Patents

Literature

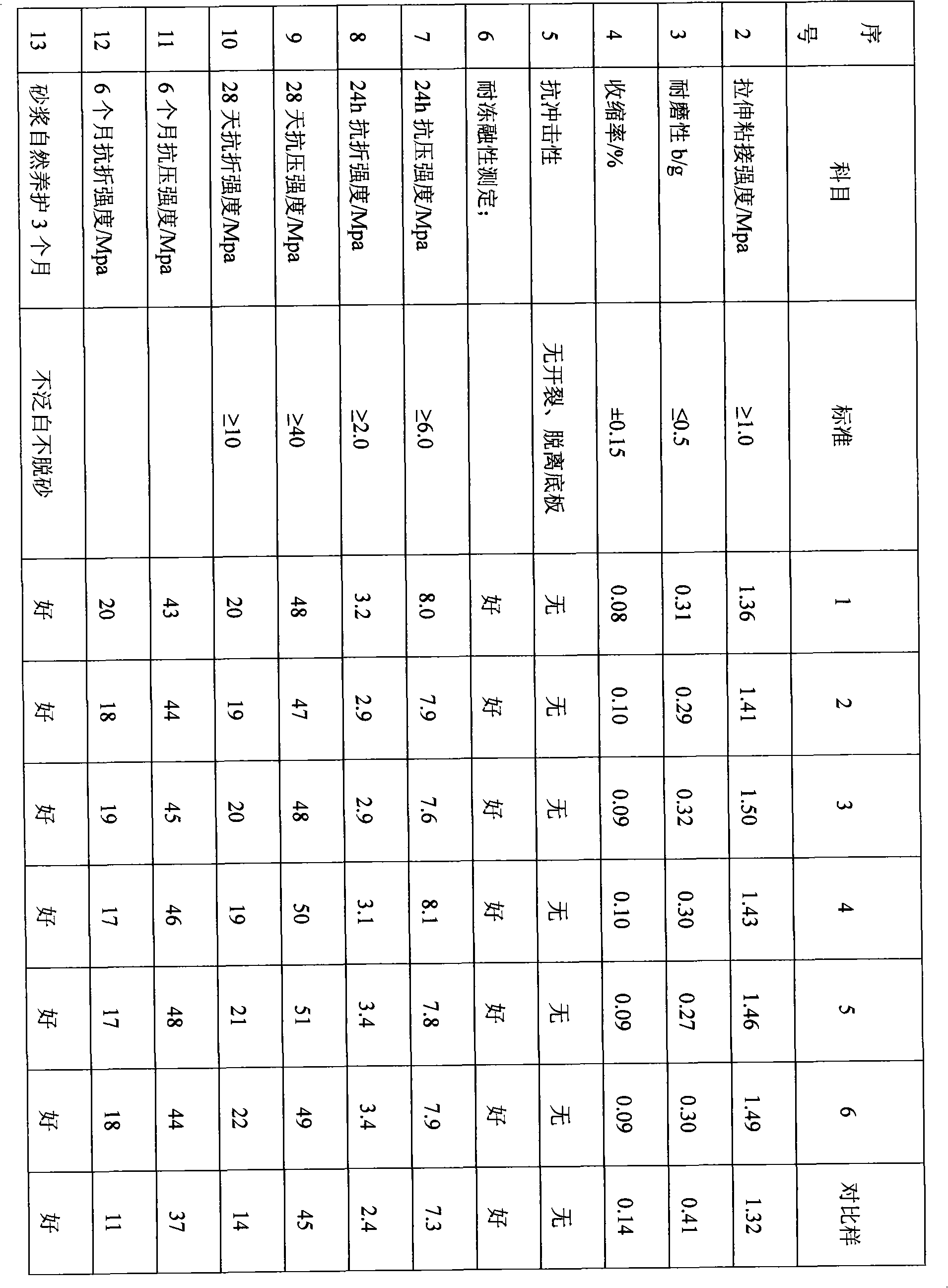

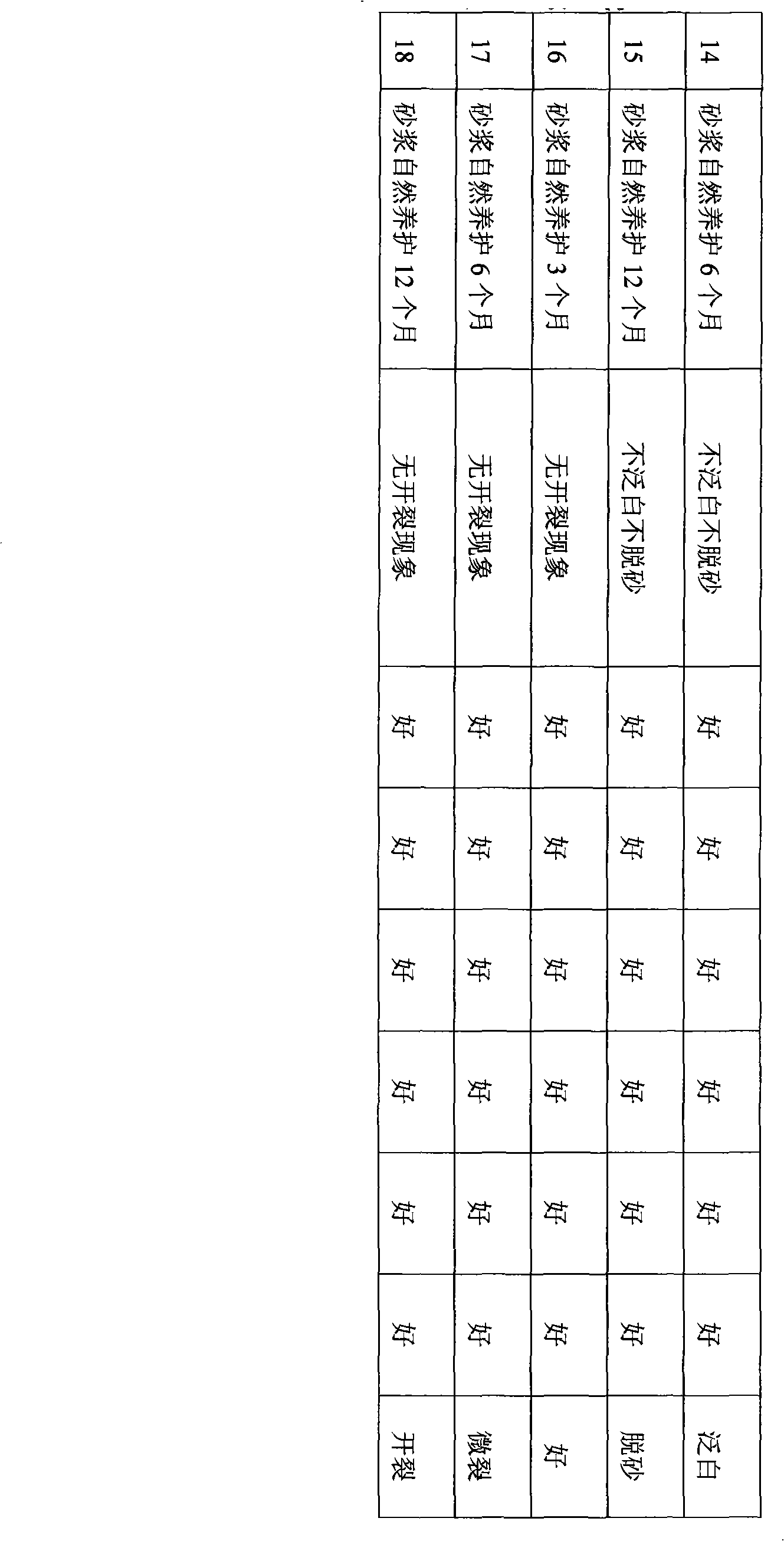

137results about How to "Improves shrink resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

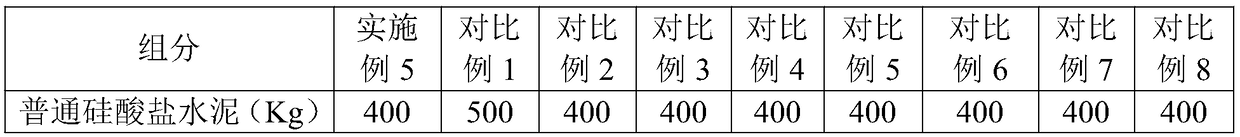

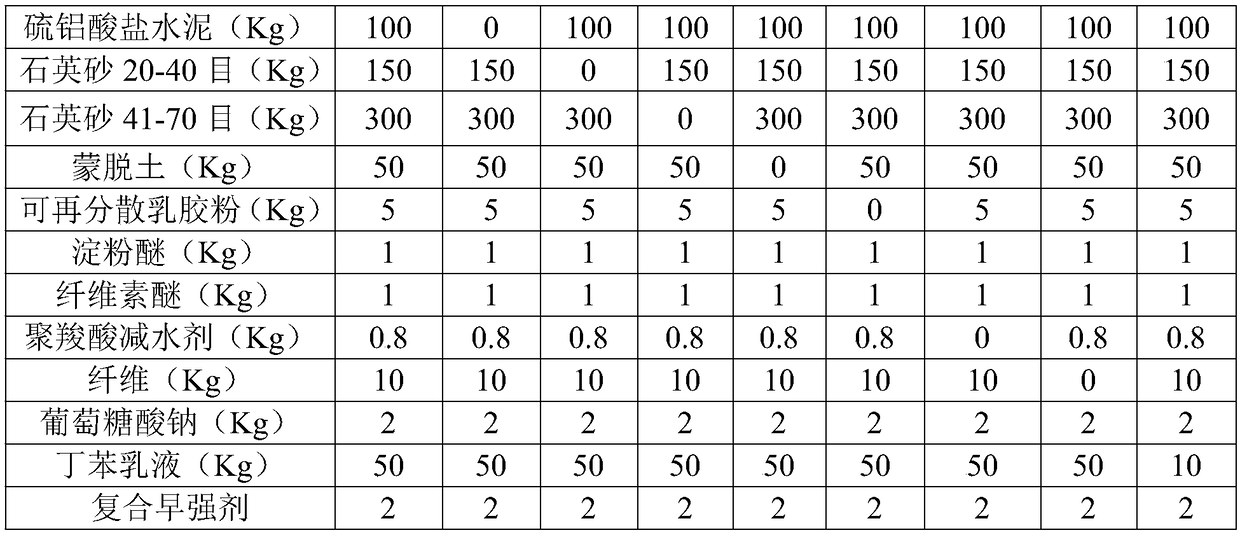

Special repair mortar for structure and preparation method thereof

The invention discloses special repair mortar for a structure. The mortar is prepared from the following components in parts by weight: 350-500 parts of common silicate cement, 50-150 parts of sulphate aluminum cement, 100-200 parts of 20-40-mesh quartz sand, 300-350 parts of 41-70-mesh quartz sand, 20-50 parts of montmorillonite, 30-50 parts of a styrene-butadiene rubber latex, 1-10 parts of redispersible latex powder, 1-5 parts of starch ether, 1-5 parts of cellulose ether, 0.5-2 parts of a polycarboxylate superplasticizer, 1-3 parts of a retarder, 1-10 parts of fibers and 1-5 parts of a compound early strength agent. According to the special repair mortar for the structure, by selecting and proportioning the components in proportion, comprehensively excellent utilizing performance of the components, the components draw on strengths of each other and act jointly, so that the shrinking percentage of the mortar is low. Mechanical properties of relatively high bonding strength, tensileand crush resistances and the like are obtained, and the cost performance is high.

Owner:GUANGDONG FUTE NEW MATERIALS TECH CO LTD

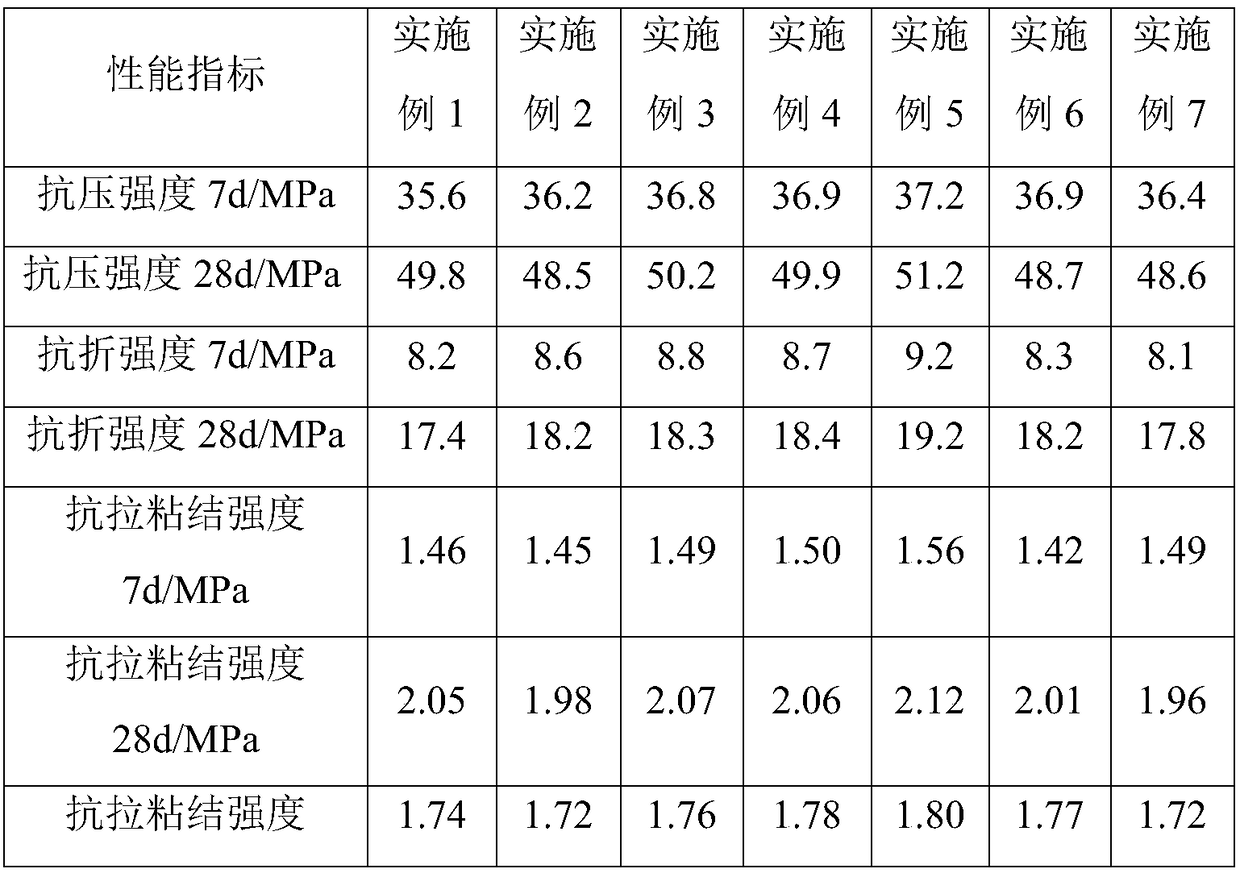

Thermoplastic polyurethane composite foamed material and preparation method thereof

