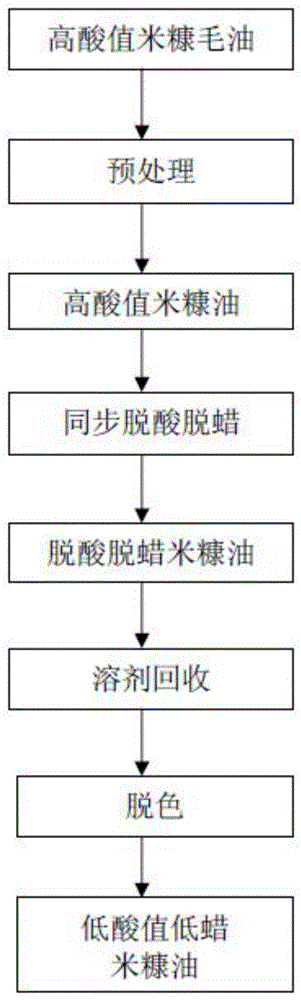

High-acid-value rice bran oil synchronous deacidification and dewaxing process

A high acid value, rice bran oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of affecting oil quality, reducing transparency, increasing oil turbidity, etc., achieving high retention rate of nutrients, reducing costs, and operating convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

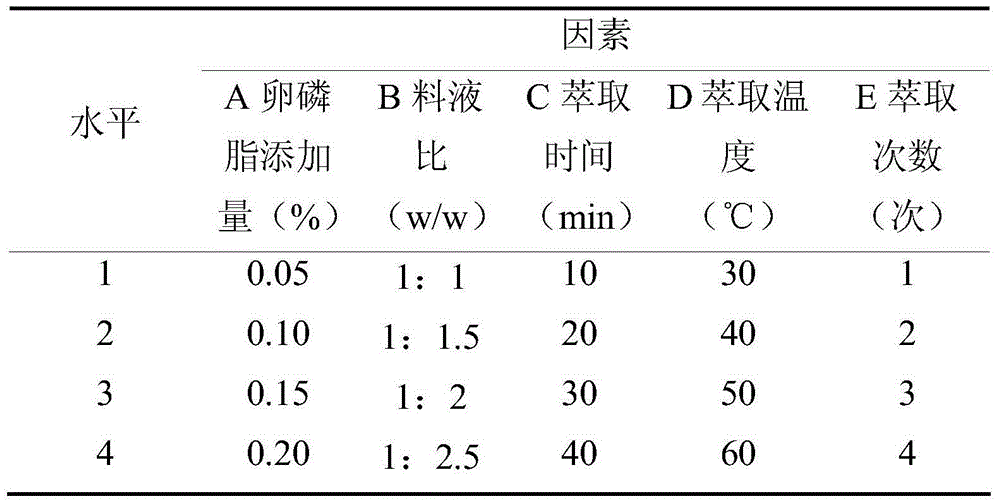

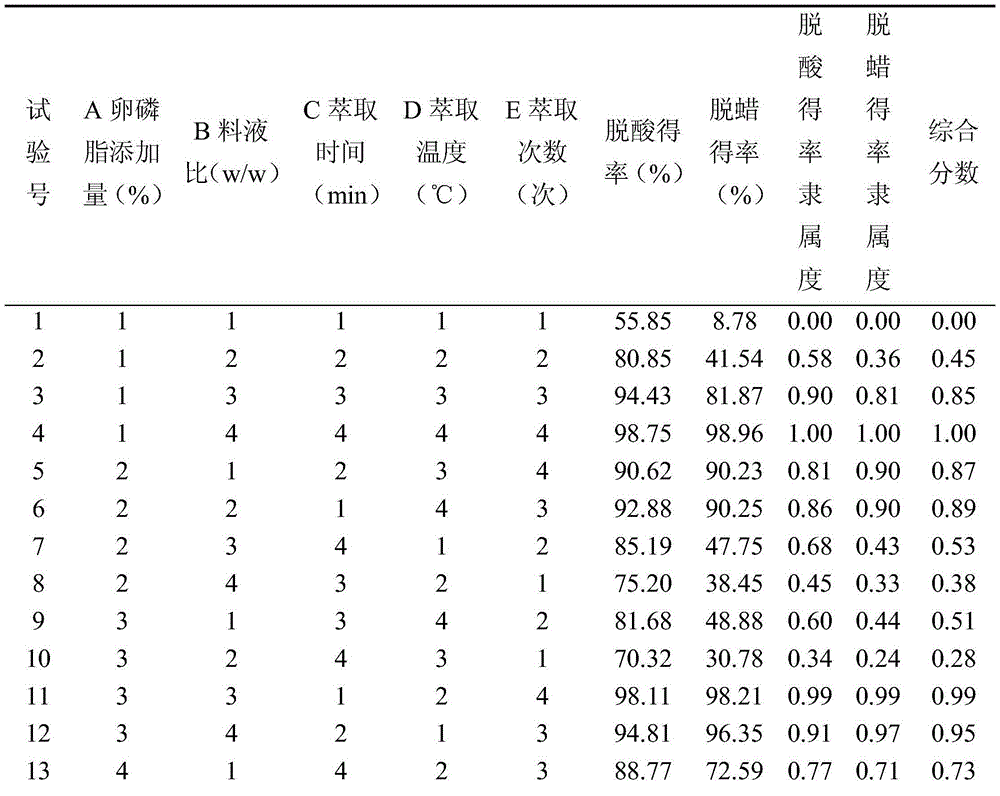

[0032] Firstly, high-acid value rice bran crude oil was centrifuged at 4500r / min for 15 minutes, and then the centrifuged high-acid value rice bran crude oil was vacuum-filtered using a Buchner funnel to remove impurities in the rice bran crude oil, and then the centrifuged Stir and heat the high-acid value rice bran crude oil obtained after the filtration treatment to 45-70°C, add a citric acid solution with a weight of 0.05%-0.30% of the high-acid value rice bran crude oil and a mass concentration of 50g / 100mL, and keep warm and stir for 5 minutes , then add 1% to 3.5% of the weight of rice bran crude oil with high acid value deionized water at the same temperature, continue to stir for 10 to 20 minutes, let stand for 2.5 to 3.5 hours, and centrifuge at a speed of 4500r / min for 15 minutes to obtain degummed high Acid value rice bran oil. At a temperature of 60°C, the amount of lecithin added is 0.05% of the weight of 95% ethanol, and the ratio of solid to liquid (mass ratio ...

Embodiment 2

