Fiber reinforced mortar for repairing ancient masonry and preparation method of fiber reinforced mortar

A fiber-reinforced and masonry technology is applied to fiber-reinforced mortar. The mortar preparation field can solve the problems of easy occurrence of cracks and low strength, and achieve the effects of improving integrity and improving tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

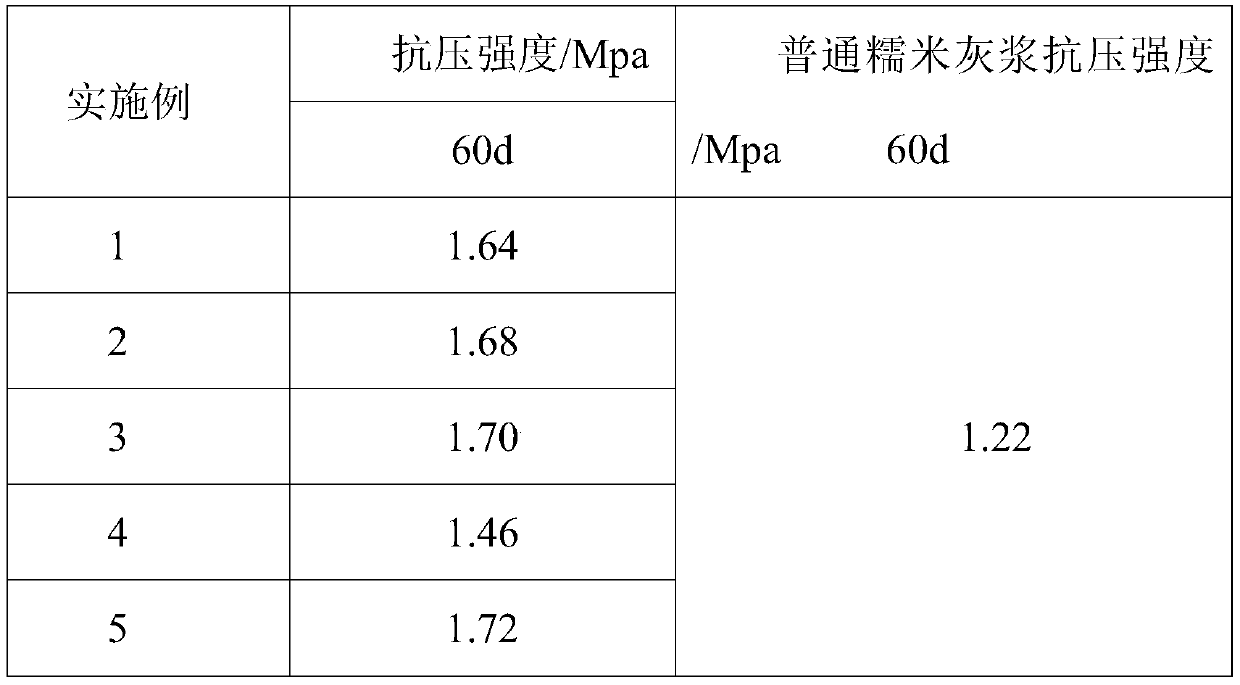

Embodiment 1

[0040] Weigh respectively 54.4% of calcium hydroxide powder, 43% of water, 0.5% of natural flax plant fiber, and 2.1% of glutinous rice flour according to mass percentages; pour the weighed glutinous rice flour and water into the container and mix evenly, and heat the container at 100 ° C. Heating, heating for 0.5h, stirring at a low speed during the heating period, the rotation speed of the low-speed stirring is 50r / min, and adding water to the container every 10min to keep the concentration of the mixture at 5%, after the heating is completed, cool the container to 33°C , to obtain glutinous rice slurry; the calcium hydroxide powder, strength additives, titanium dioxide and the obtained glutinous rice slurry were mixed uniformly, poured into a cement mortar mixer and stirred at a high speed for 16 minutes, and the rotating speed of high-speed stirring was 200r / min to obtain a glutinous rice mortar Pour the obtained glutinous rice mortar into the test mold, use a metal ruler a...

Embodiment 2

[0042] Take by weight 53.35% of calcium hydroxide powder, 43.5% of water, 1% of natural flax plant fiber, and 2.15% of glutinous rice flour according to mass percentage; The container is heated, and the heating lasts for 0.8h. During the heating period, it is kept stirring at a low speed. The rotation speed of the low-speed stirring is 60r / min, and water is added to the container every 10 minutes to keep the concentration of the mixture at 5%. After the heating is completed, the container is cooled to 30 ℃, to obtain glutinous rice slurry; the calcium hydroxide powder, polypropylene and the obtained glutinous rice slurry were mixed evenly, poured into a cement mortar mixer and stirred at a high speed for 18min, and the rotating speed of high speed stirring was 180r / min to obtain a glutinous rice mortar. Pour the obtained glutinous rice mortar into the test mold, use a metal ruler along the top plane of the test mold, and move from one end of the top of the test mold to the othe...

Embodiment 3

[0044]Take by weight 52.3% of calcium hydroxide powder, 44% of water, 1.5% of natural flax plant fiber, and 2.2% of glutinous rice flour according to mass percentage; Heating the container, heating for 1.2h, stirring at a low speed during the heating period, the rotation speed of the low speed stirring is 70r / min, and adding water to the container every 10min to keep the concentration of the mixture at 5%, after the heating is completed, cool the container to 30 ℃, to obtain glutinous rice pulp; mix the calcium hydroxide powder weighed, natural flax plant fiber and the obtained glutinous rice pulp evenly, pour it into a cement mortar mixer and stir at a high speed for 15min, and the rotating speed of high speed stirring is 160r / min, to obtain glutinous rice Mortar, pour the obtained glutinous rice mortar into the test mold, use a metal ruler along the top plane of the test mold, move from one end of the test mold top to the other end of the test mold top in a split motion along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com