Patents

Literature

94results about How to "Increase the refining rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

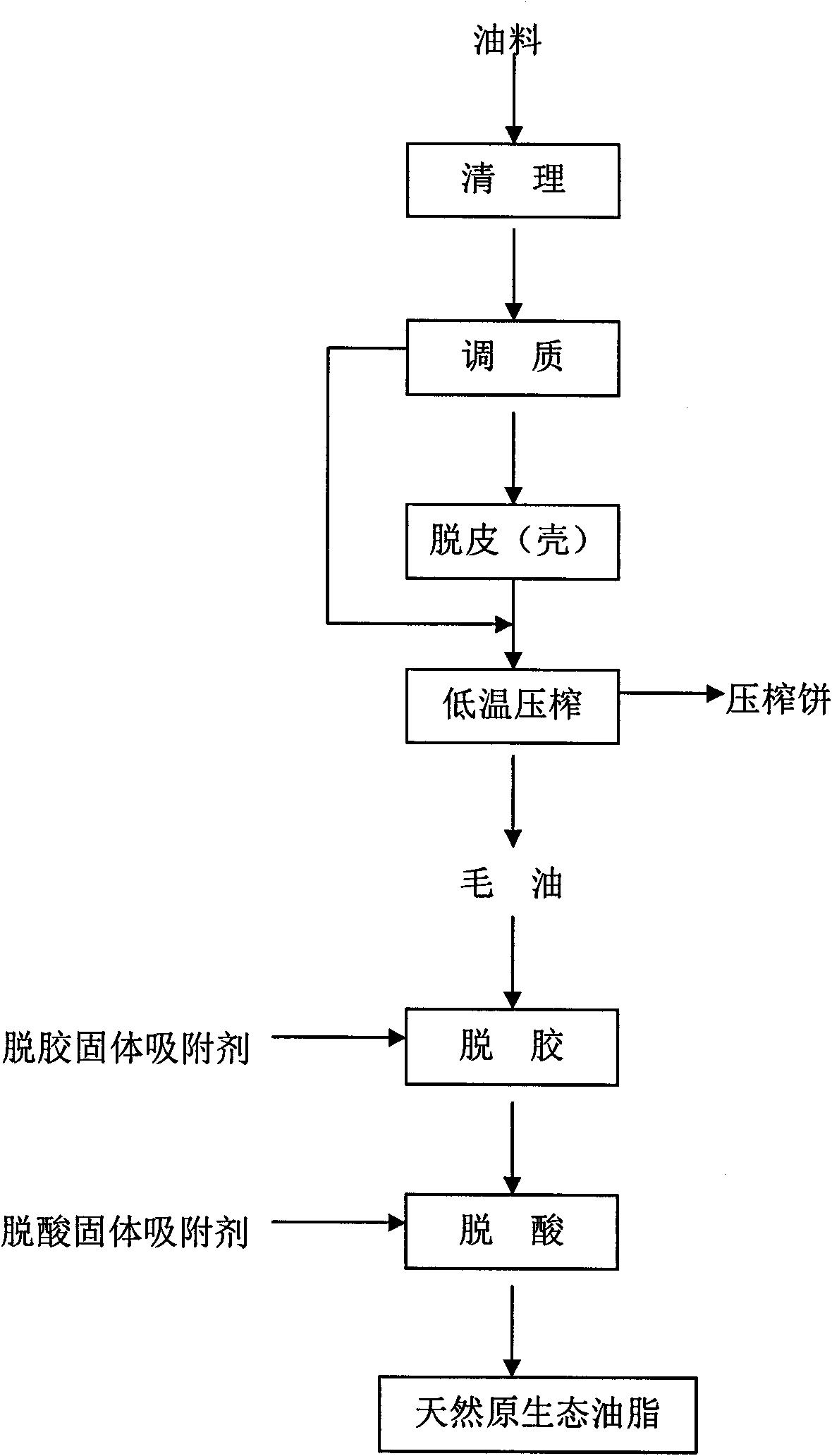

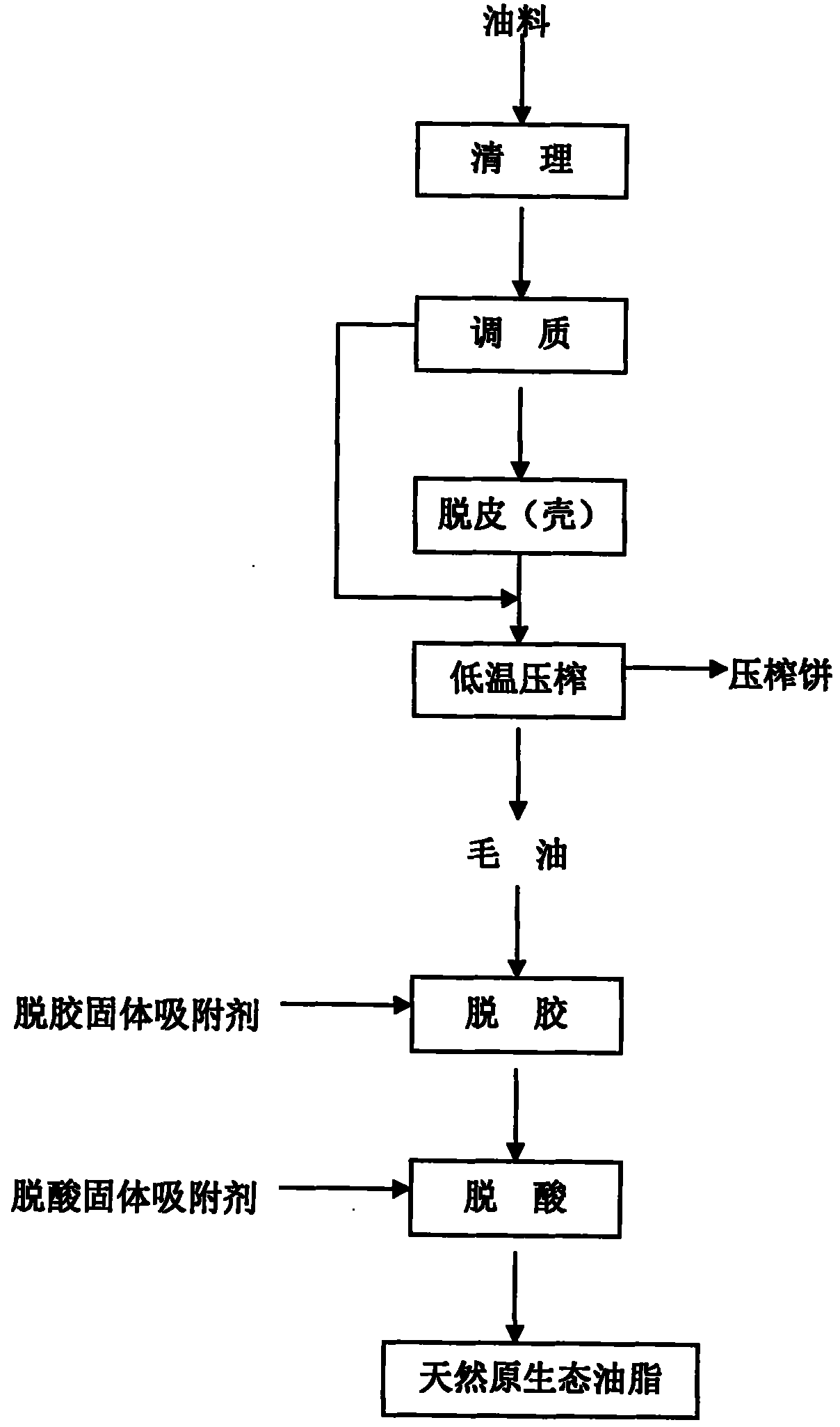

Method for preparing oil at low temperature

InactiveCN101880596ASuitable for industrial productionKeep the flavorFatty-oils/fats refiningFatty-oils/fats productionOil and greaseMoisture

The invention relates to a method for preparing oil at low temperature, which is characterized by comprising the following steps of: 1) clearing: removing impurities of an oil material; 2) conditioning: adjusting the temperature and moisture of the oil material, wherein the temperature of the oil material after the conditioning is 5 to 65DEG C, and the moisture mass of the oil material is adjusted to 4-16 percent; 3) pressing at low temperature: pressing the conditioned oil material, wherein the pressing temperature of the oil material is -10 to 65DEG C, and the moisture mass of the pressed oil material is 4 to 16 percent, and obtaining crude oil; 4) degumming: keeping the temperature of the crude oil between 5 and 65DEG C, adding a degumming solid adsorbent accounting for 0.1 to 5 mass percent of the crude oil, and controlling the degumming time to between 0.1 and 2 hours; and 5) removing acid: keeping the temperature of the degummed crude oil to between 5 and 65DEG C, adding an acid removing solid adsorbent accounting for 0.1 to 2 mass percent of the degummed crude oil, and controlling the acid removing time to between 0.1 and 3 hours to obtain the oil. The method is suitable for industrial production.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

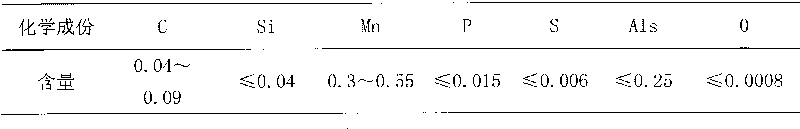

Smelting method of 9Ni steel

ActiveCN102747181AMeet the requirements of continuous castingReduce lossesManufacturing convertersCritical control pointSmelting process

A smelting method of 9Ni steel. The method has the following characteristics: 1.a smelting process comprises steps of pretreatment on molten iron (desulfuration), converter (double dephosphorization, melting nickel plate), LF furnace (desulfuration) and RH (degassing); 2. dephosphorization is conducted in the converter and comprises two steps: step one: blending molten iron desulphurized by KR and steel scrap into a dephosphorization converter for primary smelting, using ''dephosphorization converter smelting critical control point'' to desulphurize the molten iron to a phosphorus content below 0.020%, and carrying out semi-steel tapping; and step two: blending the molten semi-steel and nickel plate into a decarburization converter for converting, desulphurizing the molten steel after converting to a phosphorus content below 0.003%, and carrying out tapping; and 3. the nickel plate is melted in the decarburization furnace. According to the present invention, the two-step dephosphorization is carried out in the converter that molten steel after converting has low phosphorus content and is stably controlled, so as to benefit improvement on the yield of 9Ni steel. Decarburization converter slag has low phosphorus content, and ladle molten steel has a low rephosphorization amount, so as to clear out molten steel in the decarburization furnace and reduce molten steel loss in a steel leaving operation.

Owner:BAOSHAN IRON & STEEL CO LTD

Production process for smelting high-level low-carbon steel at low cost

The invention provides a production process for smelting high-level low-carbon steel at low cost. The production process for producing the low-carbon steel includes the following steps: a converter, RH refining, refining of a ladle furnace and continuous casting. The converter only undertakes partial function of decarbonization, the content of aim carbon is within 0.04 to 0.08% (mass percent), and the function of RH refining decarbonization is exerted to lead the carbon content to be within 0.01 to 0.04% according to the requirement for the content of the finished target carbon. The ladle furnace has the main functions of carbon content adjusting, desulfurizing, temperature rising and component fine adjusting; alloy is added for baking so as to lead the water content to be lower than 0.2%; therefore, the aim carbon content of the converter is high, less molten steel is oxidized, the FeO content in dregs is within 10 to 20%, and the yield rate of the molten steel can be up to 90% to the minimum degree. The invention lessens corrosion to a converter liner and reduces the alloy cost; the pollution to the molten steel by deoxidized products from RH carbon deoxidization is lessened, the using quantity of deoxidant is reduced, the carbon content is stabilized, and the smelting efficiency is obviously increased.

Owner:SHOUGANG CORPORATION

Puffing expression method for producing oil with low oil-containing oil-bearing material

InactiveCN101245284AImprove product qualityAvoid excessive denaturationFatty-oils/fats productionPress cakeImpurity

The invention relates to a method for extracting oil by swelling and pressing low oil content oil seeds and is characterized by comprising the following steps: 1) clearing: impurities are removed from the oil seeds; 2) quality-adjusting: the temperatures and water contents are adjusted for the oil seeds; 3) the oil seeds are pressed and swelled; 4) enzyme killing and drying are carried out for the pressed and swelled oil seeds; 5) most of the oil is pressed from the dried oil seeds; the oil seeds can be crushed and then the quality adjusting can be done after the clearing of the step 1); after the step 2) of quality-adjusting, the bloom rolling can be done to the oil seeds and then the pressing and swelling can be done. The method adds the procedures of pressing and swelling before the traditional one time pressing and obtains pure physical pressed oil with high quality and pressed cakes which can be directly used for feed processing, which increases the processing amount of a press and reduces the power consumption and wearing. The method is mainly used for producing small-scale pressed oil and pressed cakes with good qualities and raw materials of low oil content oil seeds such as soybeans and rice bran.

