Wheel and mechanical leg joint multiplexing motor transmission system and driving method

A technology of motor transmission and driving method, which is applied in the direction of motor vehicles, power devices, motion deposition, etc., can solve the problems of low transmission efficiency, large space occupation, and complex structure of mechanical legs, and achieve agile action, high energy density, and large output The effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

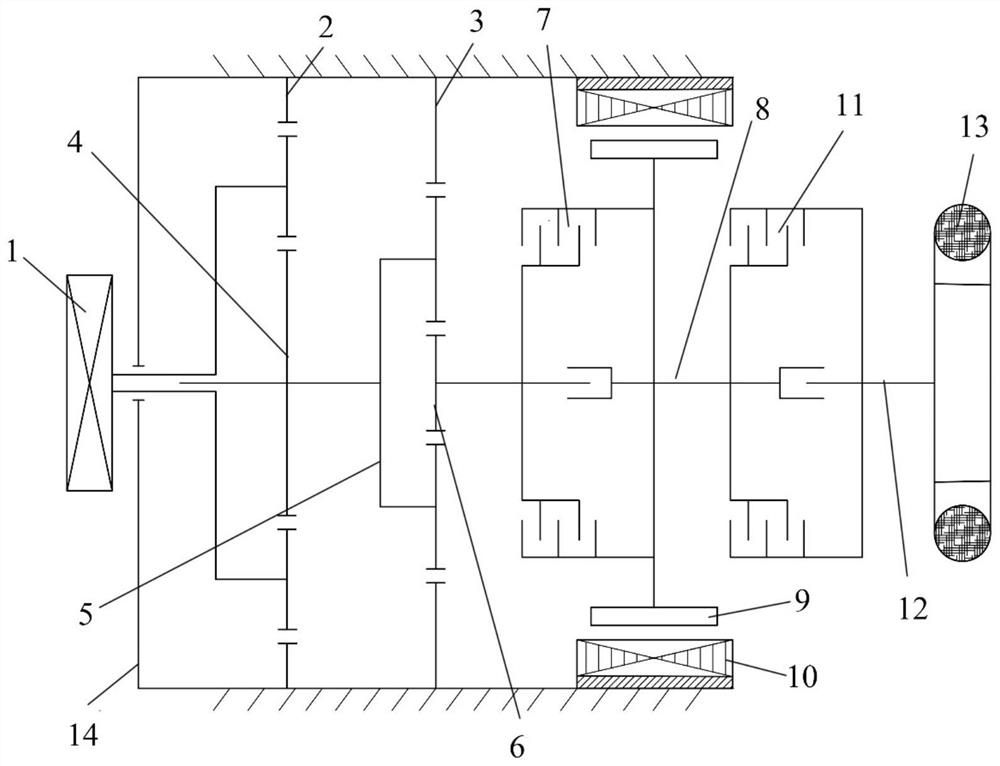

[0038] Such as figure 1 As shown, the embodiment of the present invention provides a wheel and mechanical leg joint multiplexing motor transmission system, the wheel and mechanical leg joint multiplexing motor transmission system includes: a first clutch 11, a second clutch 7, a planetary gear set reducer, Wheel 13 and hub motor; the hub motor is installed in the mechanical leg housing 14, and the planetary gear set reducer ring gear is installed in the mechanical leg housing 14; the output shaft 8 of the hub motor is connected to the input end of the first clutch 11 and the second clutch at the same time 7; the output end of the first clutch 11 is connected to the wheel 13; the output end of the second clutch 7 is connected to the input end of the planetary gear set reducer; the output end of the planetary gear set reducer is connected to the leg joint 1.

[0039] When the first clutch 11 is connected and the second clutch 7 is disconnected, in the embodiment of the present i...

Embodiment 2

[0051] An embodiment of the present invention provides a driving method for multiplexing a wheel and a mechanical leg joint. The embodiment of the present invention uses the multiplexing motor transmission system for a wheel and a mechanical leg joint in Embodiment 1.

[0052] The driving method in the embodiment of the present invention includes wheel driving and step driving. When using wheel drive, the wheel-step platform uses the transmission system in Embodiment 1 to move wheel-type, that is, the wheel hub motor finally drives the wheel 13 to rotate, so that the wheel-step platform moves in the form of a car through the rotation of the wheel 13. When using step-type drive, the wheel-step platform uses the transmission system in Embodiment 1 to move step-by-step, that is, the hub motor finally makes the transmission system rotate as a mechanical leg, so that the wheel-step platform moves by turning the mechanical leg and taking steps. Two kinds of driving methods can not b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com