Nitrogen defect control method for production of ethanol through fermentation of synthesis gas with mixed bacteria

A technology of mixing bacteria and syngas, used in fermentation, biofuels, etc., to reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

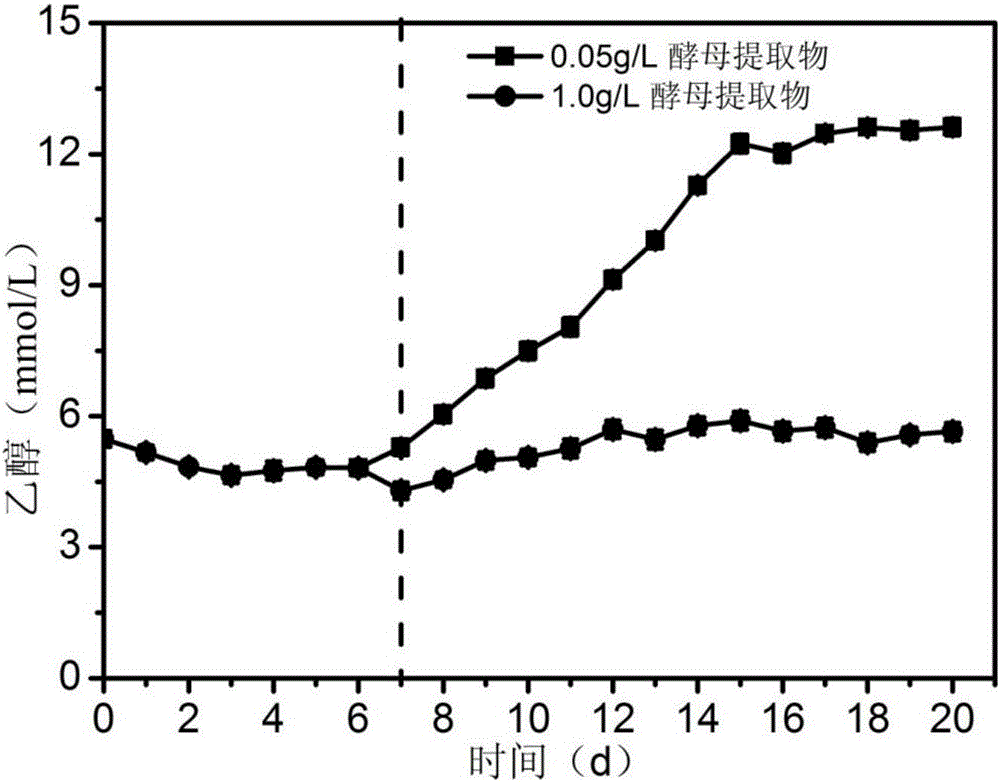

[0024] Add 50g of homoacetogenic bacteria enrichment to 500mL liquid medium containing 1.0g / L yeast extract, filled with CO / CO 2 / H 2 (4:3:3) to a standard atmospheric pressure, adjust the pH=7.0, and carry out the first stage of cultivation at 37°C. After 6 days of cultivation, the homoacetogenic bacteria grow to a stable state and enter the second stage. Take 10g of the enrichment after the first stage of cultivation and inoculate it into 100mL of basal medium containing 0.05g / L yeast extract, and place it on a constant temperature shaker at 37°C at 100rpm. The components and concentrations of the basic elements in the medium are the same as Same as first stage: K 2 HPO 4 0.25g / L, KH 2 PO 4 0.25g / L, MgCl 2 ·6H 2 O0.3g / L, BES (bromoethanesulfonate) 10.5g / L. Charge CO / CO 2 / H 2 (4:3:3) to a standard atmospheric pressure to maintain pH 7.0. Gas consumption and organic product formation were measured by gas chromatography. The results showed that the ethanol accumul...

