High-ductility thermal insulation mortar

A thermal insulation mortar, high ductility technology, applied in the field of building materials to achieve the effects of high mechanical properties, high deformation properties, and high thermal insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The material composition ratio is shown in Table 1:

[0053] Table 1 Mixing ratio of high ductility thermal insulation mortar materials (mass parts)

[0054]

[0055] The cement is P·O 42.5 ordinary Portland cement; the apparent density of high-strength microbeads is 650kg / m 3 , bulk density 375kg / m 3 , volume average diameter D(4,3) 200μm, compressive strength 150MPa, thermal conductivity 0.06W / (m K); fine aggregate is river sand, fineness modulus 2.6, maximum particle size 5mm; acrylate copolymer emulsion Condensation concentration 52g / L, solid content 40%; water is drinking tap water; water reducing agent is polycarboxylate high-performance water reducing agent, water reducing rate is 25%; fiber is polyvinyl alcohol fiber, equivalent diameter 40μm, elastic modulus 39GPa, length 12mm.

[0056] The rotating speed of the high-speed stirring is 600 rpm, and the stirring time is 3 minutes.

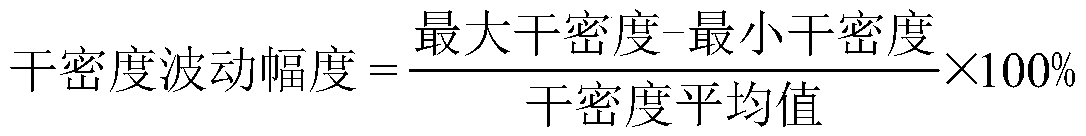

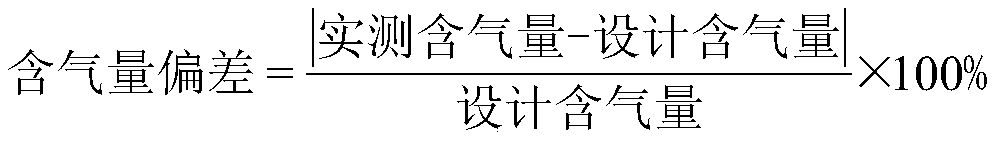

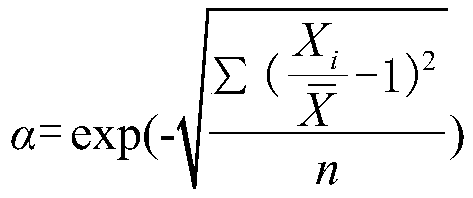

[0057] The fluctuation range of the dry density of the three parts of the ...

Embodiment 2

[0059] The material composition ratio is shown in Table 2:

[0060] Table 2 Mixing ratio of high ductility thermal insulation mortar materials (mass parts)

[0061]

[0062] The cement is P MH 42.5 medium heat Portland cement; silica fume SiO 2 The content is 95%; the apparent density of high-strength microbeads is 650kg / m 3 , bulk density 375kg / m 3 , volume average diameter D(4,3) 200μm, compressive strength 150MPa, thermal conductivity 0.06W / (m K); fine aggregate is quartz sand, fineness modulus 3.0, maximum particle size 5mm; acrylate copolymer emulsion Condensation concentration 52g / L, solid content 40%; water is drinking tap water; water reducing agent is polycarboxylate high-performance water reducing agent, water reducing rate is 30%; fiber is polyvinyl alcohol fiber, equivalent diameter 40μm, elastic modulus 39GPa, length 6mm.

[0063] The rotating speed of the high-speed stirring is 650 rpm, and the stirring time is 4 minutes.

[0064] The fluctuation range of...

Embodiment 3

[0066] The material composition ratio is shown in Table 3:

[0067] Table 3 Mixing ratio of high ductility thermal insulation mortar materials (mass parts)

[0068]

[0069] The cement is P LH 42.5 low-heat Portland cement; S75 grade slag; high-strength micro-beads with an apparent density of 650kg / m 3 , bulk density 375kg / m 3 , volume average diameter D(4,3) 200μm, compressive strength 150MPa, thermal conductivity 0.06W / (m K); fine aggregate is tailings, fineness modulus 2.3, maximum particle size 5mm; acrylate copolymer emulsion Condensation concentration 52g / L, solid content 40%; water is drinking tap water; water reducing agent is polycarboxylate high-performance water reducing agent, water reducing rate is 30%; fiber is polyvinyl alcohol fiber, equivalent diameter 20μm, elastic modulus 39GPa, length 12mm.

[0070] The rotating speed of the high-speed stirring is 700 rpm, and the stirring time is 5 minutes.

[0071] The fluctuation range of the dry density of the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Volume mean diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com