Owner:中机康元粮油装备(北京)有限公司

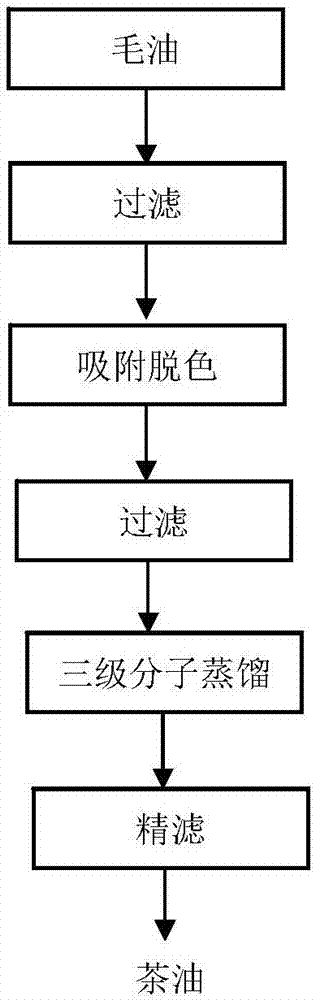

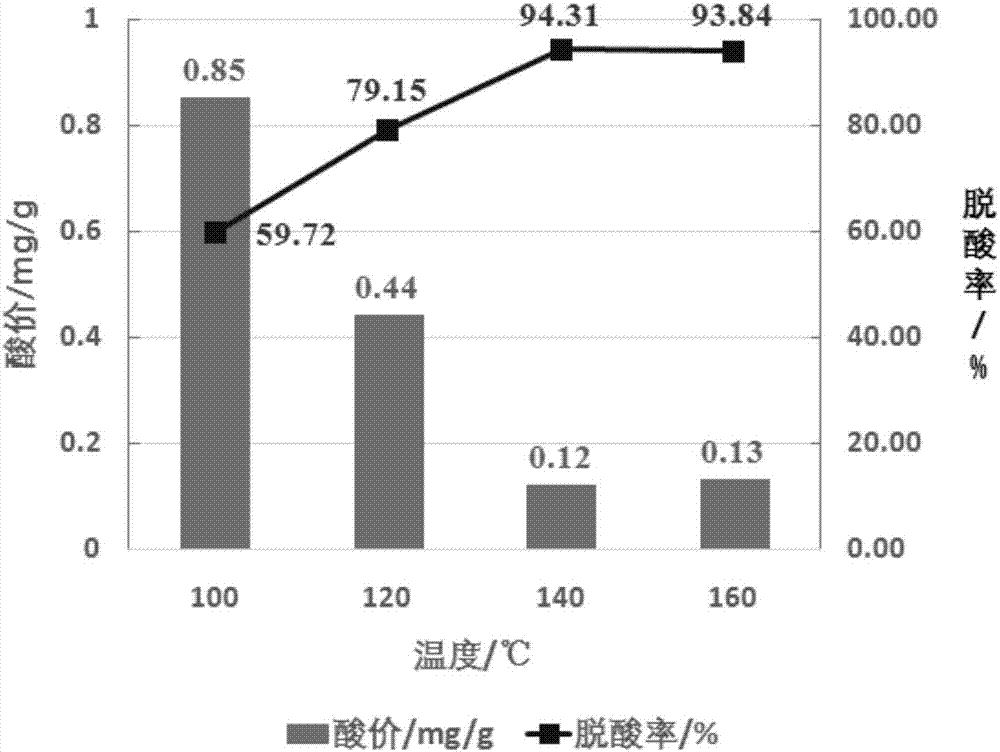

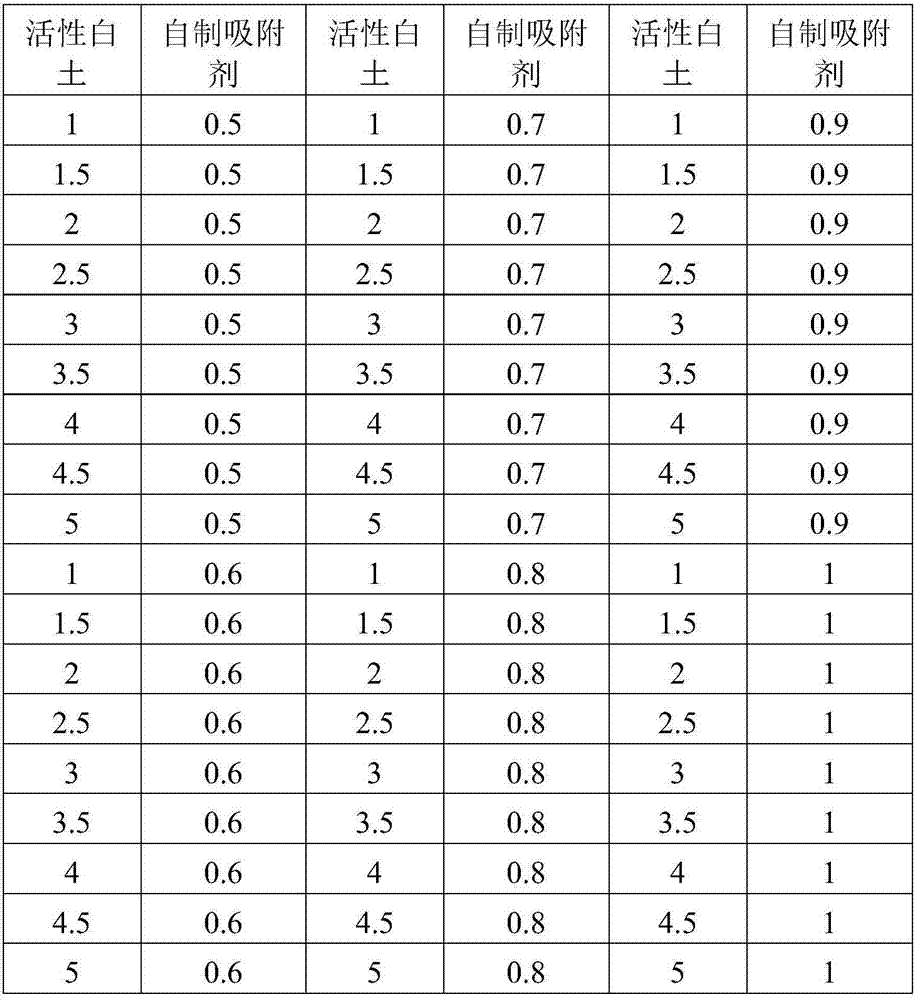

Method for preparing pure physical refined oil and camellia oleifera seed oil by using three-stage molecular distillation

InactiveCN107488503AHigh retention rateProcess environmental protectionFatty-oils/fats refiningCamellia oleiferaDistillation

The invention discloses a method for preparing pure physical refined oil and camellia oleifera seed oil by using three-stage molecular distillation. The method comprises the following steps: firstly, adsorbing crude oil of camellia oleifera seed by using a mixed adsorbent comprising activated clay and a self-prepared adsorbent, filtering, and removing colloid, peroxide and pigment to obtain bleached oil; secondly, deacidifying decolorized oil warp by the three-stage molecular distillation, further removing to obtain a peroxidation value, and carrying out refined filtration to obtain a finished product, wherein the first-stage molecular distillation realizes the effects of dewatering and degassing; the second-stage molecular distillation realizes the effect of removing free fatty acid; the third-stage molecular distillation realizes the effect of further deacidifying to obtain finished camellia oleifera seed oil with a low acid value. The whole refining process for the camellia oleifera seed oil, disclosed by the invention, is environmentally friendly, short in period and high in refining rate; the retention rate of vitamin E and squalene in finished oil is high; in addition, indicators of the finished oil all accord with the standards of national first-class edible oil.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

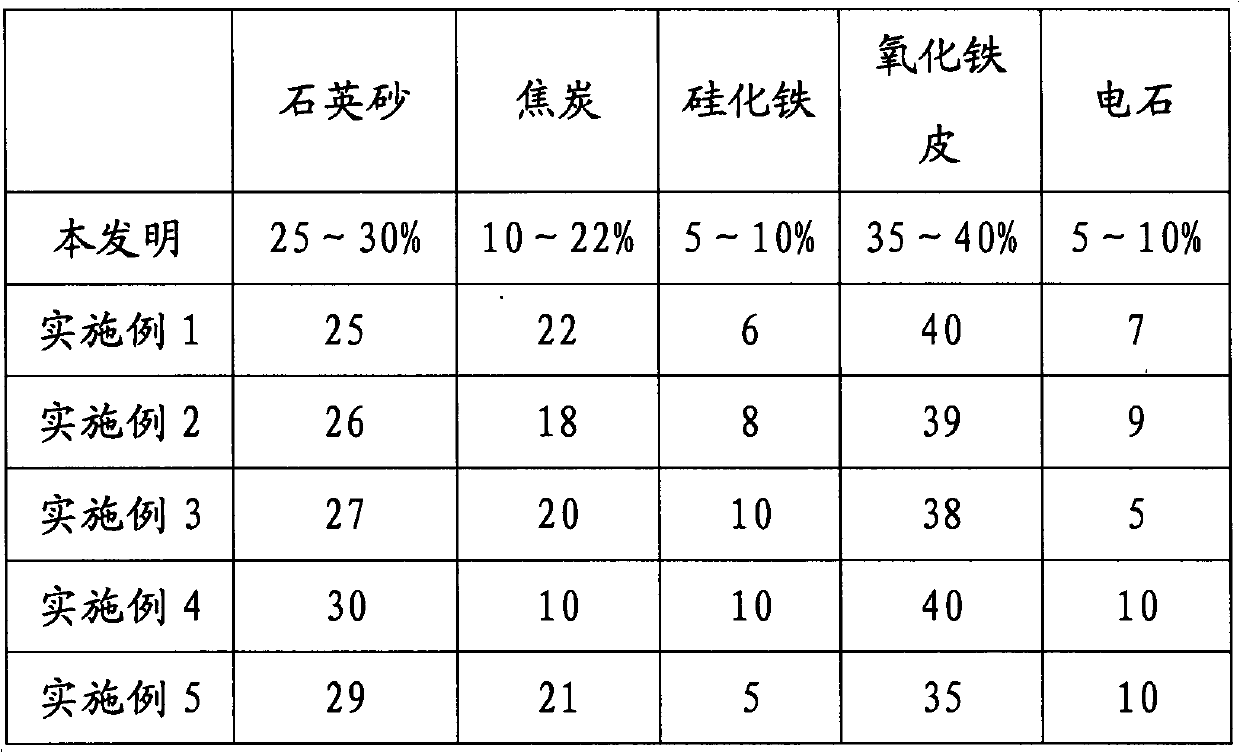

Heating slag melting agent for smelting low-silicon liquid iron and preparation method of the heating slag melting agent

InactiveCN102168163ALow melting pointFast melting pointManufacturing convertersElectric furnaceHeat conductingSmelting process

The invention relates to a heating slag melting agent for smelting low-silicon liquid iron and simultaneously relates to a preparation method of the heating slag melting agent, belonging to the technical field of metallurgy. The heating slag melting agent consists of the chemical ingredients in mass percent as follows: 41-46% of SiC, 5-10% of FeSi, 35-40% of FeO plus Fe2O3, 0-6% of CaO, 0-3% of MgO and 5-10% of CaC2. The preparation method includes the steps of smelting quartz sand and coke into silicon carbide, grinding and mixing materials, and stirring to uniform for formation. In the invention, the characteristic of low melting point of calcium carbide is utilized for assisting silicon carbide and iron silicide in reacting with oxidized iron sheets to emit a large quantity of heat, and simultaneously with good heat conducting property, the silicon carbide rapidly transmit the generated heat during the smelting process, therefore, the slag melting speed is accelerated and the flowability of the liquid iron is improved, and then the smelting yield of steel is enhanced and simultaneously the stable content of silicon in the liquid steel is ensured.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

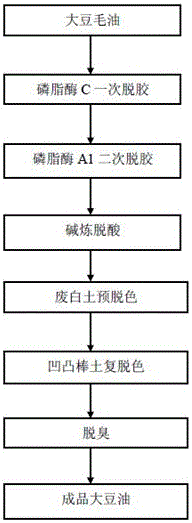

Processing method of soybean oil

InactiveCN105038977AReduce phosphorus contentRelieve pressureFatty-oils/fats refiningActivated carbonPhosphatidase

The invention discloses a processing method of soybean oil. The method comprises the following steps: 1, preparing crude soybean oil; 2, adding phosphatidase C, and carrying out primary degumming treatment to obtain primary degummed soybean oil; 3, adding phosphatidase A1, and carrying out secondary degumming treatment to obtain secondary degummed soybean oil; 4, carrying out alkali refining depickling treatment to obtain depickled soybean oil; 5, adding waste white clay to the depickled soybean oil, carrying out pre-decoloring treatment to obtain pre-decolored soybean oil, adding attapulgite and active carbon to the pre-decolored soybean oil, and carrying out re-decoloring treatment to obtain re-decolored soybean oil; and 6, carrying out deodorizing treatment on the re-decolored soybean oil to obtain finished soybean oil. The processing method of the soybean oil has the advantages of safety, environmental protection, simple process, convenient operation, low cost and high refining rate, and is suitable for soybean oil processing industrial production.

