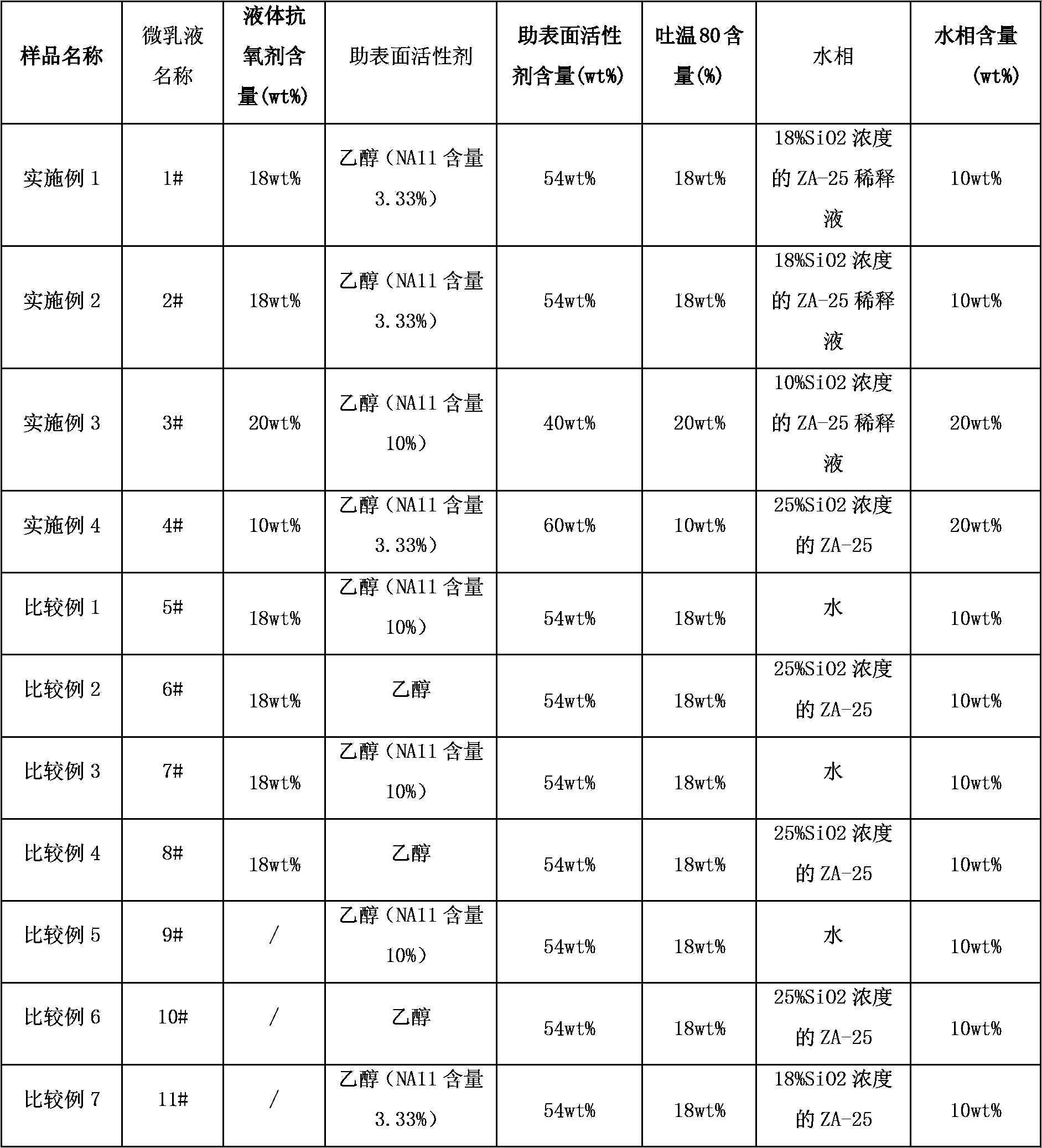

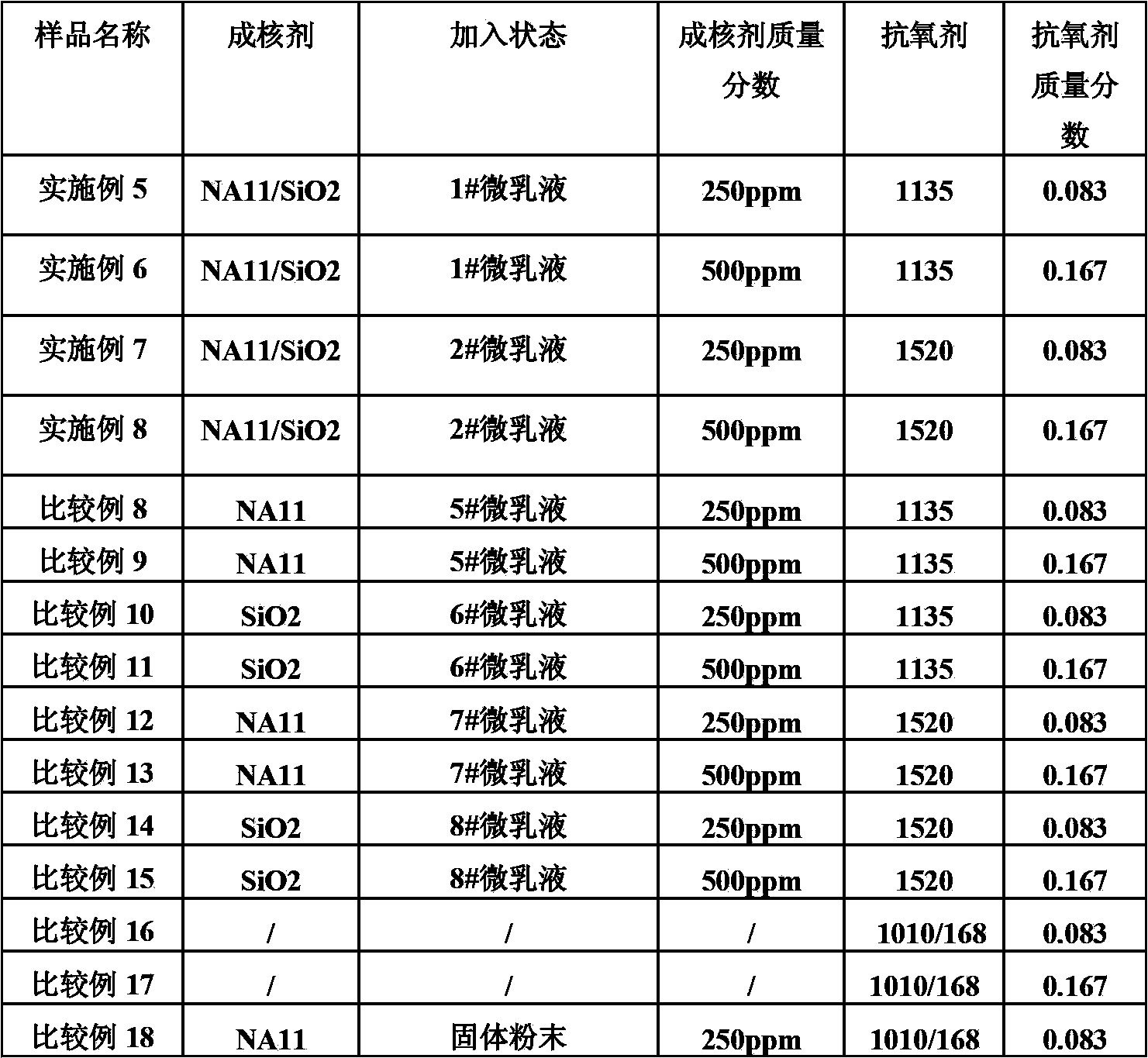

Embodiment 1

[0033] NA11[2,2'-methylenemetha-bis(4,6-di-n-butylphenol)sodium phosphate] (Zhongda Chemical Co., Ltd., brand NP-508) was dissolved in absolute ethanol ( analytically pure); dilute the silica sol with deionized water to a deionized aqueous solution with a silica particle concentration of 18wt%; stir with a magnetic stirrer, add in sequence the absolute ethanol in which NA11 has been dissolved, and 1135 liquid antioxidant [β -(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate, Guangzhou Zhiyi Trading Co., Ltd.], Tween 80 (commercially available), deionized water dispersed with silica, The mass percentages of the above components are 54wt%, 18wt%, 18wt%, and 10wt%, respectively. A magnetic stirrer is used for stirring. The rotational speed of the magnetic stirrer is 200 rpm (revolutions per minute), and the stirring time is 5 minutes. The mixed microemulsion obtains 1# binary composite nucleating agent.

Embodiment 2

[0035] NA11[2,2'-methylenemetha-bis(4,6-di-n-butylphenol)sodium phosphate] (Zhongda Chemical Co., Ltd., brand NP-508) was dissolved in absolute ethanol ( analytically pure); dilute the silica sol with deionized water to a deionized aqueous solution with a silica particle concentration of 18wt%; stir with a magnetic stirrer, add in turn the absolute ethanol in which NA11 has been dissolved, and 1520 liquid antioxidant [2 , 4-bis(n-octylthiomethylene) o-cresol, Guangzhou Zhiyi Trading Co., Ltd.], Tween 80 (commercially available), deionized water dispersed with silicon dioxide, the mass percentage of the above components The contents are 54wt%, 18wt%, 18wt%, and 10wt%, respectively. A magnetic stirrer is used for stirring. The rotating speed of the magnetic stirrer is 200 rpm (revolutions per minute), and the stirring time is 5 minutes. The mixed microemulsion obtains 2# binary composite nucleating agent.

