Patents

Literature

71results about How to "In line with the principles of sustainable development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic fertilizer from fermented manure and preparation method of organic fertilizer

ActiveCN104151020AComprehensive fertilizer nutrientsEasy to prepareBio-organic fraction processingOrganic fertiliser preparationFungicideNutrient

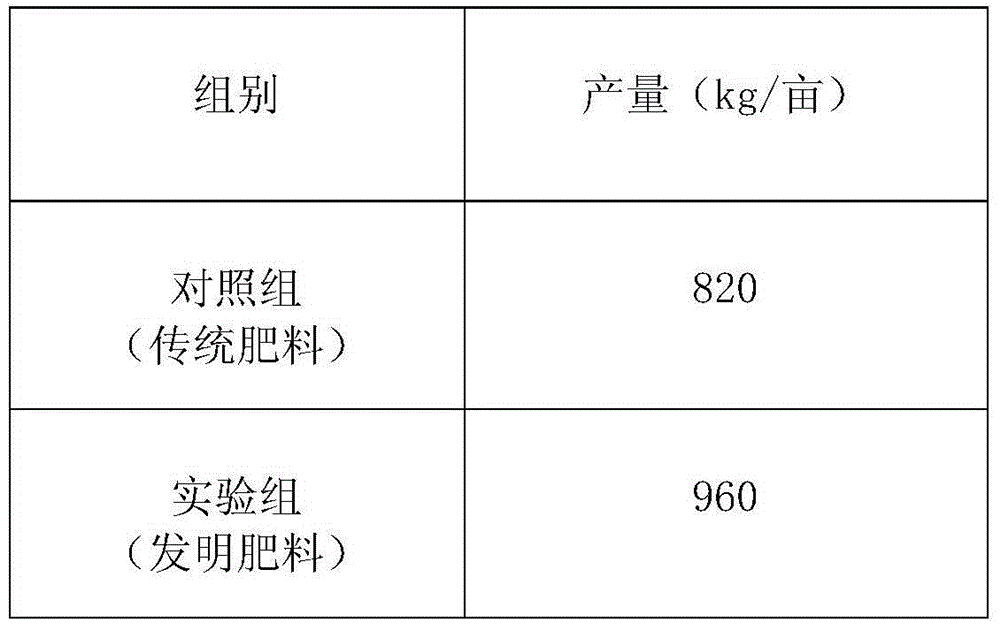

The invention discloses an organic fertilizer from fermented manure, which is prepared from the following raw materials in parts by weight: 34-42 parts of chicken manure, 24-38 parts of pig manure, 25-30 parts of cow manure, 24-28 parts of earthworm manure, 18-20 parts of lime powder, 7-15 parts of silkworm manure, 10-12 parts of corn, 8-12 parts of potassium sulphate, 6-8 parts of straw, 6-9 parts of urea, 4-6 parts of cottonseed cake, 4-8 parts of plant ash, 3-4 parts of ferrous sulphate, 3-4 parts of an EM fungicide, 4-5 parts of a soil modifier, and proper water. According to the invention, because of comprehensive nutrient, the fertilizer can be rapidly absorbed by crops; a plurality of fermented manure can be easily degraded; the organic fertilizer disclosed by the invention is free from pollution to soil and accords with the principle of sustainability; at the same time, the preparation method is simple and low in cost; pollution does not exist in the whole process; in addition, the fertilizer is capable of effectively preventing soil from being hardened; plant diseases and insect pests at roots can also be effectively prevented; and the organic fertilizer disclosed by the invention is applied to scale production and popularization.

Owner:广西农丰宝生物科技有限公司

Method for peeling almond or peach seed by freezing

The invention relates to a method for peeling an almond or a peach seed by freezing. The method comprises the following steps of: cleaning the almond or the peach seed; removing dust on the surface; soaking the almond or the peach seed in water to freeze at the lower temperature; quickly placing the frozen almond or peach seed into boiling water for heating; and taking the almond or the peach seed out, and quickly peeling the almond or the peach seed by using a machine to obtain the peeled almond or peach seed. In the method for peeling the almond or the peach seed by freezing, seed coats of the almond or the peach seed are peeled by a mechanical method and compared with the conventional technology, the method for peeling the almond or the peach seed by freezing improves peeling rate, the obtained almond or peach seed has better quality, and all the components are unmodified; and the method has the advantages of contributing to energy saving and environmental protection, satisfying the principle of sustainable development, along with no pollution, low energy consumption, and easy processing.

Owner:SHAANXI UNIV OF SCI & TECH

Thermal circulation system cooled by liquefied natural gas and flow

InactiveCN101922352AAchieve efficiencyPromote environmental protectionSolidificationLiquefactionLiquefied natural gasProcess engineering

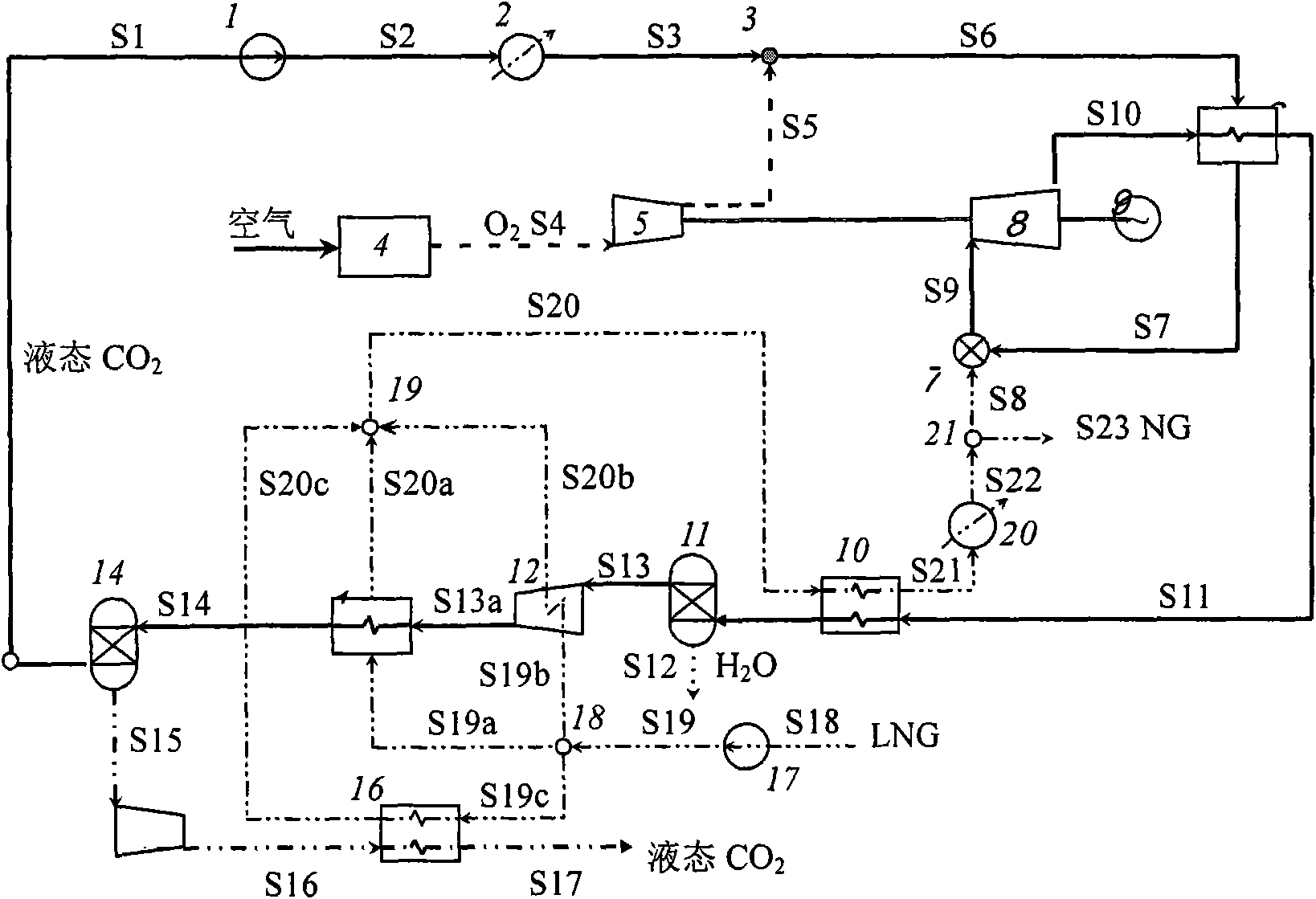

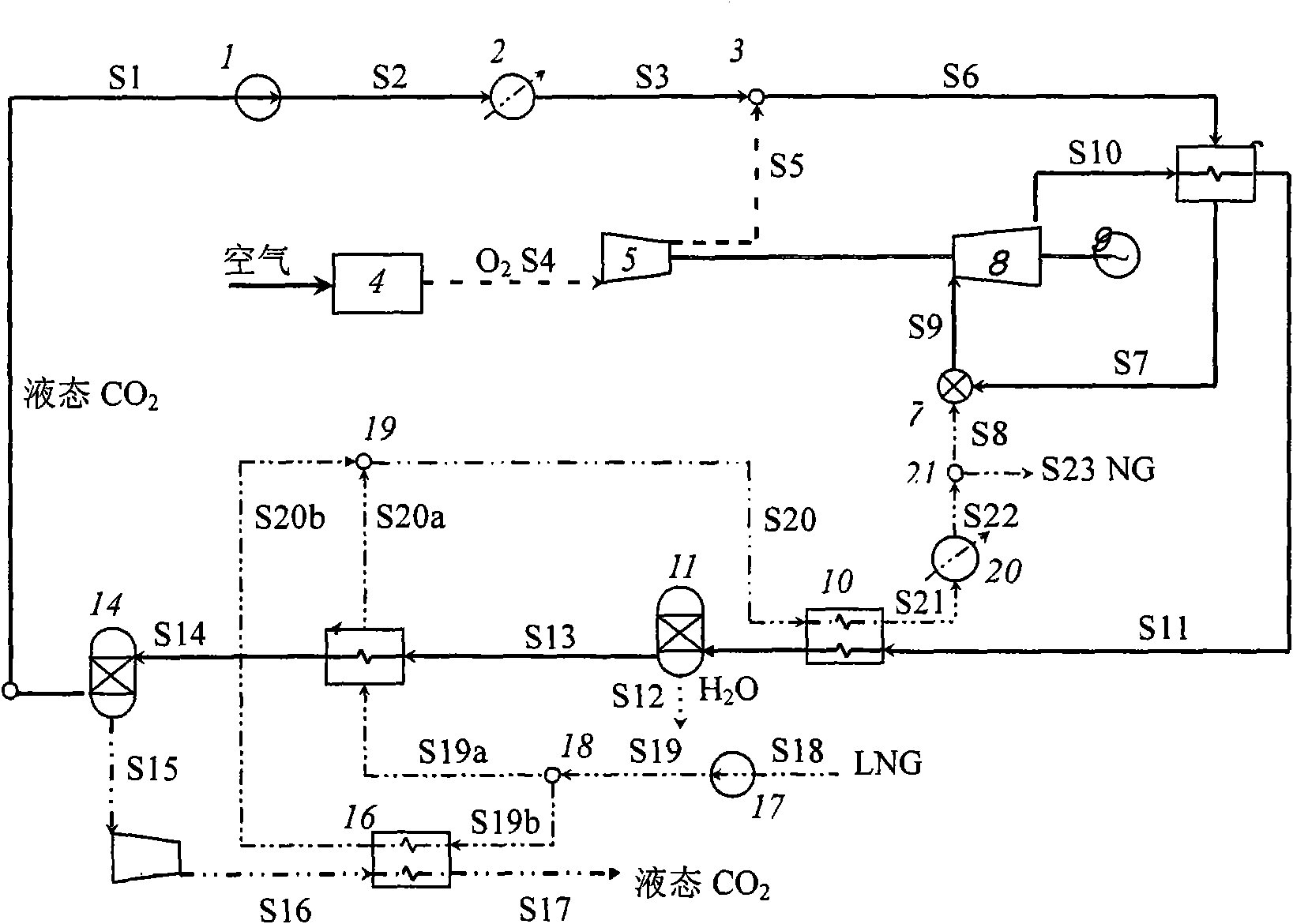

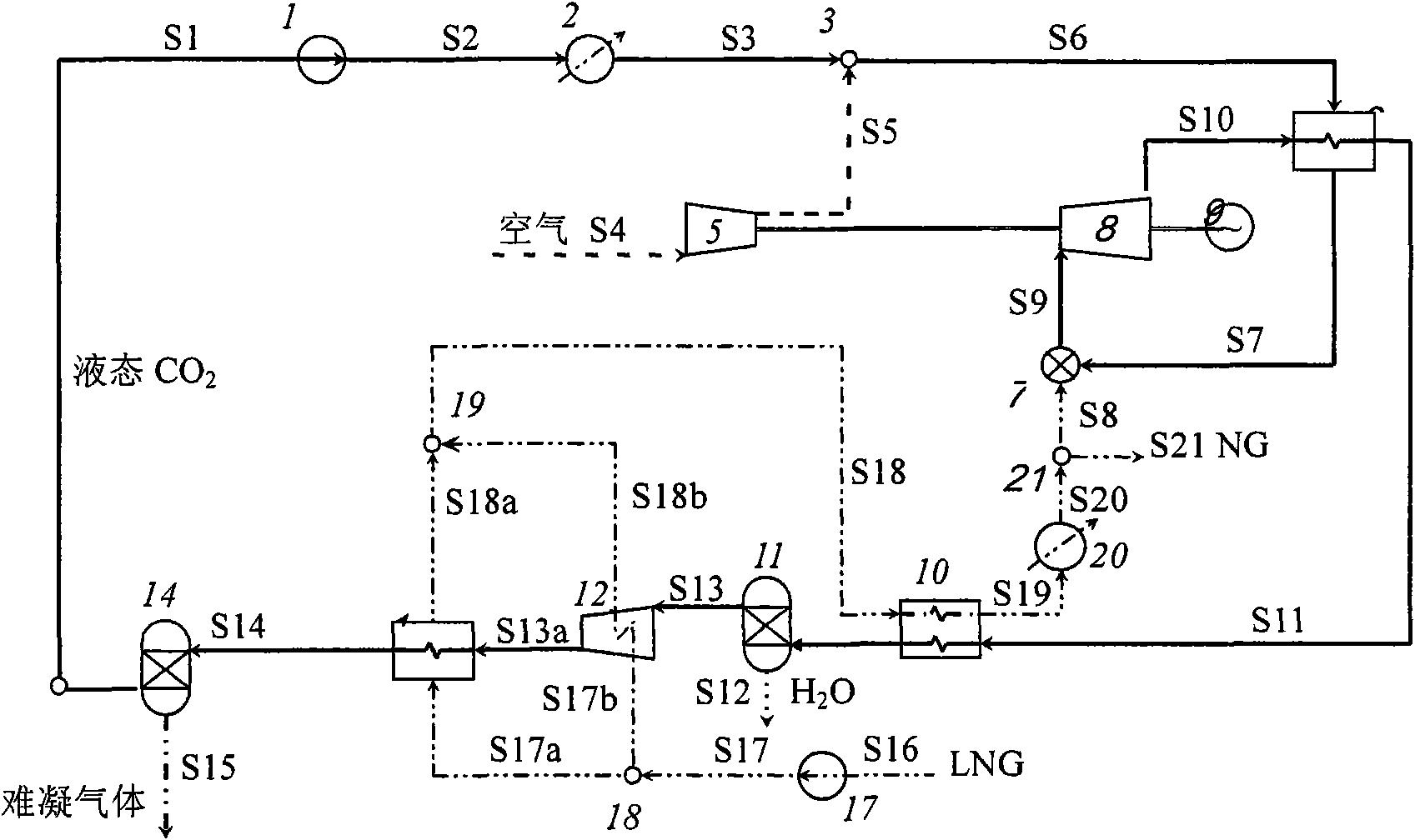

The invention discloses a thermal circulation system cooled by liquefied natural gas and a flow. The thermal circulation system consists of a Brayton-Rankine power circulation unit and an LNG liquefaction unit, wherein the power circulation is realized by using a CO2 circulating medium and coupled by the backheating-combustion-expansion work doing flow of backheating Brayton circulation and the condensation-liquid compression pressurization process of Rankine circulation and the backheating unit is used for realizing the effective heat integration in the circulation; meanwhile, through system coupling, the LNG liquefaction unit is used as a cold source of the power circulation to provide a cold source of which the temperature is always below ambient temperature for the condensation process of the power circulation, so the CO2 generated in a combustion reaction is separated from the circulation without consuming mechanical power. The thermal performance of the thermal circulation system is improved greatly. At the same time, the system realizes zero CO2 discharge while applying a pure oxygen combustion technique. Thus, the system has higher economy and environmental-protection performance and a promising engineering application prospect.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