Embodiment 2

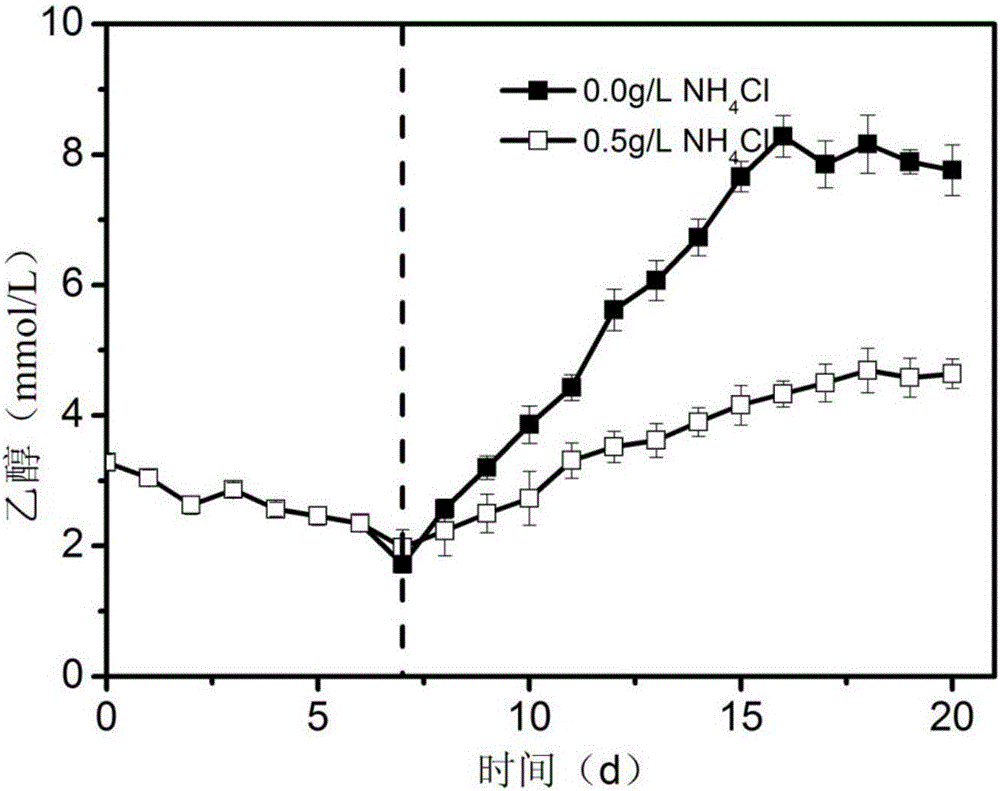

[0028] Add 50g of homoacetogenic bacteria enrichment to 500mL containing 0.5g / L NH 4 In the liquid medium of Cl, filled with CO / CO 2 / H 2(4:3:3) to a standard atmospheric pressure, adjust the pH=7.0, and carry out the first stage of cultivation at 37°C. After 6 days of cultivation, the homoacetogenic bacteria grow to a stable state and enter the second stage. Take 10g of the enrichment after the first stage culture to inoculate 100mL without NH 4 In the basal culture medium of Cl (other basic components and concentrations are the same as in Example 1 except the nitrogen source), culture on a constant temperature shaker at 37° C. and 100 rpm. Charge CO / CO 2 / H 2 (4:3:3) to a standard atmospheric pressure to maintain pH 7.0. Gas consumption and organic product formation were measured by gas chromatography. The results showed that the maximum ethanol accumulation in the second stage was 7.8mmol / L, which was 40.2% higher than the maximum ethanol accumulation in the first sta...

Embodiment 3

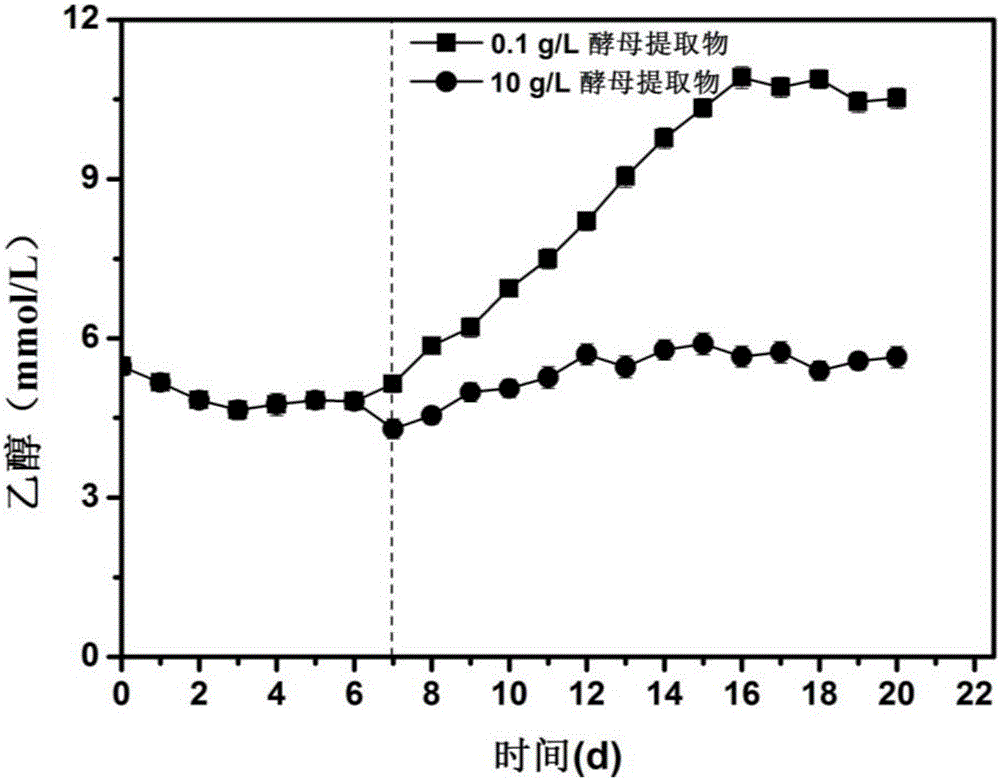

[0031] Add 50g of homoacetogenic bacteria enrichment to 500mL liquid medium containing 10g / L yeast extract, filled with CO / CO 2 / H 2 (4:3:3) to a standard atmospheric pressure, adjust the pH=7.0, and carry out the first stage of cultivation at 37°C. After 6 days of cultivation, the homoacetogenic bacteria grow to a stable state and enter the second stage. Take 10 g of the enrichment after the first-stage culture and inoculate it into 100 mL of basal medium containing 0.1 g / L yeast extract (basic element components and concentrations are the same as in Example 1), and place it on a constant temperature shaker at 37°C and 100 rpm for cultivation . Charge CO / CO 2 / H 2 (4:3:3) to a standard atmospheric pressure to maintain pH 7.0. Gas consumption and organic product formation were measured by gas chromatography. The results showed that the ethanol accumulation in the second stage was 10.9mmol / L, which was 45.9% higher than the ethanol concentration in the first stage ( imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com