Preparation method and equipment of high-strength ardealite block material and pavement brick

A phosphogypsum, high-strength technology, applied in the direction of manufacturing tools, molding indenters, ceramic molding workshops, etc., can solve problems such as the reduction of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

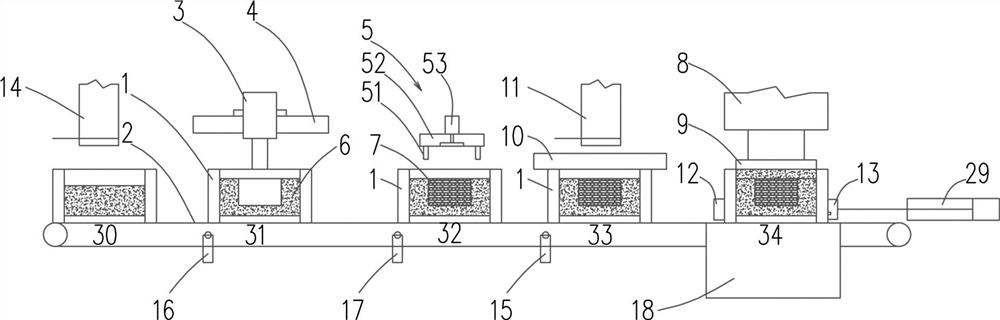

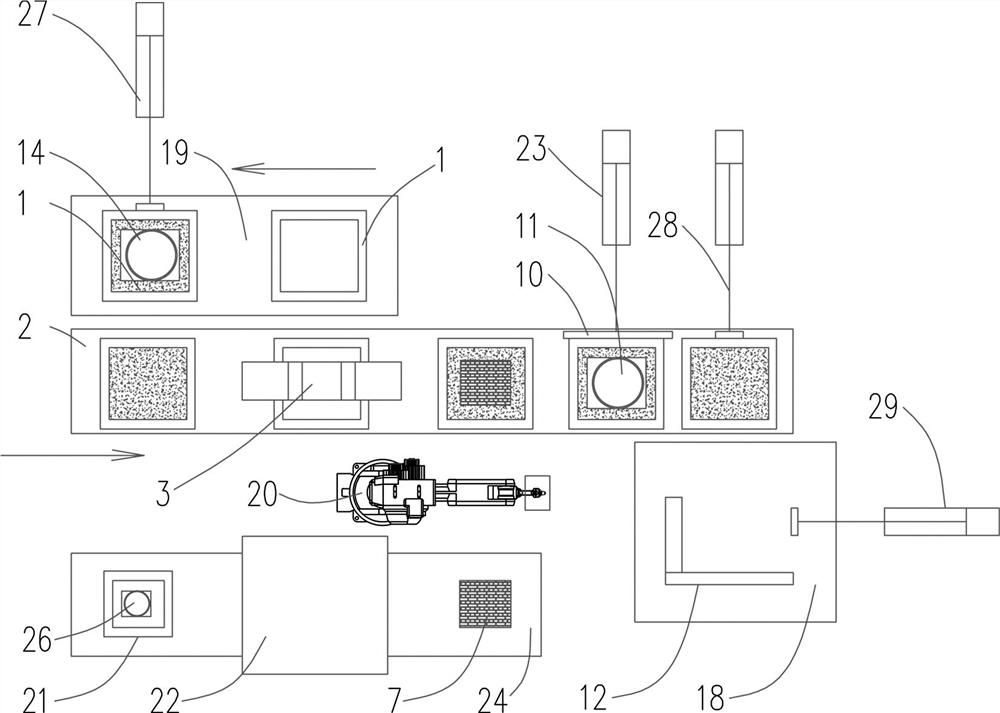

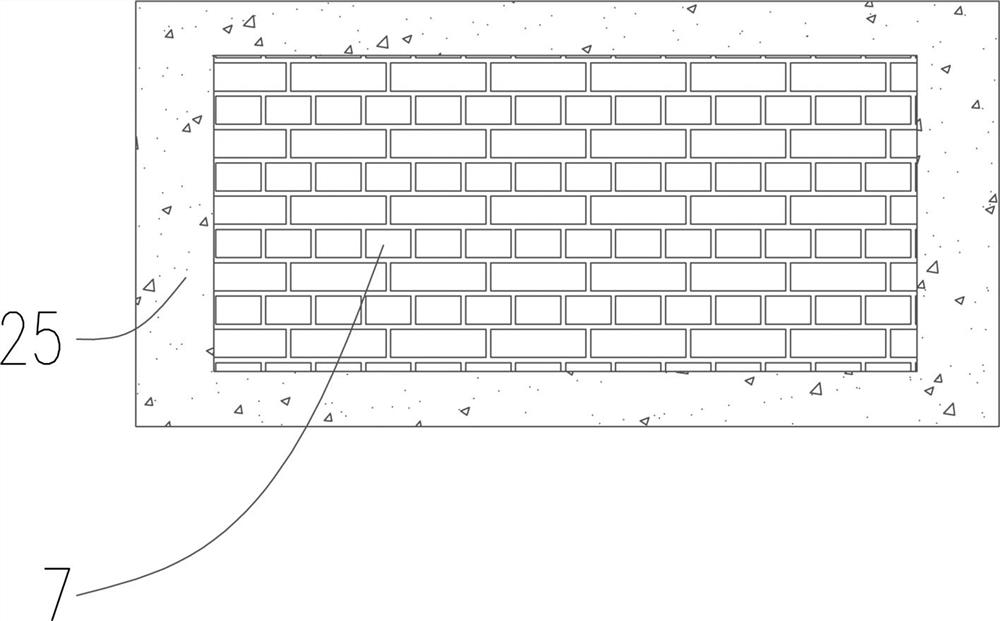

Method used

Image

Examples

Embodiment 1

[0045] Components in parts by weight: 1000 grams of neutralized dehydrated phosphogypsum material, 5 grams of cement powder, 10 grams of silicate mineral powder, 5 grams of pozzolan active powder, 1 gram of retarder, and 0.6 gram of water-retaining agent;

[0046] Water is 9% of above-mentioned mixture weight ratio;

[0047] Among them, the particle size of silicate mineral powder and volcanic ash active powder is less than 1 μm.

[0048] The neutralized dehydrated phosphogypsum material is hemihydrate phosphogypsum neutralized material prepared by mixing quicklime, which is a commercially available product of Hubei Sanning Chemical Co., Ltd.

[0049] The cement powder is ordinary C30 cement.

[0050] The silicate mineral powder is hydrated silicate nanopowder. The average particle size is less than 1 μm. Preferably, the average particle size is less than 500nm. A further preferred average particle diameter is less than 100 nm.

[0051] Volcanic ash active powder specific s...

Embodiment 2

