Filature damping technology

A process and foam silk technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of poor anti-shrinkage and anti-wrinkle effect of fabrics, poor environmental protection, poor silk softness, etc., to achieve enhanced anti-shrinkage and anti-wrinkle effects, environmental protection Strong and soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] a. Put 60kg of white factory silk into a soaking silk tank filled with hot water, and keep the water temperature at 30°C;

[0018] b. Put 25g of chitosan and 25g of tea polyphenol powder into the foam tank, stir, and keep the water temperature at 30°C;

[0019] c. After soaking for 12 hours, the shreds can be pulled out to complete the shredded shred process.

Embodiment 2

[0021] a. Put 60kg of white factory silk into a soaking silk tank filled with hot water, and keep the water temperature at 25°C;

[0022] b. Put 5g of chitosan and 25g of tea polyphenol powder into the foam tank, stir, and keep the water temperature at 25°C;

[0023] c. After soaking for 15 hours, the shreds can be removed to complete the shredded shred process.

Embodiment 3

[0025] Put 60kg of white factory silk into the soaking silk tank filled with hot water, and keep the water temperature at 35°C;

[0026] b. Put 25g of chitosan and 25g of tea polyphenol powder into the foam tank, stir, and keep the water temperature at 35°C;

[0027] c. After soaking for 10 hours, the shreds can be removed to complete the shredded shred process.

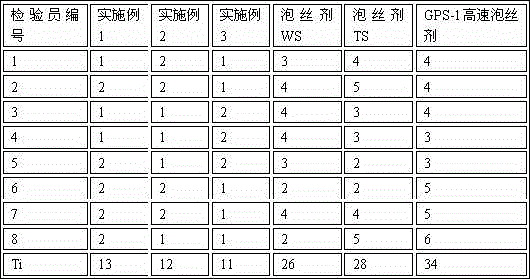

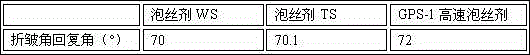

[0028] According to the subjective evaluation method in the "Journal of Textile Science" volume 29, No. 5, "Subjective and Objective Evaluation of Fabric Softness" in May, 2008, the softness of the silk foamed in the above-mentioned examples is evaluated, and the evaluation results are as follows . At the same time, in the table, three kinds of foams using foaming agent WS and foaming agent TS produced by Sangda Chemical (Nantong) Co., Ltd. and GPS-1 high-speed foaming agent produced by Zibo Aowei Adhesive Co., Ltd. are also given. Evaluation of softness of silk exuded from additives.

[0029]

[0030] From the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com