Owner:WUHAN POLYTECHNIC UNIVERSITY

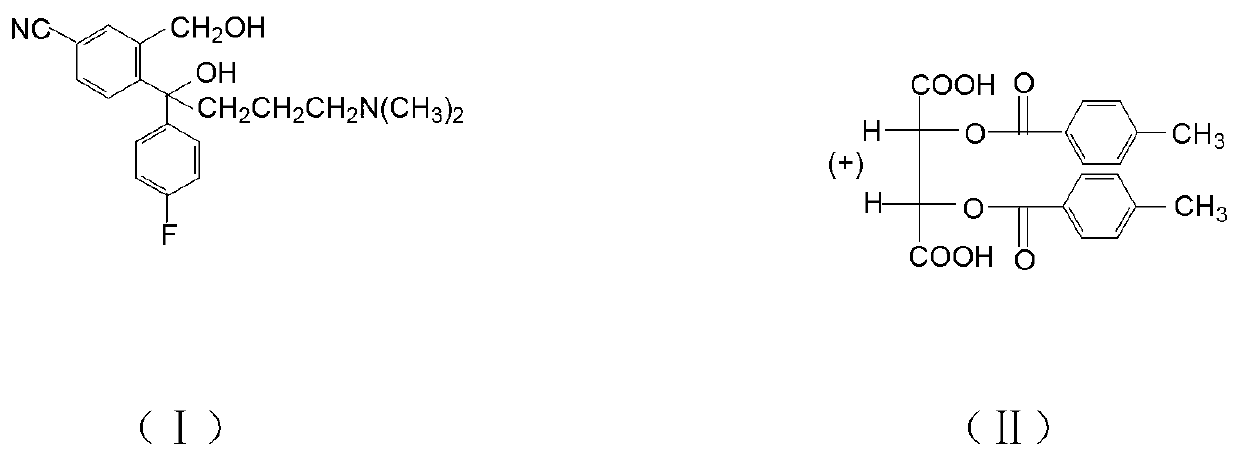

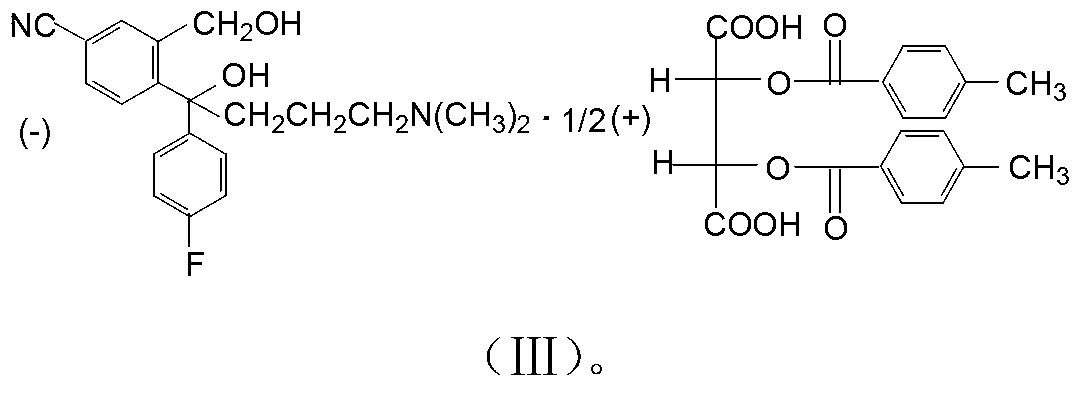

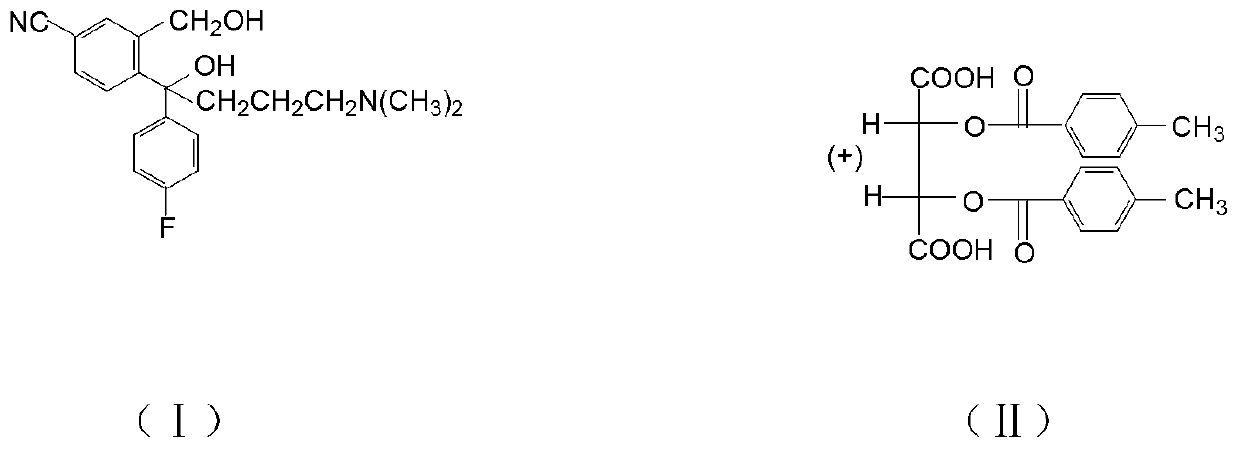

Method for preparing tartrate

ActiveCN103342664AReduce solubilityLow viscosityCarboxylic acid nitrile preparationOrganic compound preparationBenzonitrileTartrate

The invention belongs to the field of medicament synthesis, and particularly relates to a method for preparing tartrate. The method comprises the following steps of: dissolving an (RS)-4-[4-dimethylamino-1-(4-fluorophenyl)-1-hydroxybutyl]-3-(hydroxymethyl) benzonitrile (I) oily matter into isopropyl alcohol; adding water; controlling temperature; stirring and adding D-(+)-Di-para-toluoyl-tartaric acid (D-DTTA) (II); after a reaction liquid becomes transparent, continuing to stir to crystallize, filtrating, washing and drying to obtain a crude (S)-4-[4-dimethylamino-1-(4-fluorophenyl)-1-hydroxybutyl]-3-(hydroxymethyl) benzonitrile hemi-D-(+)-Di-para-toluoyl-tartaric acid (III) product; heating the crude (S)-4-[4-dimethylamino-1-(4-fluorophenyl)-1-hydroxybutyl]-3-(hydroxymethyl) benzonitrile hemi-D-(+)-Di-para-toluoyl-tartaric acid (III) product in methanol to melt; controlling temperature; dropwise adding isopropyl alcohol to crystallize; decreasing temperature, carrying out suction filtering, washing and drying to obtain the fine product. The method is easy to operate, and the prepared tartrate is high in purity and yield.

