Antibacterial health-care fabric

A technology of health-care fabrics and jade fibers, applied in the field of textile fabrics, can solve the problems of unsatisfactory fabric effects, negligible health-care effects, and inconspicuous antibacterial effects, etc., and achieve good moisture absorption and breathability, elegant and natural luster, and excellent antibacterial properties sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] An antibacterial health care fabric, interwoven by warp and weft, the warp is made of jade fiber and chitin fiber blended yarn, the fineness of jade fiber is 3.2dtex, the length is 45mm, the fineness of chitin fiber is 2.6dtex, the length is 45mm , the latitude adopts milk protein fiber and coconut carbon fiber blended yarn, the fineness of milk protein fiber is 3dtex, and the length is 45mm, the fineness of coconut carbon fiber is 1.8dtex, and the length is 45mm, and the mass percentage of jade fiber and chitin fiber in the warp is 30%: 70%, the mass percentage of chitin fiber and milk protein fiber in the weft is 40%: 60%, and it is made through spinning, weaving and finishing steps, and chitosan quarter is added in the finishing step Ammonium antibacterial agent.

Embodiment 2

[0015] An antibacterial health care fabric, interwoven by warp and weft yarns, the warp is made of jade fiber and chitin fiber blended yarn, the fineness of jade fiber is 4.2dtex, the length is 60mm, the fineness of chitin fiber is 2.8dtex, the length is 60mm , the weft is made of milk protein fiber and coconut carbon fiber blended yarn, the fineness of milk protein fiber is 3.8dtex, and the length is 45mm, the fineness of coconut carbon fiber is 3.8dtex, and the length is 45mm, the mass percentage of jade fiber and chitin fiber in the warp 50%: 50%, the mass percentage of chitin fiber and milk protein fiber in the weft is 60%: 40%, and it is made through spinning, weaving and finishing steps, and chitosan is added in the finishing step Quaternary ammonium antibacterial agent.

Embodiment 3

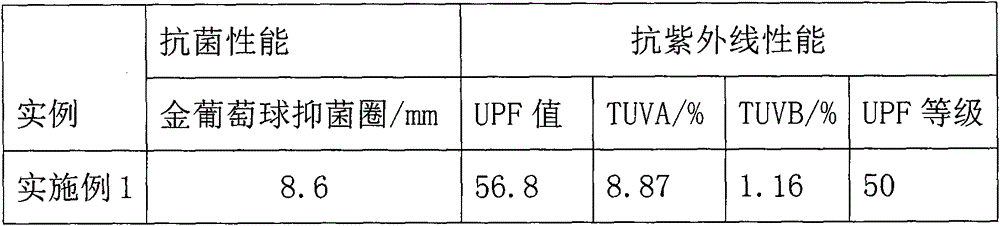

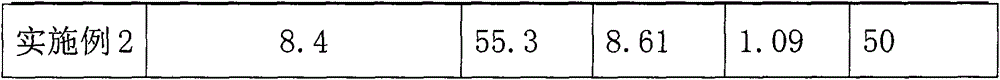

[0017] Fabric performance test, the table shows the test results.

[0018] (1) Fabric anti-ultraviolet effect (ultraviolet transmittance) test:

[0019] According to the Australian / New Zealand standard (AS / NZS4399), it is tested by the American Labsphere UV transmission and protection performance tester.

[0020] (2) Antibacterial performance test

[0021] Bacteria: Staphylococcus aureus

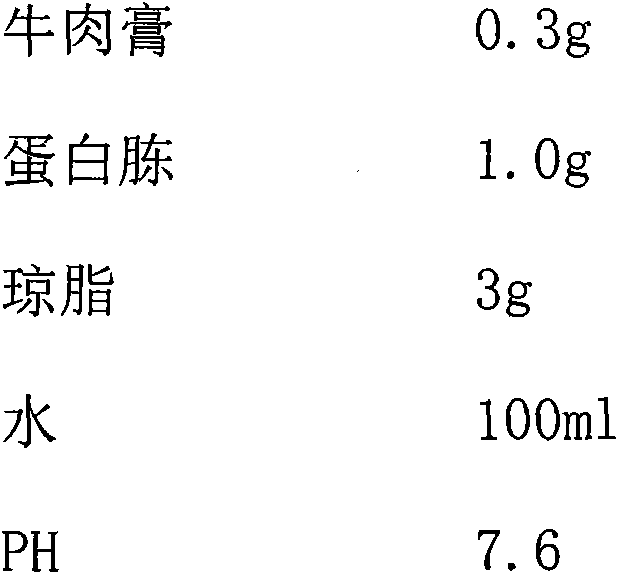

[0022] The standard formulation of the culture medium:

[0023]

[0024] Wash the Petri dishes, pipettes and test tubes, wrap them in newspaper and sterilize them in an oven at 160°C for two hours. Cultivate the medium according to the standard formula, heat to dissolve, and stir constantly, and then sterilize it in a high-temperature and high-pressure sterilizer for 20 minutes. Cool the culture medium to 50°C, divide it into petri dishes, and ensure that the culture medium covers the bottom of the culture dish. Pipette the diluted bacteria on the culture medium in a sterile environme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com