High-strength high-temperature-resistant plastic product and preparation method thereof

A technology for plastic products and high temperature resistance, which is applied in the field of plastic products, can solve the problems of reducing the heat of mixed materials, shortening the production period of plastic products, reducing and other problems, and achieves the effect of increasing the thermal deformation temperature, shortening the production period and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

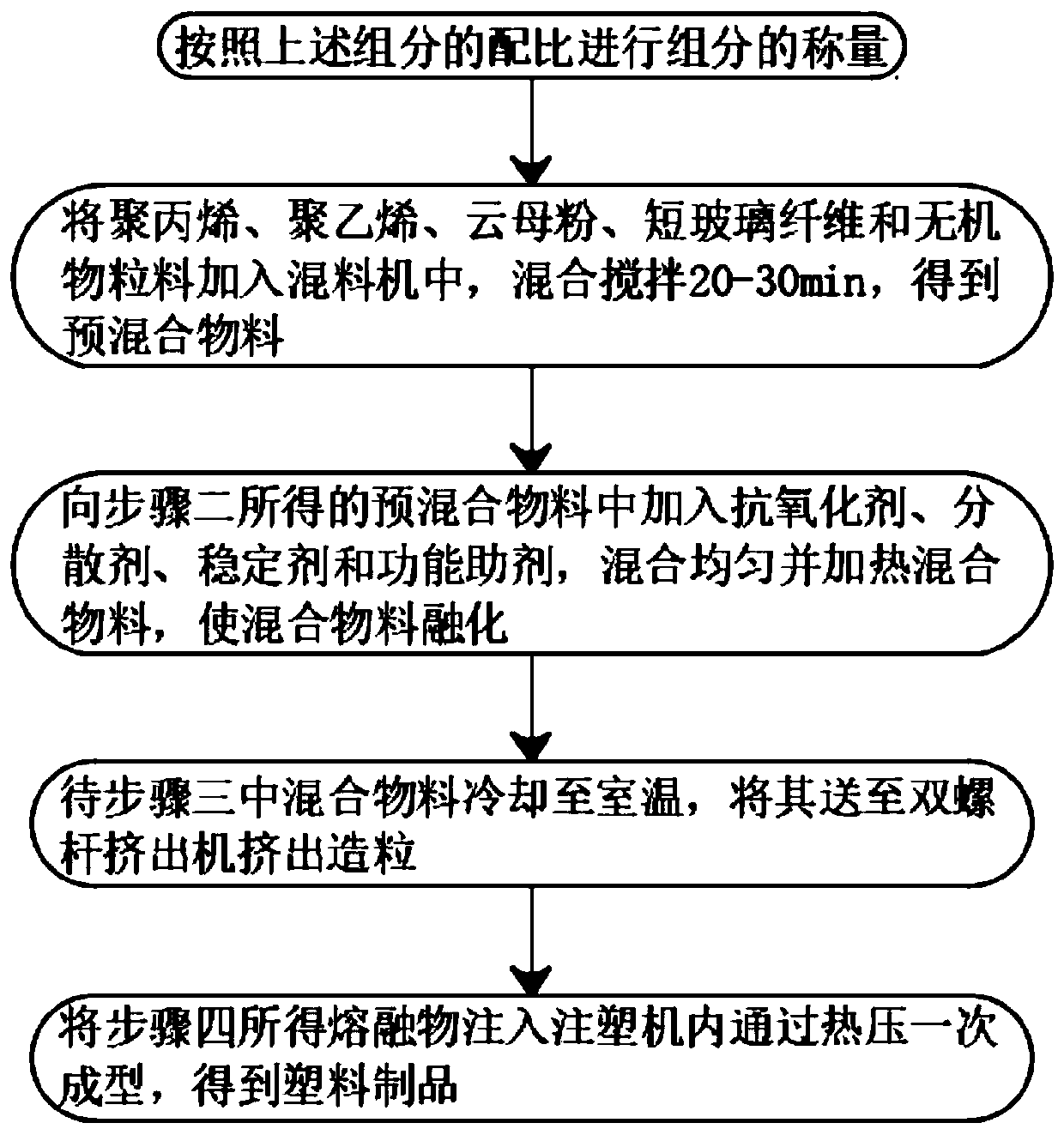

[0046] see figure 1 , a high-strength high-temperature-resistant plastic product and a preparation method thereof, comprising the following components in parts by mass: 30-40 parts of polypropylene, 20-30 parts of polyethylene, 2-8 parts of mica powder, and 1-6 parts Short glass fibers, 1-3 parts of antioxidants, 6-10 parts of dispersants, 0-2 parts of stabilizers, 10-15 parts of functional additives and 3-10 parts of inorganic material granules, the preparation method is: comprising the following steps :