[0034] When the extraction temperature is 40°C, the amount of lecithin added is 0.15% of the weight of 95% ethanol, and the ratio of solid to liquid (mass ratio of high acid value rice bran crude oil to lecithin-95% ethanol solution) is 1:2, Extract for 10 minutes, extract 4 times, and other steps are the same as in Example 1 to obtain low-acid and low-wax rice bran oil with an acid value of 0.79 mgKOH / g, a wax content of 0.06%, and deacidification and dewaxing yields of 98.11% and 98.21%, respectively. .

Embodiment 3

[0036] When the extraction temperature is 60°C, the amount of lecithin added during extraction is 0.15% of the amount of 95% ethanol, the ratio of solid to liquid (mass ratio of rice bran oil to lecithin-95% ethanol solution) is 1:2.5, the extraction time is 40 minutes, and the number of extractions is 4 Next, the other steps are the same as in Example 1 to obtain low-acid-value and low-wax rice bran oil with an acid value of 0.23 mgKOH / g, a wax content of 0.005%, and deacidification and dewaxing yields of 99.45% and 99.86%, respectively.

[0037] The synchronous deacidification and dewaxing process of rice bran oil with high acid value provided by the present invention uses lecithin dissolved in 95% ethanol solution to form micelles under a certain vacuum degree and temperature, thereby separating free fatty acids and rice bran wax to reduce free fatty acids and rice bran wax. The content of fatty acid and bran wax reduces the acid value of rice bran oil to less than 1mgKOH / g,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com