Owner:SHANDONG XINHUA PHARMA CO LTD

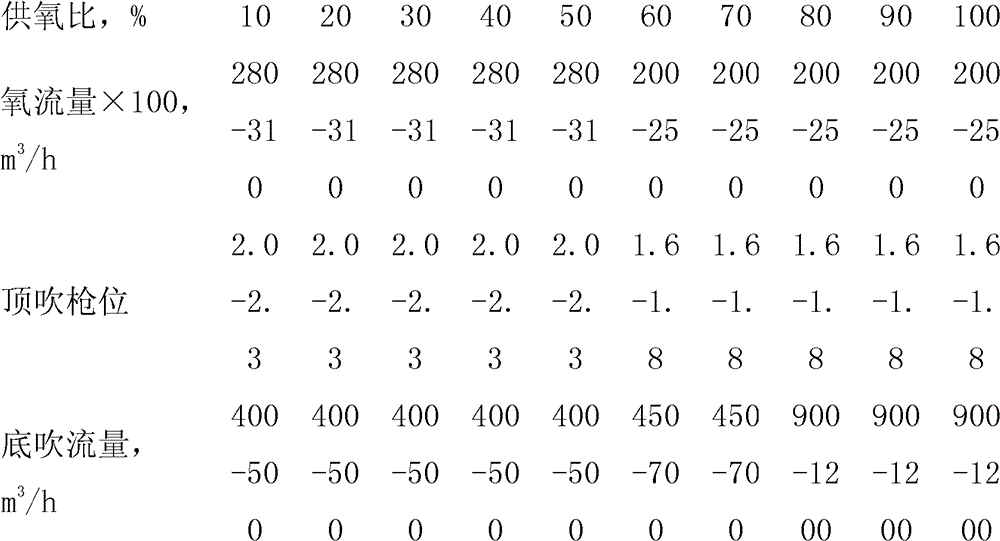

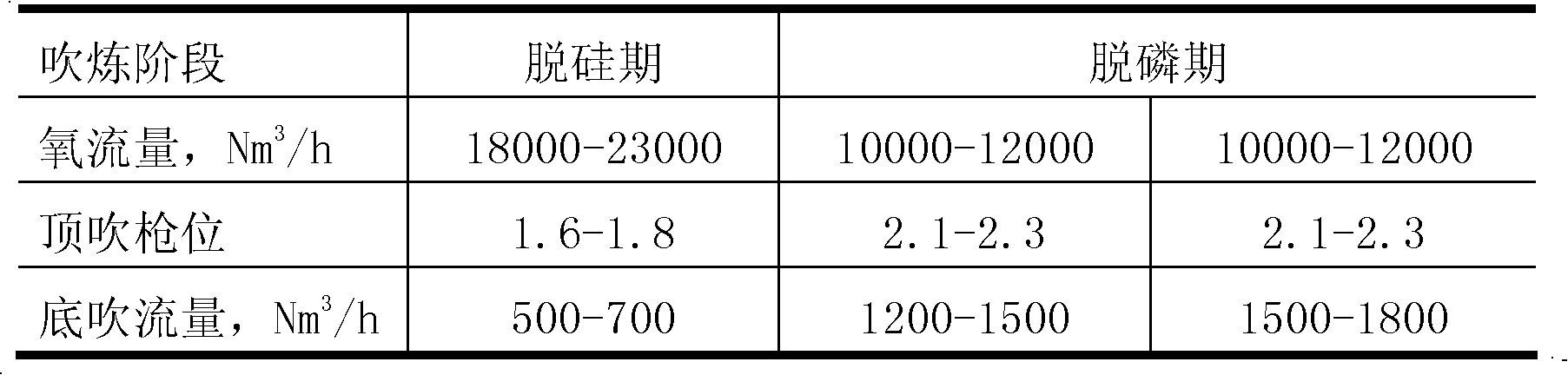

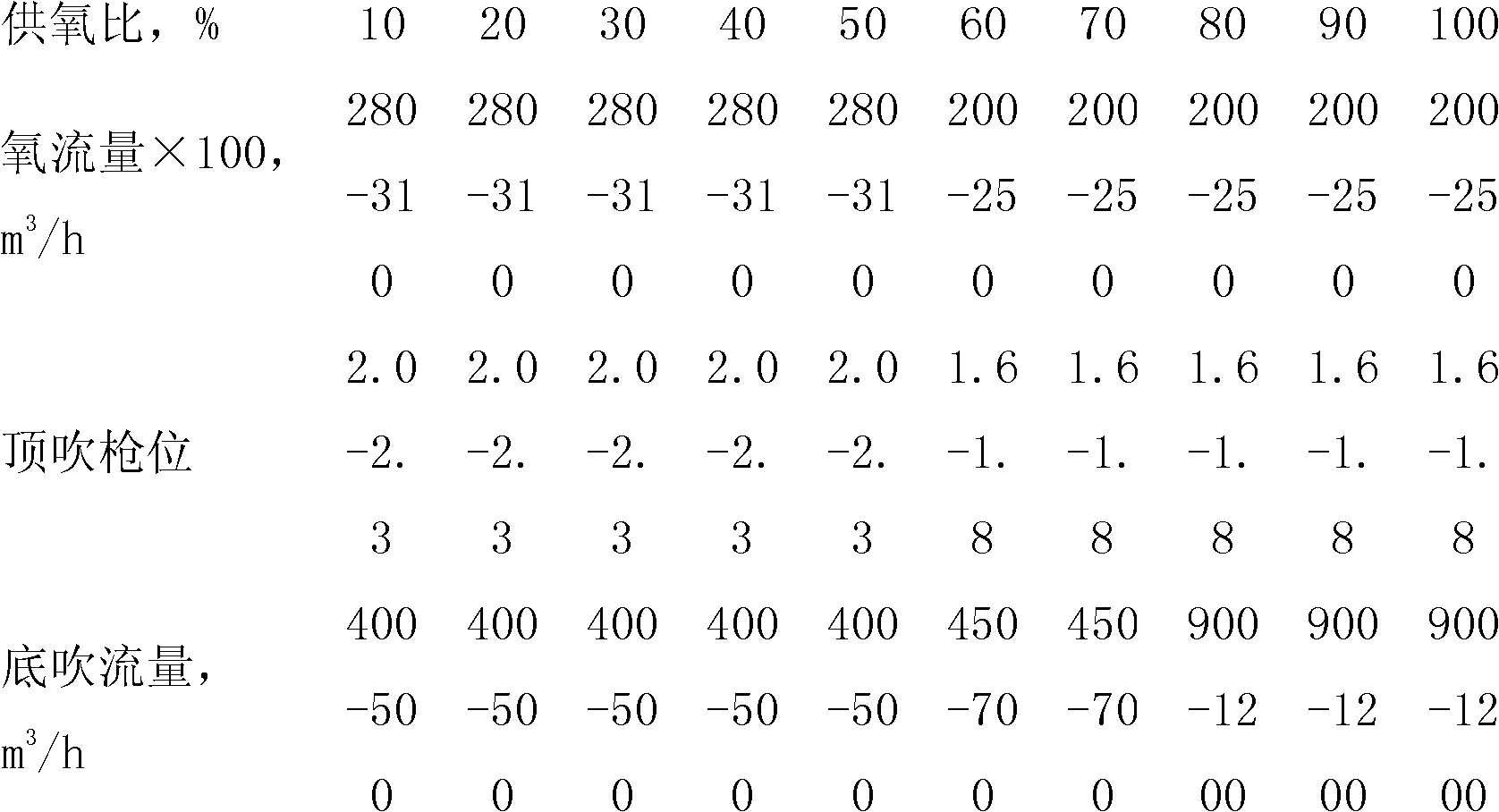

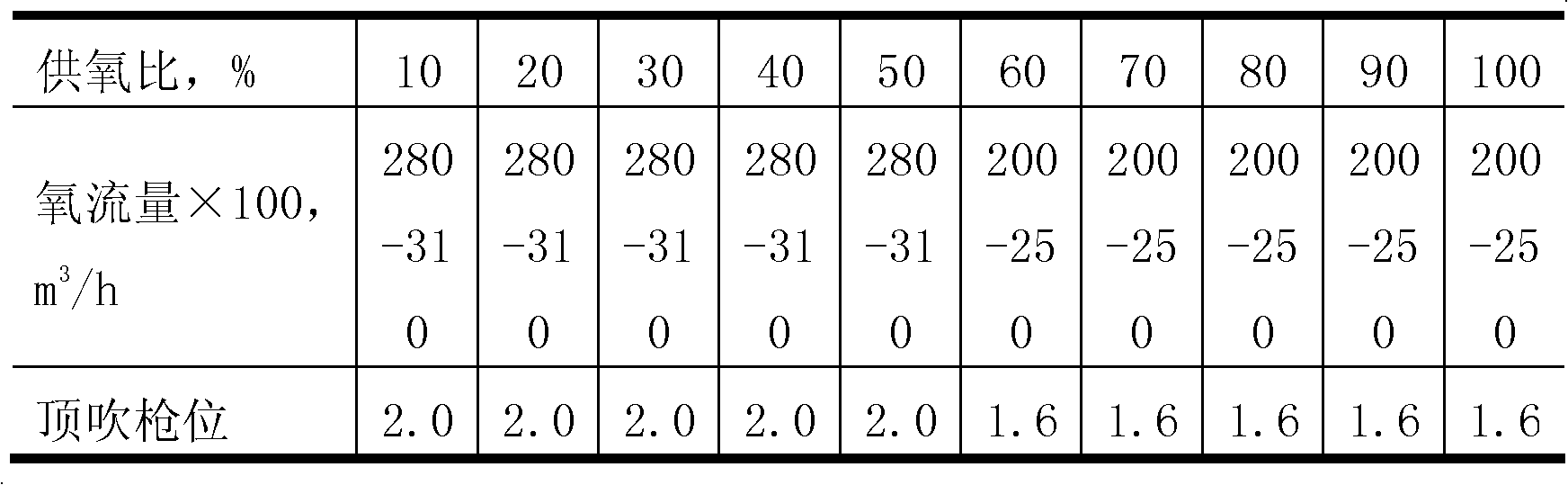

Method for reducing molten steel nitrogen in steelmaking link

The invention discloses a method for reducing molten steel nitrogen in a steelmaking link. The method comprises the following steps: controlling combined blowing parameters of a converter, and carrying out phased adjustment; controlling the bottom blowing manner and the flow rate of a steel ladle; adjusting a furnace rear alloying sequence, and adopting a deoxidation principle from weak to strong in sequence; judging whether the converter needs after-blow or not, wherein, for a steel ball of which temperature is increased by blowing oxygen through an RH technology, the converter endpoint temperature is within10 DEG C lower than the lower limit of a key point specified steel tapping temperature, and after-blow warming is not needed; for a steel ball capable of blowing oxygen in the RH technology, the converter endpoint carbon is smaller than or equal to 0.02% higher than aim carbon, and when the temperature reaches a required value, after-blow is not needed. According to the method for reducing molten steel nitrogen in the steelmaking link provided by the invention, by optimizing converter combined blow flow, steel ladle argon bottom blowing and deoxidation alloying sequence and establishing an after-blow principle, under the condition that other technological parameters are not changed, the content of nitrogen in a finished product is averagely reduced by 12 ppm, the performance of steel billets is stably improved, and a larger operation space is provided for a latter process; the method is easy to operate, the cost is not increased, and the practical application effect is good.

Owner:BEIJING SHOUGANG CO LTD

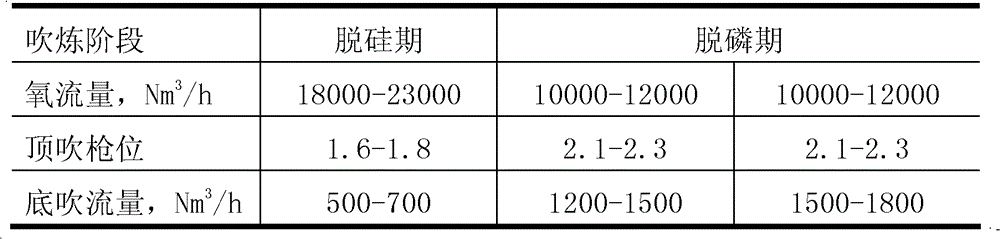

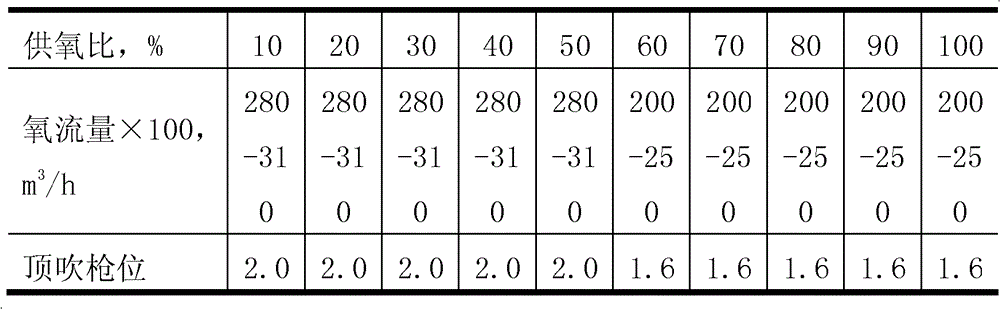

Method for producing carbon steel by using low-temperature low-silicon molten iron in 90-ton converter

InactiveCN103266196AReduce consumptionNo cryogenic splashManufacturing convertersProcess efficiency improvementSmelting processOxygen

The invention discloses a method for producing carbon steel by using low-temperature low-silicon molten iron in a 90-ton converter. The method comprises the following steps of: adding waste steel in the 90-ton converter; blowing oxygen at the top and bottom to smelt; adding slag charges in different times and adjusting the position of an oxygen lance; and stopping blowing and tapping steel when the temperature of molten steel is up to 1660-1690 DEG C. Through dynamically adding the slag charges and adjusting the position of the oxygen lance step by step, when the low-temperature low-silicon molten iron is smelted, low-temperature splashing cannot be caused, and the smelting risk of the converter is effectively avoided; the consumption of lime corresponding to low silicon is reduced, and the consumption of the lime does not exceed 33kg / ton of steel; and the disadvantage of low temperature to the smelting process can be converted into the advantage for dephosphorization under the condition of controlling the stability of the process, so that the dephosphorization effect is ensured, and the smelting rate and comprehensive utilization ratio of the molten iron are increased.

Owner:武汉钢铁有限公司

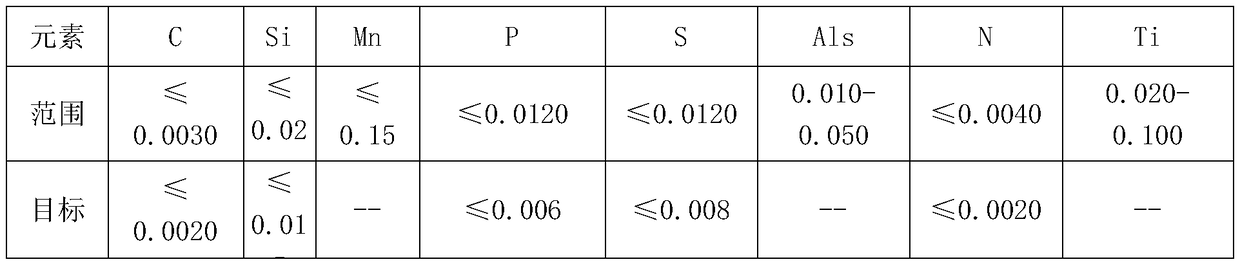

Smelting method of ultralow manganese steel

ActiveCN108998614AIncrease the refining rateManufacturing convertersProcess efficiency improvementSteelmakingManganese

The invention relates to the technical field of steelmaking, in particular to a smelting method of ultralow manganese steel. According to the method, a manufacturing process paths of molten iron pretreatment, converter, LF furnace, RH production process route are adopted, and a duplex process is adopted, a full-slag and double-slag slagging technology is adopted in the converter, a special oxygensupply technology is adopted, the converter end point oxygen value is controlled to be 600-800 ppm, and a converter end point temperature is controlled to be 1660-1680 DEG C; the mass percent contentof the molten iron manganese is less than 0.16%; after Si and Mn oxidation periods, slag is discharged, and steel tapping is carried out in a boiling mode; and lime is added, phosphorus is removed andmanganese is burned under an oxidability condition; and a steel type refining rate is greatly improved, and then the ultralow manganese steel with the Mn mass percent content of less than or equal to0.025% is produced.

Owner:ANGANG STEEL CO LTD

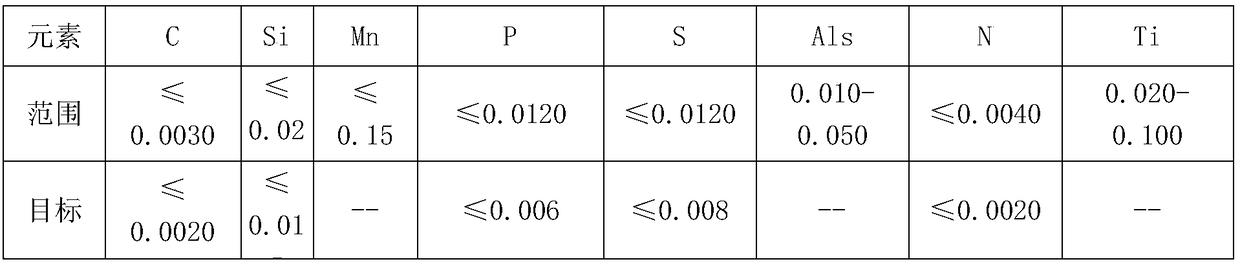

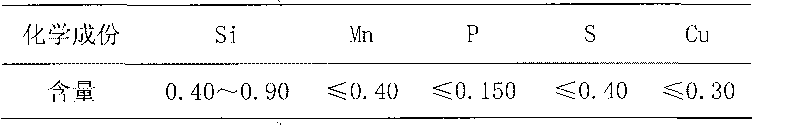

Production technology of steel used for pipe line steel electrode

InactiveCN101705327AControl oxygen contentIncrease the refining rateManufacturing convertersProcess efficiency improvementSlagOxygen

The invention relates to a production technology of steel used for a pipe line steel electrode, which sequentially comprises converter steel making technology, argon station refining technology and continuous casting technology; specific technological parameters of the converter steel making technology are as follows: (1) in molten iron in a converter, the weight percentage content of S is less that or equal to 0.003 percent; (2) converter finishing point control is as follow: steel tapping temperature is 1680 to 1690 DEG C, and in tapped molten steel, the weight percentage content of C is 0.04 to 0.06 percent; (3) converter finishing point slag-thickening operation is as follows: magnesium balls and lime dry slag are added at the converter finishing point to lead final slag in the steel tapping course to be thickened; and (4) final deoxidation technology is as follows: when steel tapping reaches 1 / 3, final deoxidizer and refining slag are added, and stirring is conducted with heavy argon; at the interval between 4 / 5 of the steel tapping and finish of the steel tapping, argon blowing is conducted for 25 to 35 seconds; and the refining slag consists of the lime and fluorite, and weight ratio of the lime to the fluorite is 2:0.4 to 0.6. The production technology well controls contents of carbon, silicon and oxygen in the production process, thus improving the steel-making success rate of the steel used for the pipe line steel electrode.