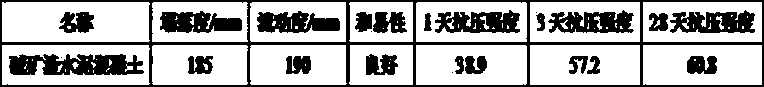

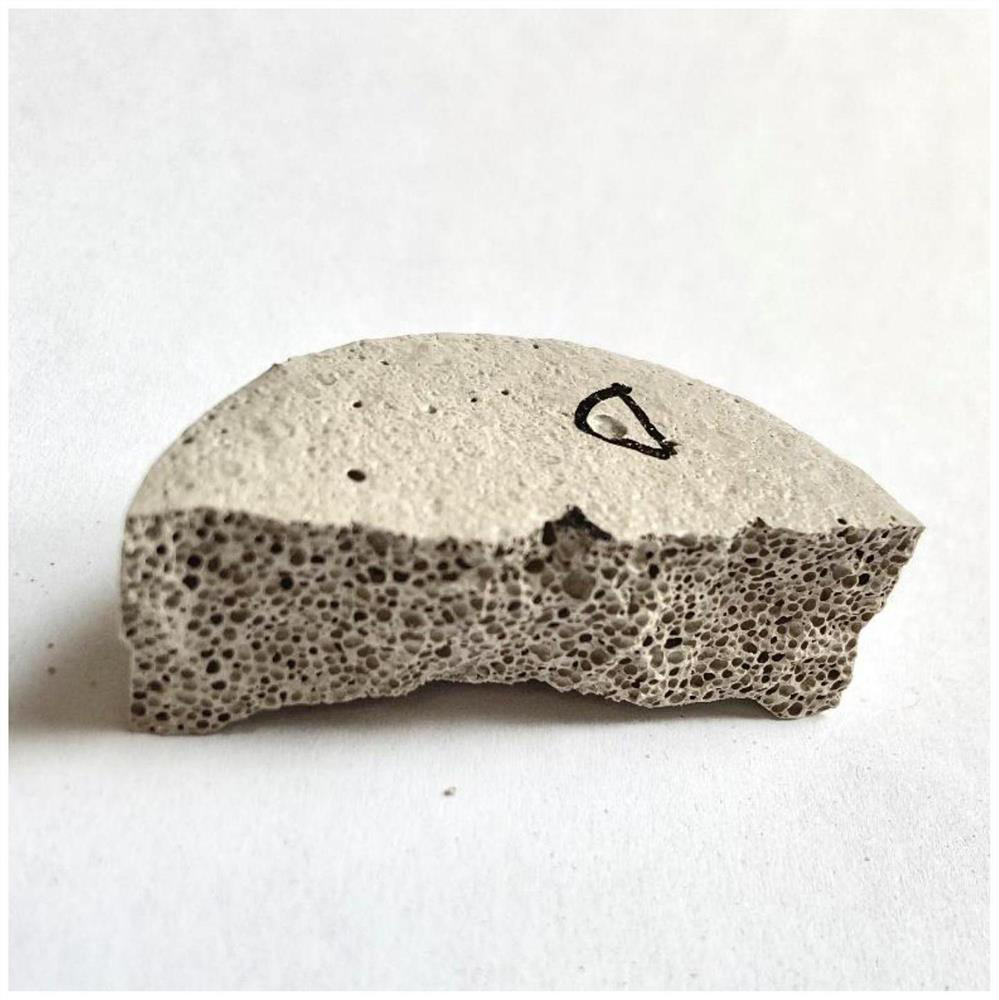

Sludge coal ash high-strength ceramsite and preparation method thereof

ActiveCN104261802AIn line with the principles of sustainable developmentRaise the ratioCeramic materials productionClaywaresSludgeExpanded clay aggregate

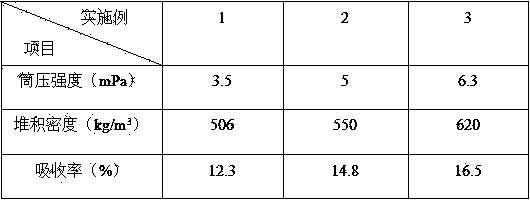

The invention discloses sludge coal ash high-strength ceramsite and a preparation method thereof. By using sludge and coal ash as main raw materials, the ceramsite is prepared by mixing, prilling and calcining by synergic match with an additive. The ceramsite is prepared from the following raw materials in parts by weight: 40-70 parts of sludge, 30-55 parts of coal ash, 0.5-1.5 parts of calcium sulphoaluminate, 0.5-1 part of phthalate, 1-3 parts of water glass and 0.5-1 part of a deodorant, wherein the water content of sludge is controlled within 35-50wt%. The sludge coal ash high-strength ceramsite is prepared by the following steps: mixing the materials; prilling; drying; calcining; and cooling. The ceramsite disclosed by the invention is economical, environment-friendly, efficient and energy-saving and scientific and reasonable in match of components of raw materials, and the prepared sludge coal ash high-strength ceramsite has the advantages of high cylinder compressive strength and high absorption.

Owner:CHONGQING HAOPAN ENERGY SAVING TECH

Preparation method of metal corrosion inhibitor

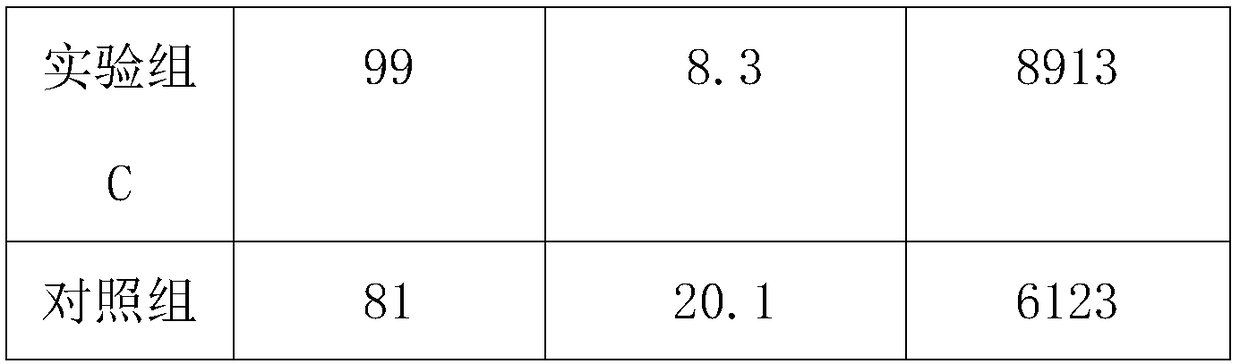

The invention relates to a preparation method of a metal corrosion inhibitor. Fatty acid and polyamine are used as initiative raw materials in the method, and the novel metal corrosion inhibitor is synthesized by amidation, quaternization and substitution reaction. The corrosion inhibition rate of the metal corrosion inhibitor prepared by the method is more than 99 percent, the corrosion inhibitor is easily biodegraded, the pH value of the corrosion inhibitor is 6 to 8 and close to neutrality, and the corrosion inhibitor is convenient to transport and use.

Owner:大庆高新区华龙祥化工有限公司

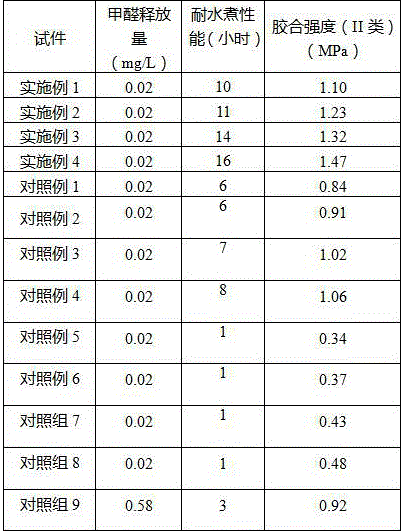

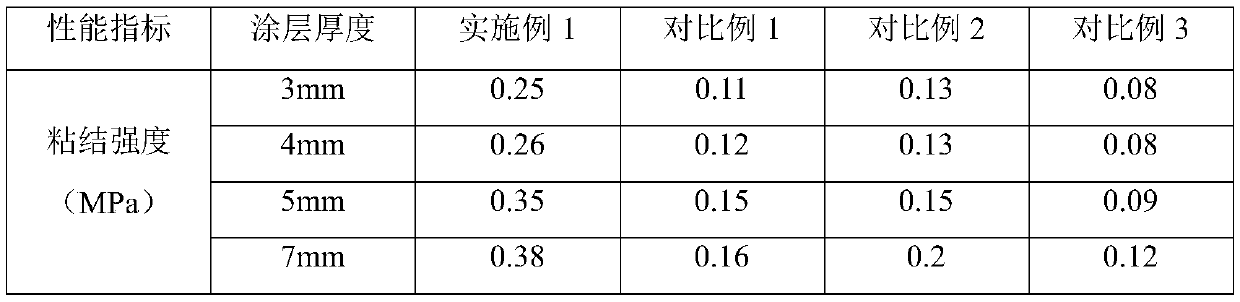

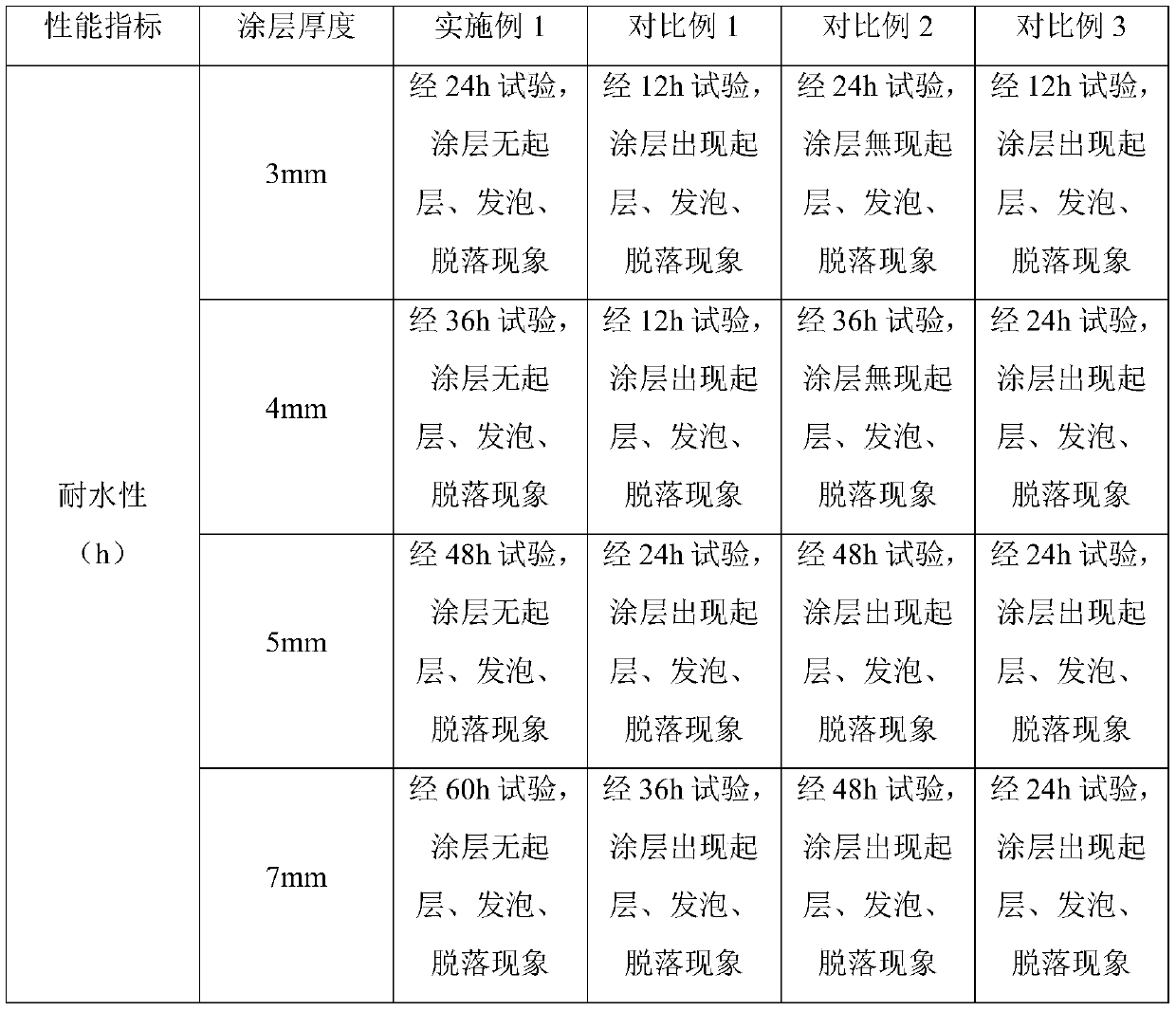

Adhesive for plywood and method for preparing same

InactiveCN102977846ASolve Exhaust ProblemsConform to protectiveNon-macromolecular adhesive additivesProtein adhesivesAdhesiveSoybean Proteins

