Organic waste water ozone oxidation catalyst and preparation method and application thereof

A technology of ozone oxidation and organic wastewater, applied in the field of oxidants, can solve the problems of low ozone utilization rate, high operating cost, and restrictions on the promotion and application of ozone oxidation technology, and achieve the effect of improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

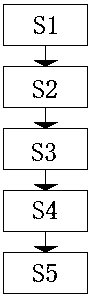

Image

Examples

Embodiment 1

[0021] An organic wastewater ozone oxidation catalyst, the organic wastewater ozone oxidation catalyst raw materials include: 0.6 mass parts of active metal, 20 mass parts of titanium dioxide, 41 mass parts of aluminum oxide, the aluminum oxide is spherical, and three The diameter of aluminum oxide is 2.4mm, 14 parts by mass of manganese dioxide, and 8.2 parts by mass of activated carbon. The active metals include titanium, copper, zinc, nickel and manganese. The activated carbon needs to be immersed in zinc acetate alcohol solution for processing. The time is 1.5 h, and the mass ratio of titanium, copper, zinc, nickel and manganese is 1.2:3:2:1.6:2.2.

[0022] A preparation method of organic wastewater ozonation catalyst, comprising the following steps:

[0023] S1) Carrier preparation: add Al2O3 particles to an ethanol solution with a volume fraction of 65%, wash with shaking at 28-32°C, wash three times in a row, and then add the Al2O3 particles to volume Remove the oxide ...

Embodiment 2

[0030] An organic wastewater ozone oxidation catalyst, the organic wastewater ozone oxidation catalyst raw materials include: 0.7 parts by mass of active metal, 21 parts by mass of titanium dioxide, 42 parts by mass of aluminum oxide, the aluminum oxide is spherical, and three The diameter of aluminum oxide is 2.4-2.8mm, 15 parts by mass of manganese dioxide, and 8.3 parts by mass of activated carbon. The active metals include titanium, copper, zinc, nickel and manganese. The activated carbon needs to be immersed in zinc acetate alcohol solution for processing , the treatment time is 1.5h, and the mass ratio of titanium, copper, zinc, nickel and manganese is 1.2:3:2:1.6:2.2.

[0031] A preparation method of organic wastewater ozonation catalyst, comprising the following steps:

[0032] S1) Carrier preparation: add Al2O3 particles to an ethanol solution with a volume fraction of 66%, wash with shaking at 28-32°C, wash three times in a row, and then add the Al2O3 particles to vo...

Embodiment 3

[0039] An organic wastewater ozone oxidation catalyst, the organic wastewater ozone oxidation catalyst raw materials include: 0.8 mass parts of active metal, 22 mass parts of titanium dioxide, 43 mass parts of aluminum oxide, the aluminum oxide is spherical, and three The diameter of aluminum oxide is 2.4-2.8mm, 16 parts by mass of manganese dioxide, and 8.9 parts by mass of activated carbon. The active metals include titanium, copper, zinc, nickel and manganese. The activated carbon needs to be immersed in zinc acetate alcohol solution for treatment , the treatment time is 1.5h, and the mass ratio of titanium, copper, zinc, nickel and manganese is 1.2:3:2:1.6:2.2.

[0040] A preparation method of organic wastewater ozonation catalyst, comprising the following steps:

[0041] S1) Carrier preparation: add Al2O3 particles to an ethanol solution with a volume fraction of 68%, wash with shaking at 28-32°C, and wash three times in a row, then add the Al2O3 particles to the volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com