Owner:武钢集团有限公司

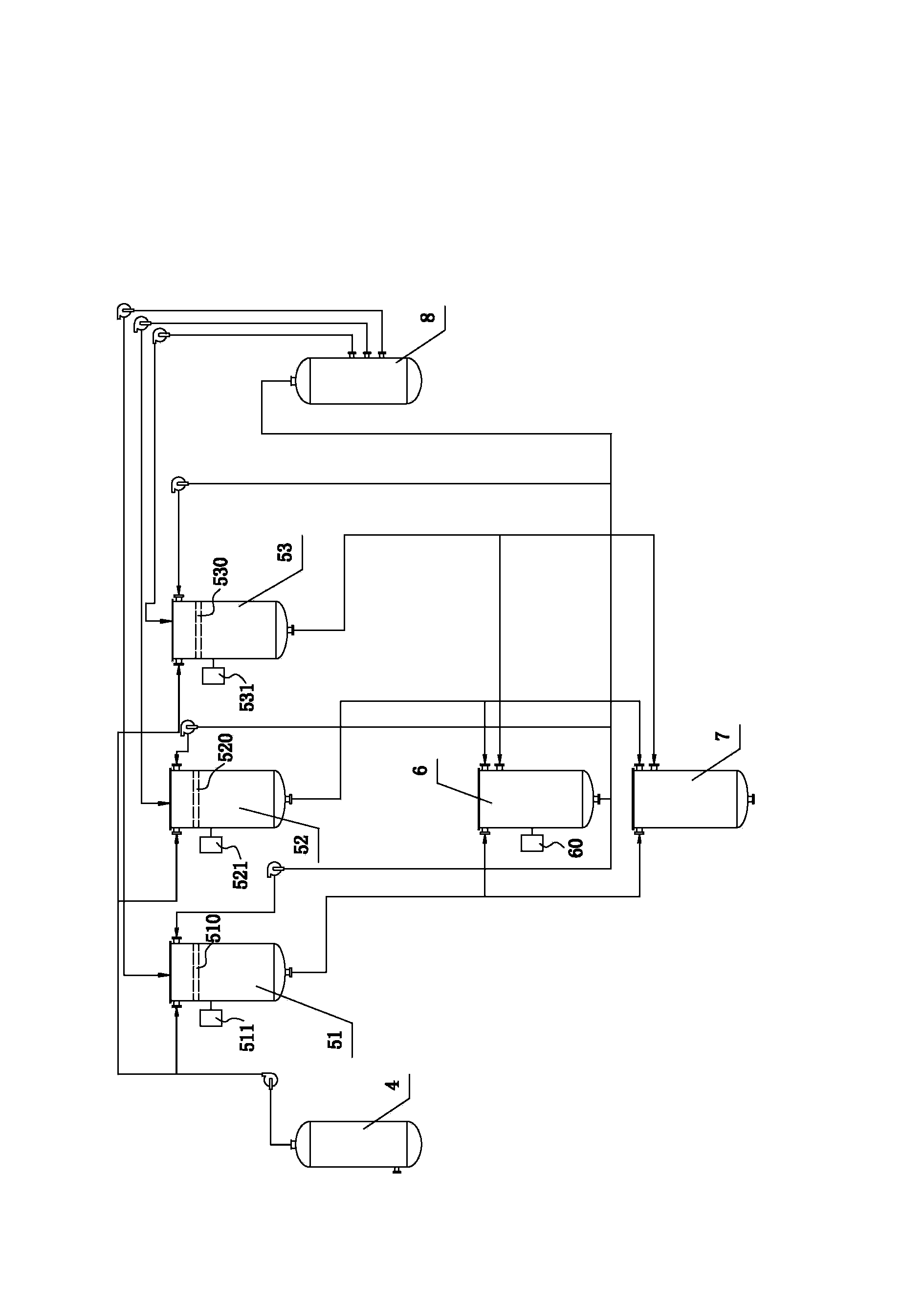

Nigre removal process and equipment for vegetable oil and vegetable oil production process

InactiveCN103589510ALow costReduce emulsification lossFatty-oils/fats refiningVegetable oilWastewater

A nigre removal process for vegetable oil comprises the steps of introducing nigre-containing vegetable oil into a hargil filter tank (52) forming a filter cake layer (520), discharging the vegetable oil into a nigre removal oil tank after the nigre removal treatment, introducing the vegetable oil with the nigre removed into a hargil mixed reaction tank for decoloring, introducing the mixture of the hargil and the vegetable oil into a hargil filter tank (51), keeping the hargil into the hargil filter tank (51) to form a filter cake layer (510), discharging the filtered vegetable oil into a decoloring oil tank, introducing and switching the nigre-containing vegetable oil into the hargil filter tank (51) forming the filter cake layer (510) when the pressure in the hargil filter tank (52) reaches the preset threshold, and discharging the vegetable oil into the nigre removal oil tank after the nigre removal treatment. The invention further discloses nigre removal equipment and a vegetable oil production process. The nigre removal process adopts a dry method to remove nigre, so that a large amount of water resource is saved, the process of wastewater treatment is omitted, and the requirements of zero pollution and zero emission are basically met.

Owner:厦门熙宝源化工技术有限公司

Carburant for manganese-carbon alloy

This invention relates to a recarburizer used in steelmaking process, especially relates to alloy recarburizer. Manganese and iron content is increased and specific gravity is increased so recarburization effect is improved. Technique plan is that manganese carbon alloy recarburizer is made by metal alloy powder and carbon material and binding agent. Metal alloy powder can be manganese iron powder or compound of manganese iron powder and iron powder. Carbon material is selected from coke, pitch coke, petroleum coke, carbon powder, coal dust and graphite. This product contains C 20~47%, Mn 35.01~55%, binding agent, silicasol 0.5~2%, it is mainlt used in liquid steel recarburization during steelmaking process.

Owner:上海盛宝冶金科技有限公司

Low-temperature refining method for pressed rapeseed oil

The invention discloses a low-temperature refining method for pressed rapeseed oil. The method sequentially comprises the steps of performing pre-filtration and deacidification, dephosphorizing, filtering and the like. The method is simple in process, low in energy consumption and low in loss, and fully retains inherent aromas and nutritive substances of the rapeseed oil.

Owner:金太阳粮油股份有限公司

Method for controlling class B inclusions of steel rail for high-speed railway

The invention relates to the technical field of steel-making, in particular to a method for controlling class B inclusions of a steel rail for high-speed railway. The method is characterized by being started with changing alloy adding variety after converter steel tapping, post-furnace deoxidization system, LF (Ladle Furnace) furnace refining slagging system and VD (Vacuum Degassing) vacuum treatment and by comprising the following steps of: (1) adding SiCaBa powder after converter steel tapping and reducing oxygen content in furnace slag; (2) controlling the addition quantity of a SiCaBa powder desoxidant under the condition guaranteeing total oxygen in steel; (3) adding lime and bauxite and employing a secondary slag practice; and (4) adding a magnesian covering agent for covering tank at the argon blowing point after vacuum breaking of VD furnace. Compared with the prior art, the method provided by the invention has the advantages that the grade of the class B inclusions in liquid steel is reduced below 0.5, steel modification due to unaccepted total aluminum is avoided, and the total aluminum content in steel is lower than the standard by 0.0010%; therefore, the heavy rail tempering rate is improved and huge economic benefit is created for steel and iron enterprises.

Owner:ANGANG STEEL CO LTD

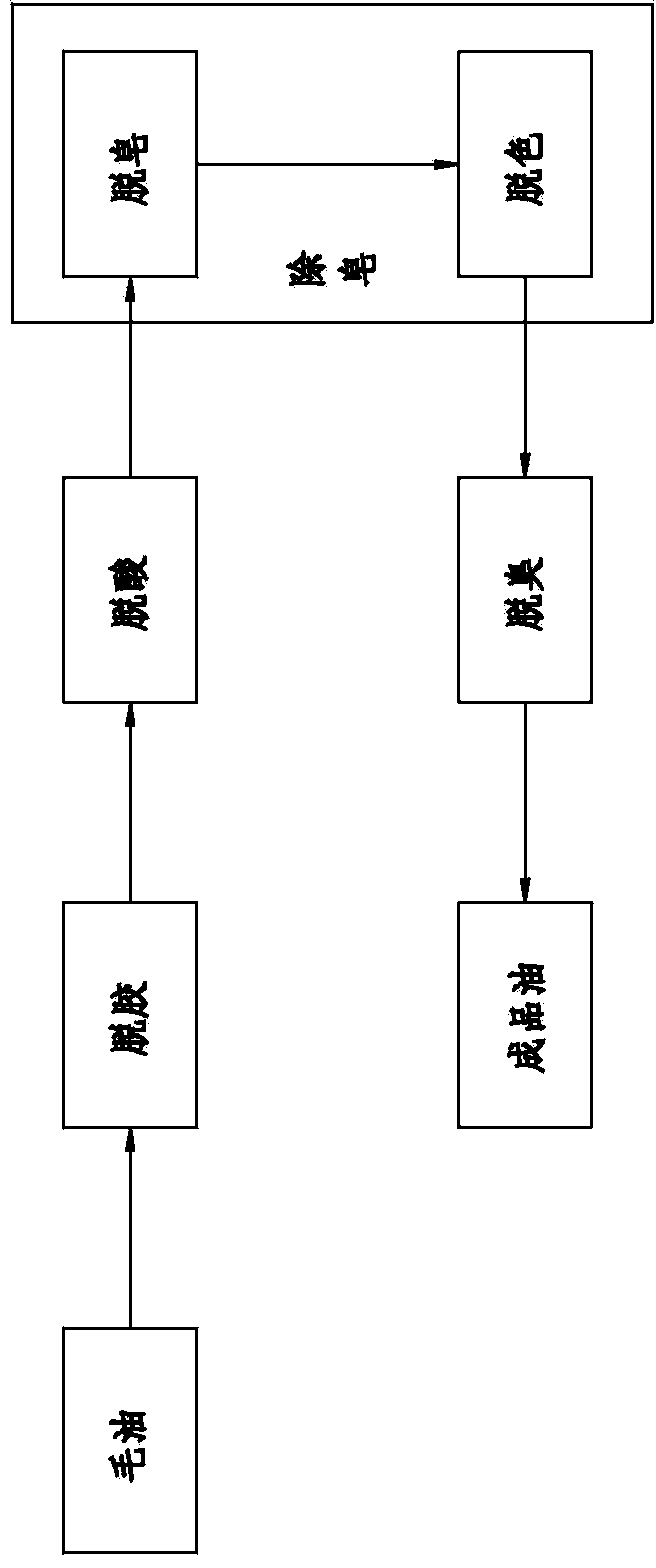

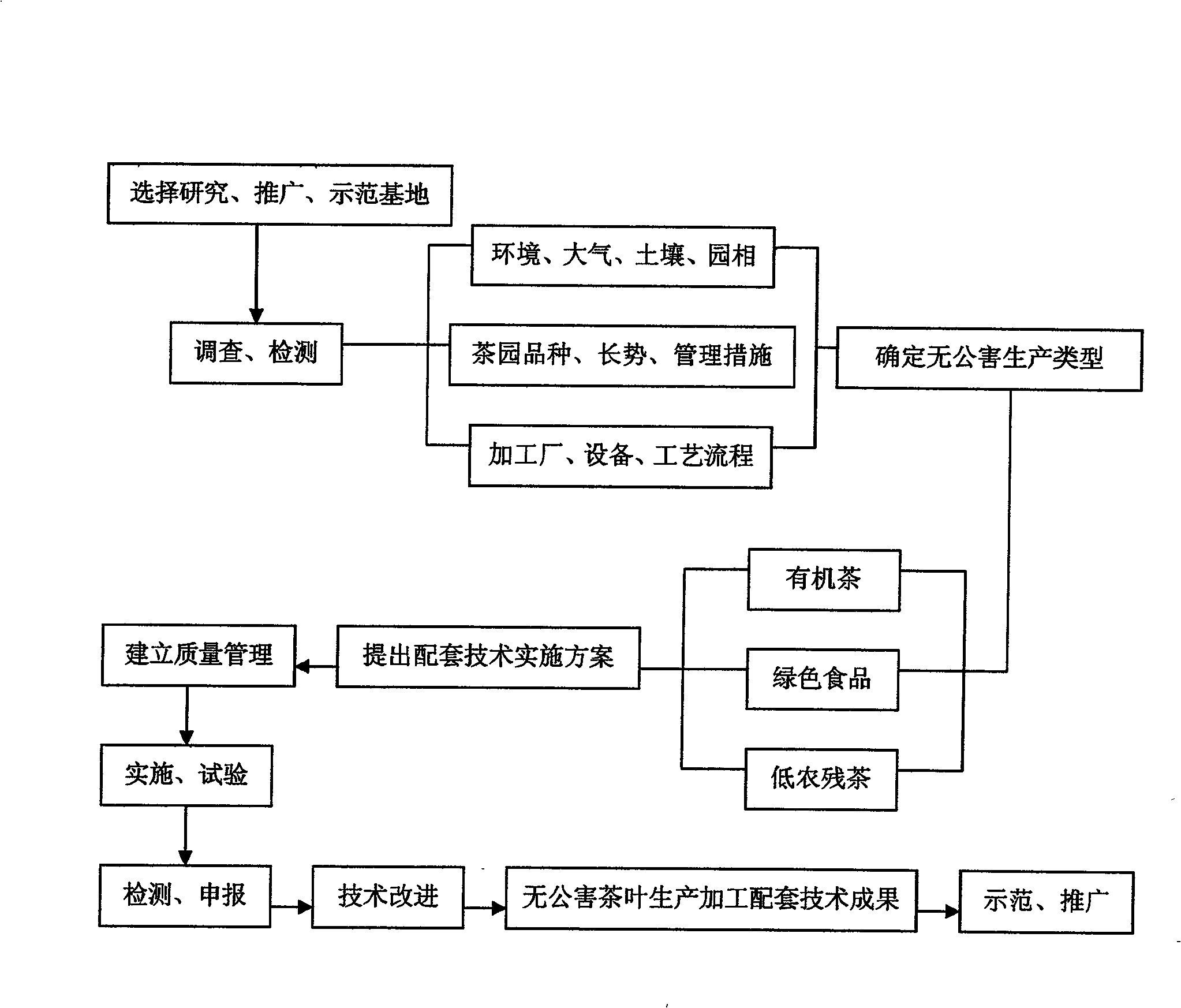

Key technique of industrialization of export high-quality, high-efficiency and low agricultural residual tea and organic tea