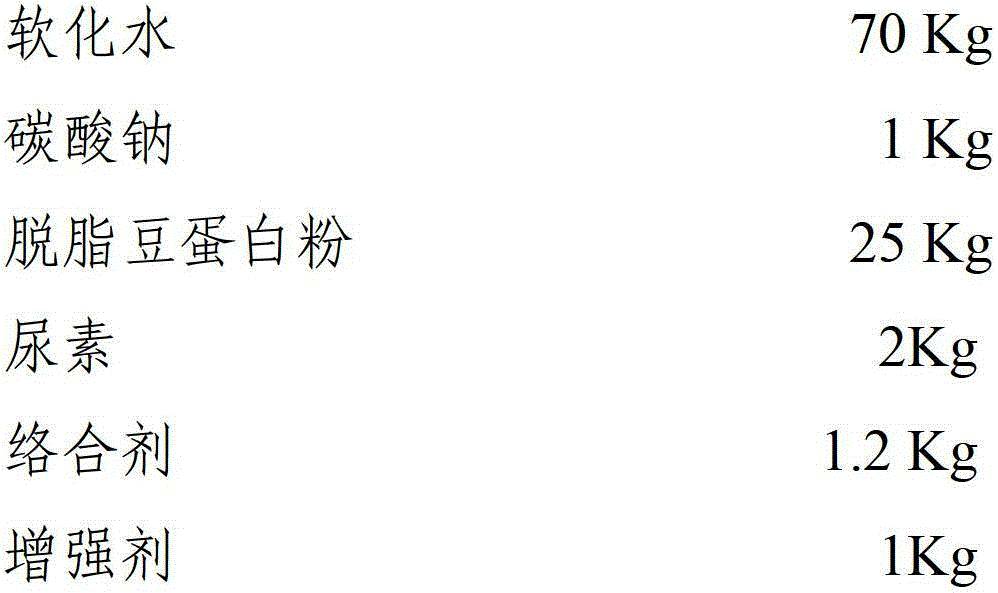

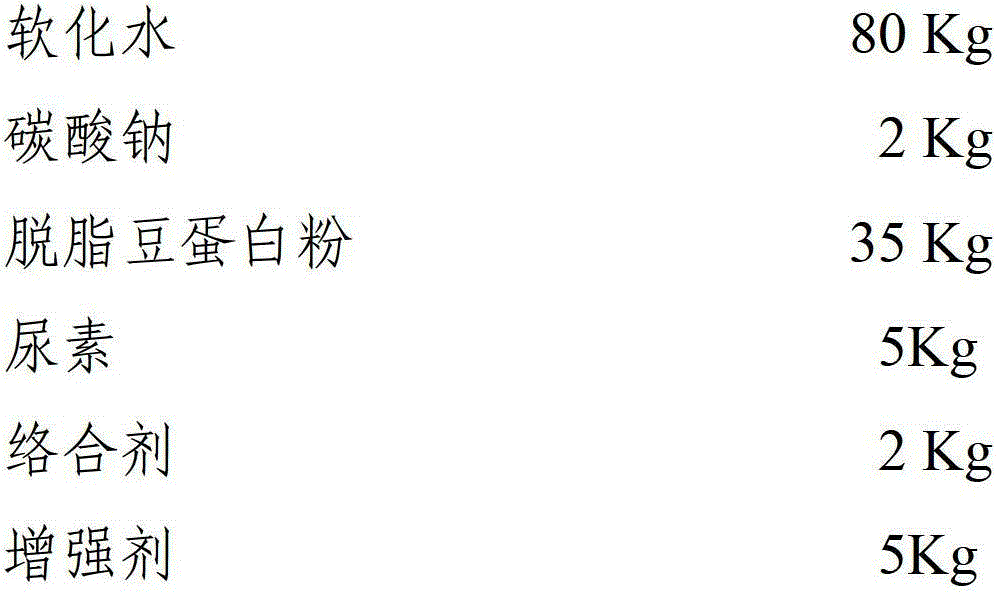

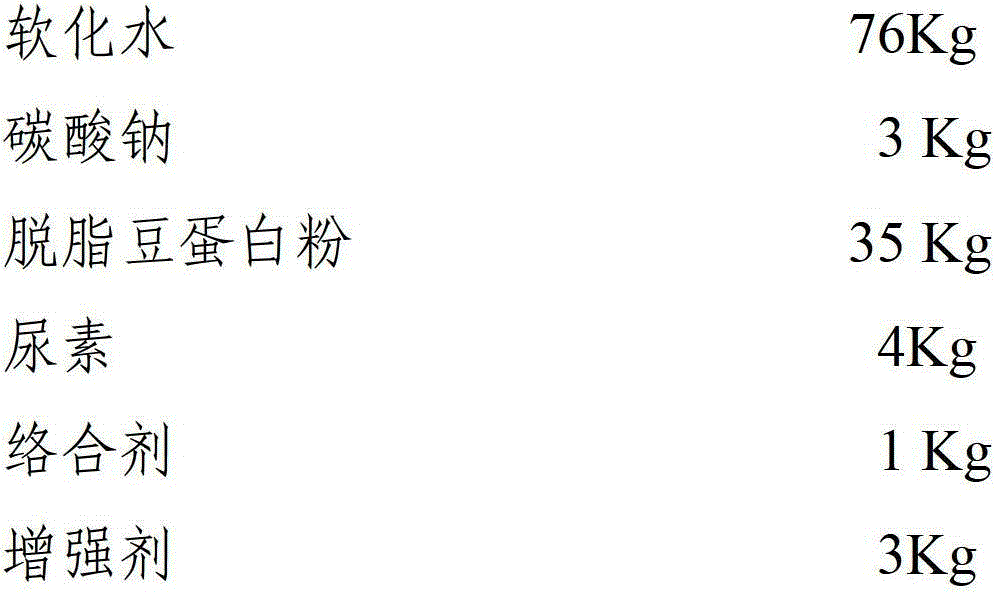

The invention provides an adhesive for a plywood, prepared from the following raw materials according to parts by weight: 70-80 parts of dispersion medium, 20-35 parts of degreased soyabean protein powder, 0.5-3 parts of sodium carbonate, 2-6 parts of urea, 1-2 parts of complexing agent and 1-5 parts of enhancer. The adhesive provided by the invention has the characteristics that all the components have excellent mutual synergistic effect, a materials such as a metal salt is compounded with the soybean protein, and simultaneously, glutaraldehyde is taken as the enhancer so that the problem of poor water resistence of the common soybean protein adhesive is solved; therefore, the adhesive is capable of meeting the waterproof requirement of the adhesive for the plywood and guaranteeing the practical performance of the soybean protein adhesive; and the plywood prepared by using the adhesive provided by the invention is capable of meeting the international requirements of the class II plywood. Besides, the invention also provides a method for preparing the adhesive for the plywood; and the method is simple in process, convenient for operation and suitable for popularization and application.

Owner:BEIJING FORESTRY UNIVERSITY

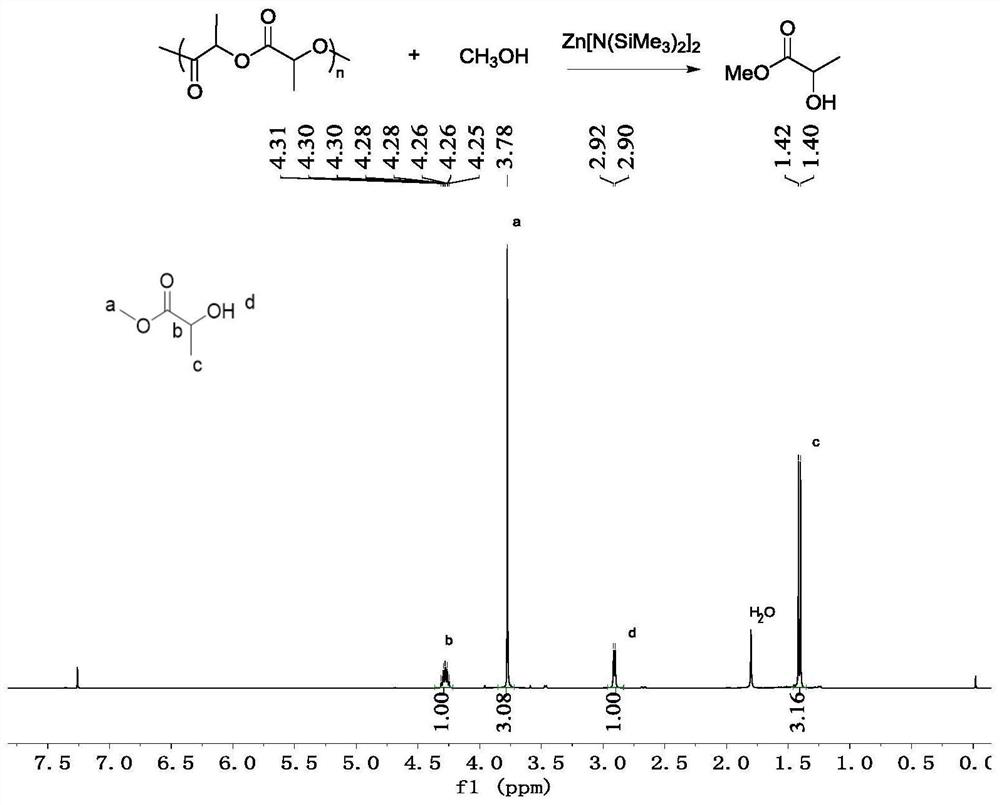

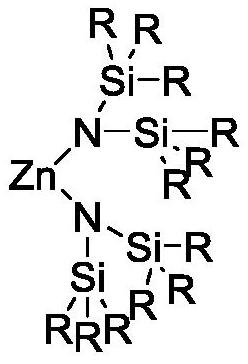

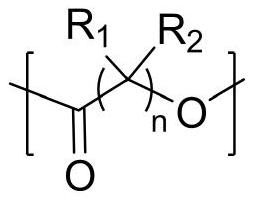

Zinc catalyst applicable to controllable depolymerization of polyester material and catalytic method thereof

ActiveCN112076790AAchieve reuseRealize secondary usePreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterTrans esterification

The invention discloses a zinc catalyst applicable to controllable depolymerization of a polyester material and a catalytic method thereof, and belongs to the technical field of polyester depolymerization. The problems that an existing zinc catalyst used for alcoholysis of waste polyester materials needs to synthesize complex ligands, and the number of synthesis steps is increased are solved. Thecatalyst adopted by the invention is a bis(hexaalkyldisilazane)zinc catalyst with a simple structure, and under the participation of an alcohol compound, the polyester material can be depolymerized into small organic molecules under mild conditions through the transesterification reaction catalyzed by the catalyst, so that the reutilization of waste polyester is realized. The zinc catalyst is adopted to catalyze polyester depolymerization, metal zinc is non-toxic, colorless, cheap and easy to obtain and serves as one of the microelements of a human body, biocompatibility is good, and the production process is more environmentally friendly; the catalyst is simple in structure, few in synthesis steps and more economical in production cost. The catalyst has very good universality, and has a very good depolymerization effect on various polyester materials with different structures.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

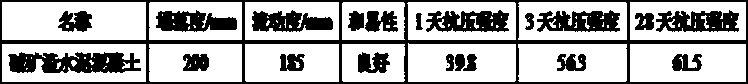

3D printing alkali-fast cement concrete and preparation method thereof

InactiveCN108178567AEasy accessImprove performanceAdditive manufacturing apparatusCement productionParticulatesSlag

The invention relates to the technical field of building materials and in particular to 3D printing alkali-fast cement concrete which is made of ore slag and steel slag as raw materials. The concreteis made of the following raw materials: solid granules, an alkali excitant, a retarder and water, wherein the mass of the alkali excitant accounts for 4-10% of the mass of the solid granules; the retarder accounts for 0.5-3.5% of the mass of the solid granules; the water accounts for 10-45% of the mass of the solid granules. Ore slag powder and steel slag powder are adopted as main raw materials,an alkali excitation technique is implemented, the preparation method is simple and easy to operate, high-temperature calcining is avoided, the energy consumption is reduced, a great amount of lands occupied by industrial waste slag discharge such as steel slag are saved, and the lands are protected and saved. Dependence to natural resources is reduced, the energy is saved, CO2 emission is reduced, environment pollution is alleviated, and in addition, due to a 3D printing technique, the construction and maintenance time can be shortened, the time for casting and demolding a concrete structureis shortened, the construction efficiency is improved, and materials are saved, and the like.

Owner:UNIV OF JINAN

Method for preparing acrylate printing adhesive

InactiveCN102108110AGood flexibilityImprove wet rubbing fastnessEster polymer adhesivesDyeing processAdhesiveAmmonia

The invention discloses a method for preparing an acrylate printing adhesive, which is prepared by the following steps: (1) weighing a common monomer, a special monomer, an emulsifier, an initiator and deionized water in a mixing ratio; (2) mixing 40 to 60 percent of deionized water weighed in the mixing ratio, 40 to 60 percent of emulsifier weighed in the mixing ratio and 40 to 60 percent of initiator weighed in the mixing ratio to prepare liquid I; (3) mixing the common monomer and the special monomer, which are weighed in the mixing ratio, with 60 to 40 percent of deionized water, 60 to 40 percent of emulsifier and 60 to 40 percent of initiator, stirring and emulsifying to prepared liquid II; (4) dripping the liquid II into the liquid I; (5) after the liquid II is dripped, stirring, keeping temperature for reaction and obtaining an initial product of the acrylate printing adhesive; and (6) dripping ammonia water into the initial product of the acrylate printing adhesive to regulating the pH value of the initial product of the acrylate printing adhesive to 6.5 to 7.5, and filtering to obtain the acrylate printing adhesive product. The adhesive prepared by the method has high performance, and the environmental-protection problem in the synthesis and use processes of the adhesive is solved.