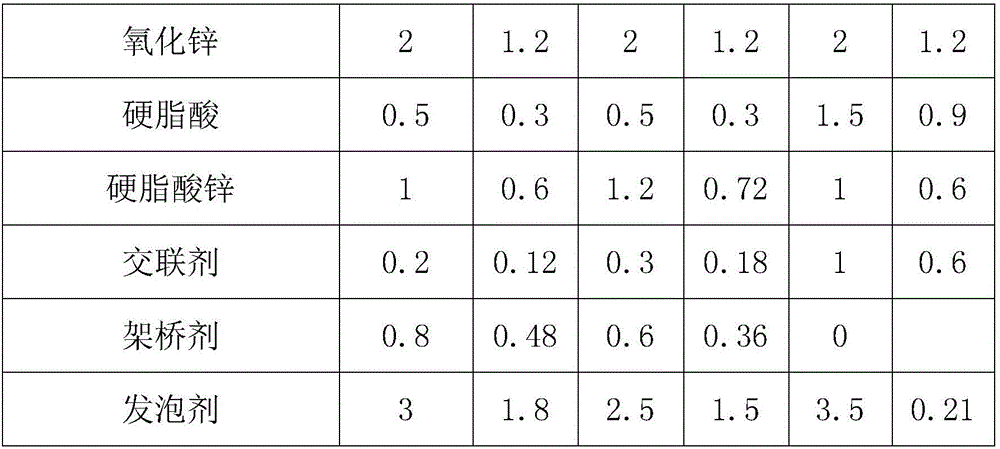

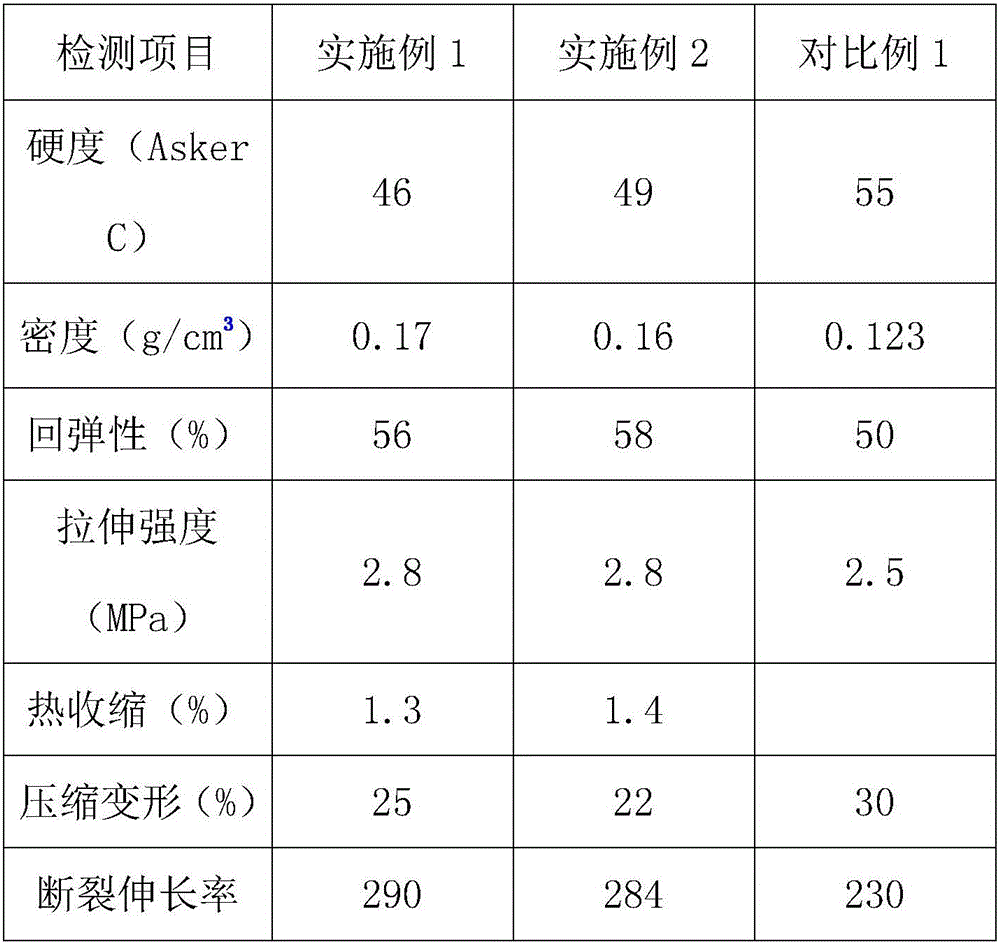

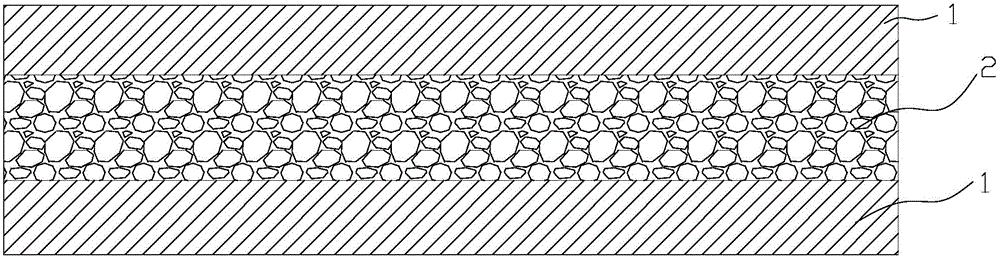

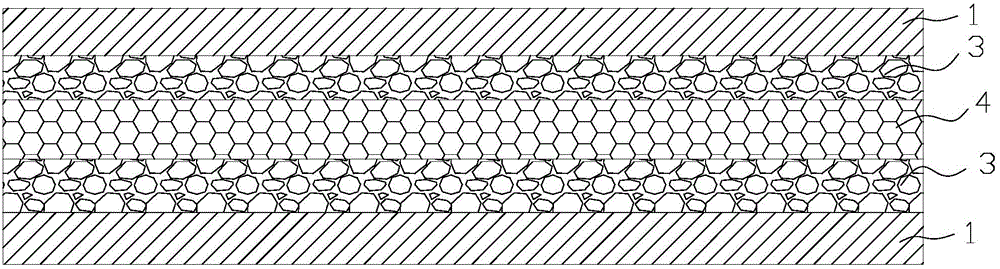

The invention provides a thermoplastic polyurethane composite foamed material and a preparation method thereof. The thermoplastic polyurethane composite foamed material is prepared from 10-25 parts of polyurethane, 35-45 parts of ethylene-vinyl acetate copolymers, 15-30 parts of polyolefin elastomers, 6-10 parts of polyethylene, 6-18 parts of ethylene propylene diene monomers, 6-15 parts of polybutadiene polymers, 3-5 parts of filler, 1.5-2.2 parts of zinc oxide, 0.4-0.6 parts of stearic acid, 0.8-1.4 parts of zinc stearate, 0.1-0.4 parts of a cross-linking agent, 0.7-1.0 part of a bridging agent and 2.5-3.5 parts of a foaming agent. The thermoplastic polyurethane composite foamed material is high in rebound resilience, resistant to compression and good in tear resistance. The preparation method of the thermoplastic polyurethane composite foamed material comprises steps as follows: 1) components except zinc oxide, the cross-linking agent, the bridging agent and the foaming agent are weighed; 2) all the components weighed in the step 1) are mixed; 3) the rest components are weighed; 4) the components weighed in the step 3) are added to a material obtained after mixing in the step 2) for mixing; 5) granulation is performed; 6) foaming is performed.

Owner:ANTA CHINA

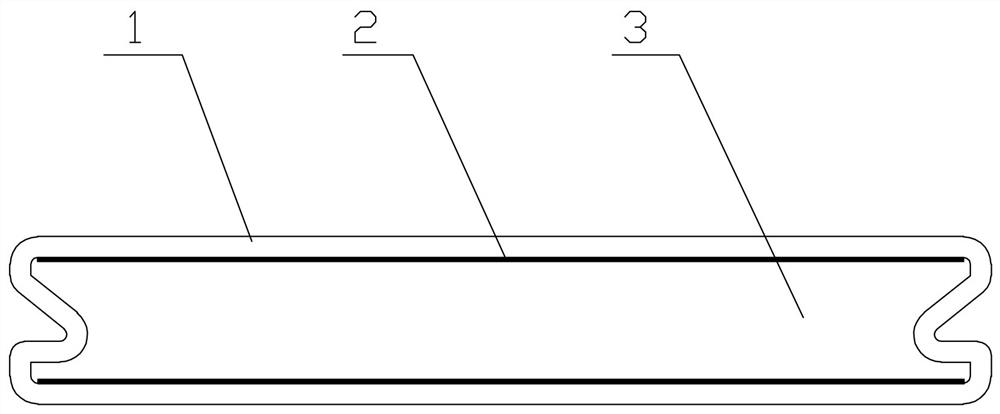

Inorganic nano particle hybridized polyolefin microporous membrane and preparation method thereof

InactiveCN104157816AImprove heat resistanceImproves shrink resistanceSecondary cellsCell component detailsPolyolefinNanometre

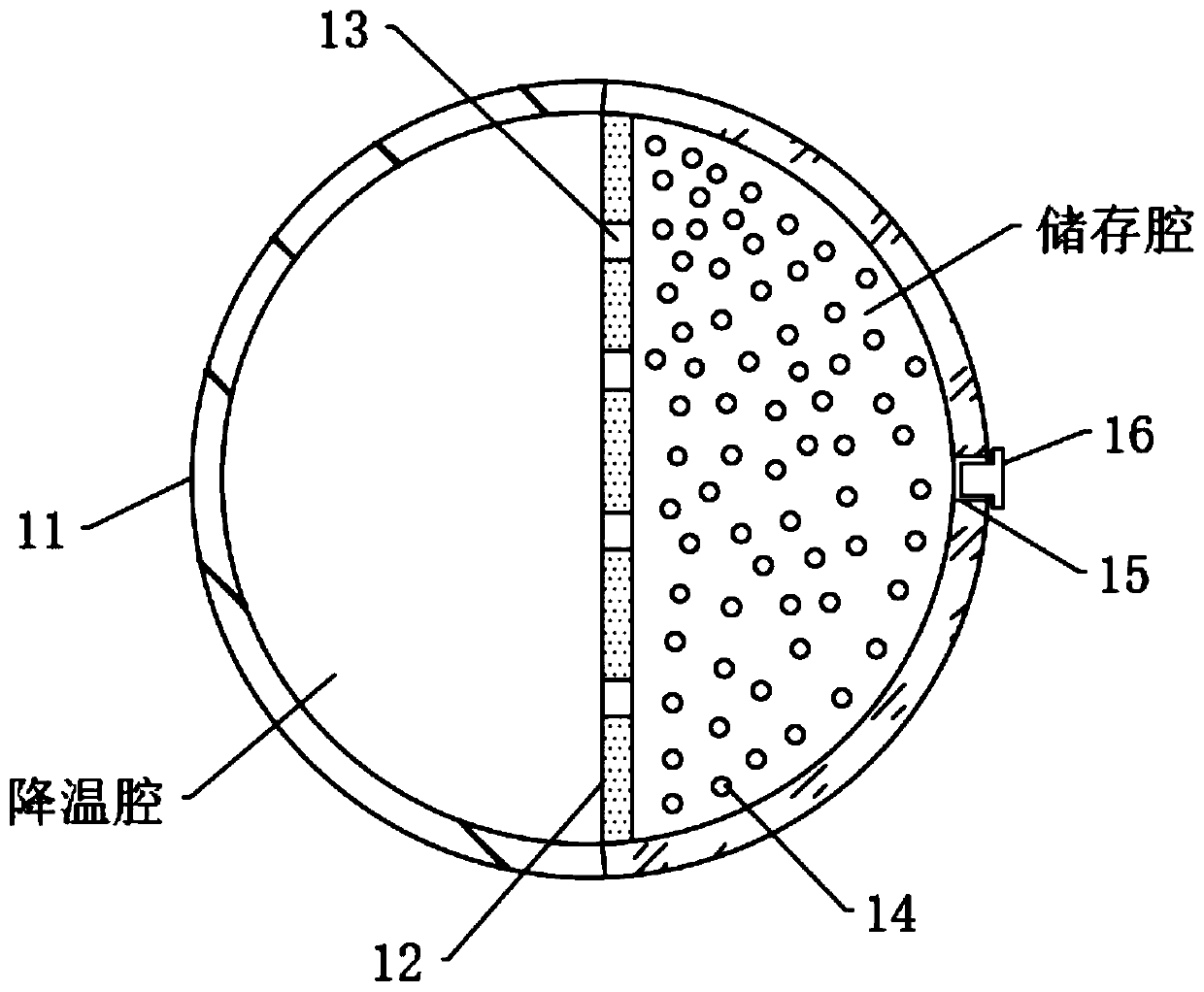

The invention discloses an inorganic nano particle hybridized polyolefin microporous membrane which includes an upper surface polyolefin layer and a lower surface polyolefin layer. At least one inorganic nano particle hybridizing layer is disposed between the upper surface polyolefin layer and the lower surface polyolefin layer in a laminated manner. The inorganic nano particle hybridizing layer is a mixed structure composed of an electrically-insulating inorganic nano particle and polyolefin, wherein the electrically-insulating inorganic nano particle is lipophilically modified through a modifying agent or a coupling agent. The microporous membrane is 5-40 [mu]m in a thickness, is 25-100 nm in an average pore size, is not more than 2.0 in a thermal shrinkage at 135 DEG C, is more than 145 MPa in an MD tensile strength and is more than 130 MPa in an TD tensile strength. The invention also discloses a method for preparing the microporous membrane. The microporous membrane has advantages of being capable of inhibiting thermal shrinkage, being high in tensile strength and being high in fusing temperature.