InactiveCN101524102AInnovation of research methodsIncrease productionPre-extraction tea treatmentEcological environmentSystems research

The invention relates to a key technique of industrialization of export high-quality, high-efficiency and low agricultural residual tea and organic tea, which is designed aiming at the current new condition of international and home tea and combining the practical condition of China. The production type of tea is determined according to the concrete condition of a base, and a technical scheme and a quality management system are designed. The ecological environment of a tea garden is protected through applying the principle of system research; soil is improved by using organic fertilizer; the internal quality of the tea is improved through selectively culturing and generalizing high-quality seeds; insect pests are prevented through adopting measures of damaging the survival and reproducing environment of insect pests of tea trees so as to reduce the use of pesticide and pesticide residue; and secondary pollution is reduced through controlling the sanitary quality of the tea in the process of processing, package and storage transportation. The invention innovates the production technology, ensures the production and processing of the tea to be safe, industrialized and standard and adopts an industrial mode of company-base-farmer and a technical course of research-examination-demonstration-generalization to be generalized and applied in the whole province, thereby ensuring the implement of a complete quality system from soil to table.

Owner:HUNAN TEA GRP

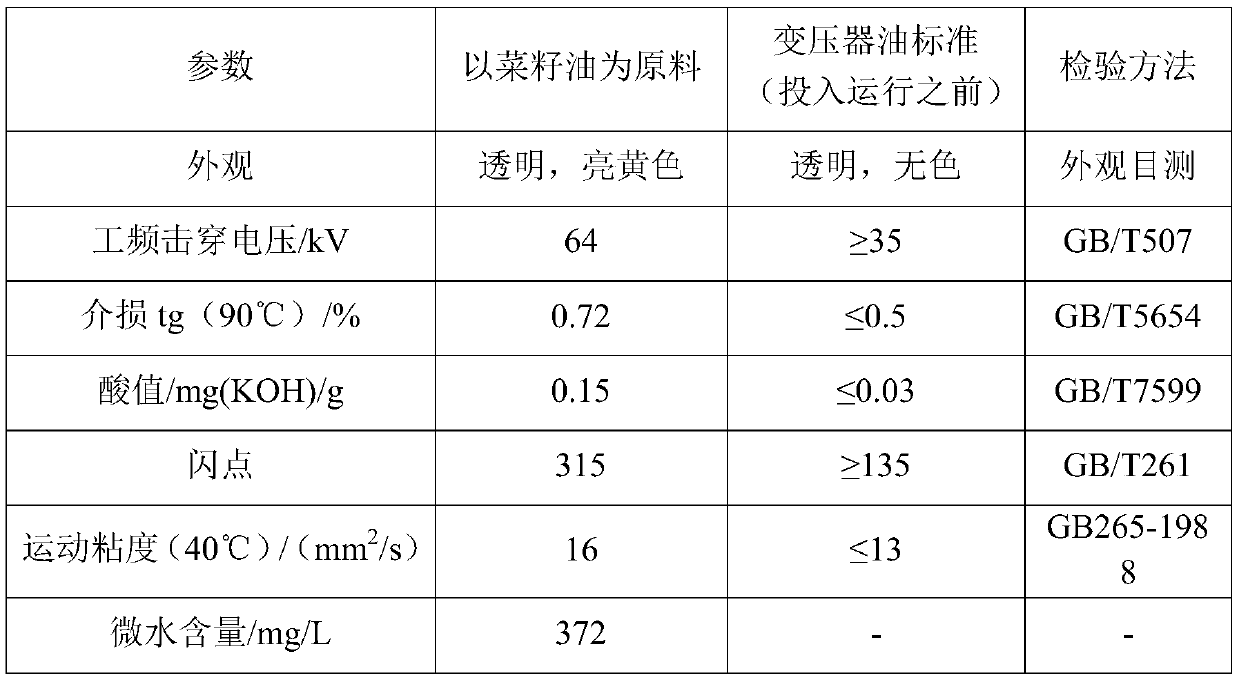

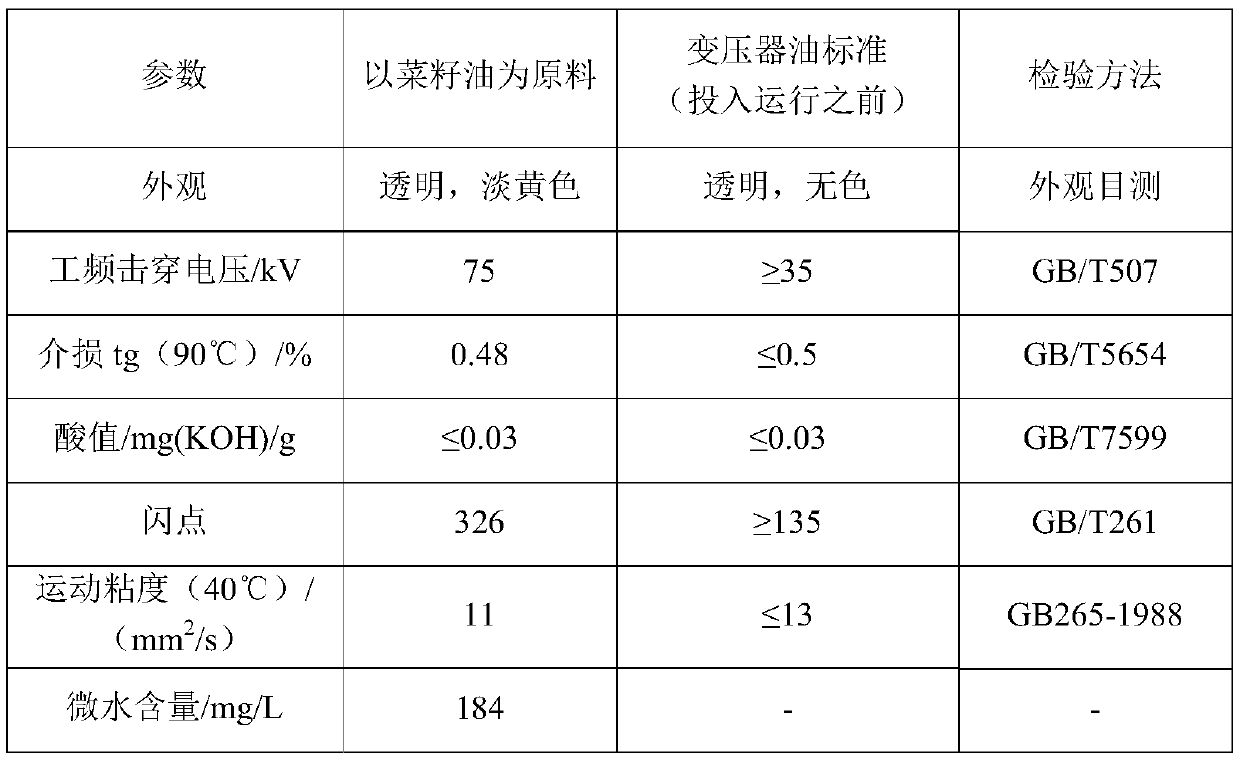

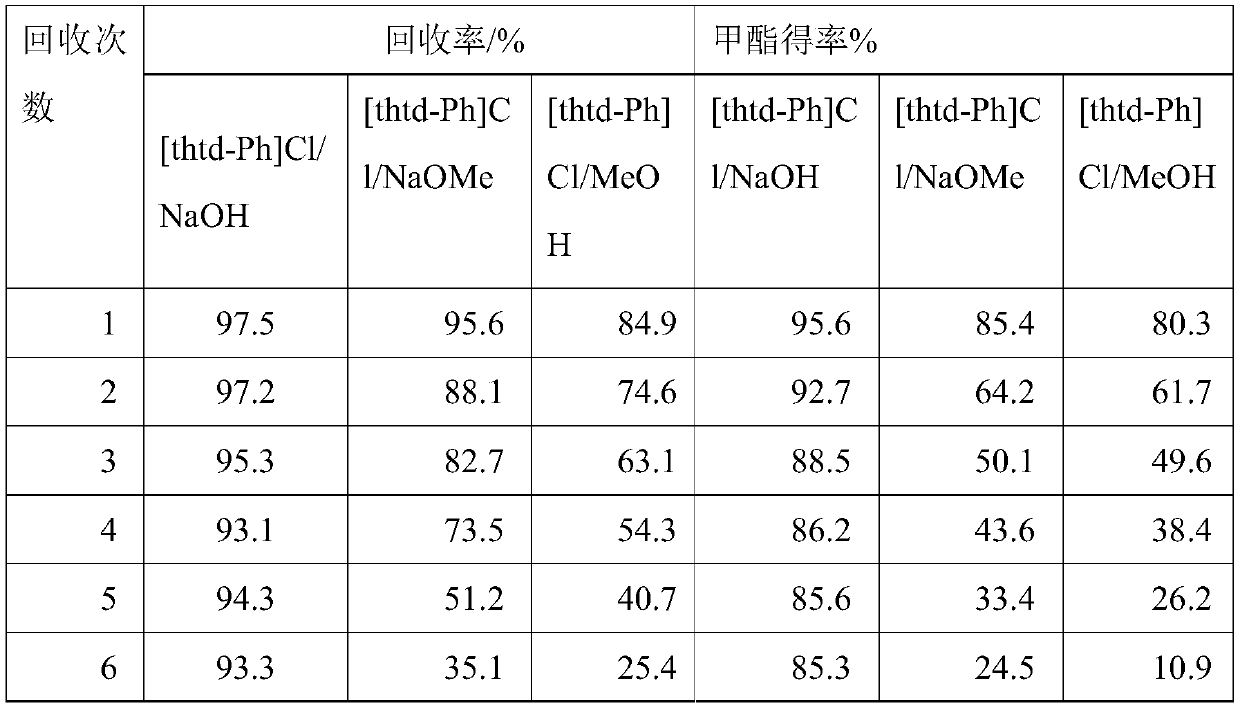

Vegetable insulating oil refining process taking rapeseed oil as raw material

ActiveCN110669583AHigh flash pointLow viscosityFatty acid esterificationLiquid organic insulatorsProcess engineeringRapeseed

The invention relates to a vegetable insulating oil refining process taking rapeseed oil as a raw material. The vegetable insulating oil refining process comprises the following steps: 1) selecting novel ionic liquid [thtd-Ph] Cl to carry out methyl esterification modification on rapeseed oil, and carrying out preliminary refining of degumming, washing, primary deacidification, reduced pressure distillation, normal pressure decoloration and deodorization on the rapeseed oil; 2) carrying out secondary alkali refining decolorization treatment and reduced pressure distillation on the rapeseed oilsubjected to primary refining to obtain refined rapeseed oil; 3) adding an antioxidant and an anticoagulant into the refined rapeseed oil to obtain modified rapeseed oil. The vegetable insulating oiltaking the rapeseed oil as a raw material has high flash point, low viscosity, low condensation point, low acid value and low water content, good physical and chemical properties and electrical properties, can meet the standard of transformer insulating oil, and can be widely popularized and used.

Owner:STATE GRID HUBEI ELECTRIC POWER CO XIAOGAN POWER SUPPLY CO

Method of making mixed oil using cotton seed puffing impregnation process

InactiveCN1869181AImprove qualityIncrease the refining rateFatty-oils/fats productionResidual oilPre treatment

The invention relates to a cotton seed oil mixture manufacturing method by straight leaching. It adopts parts of soybean preprocessing line to make cotton kernel soften, expanding after flaking, and process straight leaching without pre-squeezing and dust removal systems. It has the advantages of little investment and good effect. The phenol content of the post-leaching liberation cotton is less than 0.12%. And the residual oil of the cake is less than 0.5%.

