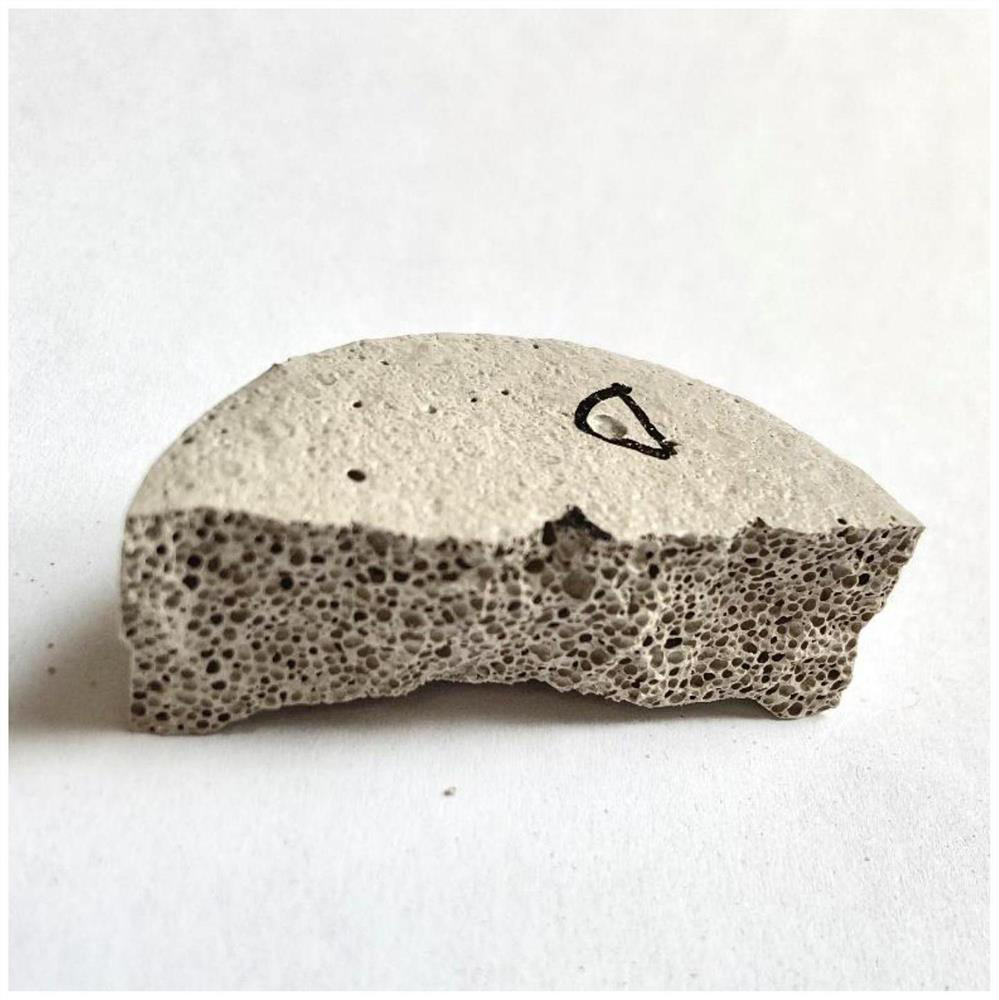

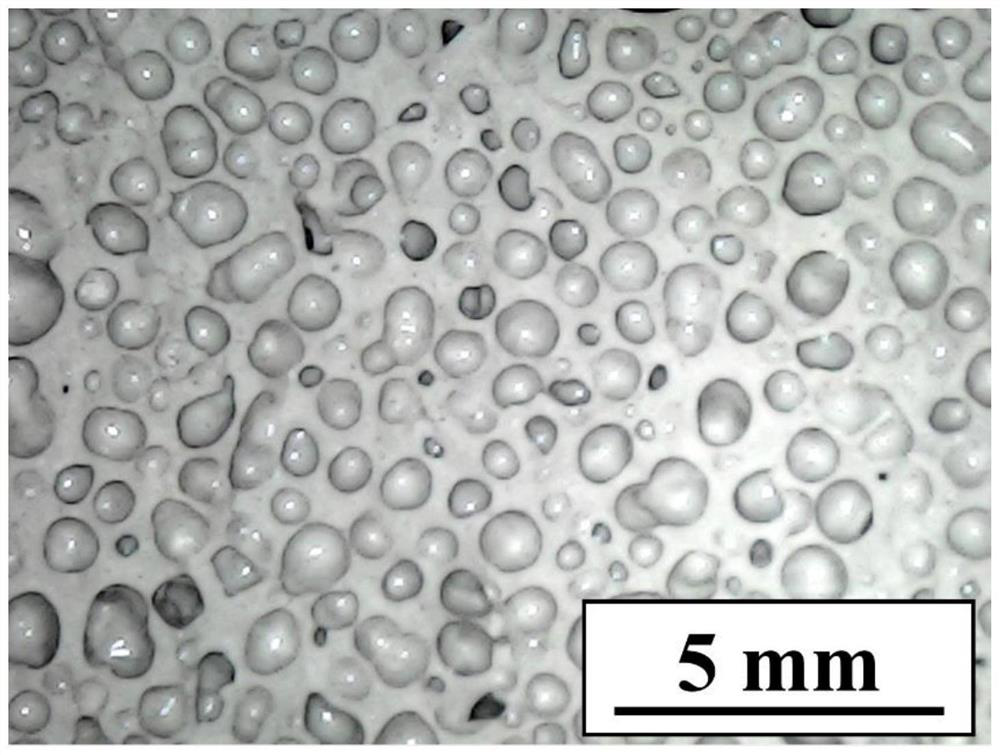

High-strength geopolymer closed-cell foam material prepared from silicon carbide, and preparation method thereof