[0047] Step 1, carry out the weighing of component according to the proportioning of above-mentioned component;

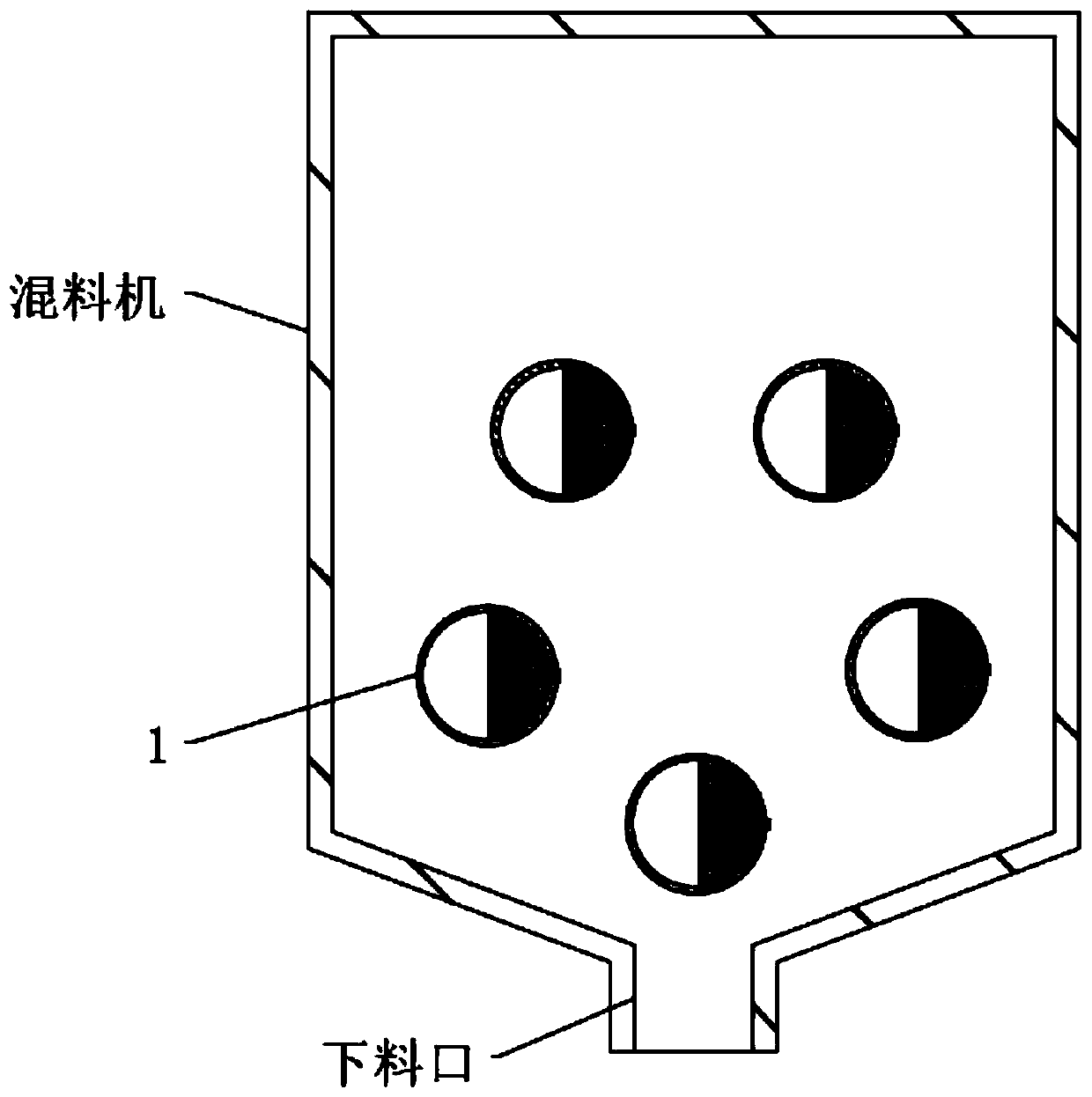

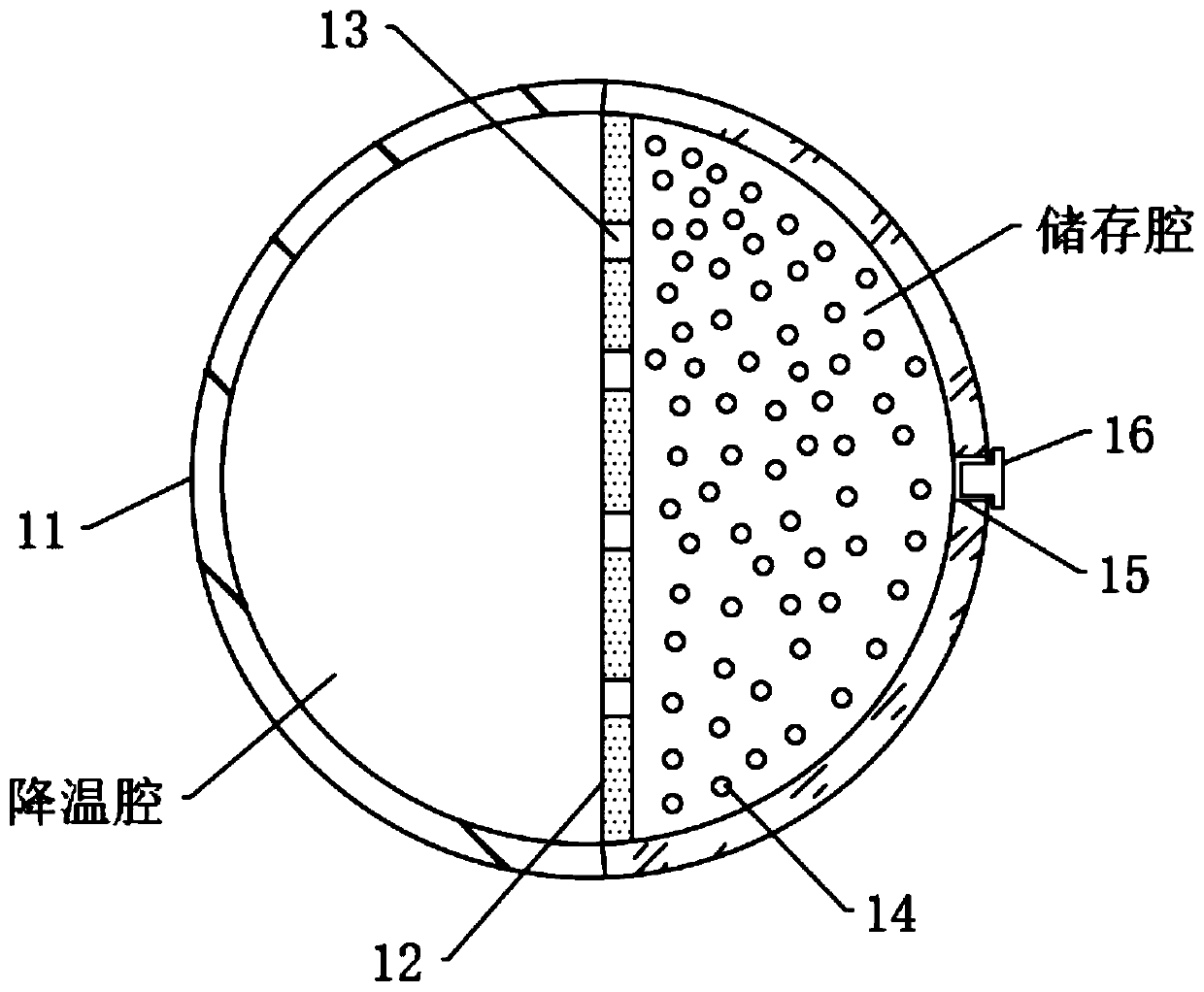

[0048] Step 2, adding polypropylene, polyethylene, mica powder, short glass fiber and inorganic material pellets into the mixer, mixing and stirring for 30 minutes to obtain a premixed material;

[0049] Step 3, adding antioxidant, dispersant, stabilizer and functional auxiliary agent to the premixed material obtained in step 2, mixing evenly and heating the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com