Jet concrete prepared from super absorbent resin and expanded vermiculite

A super absorbent resin and sprayed concrete technology, applied in the field of building materials, can solve the problems of difficult post-curing and post-curing of shotcrete, and achieve the effects of green environmental protection and pollution-free construction, shortening the setting time, and reducing the rebound rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

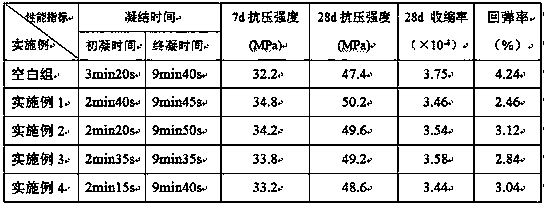

[0037] Example 1, a sprayed concrete prepared by utilizing superabsorbent resin and expanded vermiculite, each component is cement 100, sand 100, stone 140, rock fiber 5, water 30, quick-setting agent 2, superabsorbent resin 0.4, expansion The mass ratio of vermiculite 20 was prepared, and the performance test results are shown in Table 1.

Embodiment 2

[0038] Example 2, a sprayed concrete prepared by utilizing superabsorbent resin and expanded vermiculite, each component is cement 100, sand 160, stone 200, rock fiber 14, water 60, quick-setting agent 12, superabsorbent resin 0.7, expansion The mass ratio of vermiculite 2 was prepared, and the performance test results are shown in Table 1.

Embodiment 3

[0039] Example 3, a sprayed concrete prepared by utilizing superabsorbent resin and expanded vermiculite, each component is cement 100, sand 120, stone 180, rock fiber 10, water 45, quick-setting agent 6, superabsorbent resin 0.1, expansion The mass ratio of vermiculite 10 was prepared, and the performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com