Owner:白长军

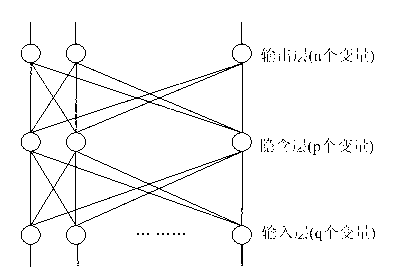

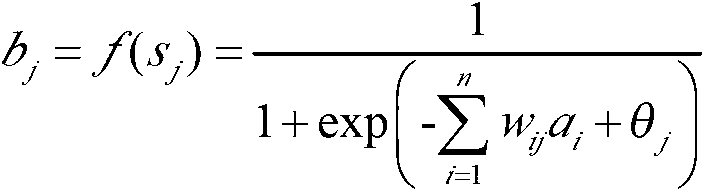

Method for forecasting alloy composition of molten steel during LF refining process

The invention discloses a method for forecasting alloy composition of molten steel during the LF refining process, which belongs to the technical of metallurgy. The method comprises the following steps: (1) collecting the composition testing data of molten steel and the quality data of pre-melting matters when the former step before refining is ended; (2) establishing an artificial neural network model during the refining process; and (3) carrying out the mode training. The method disclosed by the invention adopts the alloy composition data obtained in the former LF step as the initial value, adopts the molten steel testing value during the refining process as the standard value at sampling time, considers the influence on molten steel composition after adding the related pre-melting matters, slagging material, silk threads, desoxidant and desulphurizer, and adopts the BP neural network to forecast the alloy composition of molten steel at the non-sampling time. The method disclosed by the invention can forecast the alloy composition of molten steel in real time during the LF refining process, can effectively reduce the LF refining time and can reduce the refining cost, so that the LF refining process can be quickly finished.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Alkali refining process of cottonseed oil

ActiveCN102250683AIncrease the refining rateSimple processFatty-oils/fats refiningOil processingCottonseed oil

The invention belongs to the field of grain and oil processing and in particular relates to an alkali refining process of cottonseed oil. The process provided by the invention comprises the following steps of: (1) reducing temperature: rapidly cooling cottonseed crude oil to 20-40 DEG C; (2) removing impurities: filtering to remove impurities; (3) degumming: raising the temperature of the impurity-removed cottonseed crude oil to 60-65 DEG C; adding phosphoric acid, mixing and rapidly agitating for 0.5-1 hour; (4) carrying out alkali refining: adding alkaline liquid and uniformly mixing; then adding a sodium chloride solution, mixing, agitating and reacting for 40-60 minutes; (5) separating oil and soap: raising the temperature to 85 DEG C and then centrifuging and separating to remove nigre; (6) washing with water: adding soft water which has the temperature of 90 DEG C and is 10 wt% of the cottonseed crude oil into the oil; mixing, separating and removing wastewater to obtain the finished-product oil. The process provided by the invention has the advantages of simple process, convenience in operating and capability of increasing the refining rate of the cottonseed oil.

Owner:邯郸晨光植物蛋白有限公司

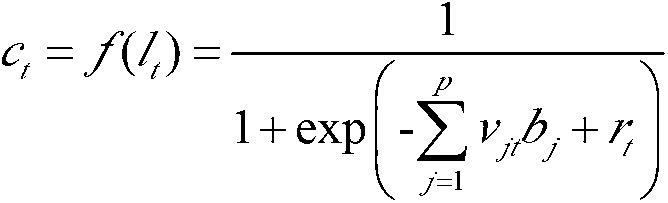

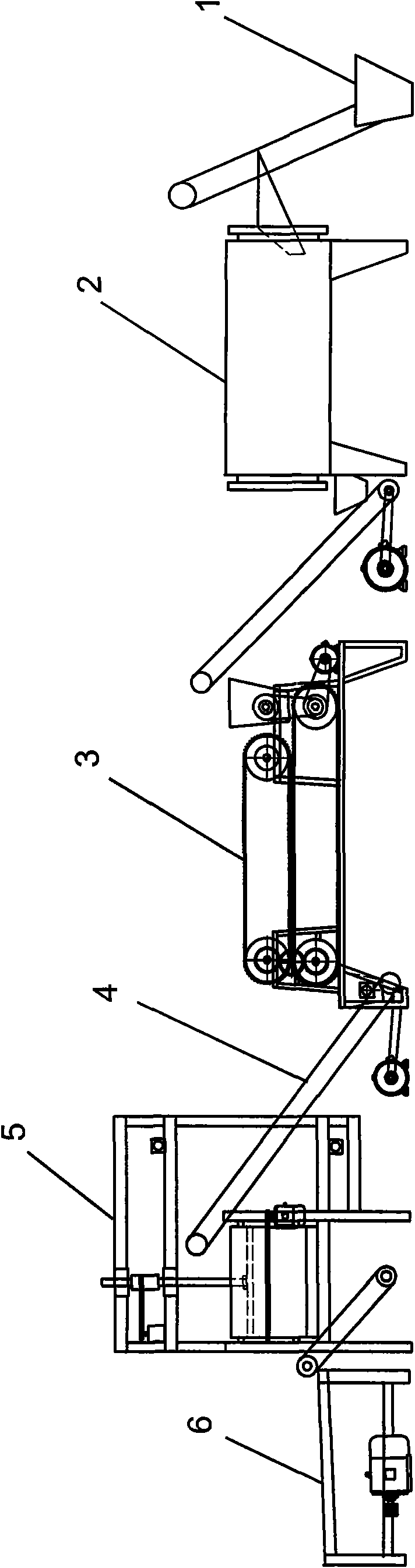

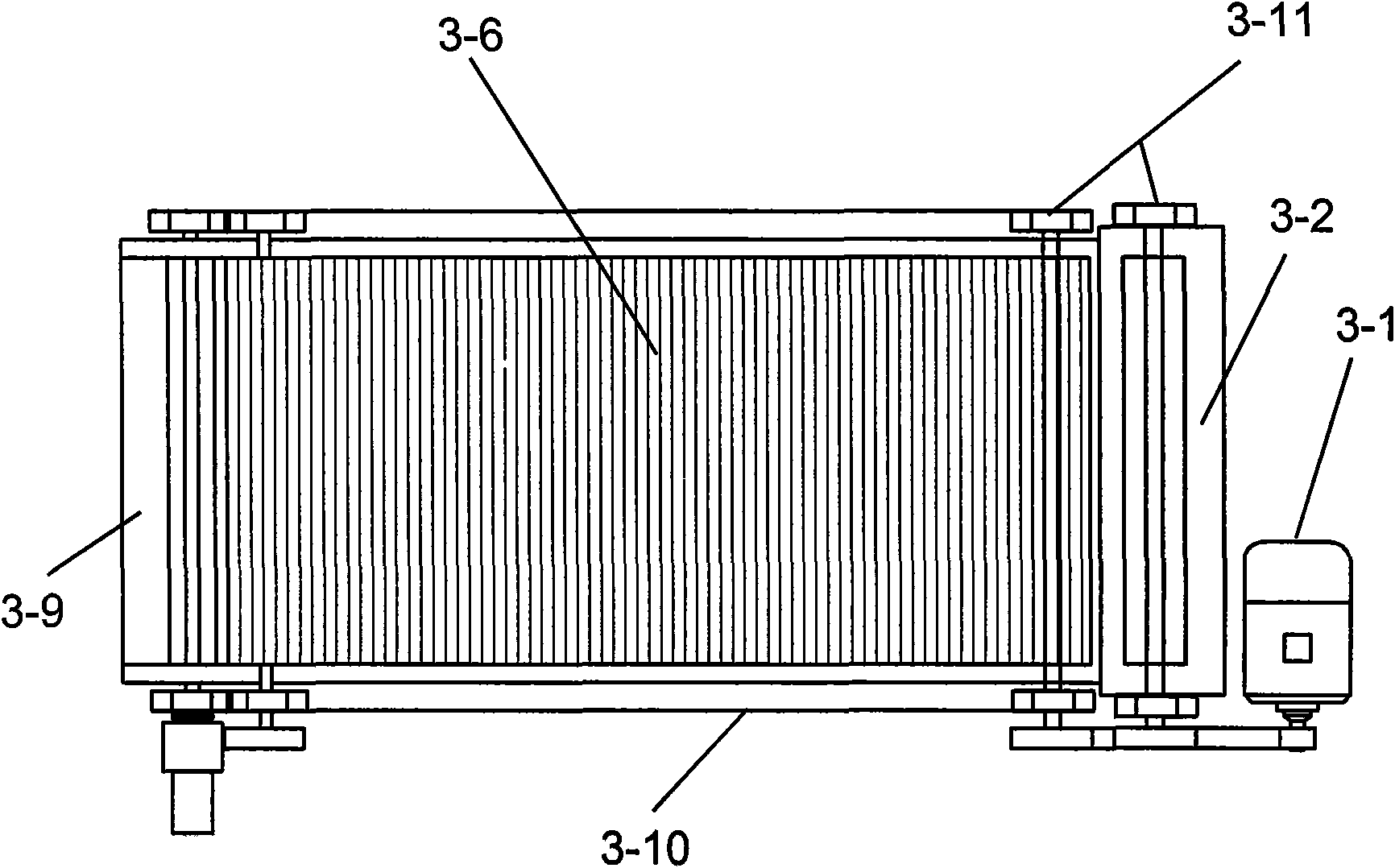

Tea fine-rolling machine and unmanned tea processing machine

InactiveCN101658214AImprove efficiencyIncrease the refining ratePre-extraction tea treatmentControl systemControl room

The invention discloses a tea fine-rolling machine and an unmanned tea processing machine. The tea fine-rolling machine comprises rolling devices A and B, wherein A comprises an upper layer guide trough plate and a lower layer guide trough plate which are arranged horizontally and evenly provided with edge bones in a band manner; tea is propelled between the two layers of guide trough plates, rolled into strips and then conveyed to B for further rolling; and B comprises a rolling cylinder with changeable working direction and a head cover and a base plate thereof. The fine-rolling machine leads the tea to be fast formed and the flow process of tea primary processing to be possible, and can obtain the unmanned tea processing machine when being combined with a fixing machine, a drying machine, a transmitting device and a control system. The whole set of tea processing machine can be operated by one person in a central control room, and the unmanned production workshop is clean and sanitary, thus avoiding the secondary man-made pollution. The quality of the produced tea is improved by more than one grade, the refining rate is improved by 10-15 percent, the energy consumption is reduced by 20 percent, the labor force is saved by 96 percent, each set of tea processing machine can produce 2.5 tons of dried tea each day, and incomes increasing while expenses decreasing of 6 months isnearly 2,000,000 Yuan.

Owner:林义生

Method for decolorizing small mechanical-reaped tuber mustard seedcake leaching oil by using phosphoric acid

ActiveCN102994223AIncrease the refining rateEasy to operateFatty-oils/fats refiningSaline waterWater vapor

The invention discloses a method for decolorizing small mechanical-reaped tuber mustard seedcake leaching oil by using phosphoric acid, comprising the following steps of: filtering to remove blank powder in leached crude oil; spraying a sodium hydroxide solution with the concentration at 60 DEG C in the filtered crude oil, stirring at the speed of 60r / min, heating to 65 DEG C, stirring at the speed of 30r / min, adding soft water with the temperature of 70 DEG C, stirring for 20minutes, standing and settling for 5-6hours to obtain unglued and deacidified oil, wherein the soft water is 8% of the weight of the oil; heating to 65 DEG C, adding 0.5% light salt brine with the temperature of 70 DEG C and stirring for 15minutes, wherein the weight of light salt brine is 5% of the weight of the oil; adding 85% phosphoric acid, stirring at the speed of 60r / min; and when the temperature is raised to 65 DEG C, splashing phosphoric acid on the surface of the oil, stirring at the speed of 60r / min for 30minutes so that phosphoric acid sufficiently contacts with the oil to be oxidized and decolorized, wherein the weight of phosphoric acid is 0.3% of the weight of the oil; heating the decolorized oil to 80 DEG C, adding hot water with the temperature of 85 DEG C, stirring at the speed of 30r / min for 15minutes, standing for 2hours, and discharging waste water, wherein the weight of hot water is 5% of the weight of the oil; and introducing vapor with the pressure of 0.2Mpa in a deodorization pot, and deodorizing when the vapor introduction time is longer than or equal to 6hours. The method has the effects that the refining ratio is increased and the cost is reduced.

