3D printing alkali-fast cement concrete and preparation method thereof

A slag cement and 3D printing technology, applied in the field of building materials, can solve the problems of difficult control of setting time and limited application, and achieve high waste utilization rate, good economic and social benefits, and significant resource protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

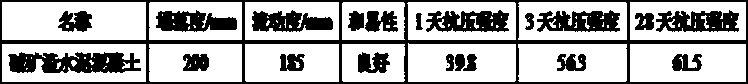

Embodiment 1

[0022] The concrete was tested according to the following formula: 40 parts of slag powder, 10 parts of steel slag powder, 15 parts of ordinary river sand, 35 parts of limestone, and the alkali activator was a mixed solution of NaOH and water glass with a modulus of 3.1 to 3.4, of which 2 parts of NaOH , 1.5 parts of water glass; 35 parts of water, 2 parts of retarder, which is a 1:1 mixture of sodium borate and sodium sulfate;

[0023] The preparation method of 3D printed alkali slag cement concrete is:

[0024] Grinding the steel slag until the specific surface area is 400-420m 2 / kg, the slag is ground to a specific surface area of 390-420 m 2 / kg, and then put them in an oven at 105°C for about 1.5 hours, mix them evenly to get a mixed powder, and set aside;

[0025] Accurately weigh the mixed powder and ordinary river sand and limestone aggregate according to the above ratio, put them in a mixer and stir evenly, dissolve sodium hydroxide in water glass to make an alka...

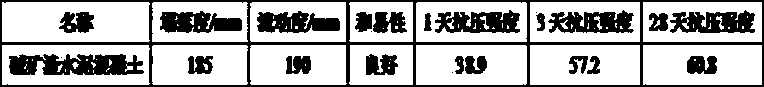

Embodiment 2

[0029] Concrete was tested according to the following formula: 45 parts of slag powder, 15 parts of steel slag powder, 15 parts of ordinary river sand, 25 parts of limestone; 6 parts of alkali activator, which is a mixed solution of NaOH and water glass, with a modulus of 2.0 and water 40 Parts, retarder 2.5 parts, for the mixture of sodium borate and sodium carbonate.

[0030] The preparation method of 3D printed alkali slag cement concrete is:

[0031] Grind the steel slag until the specific surface area is 360-410m 2 / kg, the specific surface area of slag is 380-430 m 2 / kg, then put them in an oven at 105°C for about 1.2 hours, mix them evenly to get a mixed powder, and set aside;

[0032] Accurately weigh steel slag powder, slag powder, common river sand, and limestone aggregates according to the above ratio, place them in a mixer and stir evenly, dissolve sodium hydroxide in water glass to make an alkali activator, and add the alkali activator to Stir evenly in the ...

Embodiment 3

[0037] Concrete was tested according to the following formula: 50 parts of slag powder, 10 parts of steel slag powder, 20 parts of ordinary river sand, 20 parts of limestone; 5 parts of alkali activator, which is a mixed solution of NaOH and water glass (modulus 3.1-3.4) , its modulus configuration is 1.5; 42 parts of water, 2.8 parts of retarder, which is a mixture of sodium borate, sodium sulfate and sodium carbonate.

[0038] The preparation method of 3D printed alkali slag cement concrete is:

[0039] Grind the steel slag until the specific surface area is 370-420m 2 / kg, the specific surface area of slag is 380-420 m 2 / kg, then put them in an oven at 105°C for about 2.0 hours, mix them evenly to get a mixed powder, and set aside;

[0040] Accurately weigh steel slag powder, slag powder, ordinary river sand, and limestone aggregates according to the above ratio, place them in a mixer and stir evenly, dissolve sodium hydroxide in water glass to make an alkali activator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com