Electrohydraulic controlled continuously variable gas distribution timing system in internal-combustion engine

An electro-hydraulic control and timing system technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of not being able to meet low fuel consumption, and cannot realize continuous variable gas distribution timing, so as to improve fuel economy and increase Dynamic performance, the effect of improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

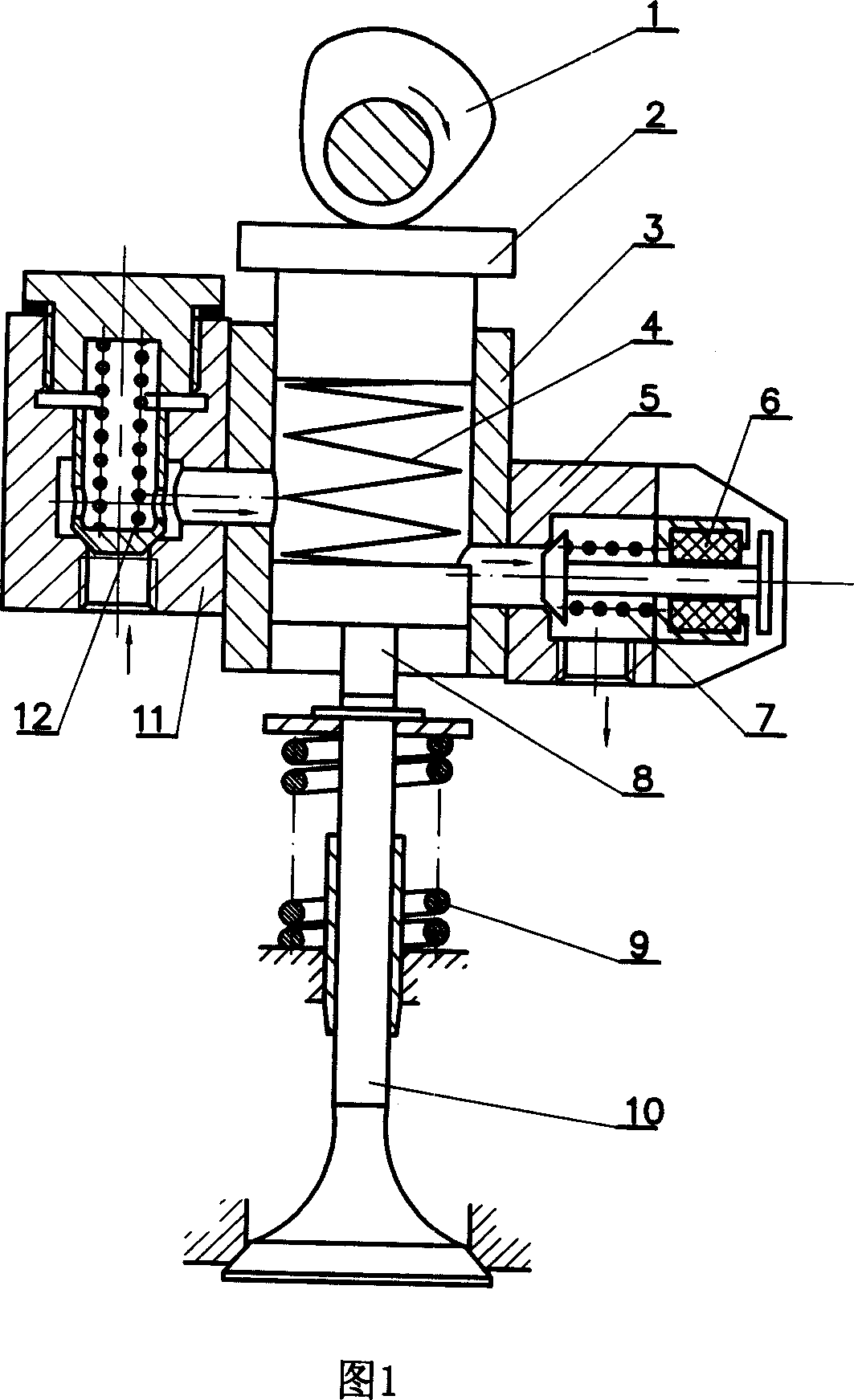

[0018] The working process of the present invention will be described in detail below in conjunction with the accompanying drawings. In Fig. 1, the left side is the inlet check valve part, including the check valve body 11, the check valve spring 12, etc.; the right side is the one-way electromagnetic booster valve part, including the solenoid valve body 5, the solenoid coil 6 and The valve spring 7, etc.; the middle part is the valve driving mechanism, including the gas distribution cam 1, the tappet 2, the tappet return spring 4, the hydraulic cylinder block 3, the hydraulic piston 8, the valve spring 9 and the valve 10, etc. The gas distribution cam 1 in the camshaft transmission assembly drives the tappet 2, and the tappet 2 is placed in the hydraulic cylinder body 3 so that it can move axially, and part of the outer circular surface of the tappet 2 is sealed with one end of the inner wall of the hydraulic cylinder. 3 The other end of the inner wall is a hydraulic piston 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com