Owner:YUNNAN ZHENWEI GREASE

Smelting method of 9Ni steel

ActiveCN102747181BMeet the requirements of continuous castingReduce lossesManufacturing convertersSmelting processMolten steel

A smelting method of 9Ni steel. The method has the following characteristics: 1.a smelting process comprises steps of pretreatment on molten iron (desulfuration), converter (double dephosphorization, melting nickel plate), LF furnace (desulfuration) and RH (degassing); 2. dephosphorization is conducted in the converter and comprises two steps: step one: blending molten iron desulphurized by KR and steel scrap into a dephosphorization converter for primary smelting, using ''dephosphorization converter smelting critical control point'' to desulphurize the molten iron to a phosphorus content below 0.020%, and carrying out semi-steel tapping; and step two: blending the molten semi-steel and nickel plate into a decarburization converter for converting, desulphurizing the molten steel after converting to a phosphorus content below 0.003%, and carrying out tapping; and 3. the nickel plate is melted in the decarburization furnace. According to the present invention, the two-step dephosphorization is carried out in the converter that molten steel after converting has low phosphorus content and is stably controlled, so as to benefit improvement on the yield of 9Ni steel. Decarburization converter slag has low phosphorus content, and ladle molten steel has a low rephosphorization amount, so as to clear out molten steel in the decarburization furnace and reduce molten steel loss in a steel leaving operation.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for acid stripping and refining of rubber seed crude oil packing thin film

The invention relates to a membrane deacidification refining method for crude rubber seed oil filler. The invention relates to a refining method for crude oil, in particular to a deacidification refining method for the crude rubber seed oil. The method comprises the following steps: a, hydration degumming; b, vacuum dehydration; c, adsorption bleaching; and d, membrane deacidification of the filler, and obtaining finished product oil. The membrane deacidification technology for the filler belongs to membrane distillation, can remove all the fatty acid in the peracid rubber seed oil, and simultaneously cannot cause loss of neutral oil so as to have high refining yield.

Owner:YUNNAN LVBAO BAIRUI SUBSTITUTE IND

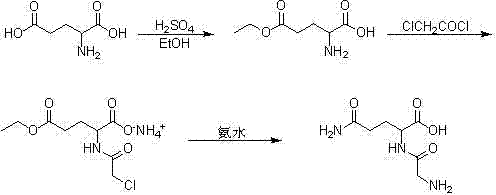

Industrialized glycyl-L-glutamine synthetizing method suitable

The invention relates to an industrialized glycyl-L-glutamine synthetizing process suitable, belonging to the field of synthesis processes of chemical products. The process comprises the steps of: reacting L-glutamate serving as a raw material with ethanol to obtain L-glutamate-gamma-ethyl; then reacting L-glutamate-gamma-ethyl with chloroacetyl chloride to obtain chloroacetyl-L-glutamate-gamma-ethyl amine salt; finally, carrying out ammonolysis and recrystallization to obtain pure products of glycyl-L-glutamine, wherein methanol is replaced by ethanol to react in the step 1 and all recrystallization solvents are absolute ethyl alcohol and water. and therefore, the pollutant discharge treated after industrial production is effectively reduced; the detection of the content of methanol in organic residues is avoided; the process is simplified; the operability is strong; and the product refining rate is higher.

Owner:湖北一半天制药有限公司

Squeezing preparation method of 6S1D soybean oil

PendingCN105400592AImprove oil yieldColor SuppressionFatty-oils/fats refiningFatty-oils/fats productionMetalSoybean oil

The invention discloses a squeezing preparation method of 6S1D soybean oil. The method comprises the following steps: 1, preprocessing soybeans; 2, squeezing the preprocessed soybeans; 3, degumming: adding an acid solution accounting for 1-10% of the mass of crude oil to the crude oil obtained after squeezing, and stirring for 20-40min; 4, precipitating; 5, filtering 5 times; and 6, carrying out ultraviolet irradiation. Phosphatide, tocopherol, metal ions and other components in soybeans, and extraneous factors (temperature, illumination and air) and other factors possibly causing oil color reversion, are mainly investigated in the invention to find out main reasons for causing the color reversion of the soybean oil in the purifying process. Compounded acid solution degumming treatment substantially reduces the phosphorus content of oil, so degummed oil with low phosphorus content, low acid valence and transparent and bright color is obtained, and the color reversion of the soybean oil is effectively inhibited; and the method has the advantages of avoiding of severe damages of present soybean oil pressing technologies to unsaturated fatty acids, VE and other nutritional components, high soybean oil yield and reduction of the environment pollution.

Owner:SHANGHAI TAOHONG CHEM TECH

Method for refining argatroban refining mother liquor recycling product

ActiveCN104558104AIncrease the refining rateReduce manufacturing costPeptide preparation methodsActivated carbonAlcohol

The invention discloses a method for refining an argatroban refining mother liquor recycling product. The method comprises the following steps: adding the argatroban refining mother liquor recycling product and absolute ethyl alcohol to a reaction bottle; heating, refluxing, and dissolving, slightly cooling, adding neutral alumina and silica gel as adsorbents; carrying out hot filtration, cooling filtrate, devitrifying, filtering and drying to obtain a primary refined product of the argatroban refining mother liquor recycling product; feeding the argatroban refining mother liquor recycling product to the reaction bottle, adding 5fold of 95% (W / V) ethanol and 0.1fold of activated carbon, refluxing for 5-10 hours and carrying out hot filtration; and devitrifying the filtrate at 0-25 DEG C for 10-12 hours, filtering and drying to obtain an argatroban refined product. The method is simple to operate; the argatroban refining rate is increased; and the production cost is reduced.

Owner:天津药物研究院药业有限责任公司

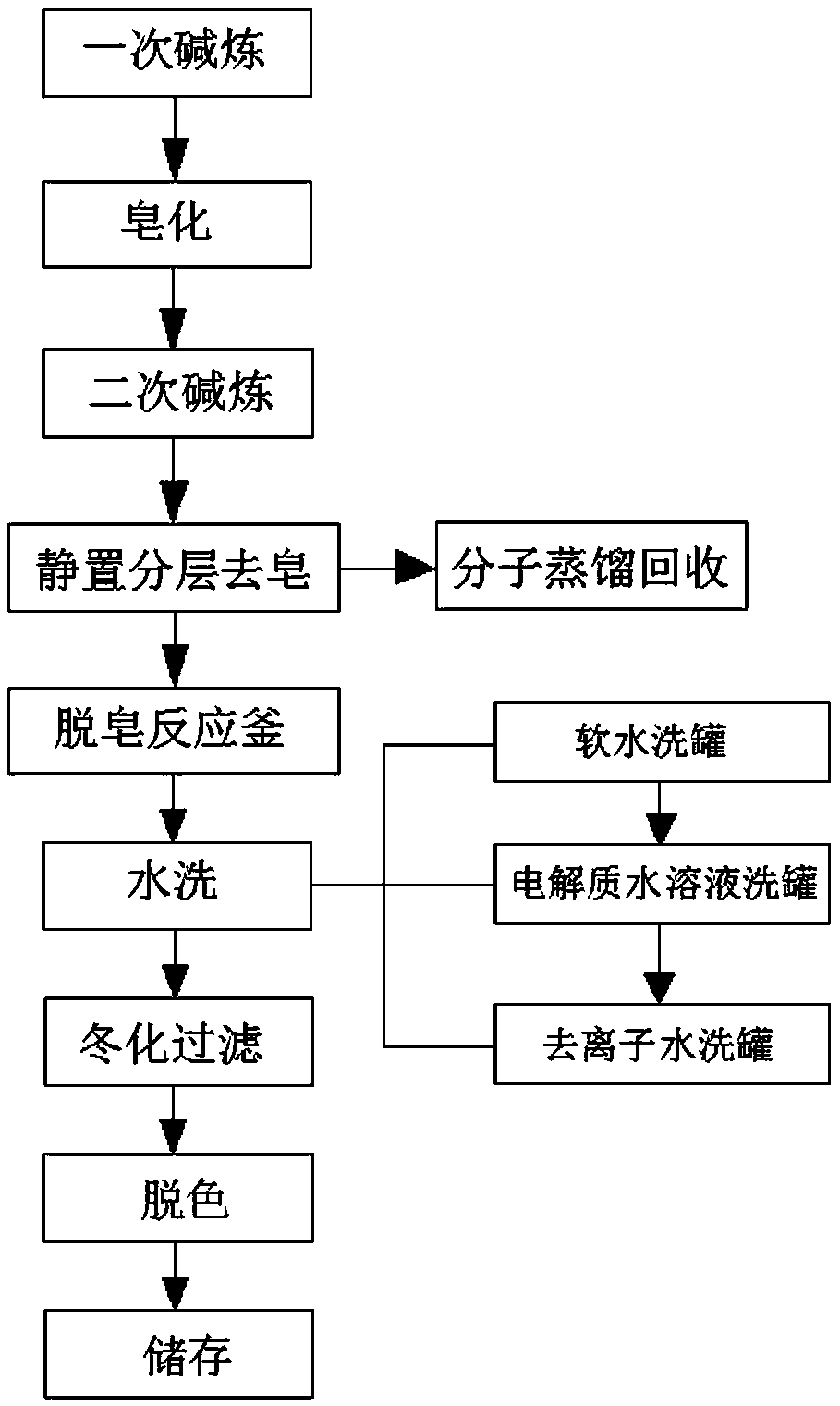

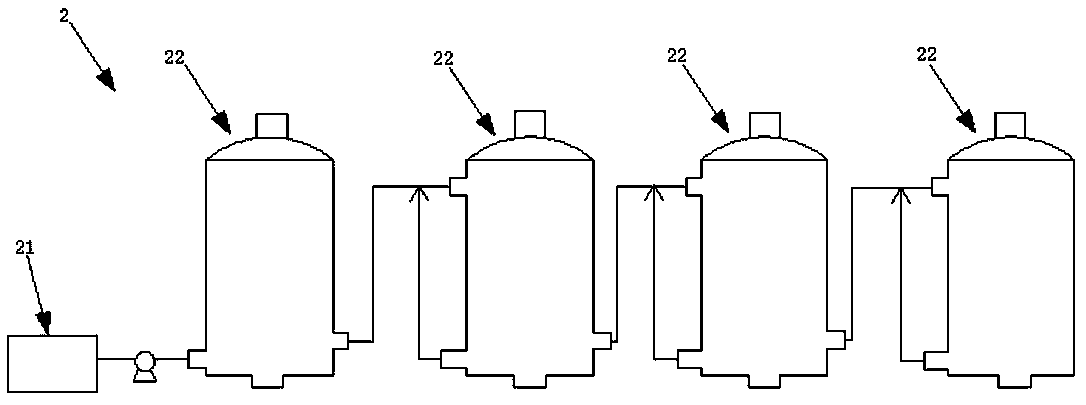

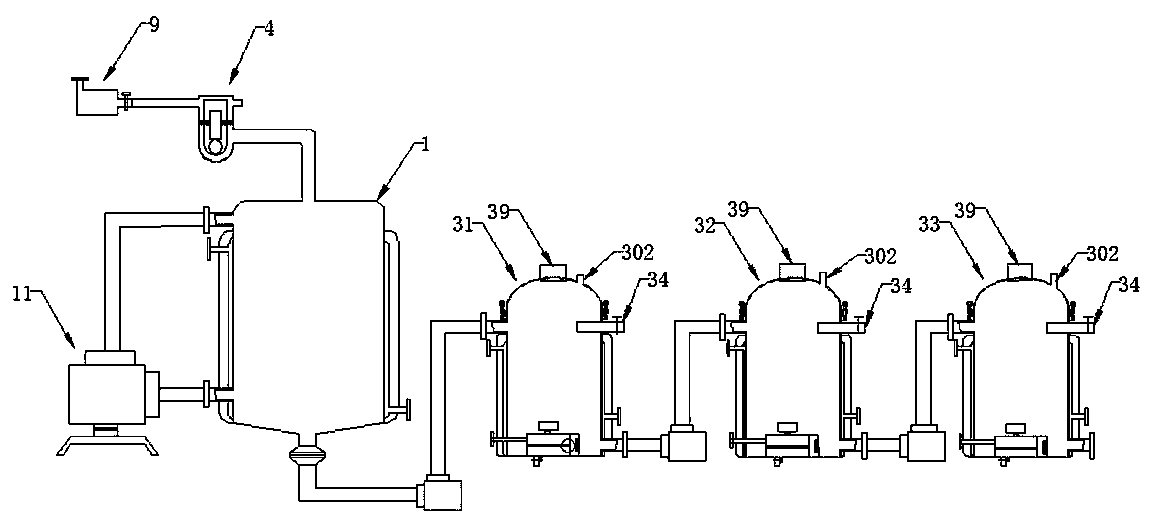

Refining process of glyceride type fish oil

The invention relates to a refining process of glyceride type fish oil. The refining process includes the steps of S1, delivering gross fish oil measured by a metering pump to an alkali refining tankthrough a feed pipe, and subjecting the gross fish oil to heating and circulating stirring; S2, preparing, by weight, 4-6% of weak caustic liquor for primary alkali refining; S3, after completion of reaction, spreading solid salt used for preventing emulsification or adding dilute salt water with the same temperature as the fish oil in the alkali refining tank, allowing the alkali refining tank tostand for 1-2 hours for insulation precipitation, and discharging a stratified soapstock layer to a molecular distillation unit; S4, preparing, by weight, 14-16% of dense alkali for secondary alkalirefining; S5, after completion of reaction, spreading the solid salt or adding the dilute salt water with the same temperature as the fish oil to allow the alkali refining tank to stand for 2-3 hoursfor insulation precipitation once again, and discharging the stratified soapstock layer to the molecular distillation unit once more; S6, subjected the fish oil via the secondary alkali refining to washing ,dewatering, winterization filtering and decoloring to finally prepare the glyceride type fish oil stored in a finished product tank.

Owner:福建高龙海洋生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com