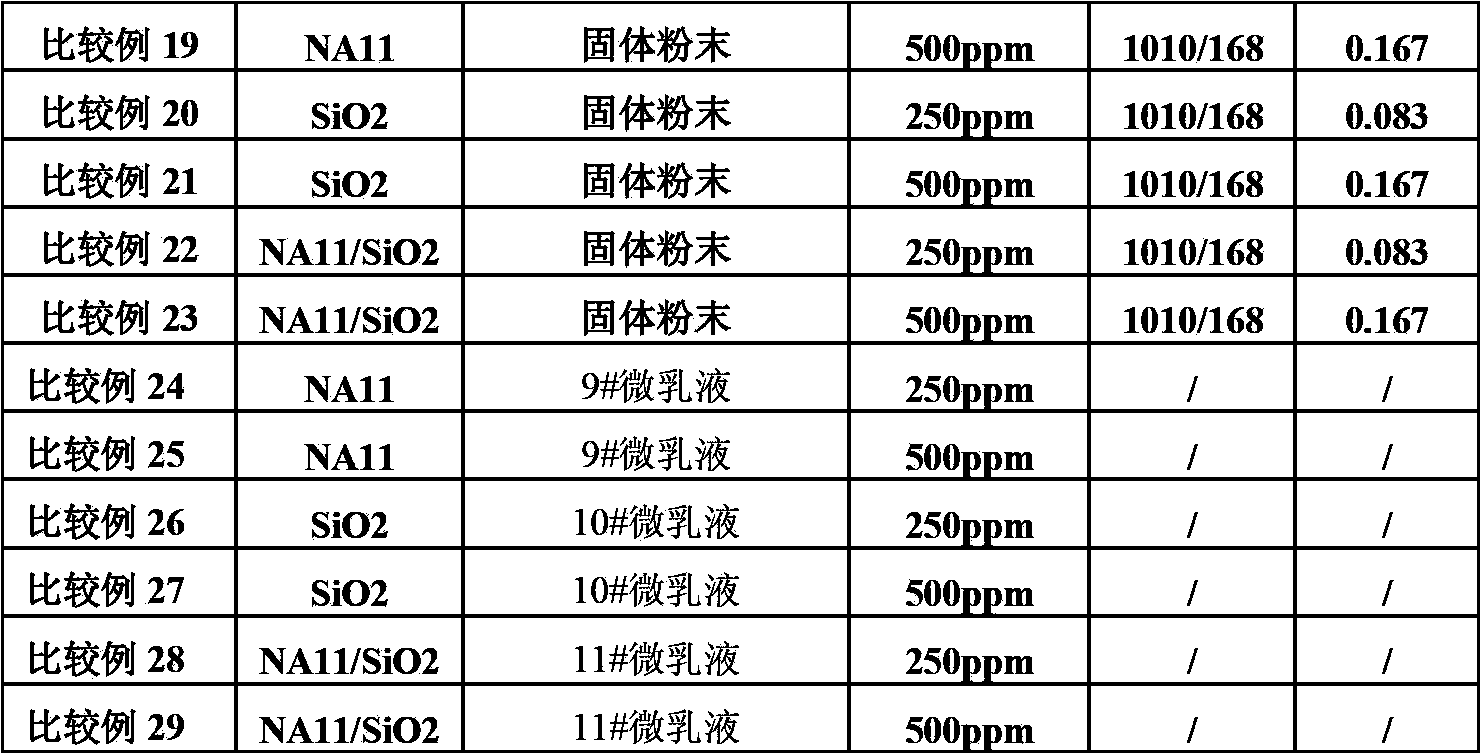

Embodiment 3

[0037]NA11[2,2′-methylenemetha-bis(4,6-di-n-butylphenol)sodium phosphate] (Zhongda Chemical Co., Ltd., brand NP-508) was dissolved in absolute ethanol at a concentration of 10wt% (analytical pure); dilute the silica sol with deionized water to a deionized aqueous solution with a silica particle concentration of 10wt%; stir with a magnetic stirrer, add in sequence the absolute ethanol in which NA11 is dissolved, and 1135 liquid antioxidant [β- (3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate, Guangzhou Zhiyi Trading Co., Ltd.], Tween 80 (commercially available), deionized water dispersed with silica, the above The mass percentages of the components are 40wt%, 20wt%, 20wt%, and 20wt%, respectively. A magnetic stirrer is used for stirring. The rotational speed of the magnetic stirrer is 200 rpm (rotation per minute), and the stirring time is 5 minutes. The mixed microemulsion obtains 3# binary composite nucleating agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com