Manufacturing method of regenerated collagen fiber

A manufacturing method and collagen fiber technology, applied in the direction of animal fiber, fiber treatment, anti-shrinkage fiber, etc., can solve the problems of appearance and feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

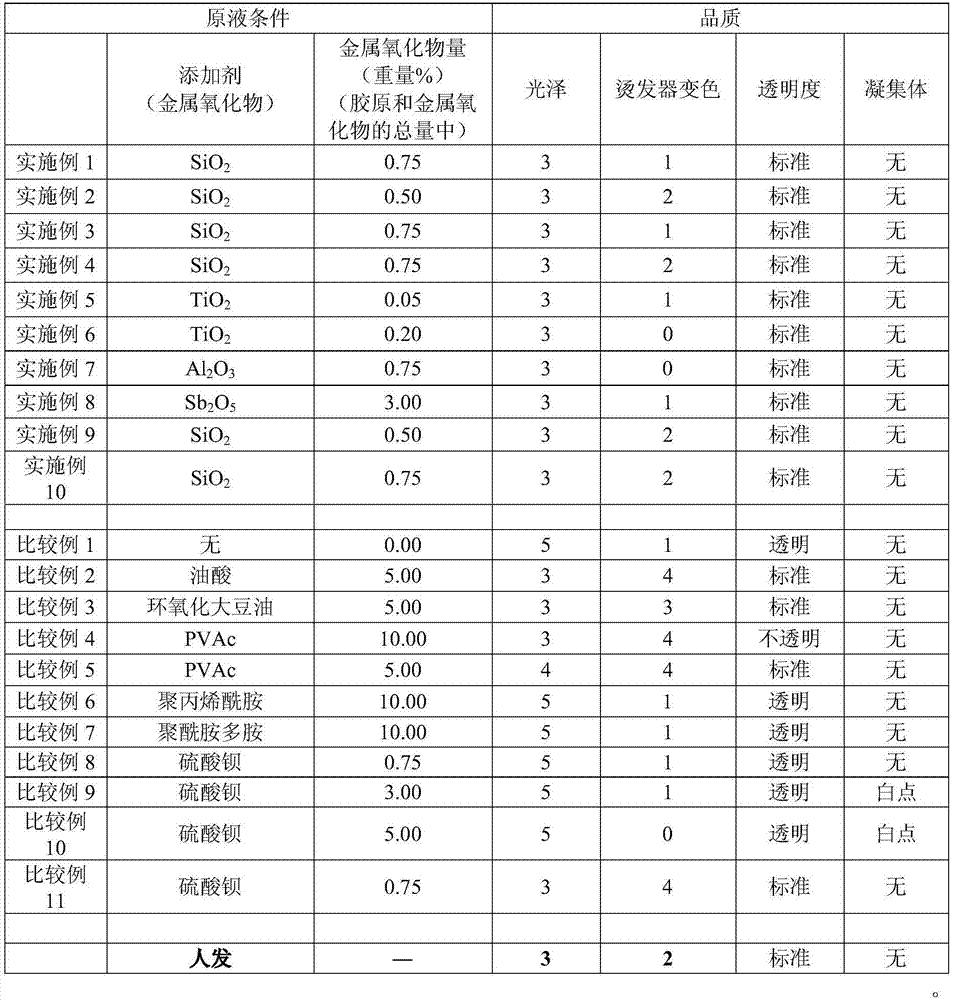

[0075] (Manufacturing example 1) Production of collagen stock solution (stock solution preparation process)

[0076] Cow's lower layer hide is used as raw material, and collagen is solubilized with alkali. Add the additives described in each example or comparative example to 1200 g of the obtained solubilized collagen (collagen content 180 g), dissolve it in an aqueous lactic acid solution, and make it pH 3.5, solid content concentration (composed of collagen and additives) Adjusted to 7.5% by weight aqueous collagen solution.

manufacture example 2

[0077] (Manufacturing example 2) Production of regenerated collagen fibers (spinning process)

[0078] The aqueous collagen solution obtained in Production Example 1 was subjected to stirring and defoaming treatment under reduced pressure, transferred to a piston-type spinning stock solution tank, and then left to stand under reduced pressure to perform defoaming. Next, the degassed aqueous collagen solution was squeezed out with a piston, quantitatively transported with a gear pump, and filtered with a sintered filter with a pore diameter of 45 μm. Then, the solubilized collagen aqueous solution after the filtration is passed through a spinning nozzle whose aperture is 0.212 mm and the number of holes is 275, and is ejected to a pH of 11 with sodium bicarbonate and sodium hydroxide at a spinning speed of 5 m / min. In a coagulation bath (25° C.) containing 17% by weight of sodium sulfate, regenerated collagen fibers were obtained.

manufacture example 3

[0079] (Manufacturing example 3) Water resistance treatment (water resistance process)

[0080] The regenerated collagen fibers obtained in Production Example 2 were immersed in an aqueous solution containing 17% by weight of sodium sulfate, 0.02% by weight of sodium hydroxide, and 0.83% by weight of epichlorohydrin at 25° C. for 5 hours, and then heated at 43° C. Under dipping for 3.5 hours, epoxy compound treatment was performed. Then, after washing the obtained regenerated collagen fibers with water, adjust the pH to 4.0 with sodium hydroxide and contain ZrO 2 Converted to 2.00% by weight of zirconium sulfate, expressed as Al 2 o 3 It was immersed in a treatment bath of 0.40% by weight of aluminum sulfate and 0.56% by weight of citric acid monohydrate in conversion for 6 hours. Then, the regenerated collagen fibers treated with the zirconium salt and the aluminum salt were washed with water, and immersed in a treatment bath (pH 11.0) containing 5.0% by weight of disodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com