Owner:金华金龙助剂厂

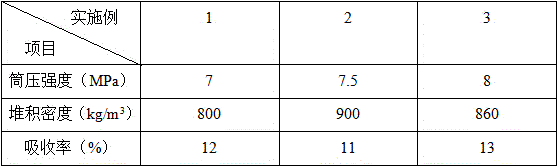

Fly ash non-burned high-strength ceramsite and preparation method thereof

ActiveCN106082731AHigh cylinder compressive strengthEasy to operateCeramicwareAdhesiveExpanded clay aggregate

The invention discloses a fly ash non-burned high-strength ceramsite and a preparation method thereof, wherein the ceramsite comprises the following components in parts by weight: 93.5-94.5 parts of fly ash, 2.95-3.05 parts of an adhesive, and 2.95-3.05 parts of an enhancer. The method comprises the steps: preparing an adhesive liquid and an enhancement liquid respectively from the adhesive and the enhancer with water; pouring the weighed fly ash into a ball formation disc, starting up the ball formation disc, spraying the adhesive liquid into the fly ash, rotating the ball formation disc, and rolling to form balls; at the same time, spraying the enhancement liquid to the surface of formed ball bodies to prepare ceramsite; and putting the ceramsite into a steam curing kiln, curing for 8-9 h, and thus obtaining the product. A sintering process is not required, and the high-strength ceramsite can be obtained; tests verify that the prepared fly ash ceramsite has the packing density of 800-900 kg / m<3>, the cylinder compressive strength of 7-8 MPa and the water-absorbing rate of less than or equal to 15% and has good quality.

Owner:CHONGQING HAOPAN ENERGY SAVING TECH

Bacteria-reducing cleaning method for garden stuff under synergetic effect of ultrasonic wave and slightly acidic hypochlorous acid water

InactiveCN106858659AEfficient removalEfficient killingFruit and vegetables preservationFood treatmentElectrolysisPesticide residue

The invention discloses a method for bacteria-reducing cleaning of fruits and vegetables in cooperation of ultrasonic waves and slightly acidic hypochlorous acid water. First inject a certain concentration of slightly acidic hypochlorous acid water into the ultrasonic cleaner, adjust the power and temperature of the ultrasonic cleaner to appropriate parameters, and then set the cleaning time to start working. The present invention can quickly sterilize the surface of fruits and vegetables under the condition of effectively removing dirt on the surface of fruits and vegetables. The co-treatment of acidic hypochlorous acid water will not affect the deformation and quality of fruits and vegetables. Slightly acidic electrolyzed water is broad-spectrum and efficient in sterilization, especially when it interacts with organic matter, it will be reduced to water. Compared with other current fungicides, it is safe and has no residue, and is friendly to the human body and the environment. The invention is suitable for sterilization and preservation of fruit and vegetable products, removal of pesticide residues, and can also be applied in the field of cleaning meat products.

Owner:ZHEJIANG UNIV

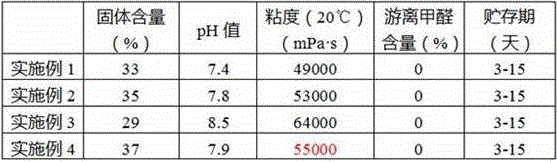

Urea-formaldehyde resin additive, urea-formaldehyde resin containing the same and preparation method thereof

ActiveCN101205348ASolve Exhaust ProblemsSave resource usageAldehyde/ketone condensation polymer adhesivesAluminium sulfateResin adhesive

The invention provides an additive with urea formaldehyde, a preparation method and a urea formaldehyde resin adhesive. The additive is provided by the invention. The raw material of the additive is comprised of the dispersion medium, the dried egg white of the degreased bean and the complexing agent, the weight ratio of the raw material is: 70-80 of dispersion medium, 20-35 of dried egg white of the degreased bean, 1-3 of complexing agent, the complexing agent is consisted of the aluminium sulphate and the zirconium carbonate with the weight ratio of 0.4-2.4:1. The additive provided by the invention contains dried egg white of the degreased bean, and then both the bond strength of the prepared veneer is increased and the formaldehyde emission of the preparing artificial slabs is effective decreased when adding the additive into the urea formaldehyde.

Owner:CHANGZHOU JOEL PLASTIC

Preparation method of sodium fluoride

InactiveCN104495875AReduce emissionsGood application prospectAlkali metal silicatesAlkali metal fluoridesSodium fluorideDecomposition

The invention provides a preparation method of sodium fluoride. The preparation method utilizes a silicon fluoride-containing gas product produced by albite decomposition and sodium hydroxide as raw materials to product sodium fluoride. The preparation method comprises the following steps that the silicon fluoride-containing gas product is fed into an absorbing tower and is hydrolyzed to produce a fluosilicic acid solution, the fluosilicic acid solution is put into a reactor and reacts with added sodium hydroxide to produce sodium fluoride, sodium hydroxide is added into the reactor until the solution pH value in the reactor is greater than or equal to 10, and sodium fluoride crystals are precipitated, then are filtered and then are dried to form sodium fluoride finished products. The preparation method has the advantages of simple processes, low energy consumption, small environmental pollution and good application prospect.

Owner:SONGXIAN ZHONGKE INCUBATOR

Soybean meal lignin-based adhesive and preparation method thereof

InactiveCN105754546AImprove water resistance bonding performanceAddress water resistanceNon-macromolecular adhesive additivesProtein adhesivesAdhesiveUltimate tensile strength

The invention discloses a soybean meal lignin-based adhesive and a preparation method thereof. The soybean meal lignin-based adhesive is prepared from 20-50 parts of defatted protein powder, 1-5 parts of a denaturant, 1-30 parts of a reinforcing agent and 60-80 parts of a dispersion medium. The preparation method comprises the steps of dispersing, mixing, stirring and the like. The soybean meal lignin-based adhesive and the preparation method thereof have the following advantages: the problems of poor water resistance, low dry cementation strength and poor boiling resistance of a common protein adhesive are solved, the water-proof requirement of an adhesive for artificial boards can be satisfied, and the practicability of the protein adhesive is guaranteed; the problem of exhaustion of synthetic fossil raw materials used in conventional artificial board adhesives can be favorably solved, and the environmental protection and sustainable development principles can be conformed; resources are comprehensively utilized, the production cost is lowered and the product added value is improved.

Owner:BEIJING FORESTRY UNIVERSITY

Foam glass insulation board

InactiveCN103304212AAddress the goals of energy saving and emission reductionSolve the problem of nowhere to stackSolid waste managementAdditive ingredientFoam glass

The invention discloses a foam glass insulation board, comprising the following ingredients in parts by weight: 40-50 parts of desulfurization gypsum, 20-22 parts of foam glass, 20-30 parts of coal ash, 20-40 parts of mineral powder, 24-26 parts of water, 2 w / w% of lime, and 1-2 w / w% of admixture. The insulation board is prepared from foam glass scraps; the waste foam glass and the waste such as the desulfurization gypsum, the coal ash and the like of a thermal power plant are changed into precious resources by utilizing local resources; not only can the targets of saving energy and reducing emission of buildings be solved; but also the problems of no place to stack waste products and the like are solved; the pollution on the environment is reduced; the foam glass insulation board accords with the principle of sustainable development; the heat conductivity coefficient of the prepared foam glass insulation board is 0.10-0.15 w / m.k; the compressive strength achieves over 0.8 Mpa; and the volume density is 600-700 kg / m<3>.

Owner:JIAXING UNIV

Foamed flue gas desulfurization gypsum heat-preservation plate based on foamed glass waste

The invention discloses a foamed flue gas desulfurization gypsum heat-preservation plate based on foamed glass wastes. The foamed flue gas desulfurization gypsum heat-preservation plate consists of the following components in parts by weight: 40 parts of flue gas desulfurization gypsum, 20 parts of coal ash, 0-40 parts of ore powder, 0.25-0.5 part of a foaming agent, 0-12 parts of foamed glass leftovers, 0-40 parts of steel slag, 70 parts of water, 2 parts of lime, 0.5-1 part of a water reduction agent and 2 parts of an early strength agent. Waste foamed glass is crushed, screened and graded into artificial light aggregate of different particle sizes, and is mixed with a flue gas desulfurization gypsum based foamed concrete blank to prepare a heat-preservation plate. The foamed flue gas desulfurization gypsum heat-preservation plate disclosed by the invention has a heat conduction coefficient of 0.06-0.09w / m*k, pressure strength up to 0.5MPa or greater and a drying apparent density of310-450kg / m<3>. According to the foamed flue gas desulfurization gypsum heat-preservation plate, the waste foamed glass and wastes such as flue gas desulfurization gypsum and coal ash in thermal powerplants are turned into effective resources and are recycled, in addition, a production process is energy-saving and environmentally friendly, environment pollution can be reduced, meanwhile, types ofenergy-saving heat-preservation wall materials can be enriched, and the environmental-friendly degree of an inorganic light material can be increased.

Owner:JIAXING UNIV

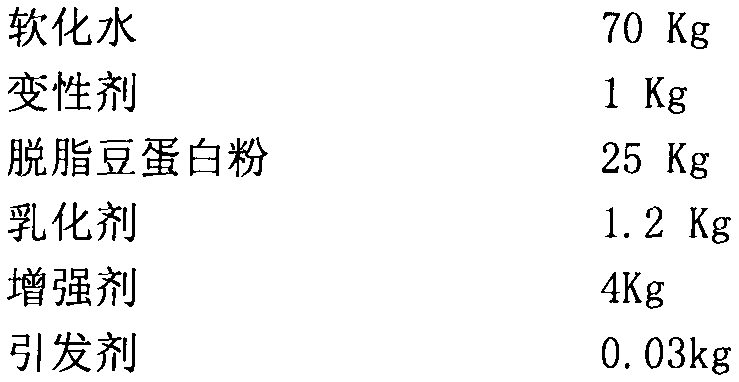

Soybean protein adhesive for plywood and preparation method of soybean protein adhesive

PendingCN110343505ASolve Exhaust ProblemsConform to protectiveNon-macromolecular adhesive additivesProtein adhesivesGlycidyl methacrylateDispersed media

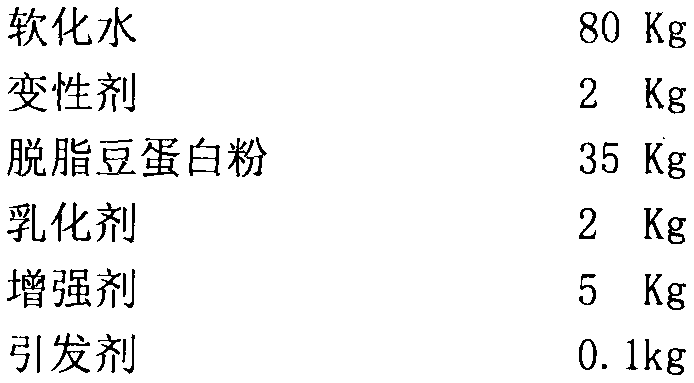

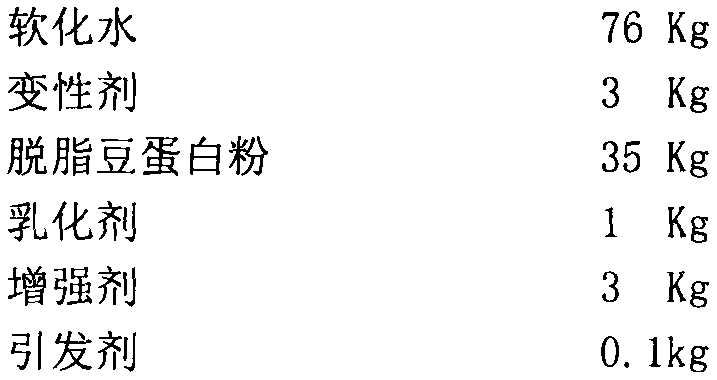

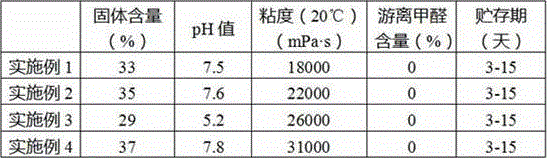

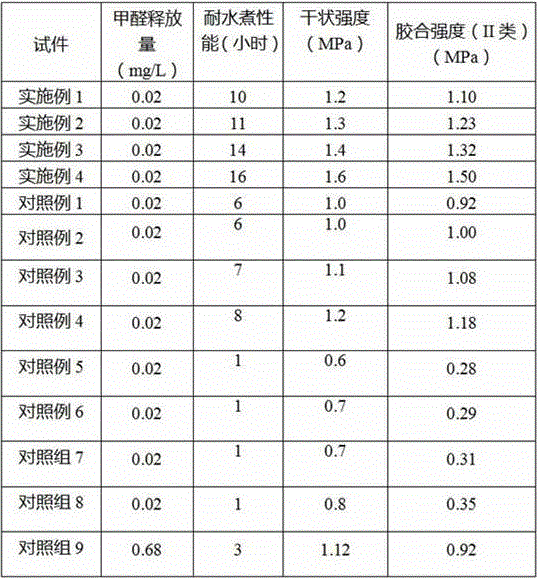

The invention provides a soybean protein adhesive for plywood. The soybean protein adhesive is prepared from the following components in parts by weight: 70-80 parts of a dispersing medium, 20-35 parts of defatted soybean protein powder, 0.5-2 parts of a denaturant, 1-2 parts of an emulsifier, 1-5 parts of an enhancer and 0.02-0.1 part of an initiator. According to the invention, all the components of the adhesive have a good synergistic effect. The defatted soybean protein powder is subjected to denaturation treatment by adopting sodium carbonate or sodium hydroxide, and glycidyl methacrylateis used as a reinforcing agent, so that the problem that a common soybean protein adhesive is poor in water resistance and complex in process is solved, the water-resistant use requirements of an adhesive for plywood can be met, and practical performance of the soybean protein adhesive is guaranteed. In addition, plywood prepared by the adhesive provided by the invention meets the requirement oftype-II plywood in the national standard. Moreover, the invention also provides a preparation method of the adhesive for soybean protein plywood. The method is simple in process, is convenient to operate and is suitable for popularization and application.

Owner:GUANGXI UNIV

Soybean-meal-based wood adhesive and preparing method thereof

InactiveCN105969303AEvenly dispersedLow viscosityNon-macromolecular adhesive additivesProtein adhesivesAdhesiveReducer

The invention discloses soybean-meal-based wood adhesive and a preparing method thereof. The soybean-meal-based wood adhesive is prepared from 27-33 parts of degreased protein powder, 0.001-0.003 part of viscosity reducer, 0.5-2.0 part of emulgator, 1-2 parts of denaturant, 7-20 parts of enhancer and 65-73 parts of a dispersion medium. The preparing method includes the steps of dispersing, mixing, temperature rising, stirring and the like. The soybean-meal-based wood adhesive has the advantages that the waterproof requirement of the artificial board adhesive can be met, and practicability of the protein adhesive is ensured; the problem of formaldehyde pollution in indoor air due to artificial boards is solved thoroughly, the main raw materials are renewable resources, and therefore the soybean-meal-based wood adhesive meets the environmental protection and sustainable development rule.

