Novel polyethylene floor heating pipe and preparation method thereof

A technology for polyethylene and floor heating pipes, applied in pipes, rigid pipes, mechanical equipment, etc., can solve problems such as scratch resistance, poor wear resistance, and cracks, and achieve the effects of improving shrinkage resistance, prolonging service life, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

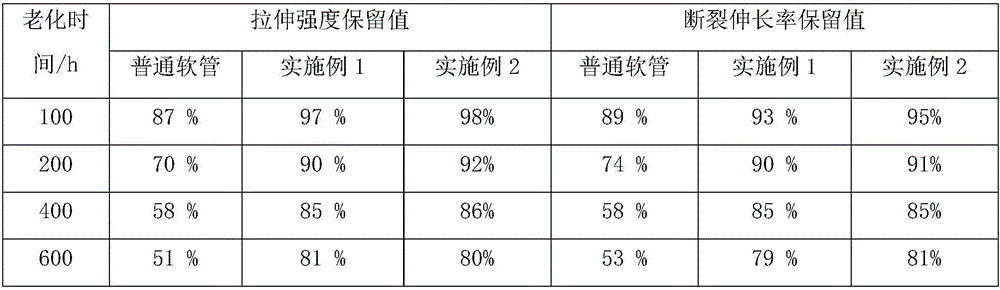

Examples

Embodiment 1

[0017] Mix and melt 90 parts of polyethylene and 3 parts of titanate coupling agent at 170-190 ° C by weight to prepare a material; mix 10 parts of polyethylene and 0.3 parts of anti-oxidation TCA by weight ℃ mixing and melting to obtain material b; mix material a and material b and add 5 parts of azodicarbonamide to the extruder for use.

[0018] Put 100 parts of heat-resistant polyethylene (PE-RT), 0.3 parts of anti-oxidation TCA, and 2 parts of black masterbatch into the mixer in sequence according to weight. vinyl material;

[0019] The heat-resistant polyethylene material of the inner layer is added to the above-mentioned extruder for co-extrusion molding. The temperature of the barrel is 180°C-210°C, and the temperature of the die is 210°C-230°C; the extruded pipe is vacuum sized and cooled to form.

Embodiment 2

[0021] Mix and melt 90 parts of polyethylene and 3 parts of titanate coupling agent at 170-190 ° C by weight to prepare a material; mix 10 parts of polyethylene and 0.2 parts of anti-oxidation TCA by weight at ℃ mixing and melting to obtain material b; mix material a and material b and add 4 parts of azobisisobutyronitrile into the extruder for use.

[0022] Put 100 parts of heat-resistant polyethylene (PE-RT), 0.3 parts of anti-oxidation TCA, and 2 parts of black masterbatch into the mixer in sequence according to weight. vinyl material;

[0023] The heat-resistant polyethylene material of the inner layer is added to the above-mentioned extruder for co-extrusion molding. The temperature of the barrel is 180°C-210°C, and the temperature of the die is 210°C-230°C; the extruded pipe is vacuum sized and cooled to form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com