Owner:SHENZHEN SENIOR TECH MATERIAL

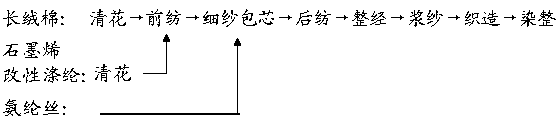

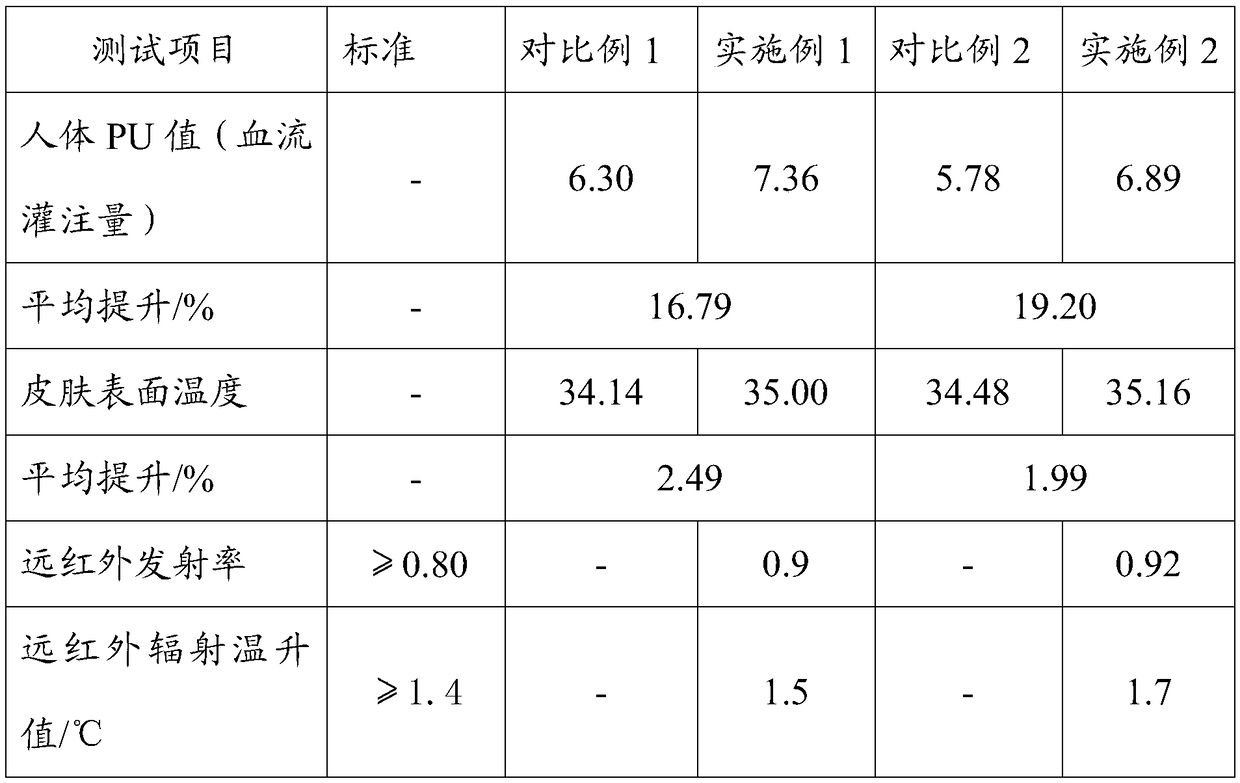

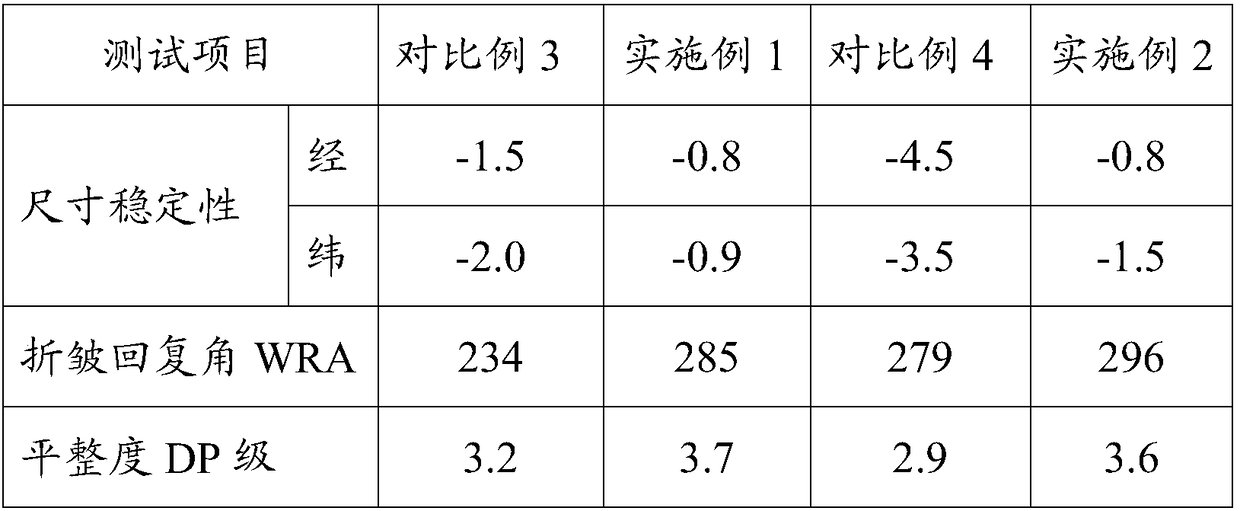

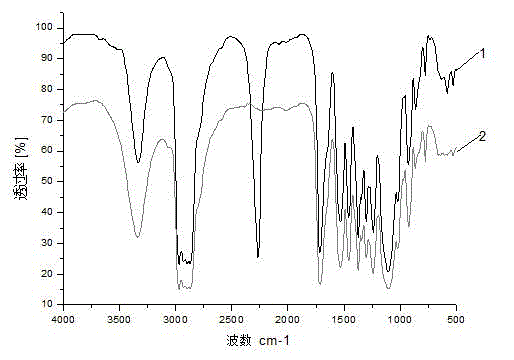

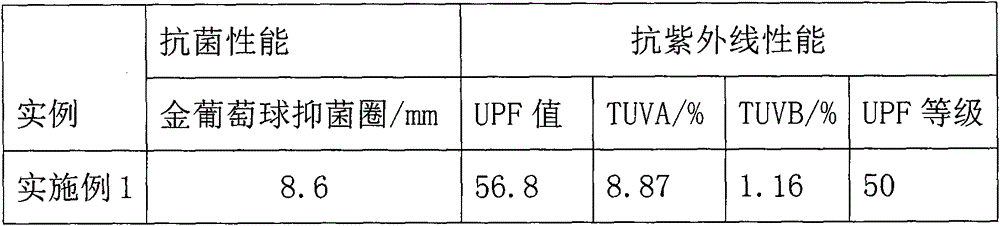

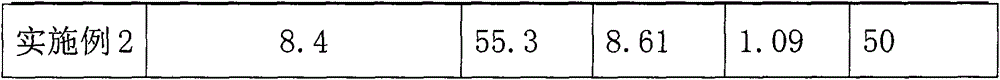

Production method of graphene-modified fiber core-spun elastic yarn and graphene-modified fiber core-spun elastic fabric

ActiveCN108823718AImproves shrink resistanceImprove wrinkle resistanceWeft knittingWarp knittingPolyesterFiber

The invention discloses a production method of graphene-modified fiber core-spun elastic yarn and graphene-modified fiber core-spun elastic fabric. The graphene-modified fiber core-spun elastic yarn is a core-spun spandex filament obtained by blending graphene-modified polyester fibers and combed cotton. The graphene-modified fiber core-spun elastic fabric comprises a woven elastic fabric body anda knitted elastic fabric body. The fabric has the functions of resisting bacteria, achieving far-infrared heating, promoting micro-circulation, preventing ultraviolet radiation and the like and has good creasing resistance and shape retention performance. The graphene-modified fiber core-spun elastic yarn and the graphene-modified fiber core-spun elastic fabric can be applied to the field of woven garments and knitting sports, and the market of elastic functional products is developed.

Owner:山东宏儒纺织科技有限公司

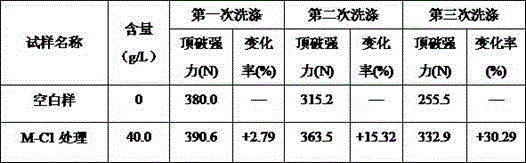

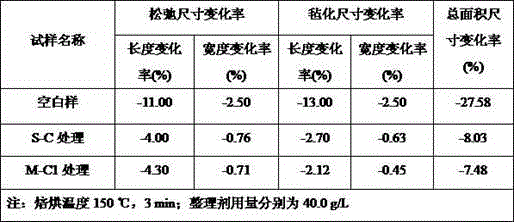

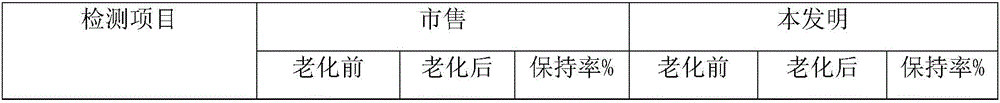

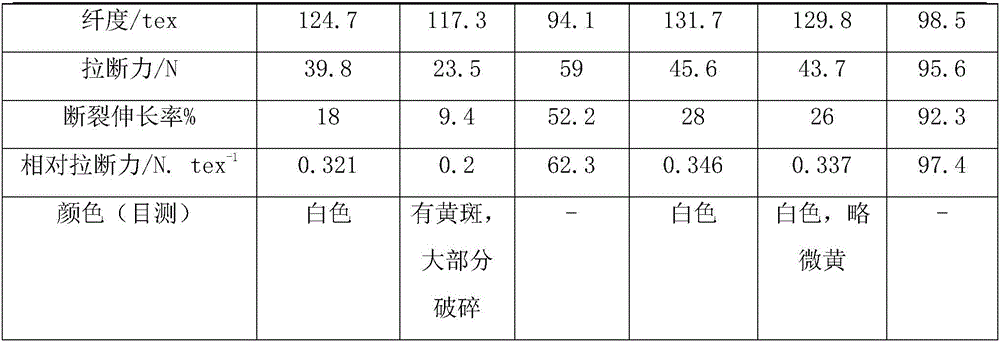

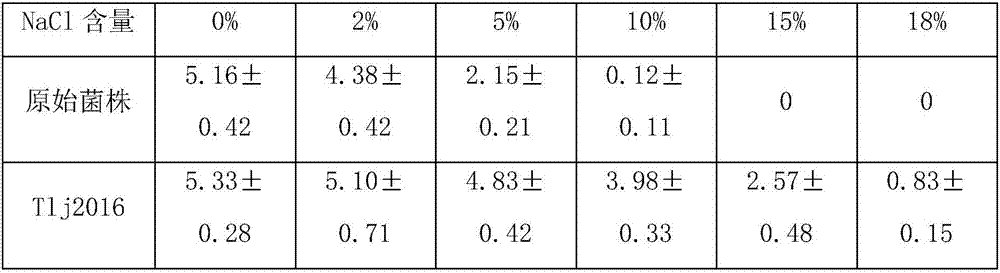

Preparation method of cation-type waterborne polyurethane wool anti-felting emulsion

InactiveCN104878604AGood storage stabilitySolid content adjustableAnimal fibresBursting strengthPolymer science

The invention relates to a preparation method of cation-type waterborne polyurethane wool anti-felting emulsion, and belongs to the field of wool fabric finishing auxiliaries. According to the preparation method of the cation-type waterborne polyurethane wool anti-felting emulsion, polyisocyanate is used as a hard segment, polyether polyol is used as a soft segment, an amine compound is used as a cation chain extender and sodium hydrogen sulfite or methyl ethyl ketoxime is used as an end-capping reagent; the adopted technical route is pre-polymerization reaction-hydrophilic chain extending reaction-end capping reaction-neutralization reaction-self-emulsifying reaction. The anti-felting emulsion synthesized by a self-emulsifying method has the characteristics of being excellent in storage stability, adjustable in solid content and convenient to use, the size change of wool knitting fabrics caused by felting during washing is remarkably reduced, the bursting strength, dyeing depth and dyeing fastness of the wool knitting fabrics are improved, and good application prospect is provided.

Owner:XINJIANG UNIVERSITY +1

Protecting mortar of express highway roadbed surface hard-face terrace

The invention provides a protecting mortar of the express highway roadbed surface hard-face terrace. The protecting mortar comprises the following components in parts by weight: 40-50 parts of ordinary silicate cement, 20-30 parts of quartz sand, 30-50 parts of carborundum, 2-4 parts of zeolite graft re-dispersible emulsion powder and 0.3-1 part of xanthan gum. The invention adopts zeolite graft re-dispersible emulsion powder; in the hydration process of silicate cement, the dense doping between anhydrite and crosslinked zeolite changes the lattice of cement so as to increase the wearability and antishrinking property of the express highway roadbed surface; the zeolite graft re-dispersible emulsion powder is crosslinked with xanthan gum to form composite polymer and the flexibility is increased to improve the anti-deforming force of the roadbed surface. The combined use of mortar and cement can increase the hardness, wear resistance, antishrinking property and anti-deforming force of the roadbed surface and prolong the service life of the highway.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Method for carrying out stone washing on soft coarse-wooled fabric

ActiveCN103114472ASoft touchImproves shrink resistanceBiochemical fibre treatmentDry-cleaning apparatus for textilesFiberYarn

The invention discloses a method for carrying out stone washing on a soft coarse-wooled fabric, aiming to providing a method for carrying out stone washing on a soft coarse-wooled fabric with a distressed, faded, clear and natural surface and less villi, wherein the fabric is high in resilience and soft in handfeel, the colors of the front and back surfaces of the fabric have a large contrast, and the fabric has a retro nostalgic feeling. The method is characterized by comprising the steps of carrying out mercerization on fibers, spinning yarns, spinning a fabric, carrying out curing and shrink-resistant treatment on the fabric, forming a garment, carrying out dyeing and stone washing on the garment, and drying and tidying up the garment. According to the method, through carrying out shrink-resistant treatment by two times in the earlier stage and carrying out stone washing by using vesuvianite into which proteases and a detergent are soaked, the defect that common wool fabrics have a serious milling phenomenon after being subjected to sand washing is successfully controlled, and excessive damage on fabrics in the process of doing old is effectively prevented, thereby prolonging the service life of garments.

Owner:山东神州毛纺织有限公司

Yarn spinning technology for multi-fiber semi-worsted melange yarn and yarn

InactiveCN104878490AImprove insulation effectIncrease elasticityWool fibre washing/scouringAnimal materialCardingWorsted

The invention relates to a yarn spinning technology for multi-fiber semi-worsted melange yarn and the yarn prepared with the technology. The technological steps of the yarn mainly comprise raw material treatment, cotton carding, drawing, roving, spinning, self-spooling, doubling, two-for-one twisting and packaging of a finished product. Raw materials comprise mercerized wool fiber, nylon fiber, viscose fiber and cashmere wool fiber. The problems of high probability of water shrinkage and pilling of wool are solved with a more environment-friendly method, meanwhile, nylon, cashmere wool and viscose ingredients are added, and the heat retention property, the elasticity, the durability and the comfort degree of the product are increased; the production cost is lower, the prepared yarn has the characteristics of shrink resistance, good anti-pilling effect, natural luster, bright color, good elasticity, smooth hand feeling, heat retention and the like.