Owner:BEIJING FORESTRY UNIVERSITY

Formaldehyde-free soybean-protein-based adhesive for multilayer solid-wood composite floorboard and preparation method of formaldehyde-free soybean-protein-based adhesive

InactiveCN106318313AImprove solubilityImprove fullyNon-macromolecular adhesive additivesProtein adhesivesSolid woodDispersed media

The invention discloses a soybean formaldehyde-free adhesive and a preparation method thereof. The adhesive is prepared from 27-33 parts of degreased protein powder, 1-2 parts of denaturant, 0.5-2.0 parts of emulsifier, 5-15 parts of reinforcing agent and 65-73 parts of dispersing medium. The preparation method comprises the steps of carrying out dispersion, carrying out ultrasonic treatment, carrying out heating, carrying out stirring, and the like. The formaldehyde-free adhesive and the preparation method thereof have the advantages that the requirements of adhesives for artificial boards on water resistance can be met, and the practicability of protein adhesives is guaranteed; the problem of formaldehyde pollution to indoor air caused by the artificial boards is thoroughly solved; main raw materials are renewable resources, so that the formaldehyde-free adhesive and the preparation method thereof are in line with environmental protection and sustainable development principles.

Owner:SCHOLAR HOME SHANGHAI NEW MATERIAL CO LTD

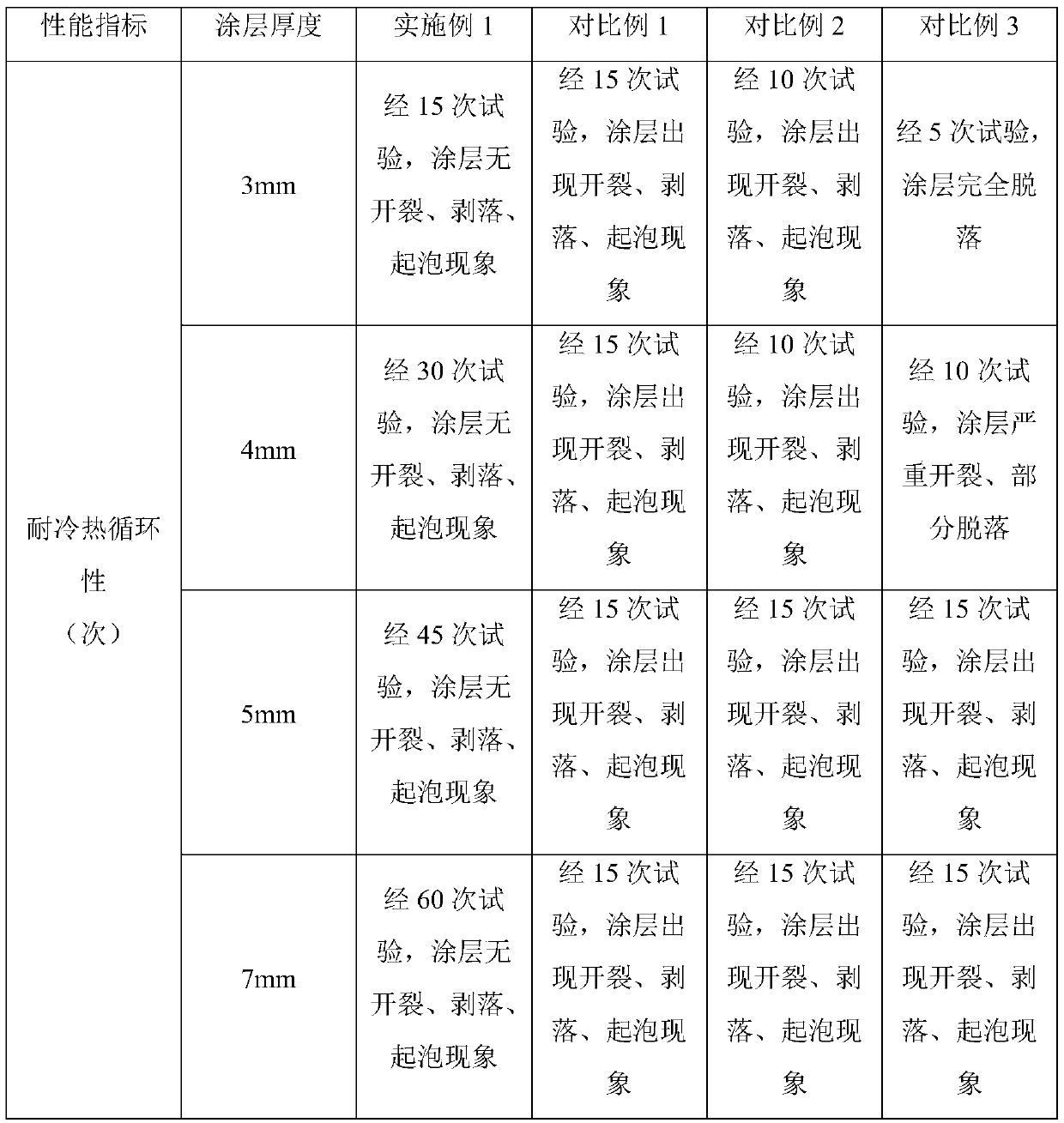

Environment-friendly fireproof paint produced by using solid waste of steel industry as raw materials

ActiveCN109971223ARealize resource utilizationProtect the environmentFireproof paintsCement coatingsResource utilizationSlag

The invention discloses environment-friendly fireproof paint produced by using solid waste of the steel industry as raw materials. The environment-friendly fireproof paint produced by using the solidwaste of the steel industry as the raw materials is produced from the following raw materials of, in parts by weight, 30-35 parts of cement, 6-10 parts of mica powder, 5-7 parts of modified sodium silicate powder, 12-18 parts of steel slag powder, 4-8 parts of water granulated slag powder, 25-35 parts of coal ash floating beads and 2-4 parts of hydrophobic silica. The main raw materials of the environment-friendly fireproof paint come from the solid waste generated in the steel industry, comprise steel slag, water granulated slag and coal ash and account for over 50% of the raw materials for producing the environment-friendly fireproof paint, so that resource utilization of the steel bulk solid waste is achieved, and the environment-friendly fireproof paint is in conformity with the principles of environmental protection and sustainable development. The environment-friendly fireproof paint is novel non-bulgy fireproof paint, is light in weight, low in cost, simple in production technology, simple and convenient to construct, environmentally friendly, safe and extremely high in cost performance, has a good fireproof effect, can be used as ultra-thin and thin fireproof paint, and iswidely used as fireproof protective materials of different fields of steel structures, concrete structures and the like.

Owner:山东亘石新材料科技有限公司

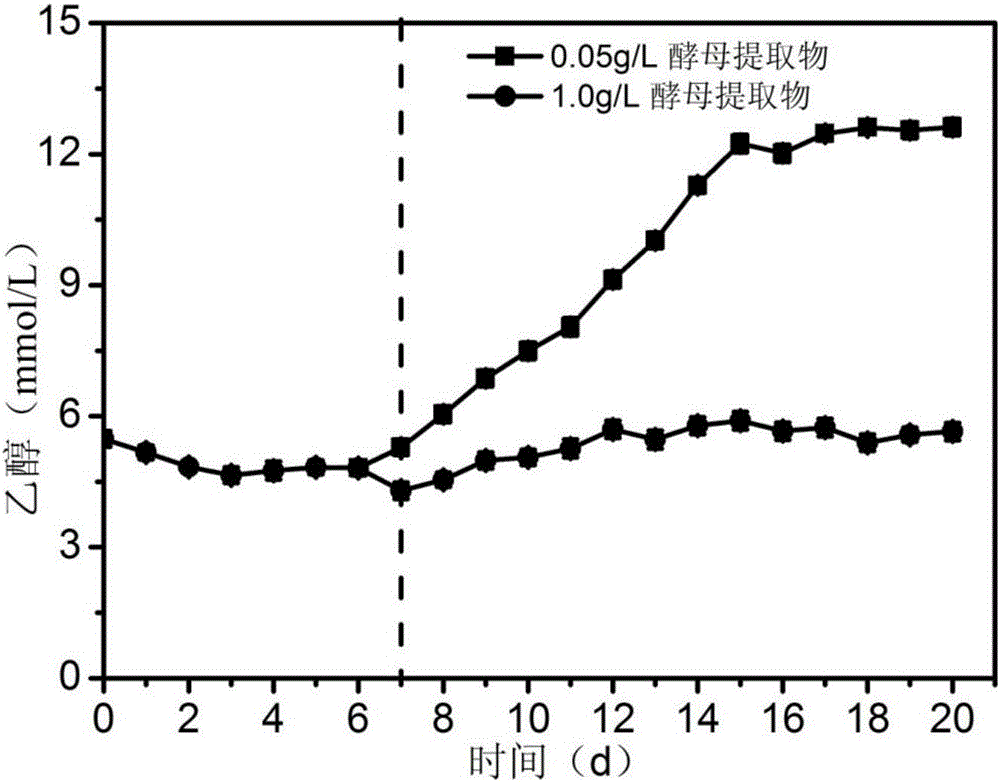

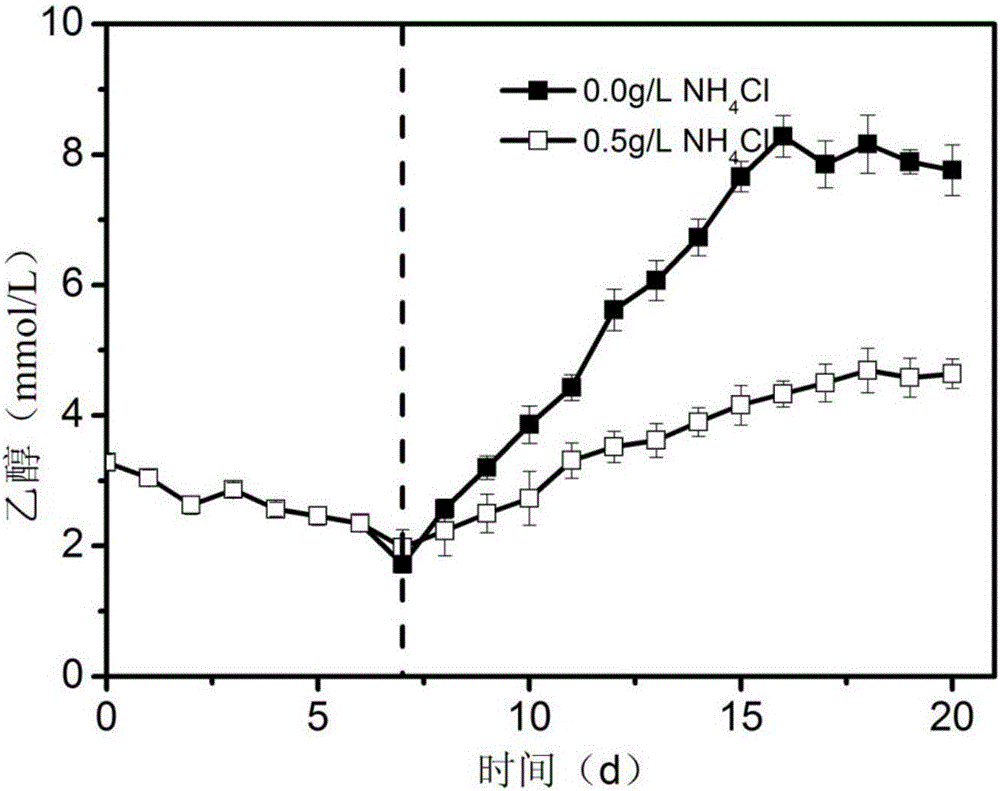

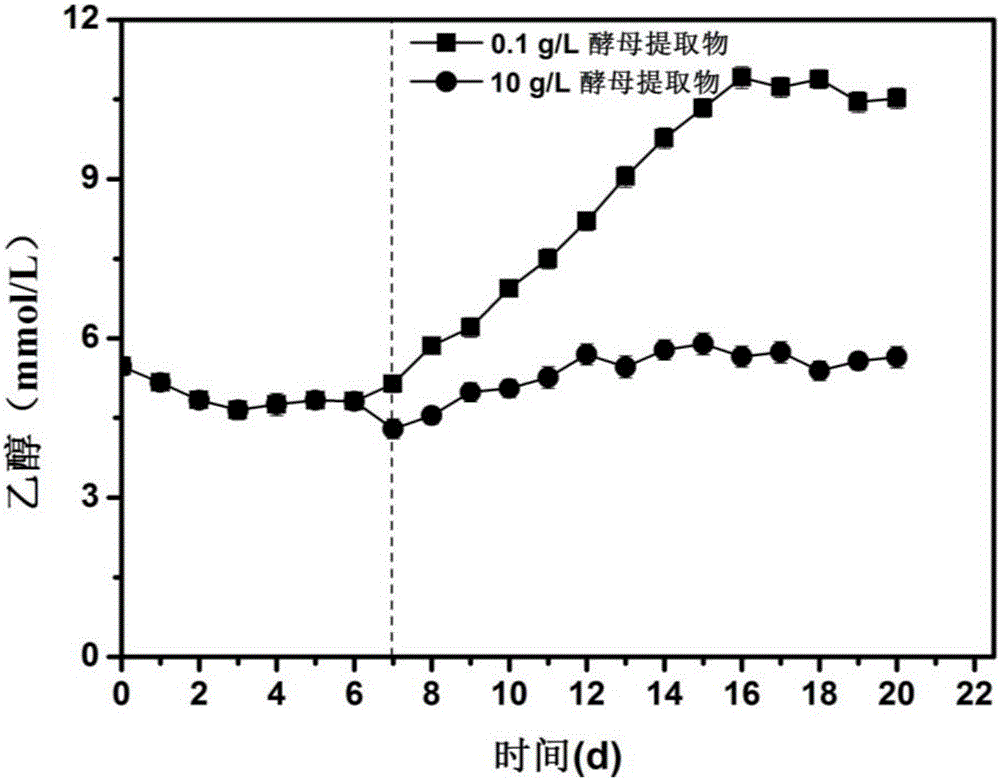

Nitrogen defect control method for production of ethanol through fermentation of synthesis gas with mixed bacteria

The invention belongs to the field of biological energy sources and particularly relates to a nitrogen defect control method for production of ethanol through fermentation of synthesis gas with mixed bacteria. The method comprises steps as follows: a first stage: mixed bacteria are cultured to grow in a fermentation medium to reach a stable state, that is, the yield of fermentation products is stable and unchanged; a second stage: the mixed bacteria growing to reach the stable state are cultured at the second stage, the nitrogen concentration of the fermentation medium at the stage is controlled to be lower than that at the first stage, the mixed bacteria are the same type of acetogenic bacteria which come from cow dung, urban excess sludge and enriched products thereof, as ethanol is a non-growth coupling type product of the acetogenic bacteria, insufficient nitrogen nutrients possibly cause abnormal cell metabolism, cells enter a non-growth state or dormant state, the condition not beneficial to growth of the acetogenic bacteria is created through nitrogen nutrient defects, so that the metabolism pathway is changed from the acid producing phase to the solvent producing phase, and ethanol production is controlled.