A technology of geopolymers and foaming materials, which is applied in the field of manufacturing new porous inorganic non-metallic materials, can solve the problems of low strength of foam materials, difficult control of pore structure, uneven foaming, etc., so as to improve thermal insulation effect, increase Density, effect of promoting dispersion and reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

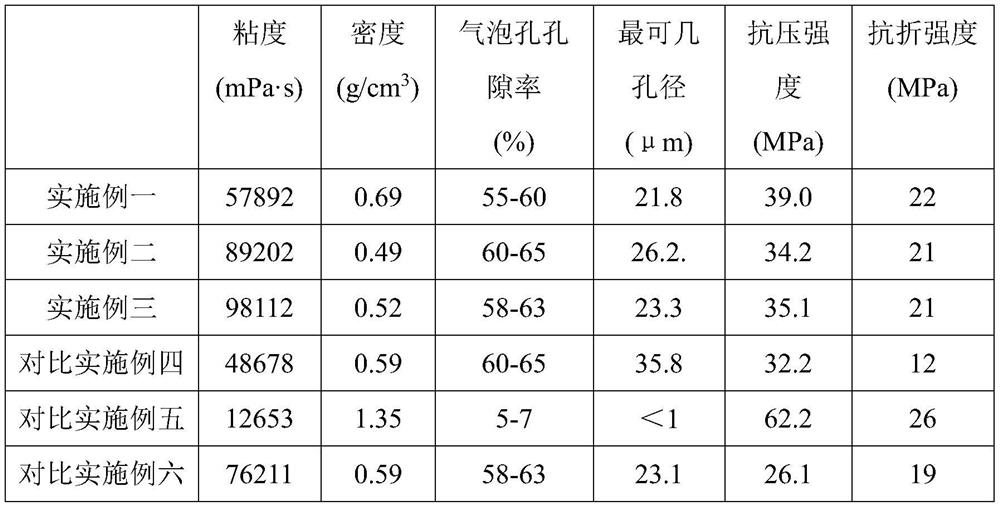

Embodiment 1

[0029] A high-strength geopolymer closed-cell foaming material prepared by silicon carbide, including 15 parts of metakaolin, 10 parts of ordinary Portland cement, 15 parts of fly ash, 10 parts of silica fume, 10 parts of sodium hydroxide solid, silicon 50 parts of sodium acid solution, 20 parts of quartz powder, 4 parts of mica powder, 2 parts of polyacrylonitrile fiber, 8 parts of silicon carbide powder, 3 parts of aluminum powder, 3 parts of sodium lauryl sulfate, 0.5 parts of grinding aid, and 10 parts of ionized water.

[0030] The water content of sodium silicate solution is 60%; the average particle size of quartz powder is 60 microns; the average particle size of mica powder is 400 microns; the particle size of silicon carbide powder is 50-100 nm; the diameter of polyacrylonitrile fiber is 10- 20 microns, the length is 4-6 mm; the average particle size of aluminum powder is 10 microns.

[0031] A method for preparing a high-strength geopolymer closed-cell foam materia...

Embodiment 2

[0039]A high-strength geopolymer closed-cell foaming material prepared by silicon carbide, including 18 parts of metakaolin, 10 parts of ordinary portland cement, 15 parts of fly ash, 12 parts of silica fume, 12 parts of sodium hydroxide solid, silicic acid 45 parts of sodium solution, 18 parts of quartz powder, 1 part of mica powder, 1 part of polyvinyl alcohol fiber, 1 part of polyamide fiber, 10 parts of silicon carbide powder, 3 parts of aluminum powder, 2.5 parts of sodium lauryl sulfate, grinding aid 0.5 parts of agent, 10 parts of deionized water.

[0040] The water content of the sodium silicate solution is 65%; the average particle size of the quartz powder is 55 microns; the average particle size of the mica powder is 350 microns; the particle size of the silicon carbide powder is 350-400 nanometers; 40 microns, the length is 6-8 mm; the diameter of polyamide fiber is 20-30 microns, the length is 4-6 mm; the average particle size of aluminum powder is 10 microns.

...

Embodiment 3

[0049] A high-strength geopolymer closed-cell foaming material prepared by silicon carbide, including 20 parts of metakaolin, 10 parts of ordinary Portland cement, 12 parts of fly ash, 15 parts of silica fume, 12 parts of sodium hydroxide solid, silicon 48 parts of sodium acid solution, 18 parts of quartz powder, 2 parts of mica powder, 2 parts of polyvinyl alcohol fiber, 10 parts of silicon carbide powder, 4 parts of aluminum powder, 2 parts of sodium lauryl sulfate, 0.5 parts of grinding aid, and 12 parts of ionized water.

[0050] The water content of sodium silicate solution is 55%; the average particle size of quartz powder is 65 microns; the average particle size of mica powder is 370 microns; the particle size of silicon carbide powder is 150-200 nm; the diameter of polyvinyl alcohol fiber is 10- 20 microns, the length is 5-7 mm; the average particle size of aluminum powder is 15 microns.

[0051] A method for preparing a high-strength geopolymer closed-cell foam mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com