Owner:TONGXIANG YUNSHENG TEXTILE

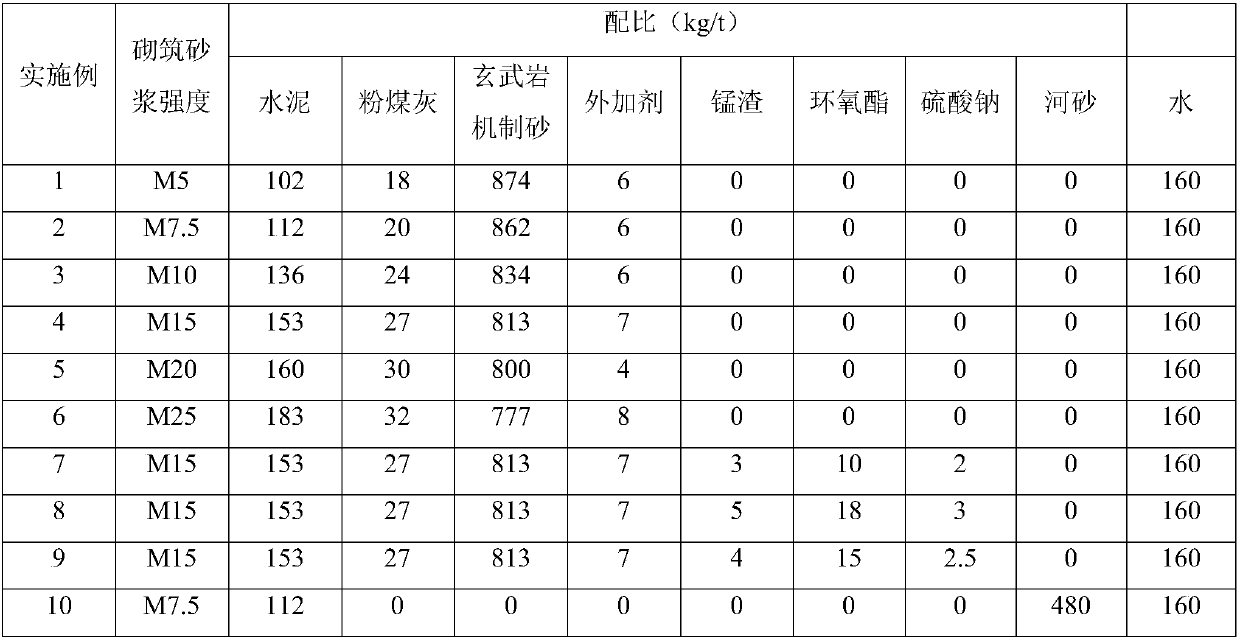

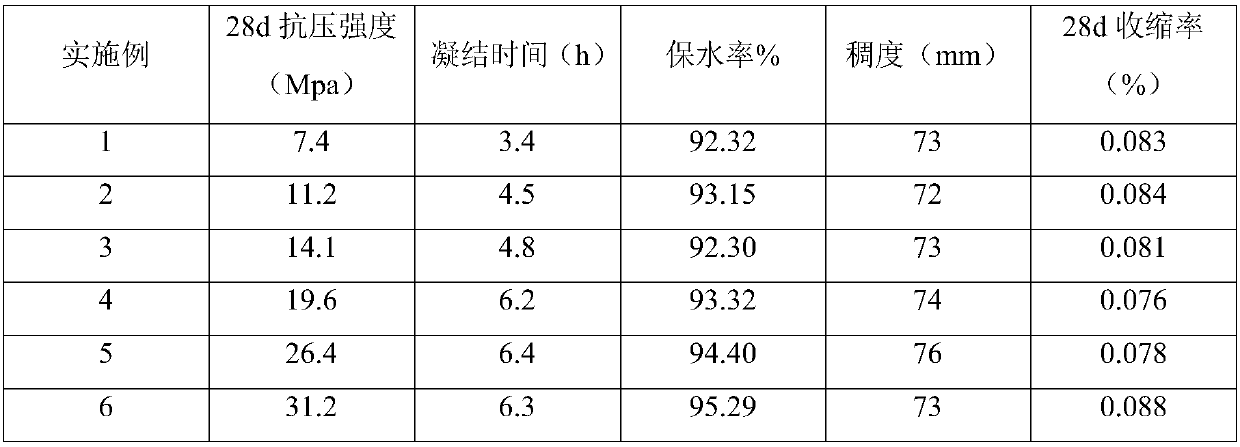

Basalt machine-made sand dry-mixed mortar and preparation method thereof

The invention discloses basalt machine-made sand dry-mixed mortar and a preparation method thereof. The preparation method comprises the following steps: drying machine-made sand in a raw material, and controlling the moisture content in the machine-made to be less than 0.4 percent, the silt content to be less than 1.0 percent and the grain diameter to be less than 5mm; then uniformly mixing and stirring all components in the raw material, metering and bagging, thus obtaining the basalt machine-made sand dry-mixed mortar, wherein the raw material is prepared from 10.2 to 18.3 parts of cement,1.8 to 3.2 parts of pulverized fuel ash, 77.7 to 87.4 parts of basalt machine-made sand and 0.4 to 0.8 part of an additive. The basalt machine-made sand dry-mixed mortar disclosed by the invention isprepared by using the basalt machine-made sand locally produced in Lanzhou to replace original river sand and mixing with the cement, the pulverized fuel ash and the additive special for mortar and belongs to application of new materials, performance indexes of the basalt machine-made sand dry-mixed mortar meet the requirements, the technology is simple, and the cost is low.

Owner:甘肃建投矿业有限公司

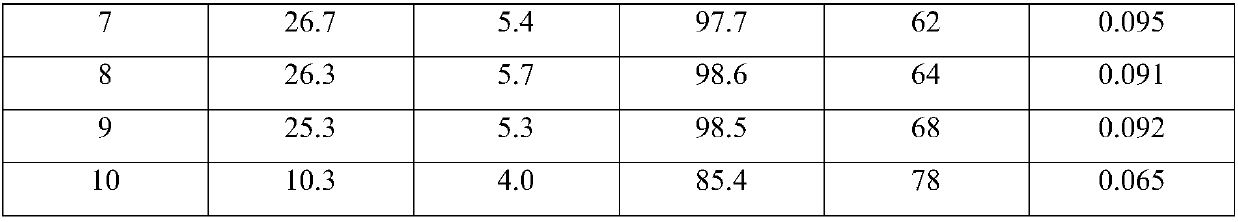

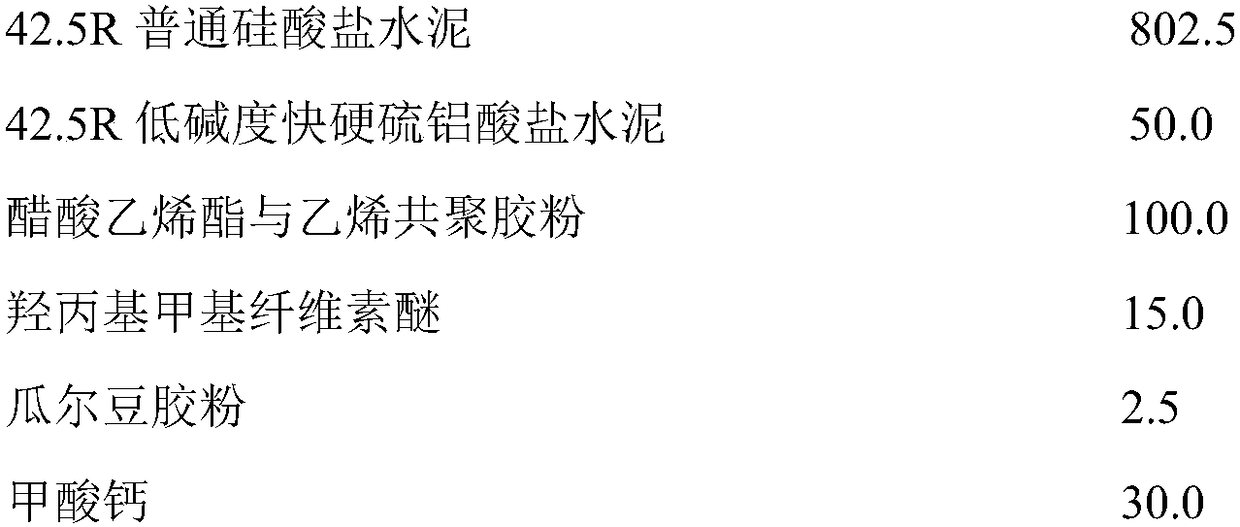

Cement-based tile adhesive and composition for preparing same

The invention discloses a cement-based tile adhesive. The adhesive comprises composition prepared from raw materials in percentage by mass as follows: 80.00%-90.00% of ordinary Portland cement, 5.00%-10.00% of low-alkalinity sulphoaluminate cement, 2.00%-10.00% of redispersible latex powder, 1.25%-2.00% of cellulose ether, 0.25%-0.50% of guar gum powder, 1.00%-6.00% of an early strength agent, sand and water, Wherein the mass ratio of the composition to the sand is 1:4, and water accounts for 10%-15% of the total mass. Compared with the prior art, the cement-based tile adhesive has the advantages that the amount of aggregate (sand) in a formula is increased to 65% or above, the shrinkage of the system is well reduced, so that the tile adhesive can be thick, and the production cost is greatly reduced.