[0060] Components in parts by weight: 1000 grams of neutralized dehydrated phosphogypsum material, 30 grams of cement powder, 20 grams of silicate mineral powder, 30 grams of pozzolan active powder, 2 grams of retarder, and 10 grams of water-retaining agent;

[0061] Water is 11% of above-mentioned compound weight ratio;

[0062] The preparation steps are the same as in Example 1, and the compressive strength of the high-strength phosphogypsum block obtained by this scheme is 25.5 MPa.

Embodiment 3

[0064] Components in parts by weight: 1000 grams of neutralized dehydrated phosphogypsum material, 30 grams of cement powder, 20 grams of silicate mineral powder, 30 grams of pozzolan active powder, 2 grams of retarder, 10 grams of water-retaining agent, and 20 grams of fiber gram;

[0065] The fiber adopts polyvinyl alcohol fiber;

[0066] Water is 11% of above-mentioned compound weight ratio;

[0067] S1, fully mixing the neutralized dehydrated phosphogypsum material, the silicate mineral powder and the pozzolan active powder to obtain the phosphogypsum mixture;

[0068] S2. Fully break up the fiber with a shear pump, the length is 5~10mm, fully mix the fiber, cement powder, retarder and 20% of the total water, and then fully mix with the phosphogypsum mixture, and finally add the remaining water Mix with water retaining agent to obtain phosphogypsum pressed material;

[0069] S3, pressed under 20MPa to form a block sample;

[0070] A high-strength phosphogypsum block is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com