Owner:JIANGNAN UNIV

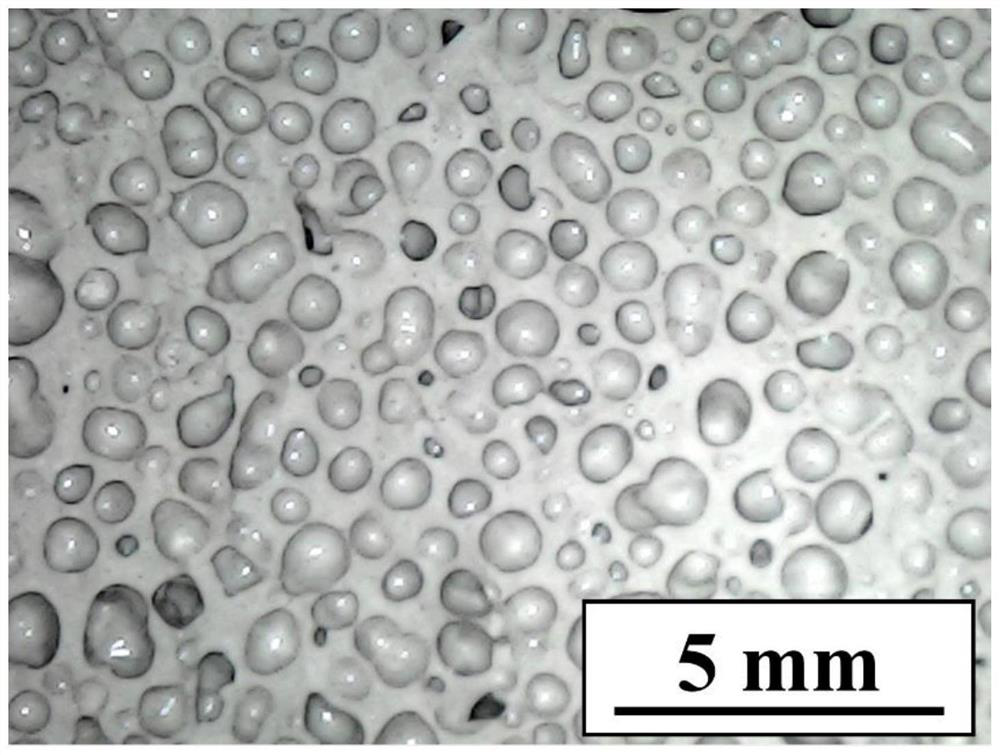

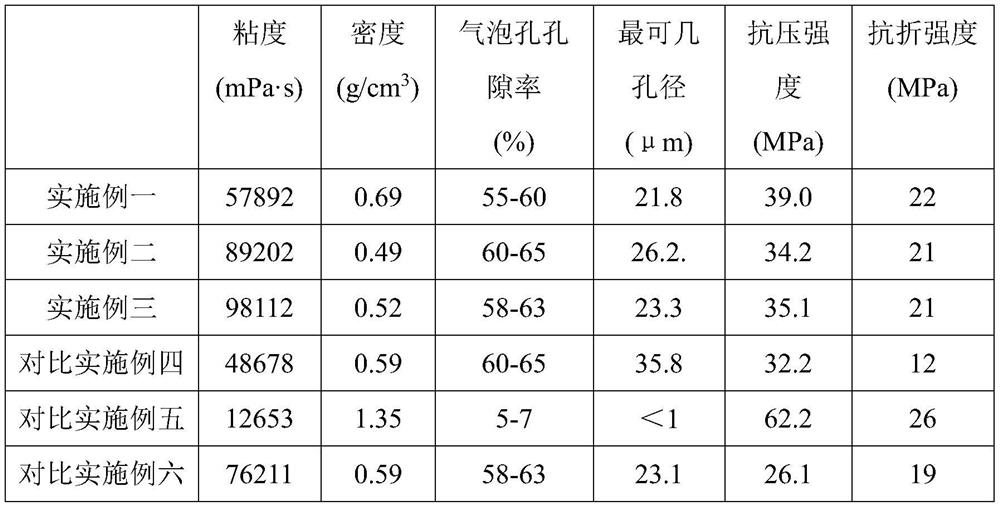

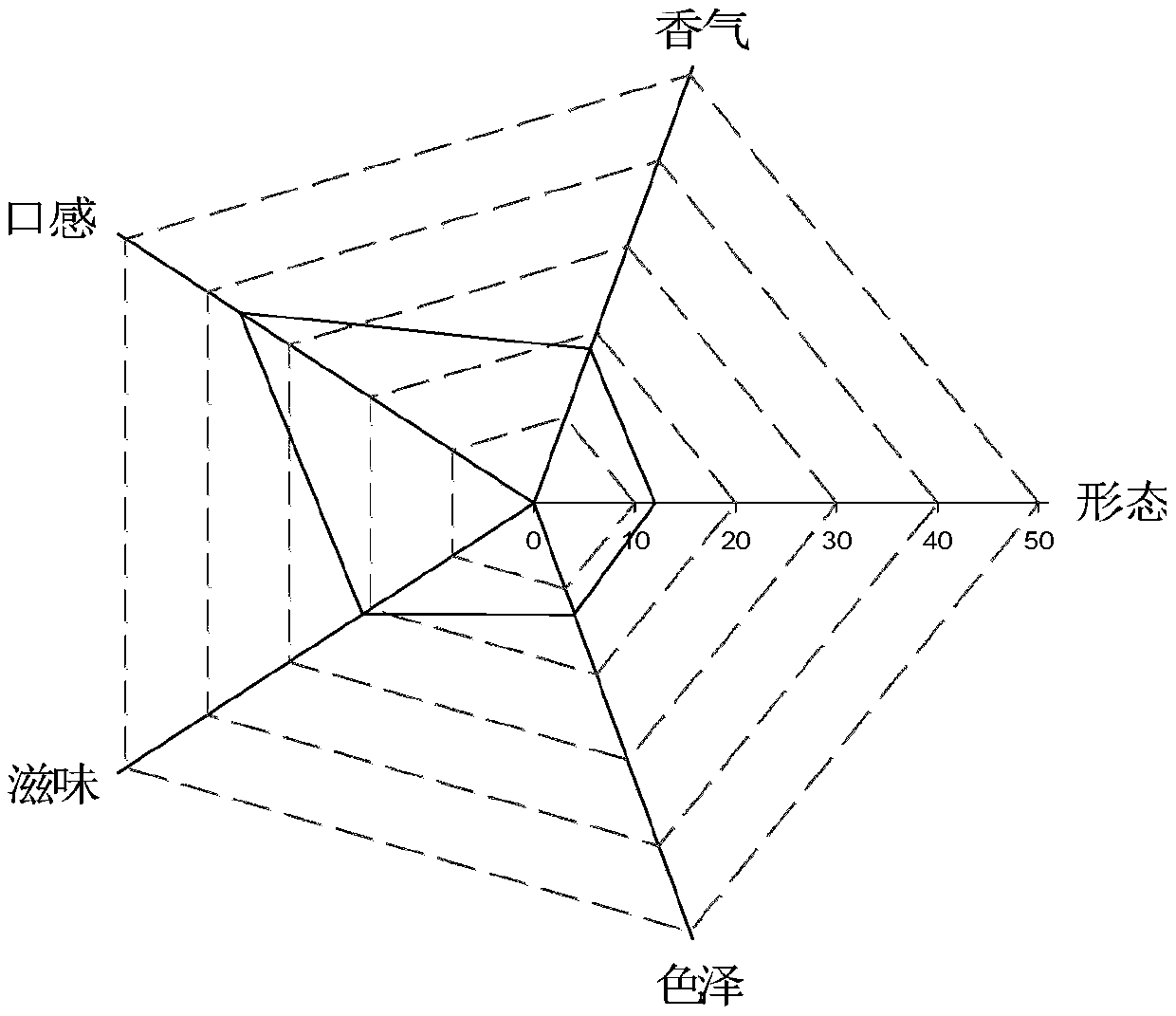

High-strength geopolymer closed-cell foam material prepared from silicon carbide, and preparation method thereof

The invention discloses a high-strength geopolymer closed-cell foam material prepared from silicon carbide. The high-strength geopolymer closed-cell foam material comprises the following raw materialsin parts by weight: 45-60 parts of silicon-aluminum mineral raw material, 10-15 parts of sodium hydroxide solid, 45-60 parts of sodium silicate solution, 15-25 parts of quartz powder, 2-4 parts of mica powder, 2-3 parts of organic fiber, 8-12 parts of silicon carbide powder, 3-4 parts of aluminum powder, 3-5 parts of lauryl sodium sulfate, 0.4-0.6 part of a grinding aid, and 10-15 parts of deionized water. The invention also discloses a preparation method of the high-strength geopolymer closed-cell foam material prepared from silicon carbide. According to the invention, the geopolymer foamingmaterial which mainly comprises closed pores, is uniform in pore distribution and is controllable in pore size is prepared by regulating and controlling the ratio of the raw materials, the content ofsilicon carbide and the particle size of silicon carbide; and the silicon carbide, the quartz powder, the mica powder, the organic fibers and the compound raw materials are used, so that the foamingmaterial has the properties of low density, high mechanical strength, high toughness, strong high-temperature resistance and corrosion resistance.

Owner:ZHEJIANG UNIV +2

Processing method of skin-less Chinese torreya kernels

The invention discloses a processing method of skin-less Chinese torreya kernels and belongs to the field of processing of agricultural and sideline products. Chinese torreya kernels undergo earlier preprocessing, the moisture content is adjusted, freezing processing is executed, unfreezing is executed, and Chinese torreya baking and processing are completed; skin removal and package are executed.Compared with a traditional process, the skin removal rate is improved by adopting a freezing and skin-removing method, the obtained Chinese torreya kernels have better quality, and all constitutional components are not degenerated. The processing method is simple in operation, free of contamination, low in energy consumption and easy to process, is conductive to energy saving and environment protection and conforms to the principle of sustainable development. The comprehensive utilization rate of Chinese torreya and the added value of Chinese torreya products are improved, and a new way is explored for deep Chinese torreya processing.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Preparation method of strontium hydrogen phosphate

The invention provides a preparation method of strontium hydrogen phosphate. The preparation method comprises the following steps: adding a hydrophosphate-dihydric phosphate buffer solution with a pH value of 6-9 to a reactor, and then adding a strontium hydroxide solution and a phosphoric acid solution, which have the equal molar concentration, to the reactor in an equal flow rate manner; enabling the volume ratio of the buffer solution, the strontium hydroxide solution and the phosphoric acid solution to be 1:1:1; performing reaction on strontium hydroxide with phosphoric acid to generate strontium hydrogen phosphate, wherein the reaction temperature is normal temperature, and the reaction time is 1 hour; after the reaction, performing centrifugal separation on the reaction solution, and precipitating and drying to obtain the strontium hydrogen phosphate product; recovering the supernatant after membrane concentration, and preparing the buffer solution to be reused from the supernatant. According to the preparation method disclosed by the invention, strontium hydroxide is used for substituting strontium nitrate or strontium chloride in the conventional technology, and phosphoric acid is used for substituting ammonium hydrogen phosphate to produce strontium hydrogen phosphate; the preparation method is simple in production process; the product is free of entrained chloride ions and nitrate ions, high in purity, and controllable in grain size; the preparation method is low in cost and free of ammonia nitrogen waste liquid discharge.

Owner:重庆新申世纪新材料科技有限公司

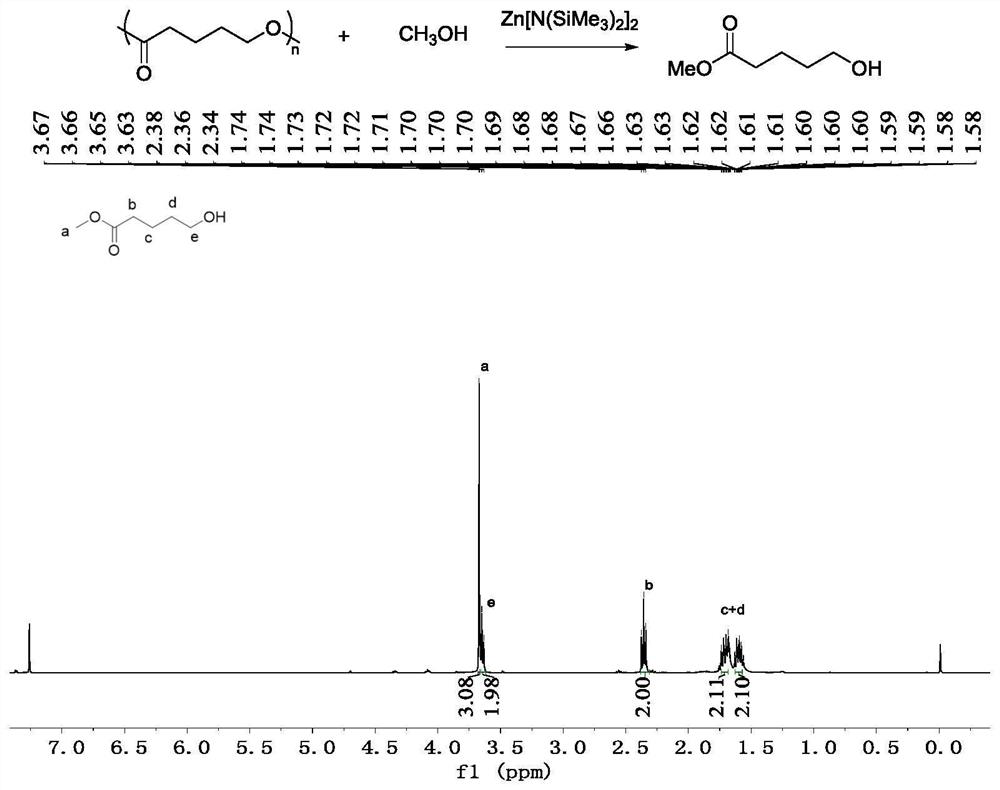

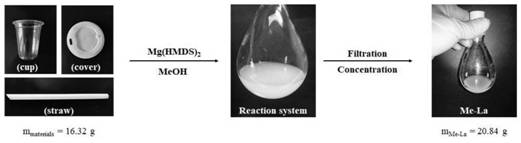

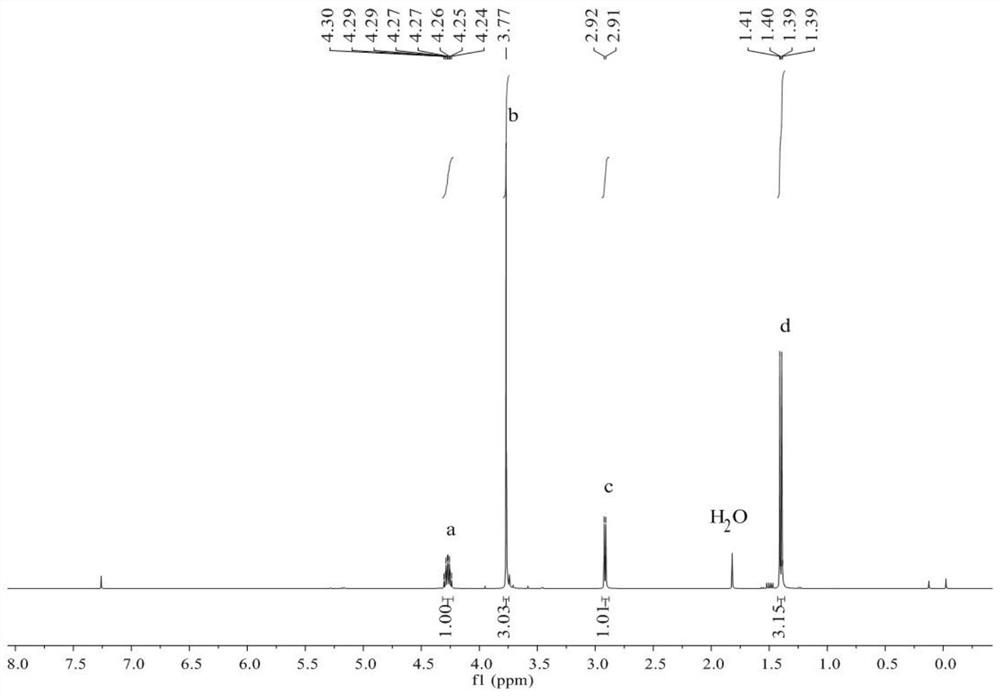

Method for catalytically depolymerizing polylactic acid and analogues thereof by magnesium catalytic system