Owner:KESHUN WATERPROOF TECH CO LTD

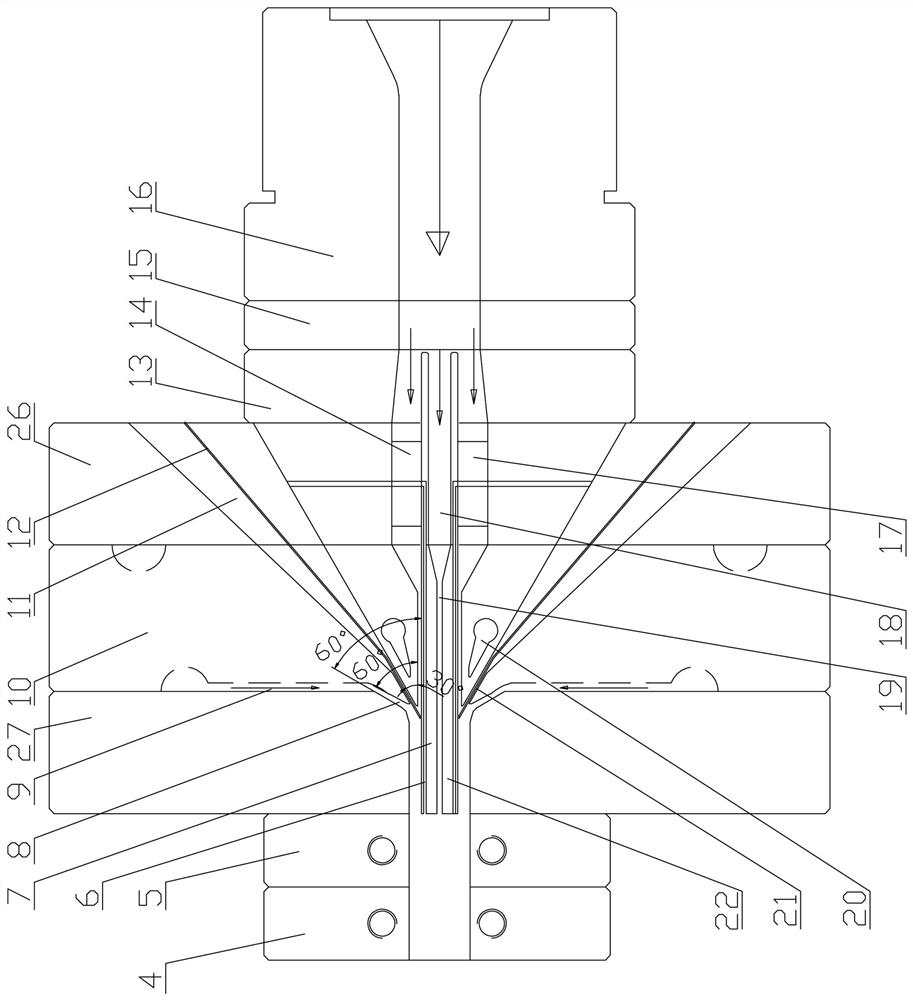

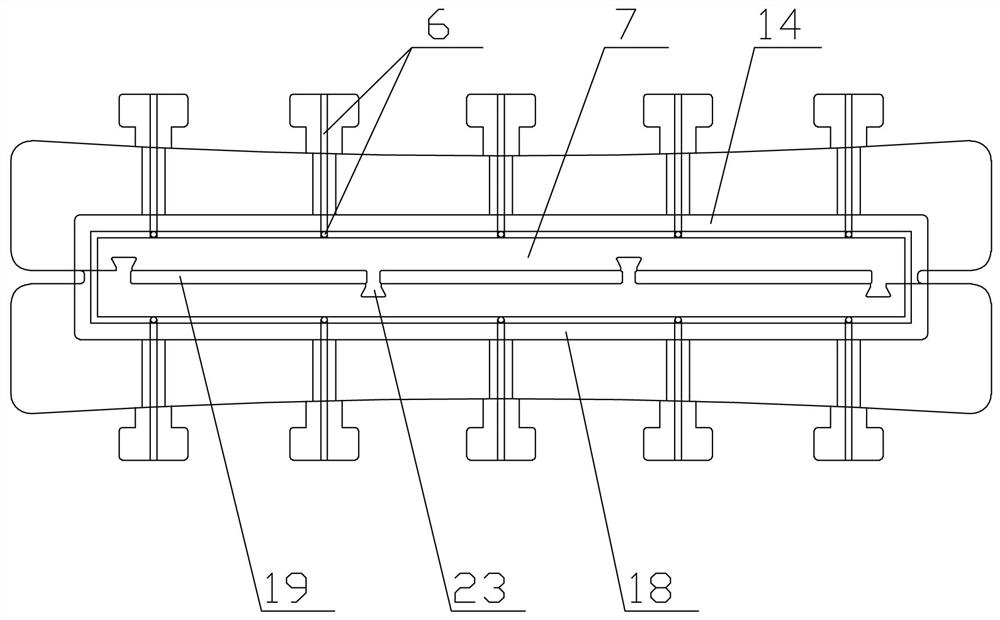

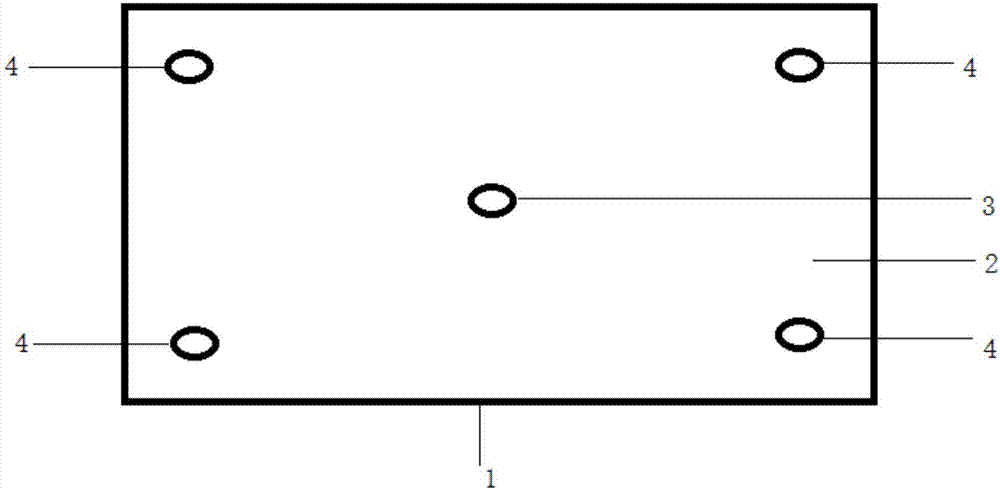

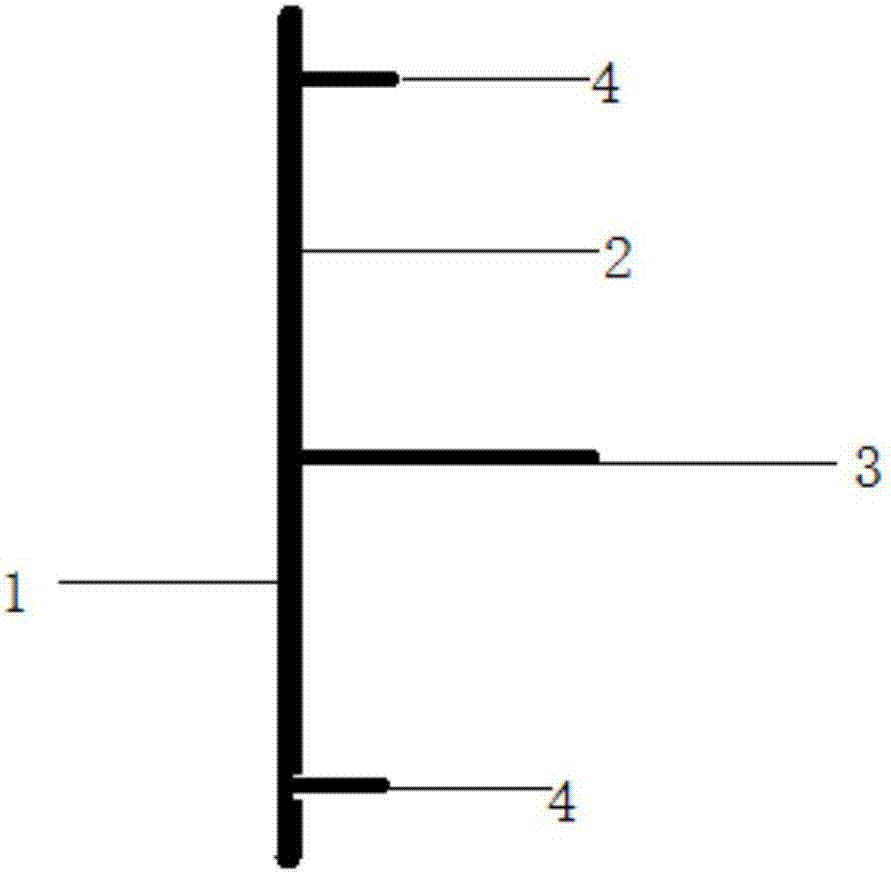

Composite forming die for solid non-air-hole floor in outdoor garden

The invention relates to a composite forming die for a solid non-air-hole floor in an outdoor garden. The composite forming die comprises a die body, a second transition plate, a first transition plate, a support, a second opening die, a first opening die, a second water jacket, a first water jacket, a cavity and a core rod; a section of bent flow channel A is arranged at the front end of a wood-plastic foaming material injection flow channel, and the included angle between the bent flow channel A and the center plane is 60-62 degrees; a bent flow channel B is arranged at the front end of a carbon fiber sheet penetrating channel; a circularly flowing cooling water hole is further formed in the tip part, close to the bent flow channel B, inside the second opening die; an upper core rod and a lower core rod divide a PVC foaming material circulation channel on the inner layer into an upper PVC foaming material flow channel, a middle PVC foaming material flow channel and a lower PVC foaming material flow channel; and a plurality of exhaust ducts are formed in the upper core rod and the lower core rod. According to the composite forming die, not only is the biggest defect of an existing die overcome, but also the effects that the product performance is not reduced while the material losses of the produced and formed product are reduced are achieved.

Owner:湖北星科模具有限公司

Antibacterial protective environment-friendly composite polymer material and preparation method and application thereof

InactiveCN111286121AWith photocatalytic effectStrong antibacterial activityMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentFiberMethyl carbonate

The invention discloses an antibacterial protective environment-friendly composite polymer material and a preparation method and application thereof, wherein the composite polymer material comprises the following components by weight: 20 parts to 30 parts of benzyl quaternary ammonium salt, 50 parts to 75 parts of a biocompatible high-molecular polymer, 15 parts to 30 parts of modified nano metaloxide, 10 parts to 20 parts of nano metal particles, 30 parts to 40 parts of modified fiber, 25 parts to 45 parts of trisilanol ethyl ester silsesquioxane, 5 parts to 10 parts of a silane coupling agent, 3 parts to 5 parts of ammonium persulfate, 3 parts to 5 parts of dimethyl carbonate, 8 parts to 15 parts of 3-mercaptopropyl trimethoxy silane, and 2 parts to 3 parts of allyl glycidyl ether. Thematerial is capable of blocking and self-cleaning apatter or air with viruses, bacteria or microorganisms, is antibacterial, capable of killing viruses, capable of being repeatedly used, good in shrinkage resistance, high in elastic property and easy to degrade, and can be used for manufacturing window cloth, air conditioners, air purifiers, screen windows, clothes, trousers and masks.

Owner:上海古太创意服务有限公司

Antibacterial health-care fabric

InactiveCN104060369AAntibacterialGood moisture absorption and air permeabilityCarbon fibresWoven fabricsFiberMilk protein

The invention discloses an antibacterial health-care fabric. The antibacterial health-care fabric is formed by interweaving warps and wefts, and is characterized in that the warps are jade fiber and chitin fiber blended yarns, the wefts are milk protein fiber and coconut carbon fiber blended yarns, the warps and the wefts are spun, woven and finished, and a natural antibacterial finishing agent is added to the finishing process. The antibacterial health-care fabric has not only the antibacterial, anti-inflammation, deodorant and ventilated effects but also the ultraviolet-proof and antistatic functions, is comfortable, soft and smooth in hand feeling, has the moisture absorbing and holding functions, panders to the environment-friendly, healthy and fashionable consumption concepts of people and is convenient to process.

Owner:NANTONG FANGKE TEXTILE TECH

High-ductility thermal insulation mortar

ActiveCN110342888AImprove insulation effectImprove deformation abilityCeramicwareFiberThermal insulation

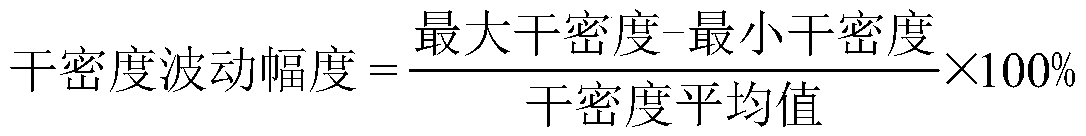

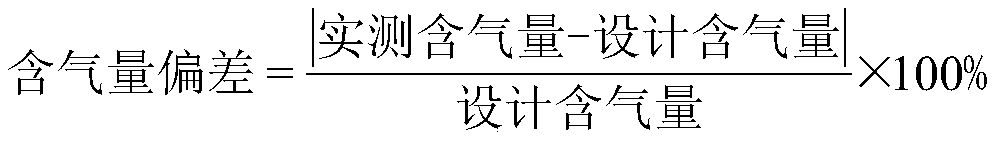

The invention discloses high-ductility thermal insulation mortar. The high-ductility thermal insulation mortar is prepared from the following components in parts by weight: 20-100 parts of cement, 0-80 parts of a mineral admixture, 5-40 parts of high-strength microbeads, 0-35 parts of aggregate, 10-50 parts of an acrylate copolymer emulsion, 5-30 parts of water, 1-1.5 parts of a water reducer, and0.75-6 parts of fibers. An air entraining material or prefabricated bubbles do not need to be added, and the bubble content and dry density of the thermal insulation mortar are adjusted by adjustingthe rotating speed and stirring time of a stirrer; the prepared high-ductility thermal insulation mortar is small in dry density fluctuation amplitude, the high-strength microbeads are evenly distributed and do not float, the deviation of the actually-measured air content and the designed air content of the mixture is small, and the dispersion coefficient of the fibers is high; the mortar is highin ductility, high in deformation capacity, low in thermal conductivity coefficient, high in compressive strength and high in bonding strength with a base body; a preparation process is simple and convenient, and the raw materials are wide in source; and the high-ductility thermal insulation mortar disclosed by the invention can be applied to thermal insulation of wall bodies and roofs, thermal insulation of the surfaces of concrete dams in severe cold regions and the like.

Owner:NANJING HYDRAULIC RES INST

Easily-degradable anti-shrinkage polypropylene master batch and preparation method thereof

InactiveCN106674728AImprove high temperature resistanceImproves shrink resistanceFungiMicroorganism based processesPolypropyleneAntioxidant

The invention discloses an easily-degradable anti-shrinkage polypropylene master batch, wherein polypropylene serves as a base material, the types and the formula of the master batch are optimized, and a production process is improved. A complex antioxidant which contains a biologic antioxidant, modified nanocarbon which can obviously improve high temperature resistance, shrinkage resistance, relative tensile load, strength and toughness and elasticity modulus of the polypropylene master batch, calcium fruit fibers which can obviously improve shock resistance of the polypropylene master batch, are easily biodegradable and lower production cost, polyethylene / winter rye peptide complexes which can greatly improve low temperature resistance of the polypropylene master batch and bitter almond oil which can effectively improve lubricating property and oxidation resistance of the polypropylene master batch are scientifically compounded; the obtained compound has a synergistic effect with other processing aids; finally, the environment-friendly easily-degradable anti-shrinkage polypropylene master batch with good physical property is obtained.

Owner:NINGXIA YANCHI WEST CHANGXIANG AGRI BIOTECH

Hybrid fiber air-entrapping wall material and preparation method thereof

InactiveCN108516783AImprove crack resistanceImproves shrink resistanceCeramicwareCarbon fibersResource utilization

The invention discloses a hybrid fiber air-entrapping wall material and a preparation method thereof. The wall material is prepared from, by mass, 0.25-0.32% of hybrid fiber, 15-25% of quartz tail-sand, 35-50% of volcanic rock powder, 15-20% of cement, 8-11% of quick lime, 3-6% of flue gas desulfurization gypsum, 0.12-0.2% of composite foaming agent and 0.08-0.12% of foam stabilizer, wherein the ratio of water to material is 0.4-0.5%. The hybrid fiber air-entrapping wall material and the preparation method thereof have the advantages that the hybrid fiber formed by combining a polypropylene fiber with a carbon fiber is added into the air-entrapping concrete wall material, the strength of the air-entrapping wall material is greatly improved, the anti-cracking ability is strengthened, and the problem of missing edge off angle is overcome, in addition, the quartz tail-sand and waste gas volcanic rock stone are taken as siliceous materials to replace fly ash, the resource utilization of the waste is achieved, and the problems of the resource shortage and environmental pollution of the fly ash are solved.

Owner:SHENZHEN GANGCHUANG BUILDING MATERIAL

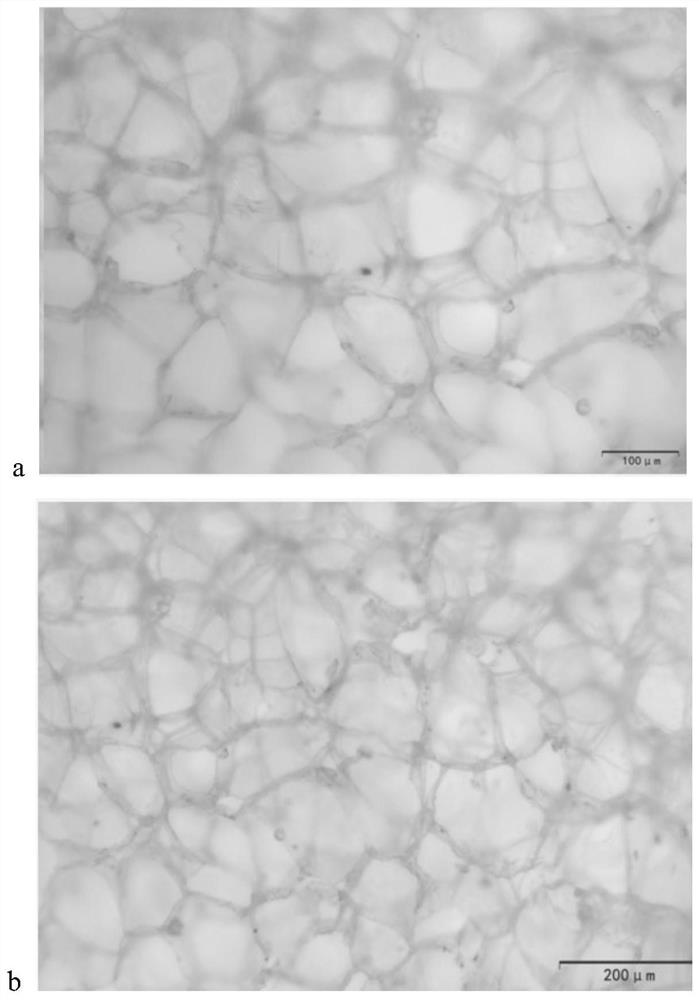

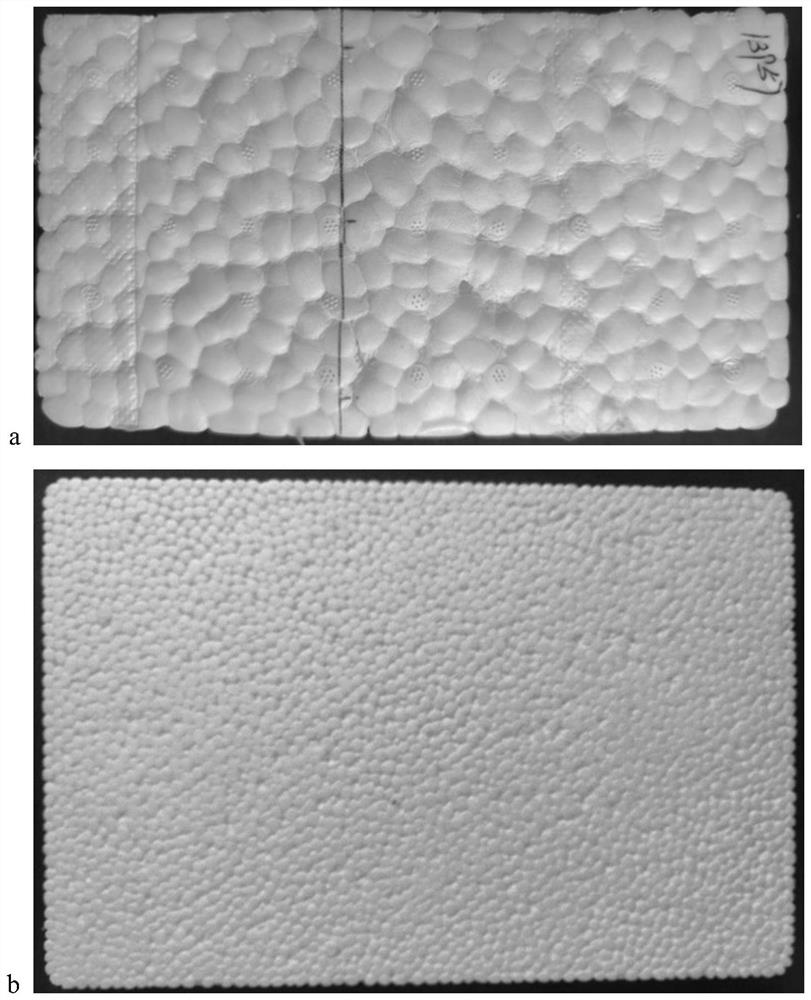

Biodegradable composite bead foaming material for packaging field and preparation method of biodegradable composite bead foaming material

ActiveCN113603923AAvoid adverse effects of degradationIncrease productionFlexible coversWrappersPolymer scienceFoaming agent

The invention discloses a biodegradable composite bead foaming material for the packaging field and a preparation method of the biodegradable composite bead foaming material; blended particles prepared from materials containing poly(butylene adipate-co-terephthalate) and low-crystallinity polylactic acid are placed in a high-pressure mold, and a foaming gas is used as a foaming agent for mold pressing foaming. A low-crystallinity PLA and PBAT compounding method is adopted, and a good foaming effect can be achieved without adding a nucleating agent.

Owner:NANJING TECH UNIV

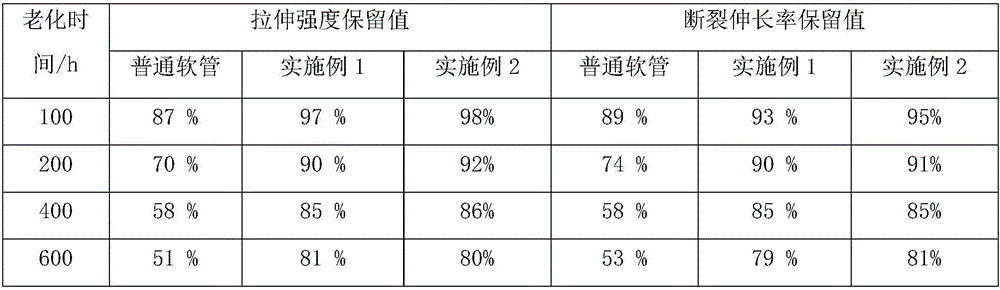

Novel polyethylene floor heating pipe and preparation method thereof

InactiveCN106279875AImproves shrink resistanceImprove anti-aging propertiesRigid pipesMasterbatchPolymer science

A preparation method of a novel polyethylene floor heating pipe is characterized in that outer-layer foamed polyethylene is prepared by mixing and heating the following raw materials in parts by weight: 80 to 100 parts of polyethylene, 1 to 5 parts of a modifying agent, 0.1 to 0.5 part of an antioxidant and 4 to 8 parts of a foaming agent; inner-layer heat-resistant polyethylene is prepared by mixing and heating the following raw materials in parts by weight: 80 to 100 parts of heat-resistant polyethylene, 0.1 to 0.5 part of an antioxidant and 2 to 4 parts of black color masterbatch; and the outer-layer foamed polyethylene and the inner-layer heat-resistant polyethylene are subjected by co-extrusion moulding by a double-layer co-extrusion machine to obtain the polyethylene floor heating pipe with a double-layer structure. The invention has the beneficial effects that the outer-layer foamed polyethylene improves shrinkage resistance and ageing resistance, prolongs service life and improves the rigidity of the floor heating pipe; and the inner-layer heat-resistant polyethylene has high-temperature durability and improves the durability and the heat resistance of the floor heating pipe.

Owner:大禹节水(天津)有限公司

Method for preparing flame retardant anti-UV radiation cashmere fiber product

ActiveCN103361964AIncrease added valueGood flame retardant and anti-ultraviolet radiation functionAnimal fibresFiberTextile technology

The invention provides a method for preparing flame retardant anti-UV radiation cashmere fiber product, belongs to the technical field of textile. The method includes the main steps of firstly washing pure cashmere fibers and drying, secondly preparing a silicon alumina oxide sol impregnation solution, wherein the silicon alumina oxide sol is an environmental-friendly flame retardant, then impregnating the pure cashmere fibers with the silicon alumina oxide sol, performing flame retardant treatment for the pure cashmere fibers, then preparing a TiO2-ZnO hydrosol which is also an environmental-friendly chemical reagent, finally impregnating and roll-drying the pure cashmere fibers with the TiO2-ZnO hydrosol repeatedly, performing anti-UV radiation treatment on pure cashmere fibers, and then washing and drying the pure cashmere fibers to get the flame retardant anti-UV radiation cashmere with high performance. Compared with the prior art, cashmere fibers processed by the method have good flame retardant anti-UV radiation function, and the added value of cashmere is further improved. Treated by the sol-gel technique, breaking strength and shrinkproof performance of the cashmere fabric are improved to some extent.

Owner:CONSINEE GRP CO LTD

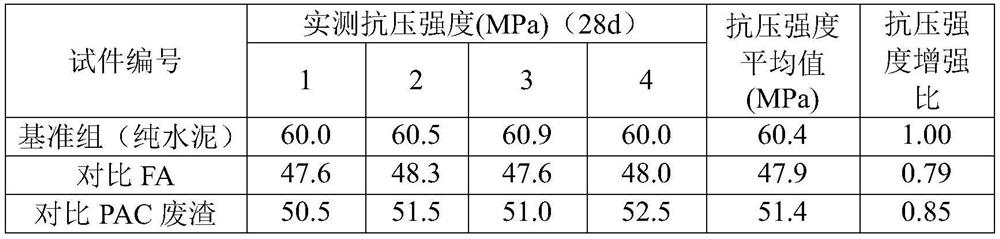

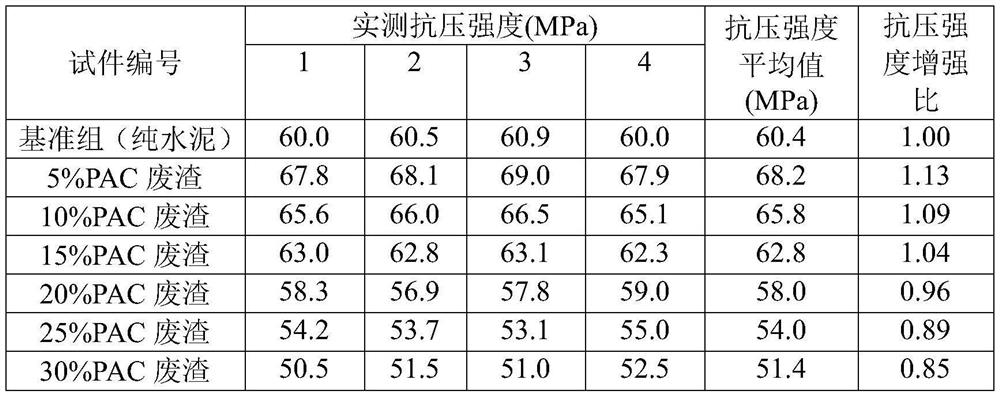

Polyaluminum chloride waste residue dry-mixed mortar and preparation method thereof

ActiveCN111978050APotentially chemically active and effectivePotential chemical activationSolid waste managementEnvironmental engineeringCement mortar

The invention discloses polyaluminum chloride waste residue dry-mixed mortar and a preparation method thereof. The dry-mixed mortar comprises the following raw materials in parts by mass: 4-8 parts ofheat activated polyaluminum chloride waste residues, 23-25 parts of cement, 55-60 parts of sand, 4-6 parts of fly ash, 0.05-0.15 parts of a defoamer, 0.20-0.22 parts of a water reducing agent and a polymer emulsion accounting for 5%-9% of the total mass of the raw materials. The industrial waste polyaluminum chloride waste residues and fly ash are adopted to replace high-energy-consumption cementto prepare the cement mortar, mass stacking of the polyaluminum chloride waste residues can be reduced effectively, the use amount of high-energy-consumption cement can be reduced, and the social andeconomic benefits are good. The preparation method of the polyaluminum chloride waste residue dry-mixed mortar is simple, low in cost and beneficial to industrialized production and promotion, can significantly improve the resource utilization of polyaluminum chloride waste residues, and has important significance in reducing construction costs, reducing environmental pollution and the like.

Owner:HENAN POLYTECHNIC UNIV +1

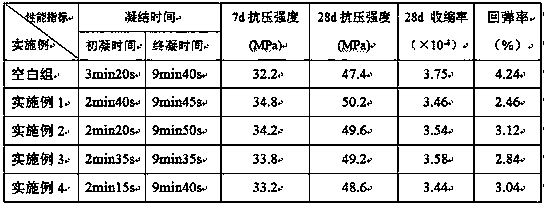

Jet concrete prepared from super absorbent resin and expanded vermiculite

InactiveCN108395159AShorten the setting timeImproves compressive strength and shrinkage resistanceSuper absorbentPolyresin

The invention discloses jet concrete prepared from super absorbent resin and expanded vermiculite. The jet concrete is prepared from the following ingredients including cement, sand, stone, rock fiber, water, setting accelerating agents, super absorbent resin and expanded vermiculite. The super absorbent resin accounting for 0.3 to 0.5 percent of the mass of the cement and expanded vermiculite accounting for 1 to 5 percent of mass of aggregates are uniformly mixed into the jet concrete; an inner caring effect is achieved on the later period of the jet concrete; the condensation time of the jetconcrete can be obviously shortened; the pressure-resistant intensity and the anti-shrinkage performance can be improved; the rebounding rate is reduced; the green environment-friendly pollution-freeconstruction is realized; the jet concrete is particularly suitable for being used for construction such as culverts, bridges and underground engineering.

Owner:TONGJI UNIV

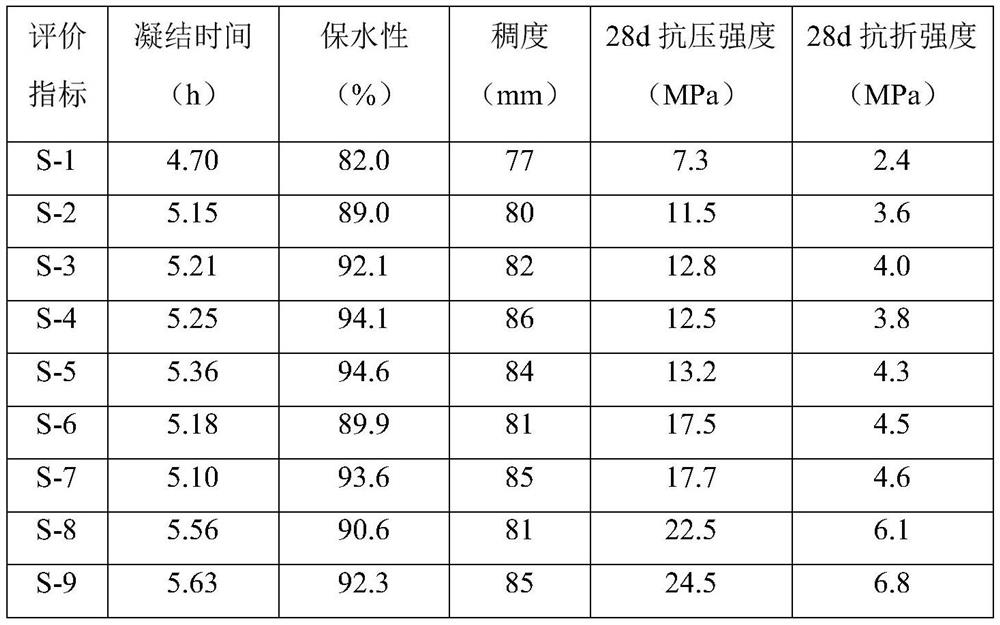

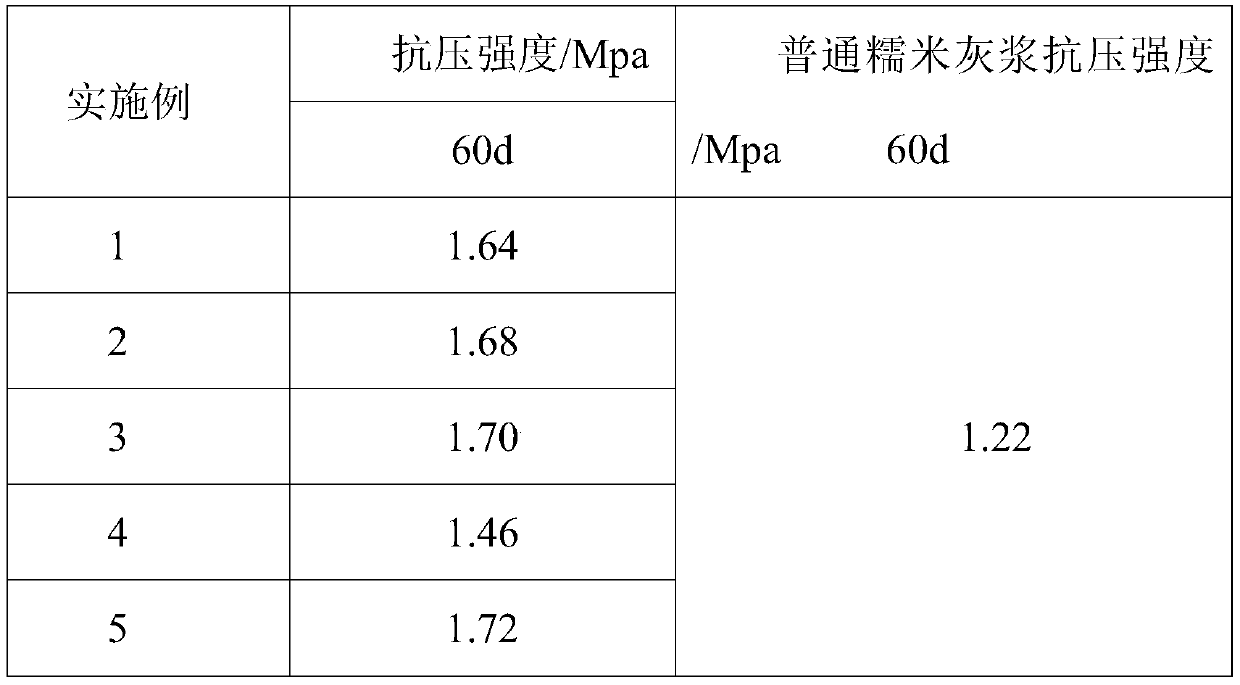

Fiber reinforced mortar for repairing ancient masonry and preparation method of fiber reinforced mortar

The invention discloses a fiber reinforced mortar for repairing ancient masonry. The fiber reinforced mortar consists of the following raw material components in percentage by mass: 50.2-54.4% of calcium hydroxide powder, 43-45% of water, 0.5-2.5% of plant fibers and 2.1-2.3% of glutinous rice flour, wherein the sum of mass percentages of the components is 100%. The invention also discloses a preparation method of the mortar. The preparation method comprises the following steps: weighing the raw materials, preparing glutinous rice pulp, preparing glutinous rice mortar, preparing the glutinousrice mortar into an experiment test piece, and carrying out curing. The mortar prepared by the method has obviously improved compressive strength and meets requirements of restoration of cultural relics and buildings.