PendingCN113754535AAchieve reuseIn line with the principles of sustainable developmentPreparation by ester-hydroxy reactionPolyesterPolymer science

The invention discloses a method for catalytically depolymerizing polylactic acid and analogues thereof by a magnesium catalytic system, which belongs to the technical field of polyester depolymerization. According to the method disclosed by the invention, under the catalysis of a bis (hexamethyldisilazane) magnesium or dibutyl magnesium catalyst, alcoholysis of polylactic acid and analogues thereof is realized in the presence of an alcohol compound to obtain small organic molecules, so that effective utilization of waste polylactic acid and analogues thereof is realized. The green and environment-friendly magnesium catalyst with a simple structure is adopted for catalysis, the process is green and environment-friendly, the reaction can be efficiently carried out under mild conditions, and the catalyst has good universality and has a good depolymerization effect on polylactic acid with various different structures and analogue materials thereof.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

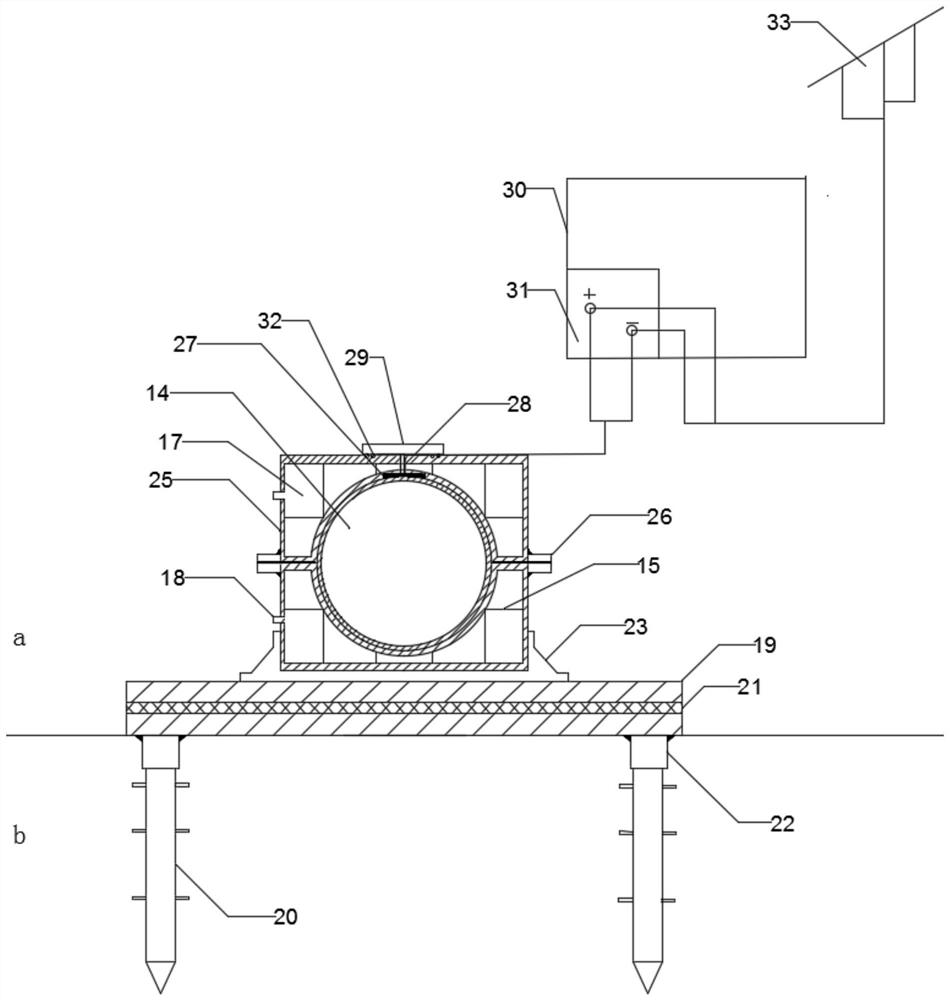

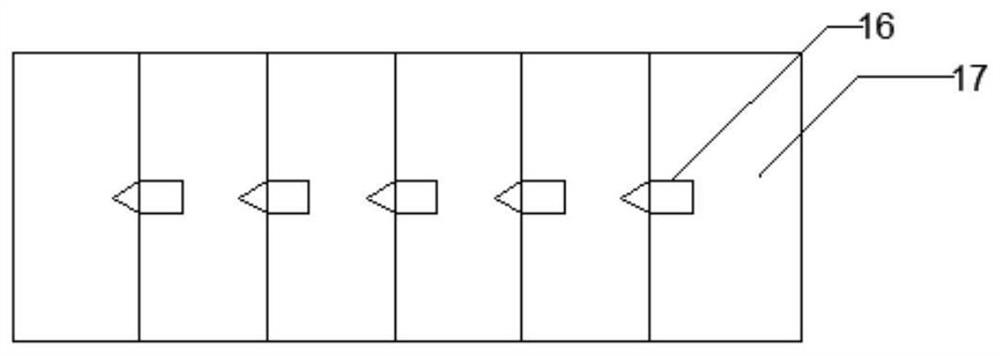

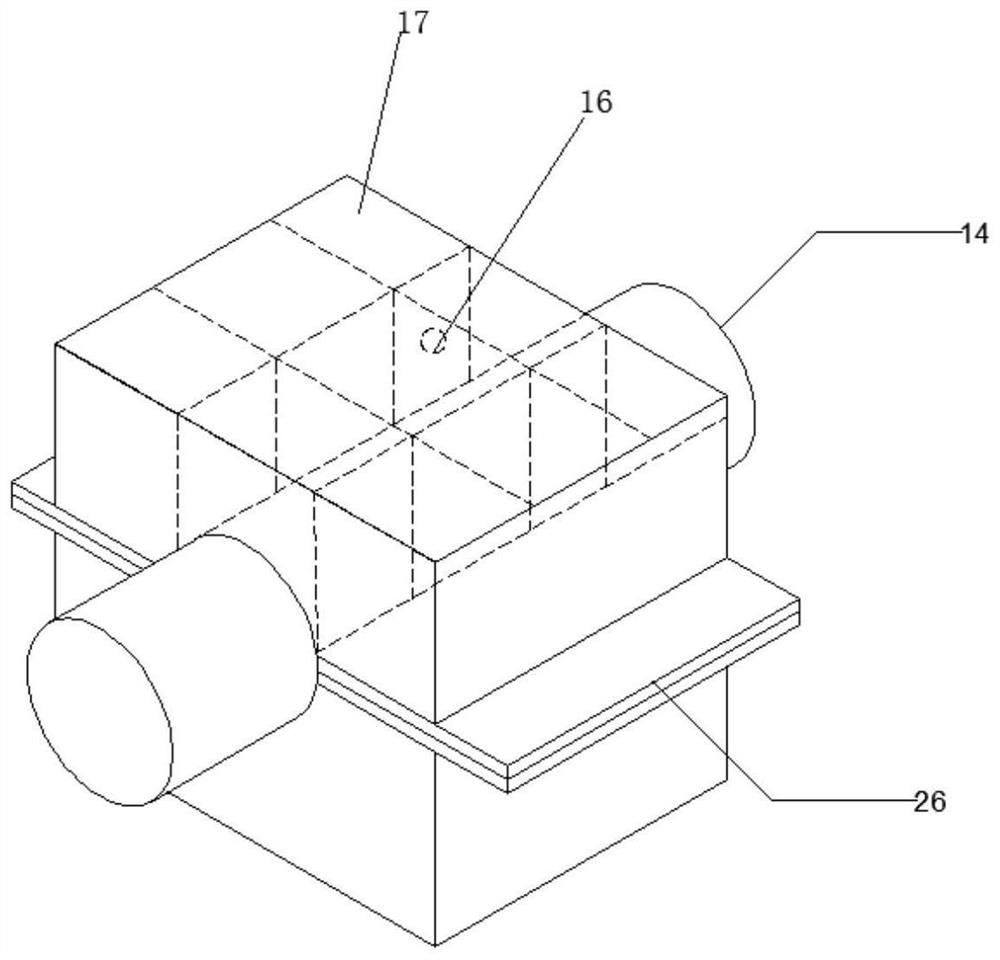

Pipeline fixing method suitable for frozen soil area

ActiveCN112663594AAvoid natural disaster riskFunction increasePipe laying and repairSoil preservationSoil scienceEngineering

The invention discloses a pipeline fixing method suitable for a frozen soil area. A pipeline is fixed to a heat insulation mounting plate through a heat insulation fixing assembly, the heat insulation mounting plate is fixed above a perennial frozen soil layer through anti-freezing supporting legs, the heat insulation fixing assembly comprises an upper positioning mounting part and a lower positioning mounting part, the two positioning mounting parts are in butt joint to form a circular channel allowing a crude oil pipeline to penetrate through, and each positioning mounting part comprises a shell plate with a sealed cavity formed inside; and an energy recovery assembly is arranged on the fixing mounting parts, the energy recovery assembly comprises a semiconductor power generation piece which is fixed to the bottom of the shell plate and can be tightly attached to the outer wall of the pipeline, the top of the semiconductor power generation piece is connected with a cold plate fixed to the top of the shell plate through a heat conduction rod, and the semiconductor power generation piece is electrically connected with a battery in a data acquisition protection box. The pipeline fixing method is green, environment-friendly and high in fixing stability.

Owner:NORTHWEST INST OF ECO-ENVIRONMENT & RESOURCES CAS

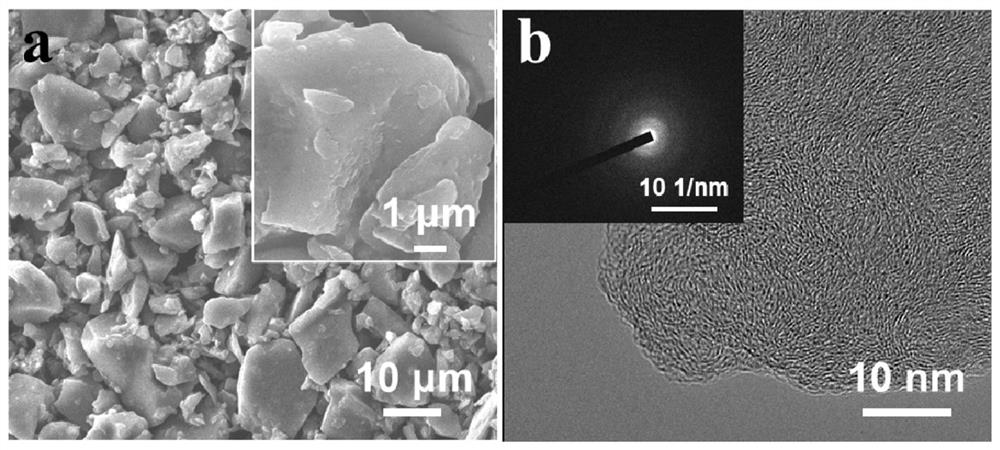

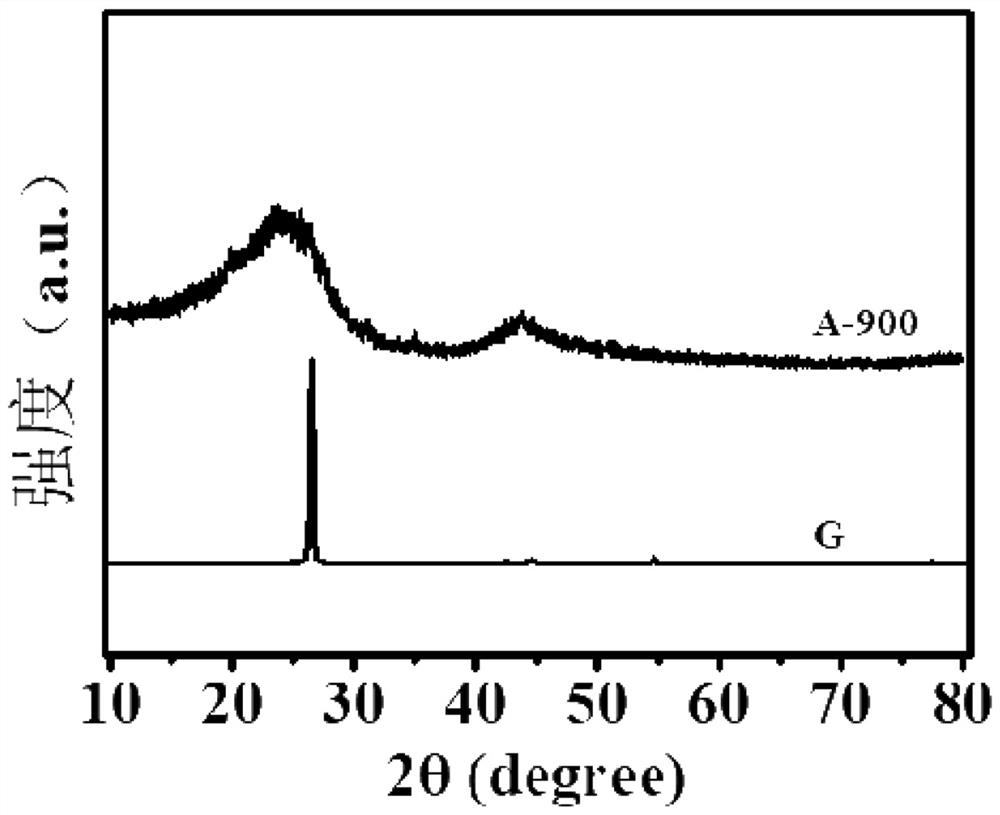

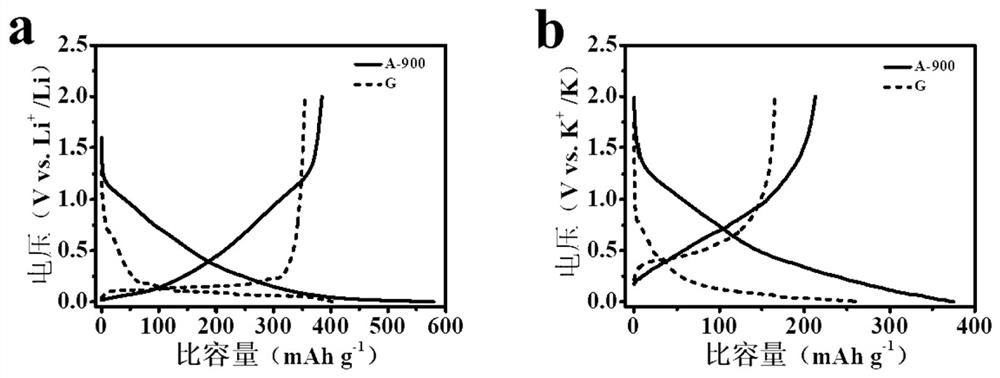

Preparation method of lithium/potassium ion battery negative electrode material

PendingCN113363465ARich reservesLow costNegative electrodesSecondary cellsPotassium ionsPyrolytic carbon