Owner:XIAN UNIV OF TECH

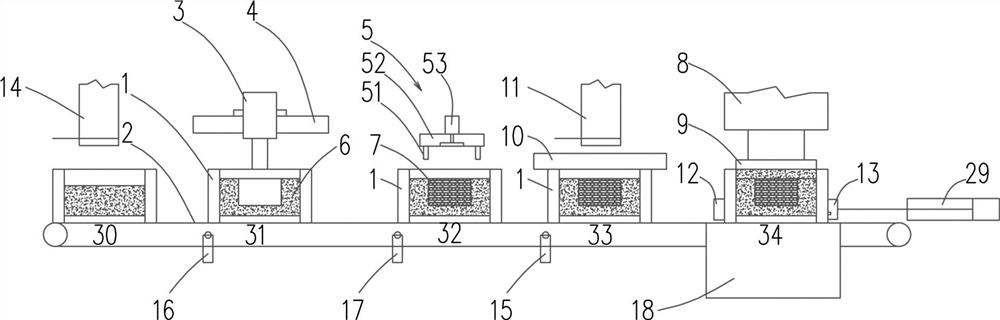

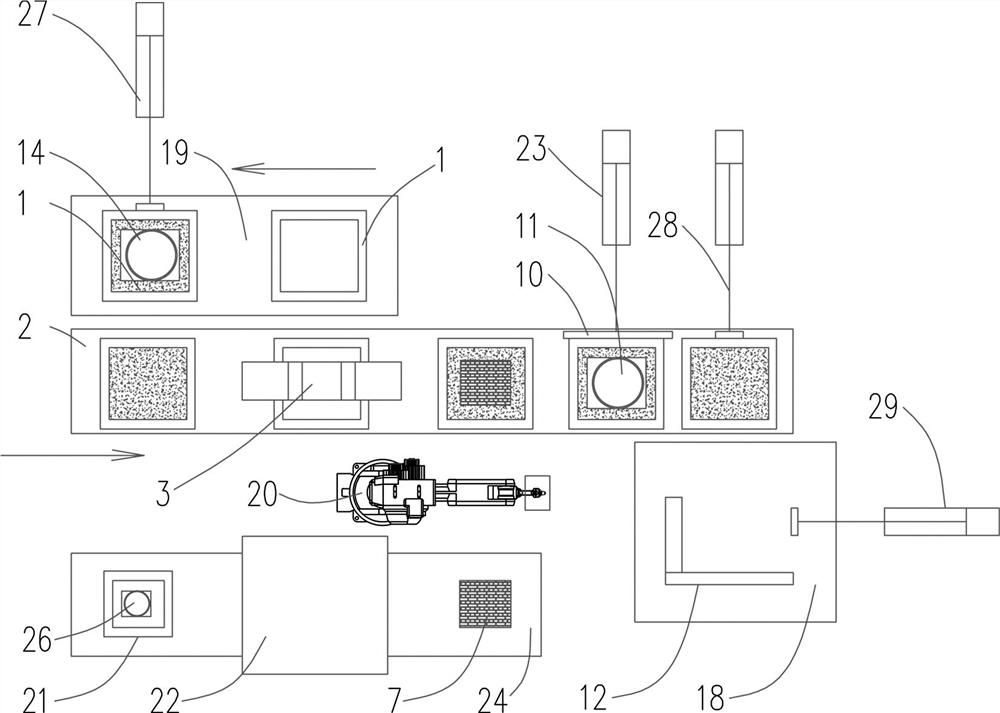

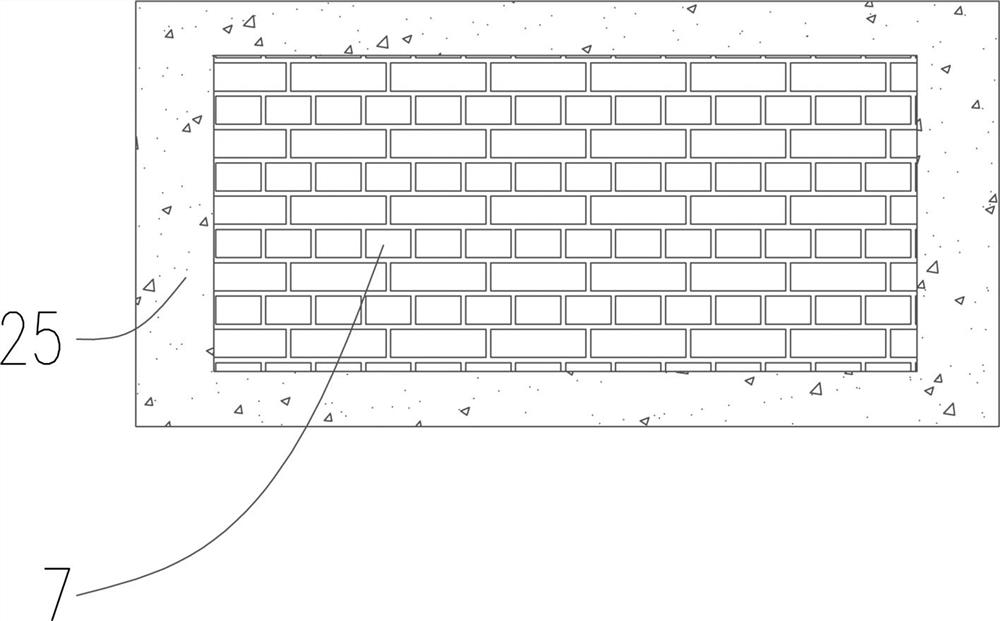

Preparation method and equipment of high-strength ardealite block material and pavement brick

ActiveCN113354379AHigh strengthReduce bite forceCeramic shaping plantsShaping press ramBrickPozzolana

The invention provides a preparation method and equipment of a high-strength ardealite block material and a pavement brick. The high-strength ardealite block material is prepared from the following components in parts by weight: 100 parts of neutralized and dehydrated ardealite material, 0.5-5 parts of cement powder, 1-5 parts of silicate mineral powder, 0.5-5 parts of volcanic ash active powder, 0.1-0.2 part of retarder and 0.06-0.1 part of water-retaining agent. The water accounts for 9-13% of the weight of the mixture; and the particle sizes of the silicate mineral powder and the volcanic ash active powder are less than 1 mum. The preparation method comprises the following steps of preparing a shell from impervious cement concrete, and putting a high-strength phosphogypsum block material into the impervious cement concrete shell, feeding from the top of the impervious concrete, and pressing into pavement bricks under 15-20MPa, and performing steam curing for 3-4 days to obtain the high-strength high-content phosphogypsum pavement brick. The production line for preparing the phosphogypsum pavement brick is sequentially provided with a shell feeding station, a shell forming station, a block material placing station, a top feeding station and a pavement brick pressing station. The compressive strength of the prepared pavement brick exceeds 30 MPa.

Owner:HUBEI YITONG CONSTR ENG CO LTD

Mining high-strength anti-shrinkage water plugging material and preparation method thereof

The invention discloses a mining high-strength anti-shrinkage water plugging material and a preparation method; the mining high-strength anti-shrinkage water plugging material is composed of the following raw materials by mass: 3-10 parts of polyvinyl alcohol, 50-70 parts of sulphoaluminate cement, 5-20 parts of quartz powder, 3-15 parts of slag powder, 2-6 parts of gypsum powder, 2-5 parts of quicklime, 1-5 parts of a retarder, 1-3 parts of a cross-linking agent, 1-5 parts of a coagulant, and 1-5 parts of a stabilizer. The preparation method comprises the following steps: adding the polyvinylalcohol, sulphoaluminate cement, quartz powder, slag powder, gypsum powder and quick lime into a ball mill, grinding into particles with the average particle size of 2 mm, putting the particles, thecross-linking agent, the coagulant and the stabilizer into a stirrer, and uniformly stirring, thereby obtaining the high-strength shrinkage-resistant water plugging material for mining. According to the invention, the disadvantages of large shrinkage and low strength of the original inorganic material are effectively improved.

Owner:渭南陕煤启辰科技有限公司

Dry-mixed wear-resistant floor mortar and preparation method thereof

The invention relates to a dry-mixed wear-resistant floor mortar and a preparation method thereof. The dry-mixed wear-resistant floor mortar is prepared from the following raw materials in parts by weight: 80-100 parts of Portland cement, 10-20 parts of corundum, 10-20 parts of aluminum powder, 15-20 parts of nano bentonite, 5-8 parts of nano ceramic powder, 7-10 parts of modified nano calcium carbonate, 20-40 parts of rubber powder, 3-6 parts of methyl cellulose ether, 3-5 parts of polypropylene fiber, 10-12 parts of fly ash, 8-10 parts of gypsum, 1-3 parts of silicon defoaming agent and 1-3 parts of naphthalene sulfonate water reducing agent. The dry-mixed wear-resistant floor mortar has excellent wear resistance, impact resistance and bonding properties, and can reduce the ground dust and increase the oil resistance of the ground, thereby forming the high-density easy-to-clean anti-permeation ground, and avoiding the phenomena of whitening, sand fallout and the like of the mortar in the later period.

Owner:安庆市凯瑞建材有限公司

Filature damping technology

The invention discloses a filature damping technology. The technology comprises the following steps: putting white steam filatures in a filature damping tank containing hot water, and maintaining the temperature of the hot water in a range of 25-35DEG C; adding a filature damping assistant to the filature damping tank, stirring, and continuously maintaining the temperature of the hot water in a range of 25-35DEG C; and immersing for 10-15h, and taking out the filatures to complete the filature damping technology. Filatures damped through the technology have a good pliability, and the shrink and crease resistance effect of cloths produced by using the filatures is obviously improved.

Owner:HUANGSHAN LANTIAN FANGYUAN IND

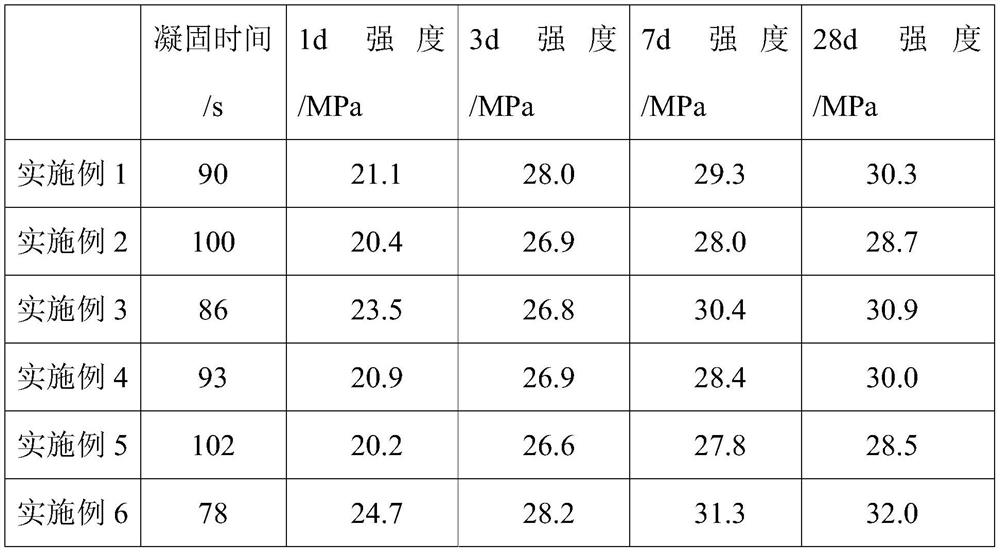

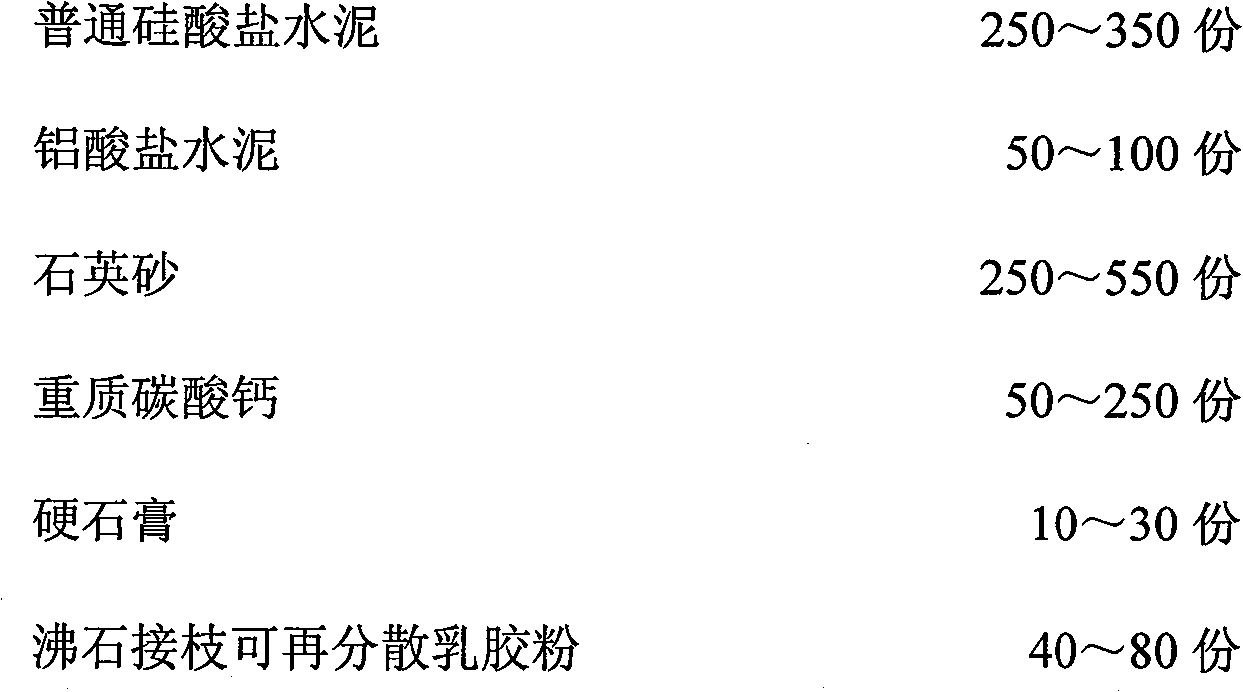

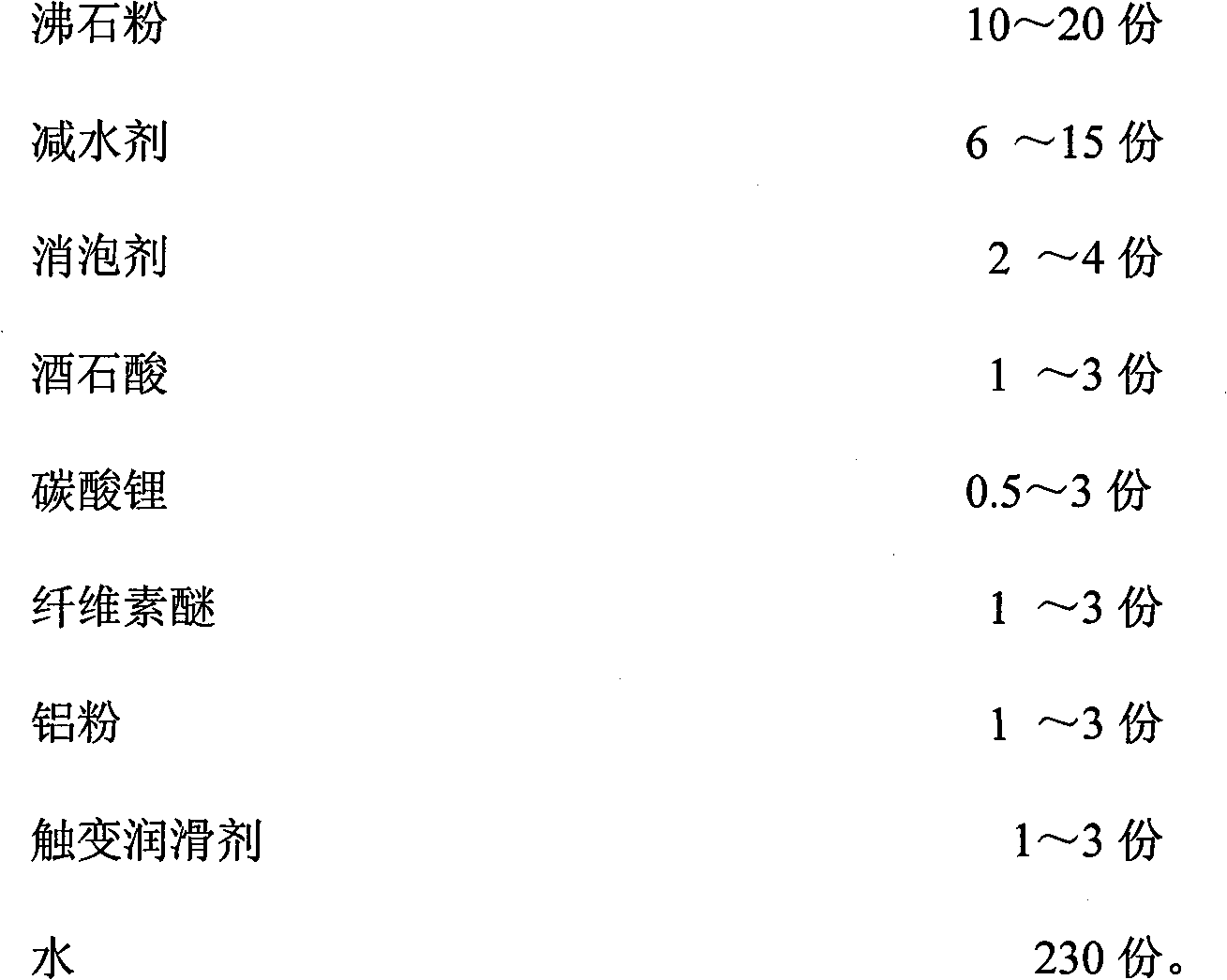

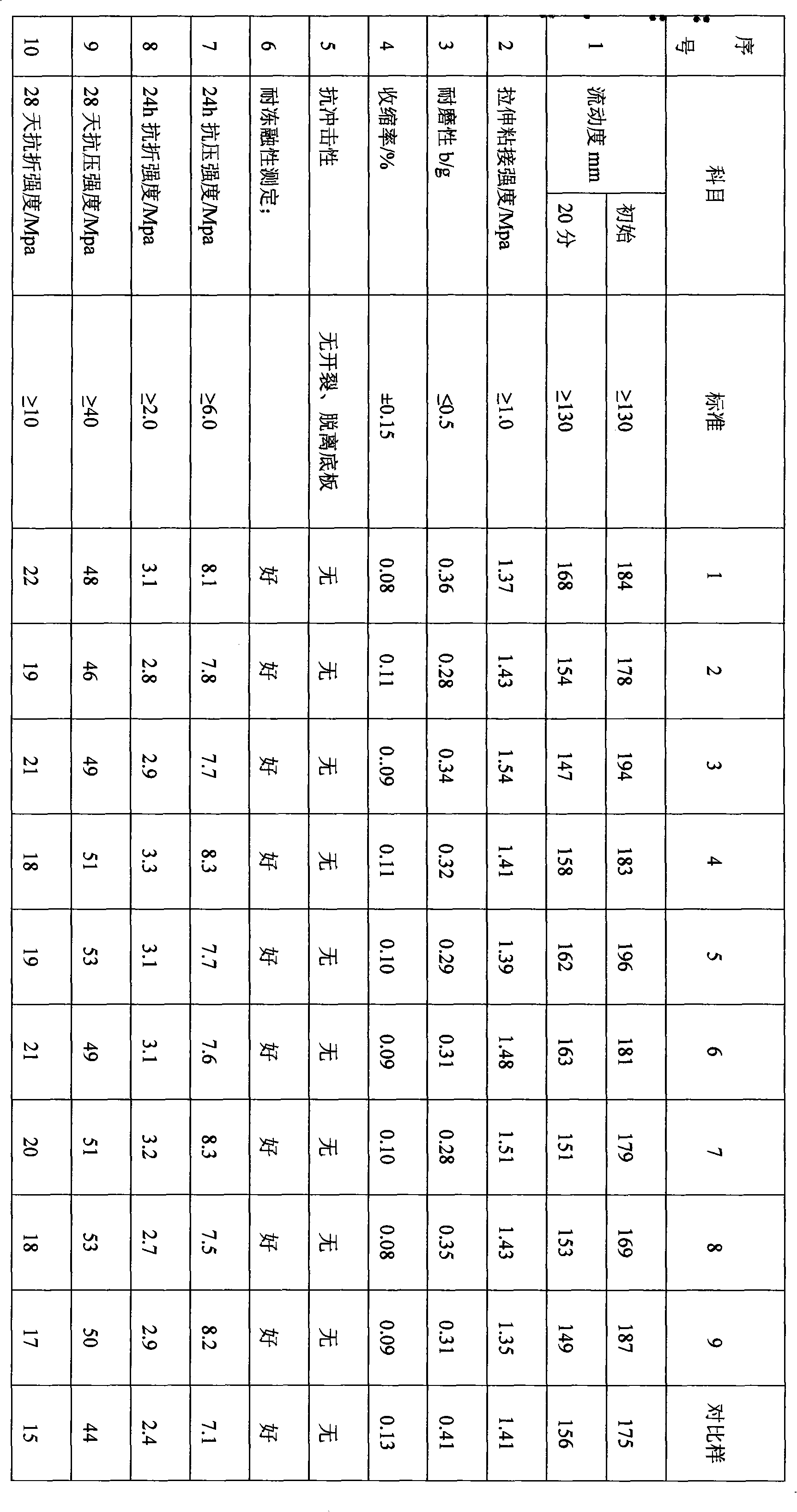

Self-leveling terrace powder mortar composition

The invention provides a self-leveling terrace powder mortar composite and the composite comprises the following components in parts by weight: 250-350 parts of ordinary silicate cement, 50-100 partsof aluminate cement, 250-550 parts of quartz sand, 50-250 parts of heavy calcium carbonate, 10-30 parts of anhydrite and 40-80 parts of zeolite graft re-dispersible emulsion powder. The invention adopts zeolitic inner hole adsorption principle to disperse zeolite evenly in mortar; solid zeolite is crosslinked with graft zeolite inside and outside; in the hydration process of silicate cement, the dense doping among anhydrite, heavy calcium carbonate and crosslinked zeolite changes the lattice of cement so as to ensure the stable long-term strength of mortar and eliminate the phenomenons such asthe efflorescence of the self-leveling terrace mortar in later period, sand-stripping and cracking and the like; in addition, aluminum powder is added to increase the wearability and antishrinking property of the terrace mortar and the flexibility of the polymer is increased to improve the breaking strength of the mortar.

Owner:常熟市金龙装饰有限责任公司

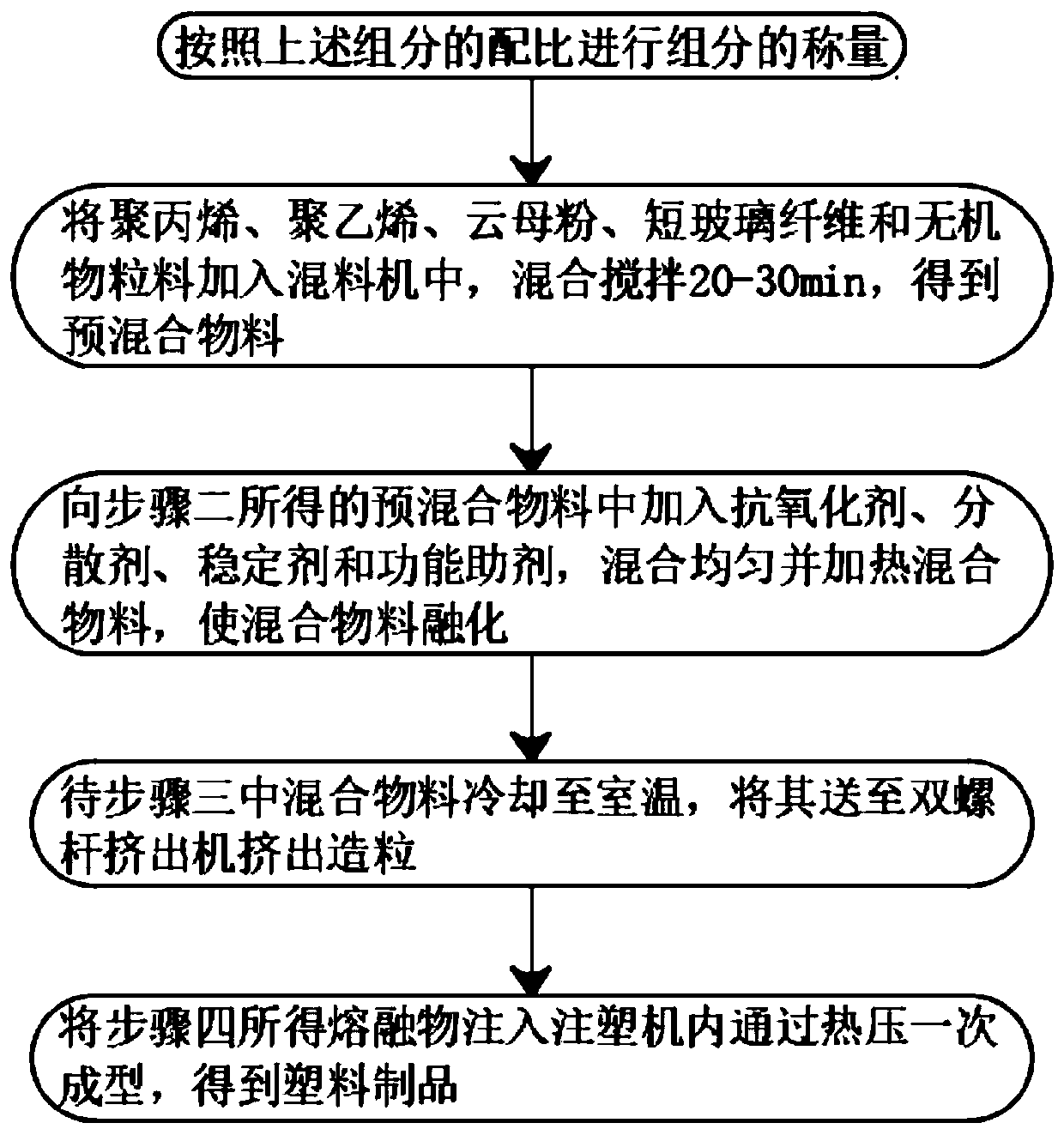

High-strength high-temperature-resistant plastic product and preparation method thereof

InactiveCN110982176ARaise the heat deflection temperatureImproved heat and shrink resistanceCoatingsPelletizingThermal deformation

The invention discloses a high-strength high-temperature-resistant plastic product and a preparation method thereof, and belongs to the technical field of plastic products. According to the high-strength high-temperature-resistant plastic product and the preparation method thereof, various materials are successively mixed according to a certain ratio, and the obtained mixed solution is granulatedby an extruder and hot-pressed to obtain the plastic product. Mica powder and short glass fibers can be added in the preparation process of the plastic product to improve the thermal deformation temperature of the plastic product and make the plastic product not easy to soften when bearing higher temperature. Meanwhile, because of the addition of inorganic granules, the flame retardance, the heatresistance and the shrinkage resistance of the plastic product are improved, and the range of application of the plastic product can be expanded. In addition, in the process in which the mixed material is cooled to the room temperature after being heated, cooling grinding balls are added into the mixed material to reduce the heat of the mixed material, so that the time required for cooling the mixed material to the room temperature is shortened, and the preparation period of the plastic product is shortened.

Owner:HANGZHOU LESHOU TECH CO LTD

Method for producing plastic tray by utilizing hollow blow molding machine

The invention discloses a method for producing a plastic tray by utilizing a hollow blow molding machine. The method comprises the steps of sealing an original air outlet of a blowing hole in the bottom of a traditional front die of the plastic tray, and arranging five blowing needles on the forming surface of the front die by utilizing a ventilation channel of the original bottom blowing hole; clamping the bottom of a tubular hollow blank when the blank is discharged, beginning to assemble, preblowing air to the hollow position of the tubular hollow blank through a blowing port in an extruding machine at the same time, stopping preblowing air when the tubular hollow blank is expanded to the set size, and continuing assembling; at the time, the five blowing needles are slowly close to the hollow blank, firstly, the hollow blank is punctured by the longest central blowing needle so as to blow air, and secondly, the hollow blank is punctured by the corner blowing needles with the same length at four corners so as to blow air, so that simultaneous blowing from five side surfaces is realized, and the tray blank is uniformly and closely adhered to the surface of a die cavity instantly. Finally, the method for producing the plastic tray, which has the advantages of uniformity in wall thickness, high intensity, low raw material consumption, low cost, stable quality and high efficiency, is provided.

Owner:吴忠市恒通塑料制品有限公司

Easy-to-clean soundproof automobile roof material

InactiveCN105985626AHarmless to healthImprove waterproof performanceBiochemical fibre treatmentLight resistant fibresPolyethylene glycolDidodecyldimethylammonium bromide

The invention discloses an easy-to-clean soundproof automobile roof material which is prepared from, by weight, 25-30 parts of wool fiber, 4-5 parts of chitosan, 2-3 parts of titanium dioxide, 0.6-1 part of polyethylene glycol, 100-110 parts of waterborne polyurethane, 0.2-0.4 part of didodecyldimethylammonium bromide, 5-6 parts of clay, 6-7 parts of rock fiber, 3-4 parts of styrene-acrylic emulsion, 4-5 parts of polyacrylonitrile, 5-6 parts of nano zeolite molecular sieve and a proper amount of deionized water. A preparation method is simple, the material has high light resistance, antibacterial performance, soundproof performance and easiness in cleaning; serving as a novel automobile roof material, the problem that existing roof materials are difficult to clean and prone to smudginess is solved, and the material is worthy of popularization.

Owner:芜湖跃飞新型吸音材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com