The invention discloses a preparation method of a lithium / potassium ion battery negative electrode material, which comprises the steps of crushing blocky anthracite to obtain anthracite powder, placing the anthracite powder in a protective atmosphere, and carrying out heat treatment to obtain an anthracite pyrolytic carbon negative electrode material. The obtained lithium ion battery anthracite pyrolytic carbon negative electrode material still shows the reversible specific capacity of 62.0 mAh g <-1 > after 500 cycles under the current density of 1 A g <-1 >, the capacity retention rate reaches 69.3%, while a commercial graphite negative electrode shows the specific capacity of 24.4 mAh g <-1 >, and the capacity retention rate is only 28.4%. The prepared anthracite pyrolytic carbon shows more excellent electrochemical performance than graphite in a potassium ion half-cell, and the potassium storage capacity, the cycling stability and the like of the anthracite pyrolytic carbon material can be effectively improved through doping of elements such as N or P.

Owner:CHINA THREE GORGES UNIV

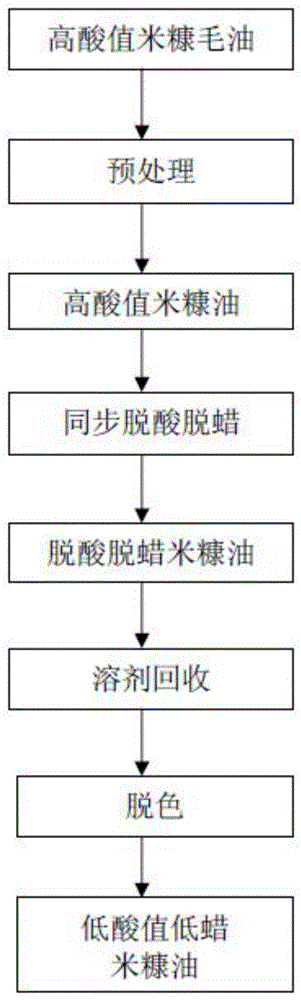

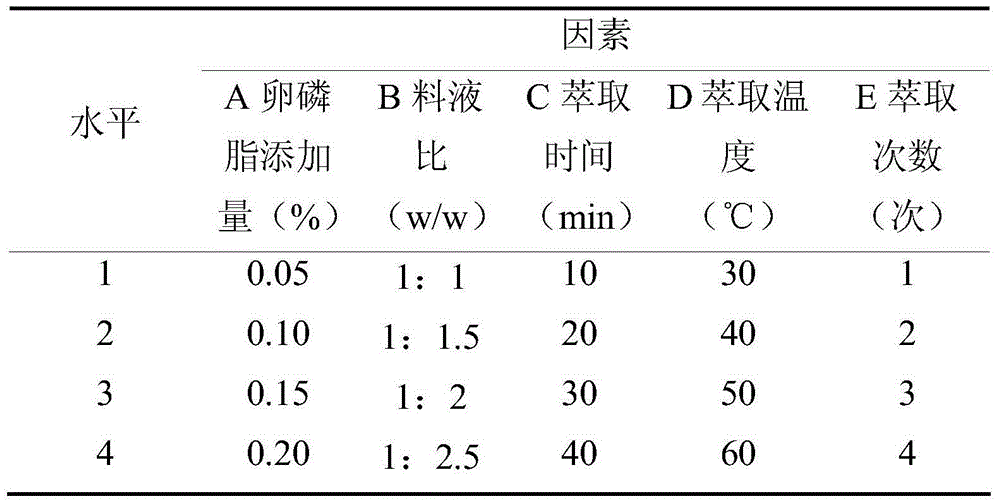

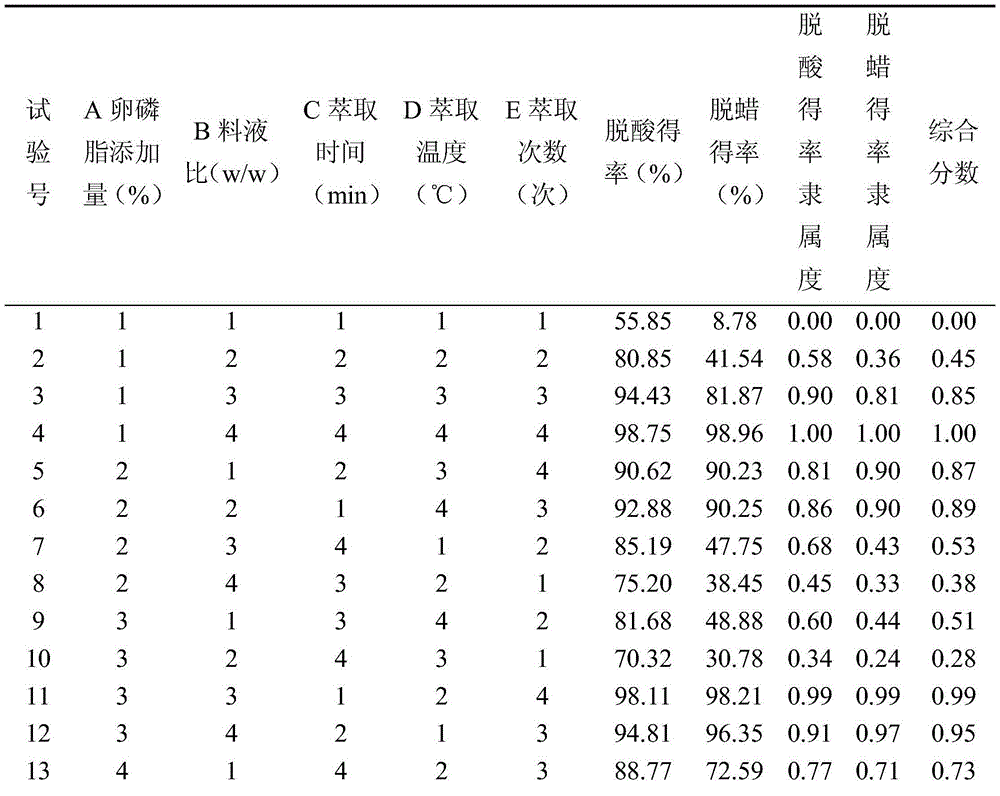

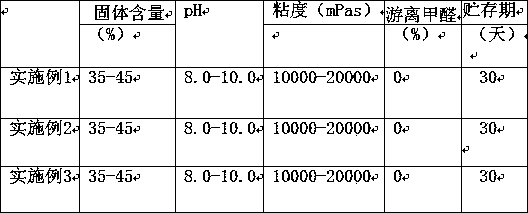

High-acid-value rice bran oil synchronous deacidification and dewaxing process

ActiveCN104877757AIncrease the refining rateProcess safety and environmental protectionFatty-oils/fats refiningAcid valueRice Bran Extract

The invention discloses a high-acid-value rice bran oil synchronous deacidification and dewaxing process, which comprises the following steps that 1, high-acid-value rice bran crude oil is pretreated to obtain high-acid-value rice bran oil; 2, synchronous deacidification and dewaxing is carried out to obtain deacidified and dewaxed rice bran oil; 3, the deacidified and dewaxed rice bran oil is sequentially subjected to solvent recovery and decoloring treatment to obtain the low-acid-value and low-wax-content rice bran oil. The high-acid-value rice bran oil synchronous deacidification and dewaxing process provided by the invention has the advantages that lecithin is adopted and is dissolved into a 95-percent ethanol solution to form micelle, so that free fatty acid and rice bran wax are separated out to reduce the content of the free fatty acid and the rice bran wax; therefore the acid value of the rice bran oil is lowered to be below 1mg KOH / g, the wax content is lowered to be below 0.1 percent, and the deacidification rate and the dewaxing rate respectively reach higher than 95 percent. The high-acid-value rice bran oil synchronous deacidification and dewaxing process has the advantages that safety and environment protection are realized, the process is simple, the operation is convenient and fast, the cost is low, the refinery rate is high, the nutrition ingredient remaining rate is high, and the process is suitable for the production of edible grease.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Formaldehyde-free soybean meal based artificial board adhesive and preparation method thereof

InactiveCN107586533ASolve pollutionSolve the exhaustion problemNon-macromolecular adhesive additivesProtein adhesivesPolyethylene glycolSodium bisulfite

The invention discloses a formaldehyde-free soybean meal based artificial board adhesive and a preparation method thereof. The formaldehyde-free soybean meal based artificial board adhesive is prepared from 60-70 parts of a dispersion medium, 20-35 parts of defatted soybean protein powder, 0.1-0.8 part of sodium hydroxide, 5-10 parts of polyethylene glycol, 0.5-3 parts of sodium bisulfite, 0.1-2.0parts of a crosslinking enhancer, and 1-5 parts of sodium benzoate. The preparation method includes: adding the defatted soybean protein powder, the crosslinking enhancer, sodium hydroxide, sodium bisulfite and polyethylene glycol into the dispersion medium, stirring the substances evenly, then conducting heat preservation at 60-80DEG C for 3-6h; and then cooling the obtained mixture to 25-35DEGC, adding sodium benzoate, and stirring the substances evenly. The method provided by the invention has the advantages of simple process and convenient operation, the produced adhesive is free of formaldehyde, the main raw materials come from renewable materials, and are safety and environment-friendly.

Owner:TIANJIN YISEN MATERIAL TECH CO LTD

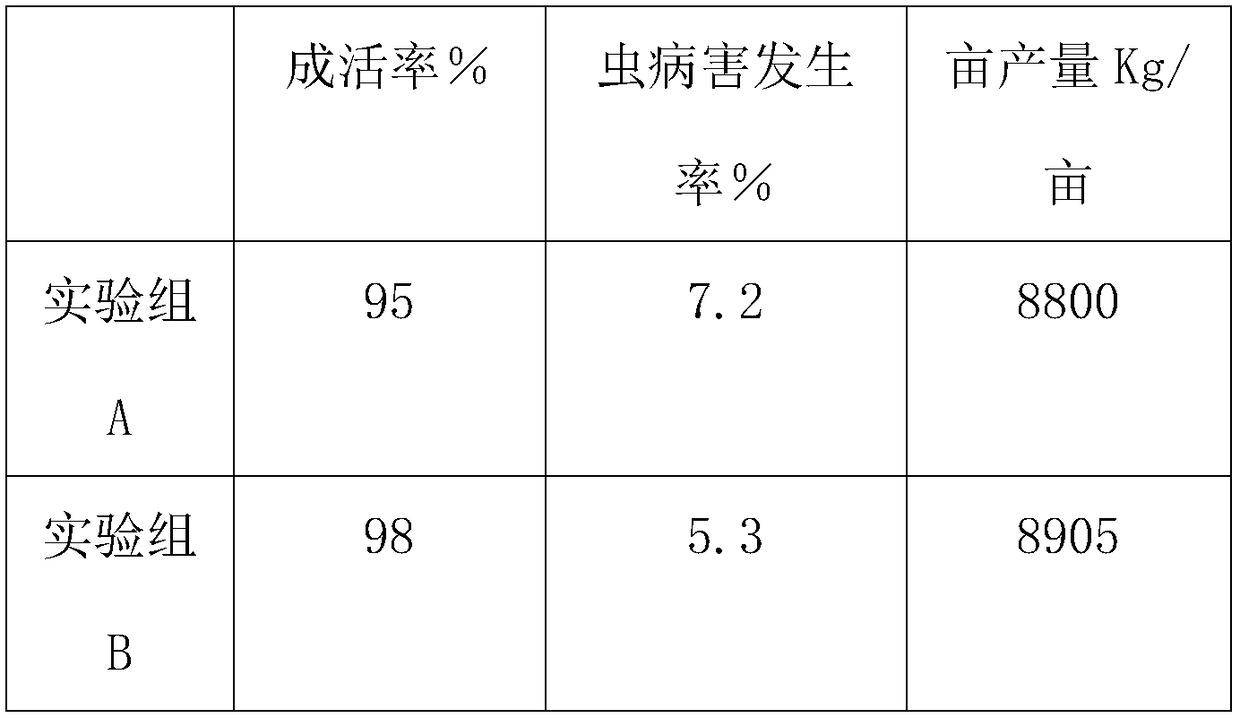

Novel process for regenerating and cultivating organic small watermelons

InactiveCN108849306AVigorousStrong low temperature resistanceGraftingPlant protectionDiseasePesticide residue

The invention discloses a novel process for regenerating and cultivating organic small watermelons. The method solves the vicious circle problems caused by unfavorable factors that in current production of the small watermelons, the soil texture deterioration is caused by long-term use of chemical fertilizer, chemical pesticide and hormones; the pesticide resistance of diseases and pests is enhanced; the pesticide residues are aggravated; the quality of agricultural products is declined. By means of the novel process, the potentials of the small watermelons are mined. The potential regeneration characteristics of crops are utilized, and a high-yield cultivation mode for the small watermelons by conducting sowing once and harvesting multiple times is created. The technical problems are solved that the yield in current cultivation of the small watermelons is not increased, and the development is weak.

Owner:付再上

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com