Tea fine-rolling machine and unmanned tea processing machine

A tea making machine and tea technology, which is applied in the field of tea fine kneading machine and automatic tea making machine, can solve the problems of inconvenient tea in and out, long time, low refining rate, etc., to avoid secondary human pollution, improve tea refining rate, The effect of improving the quality of tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail through examples below in conjunction with the accompanying drawings, but the scope of the present invention is not limited in any way.

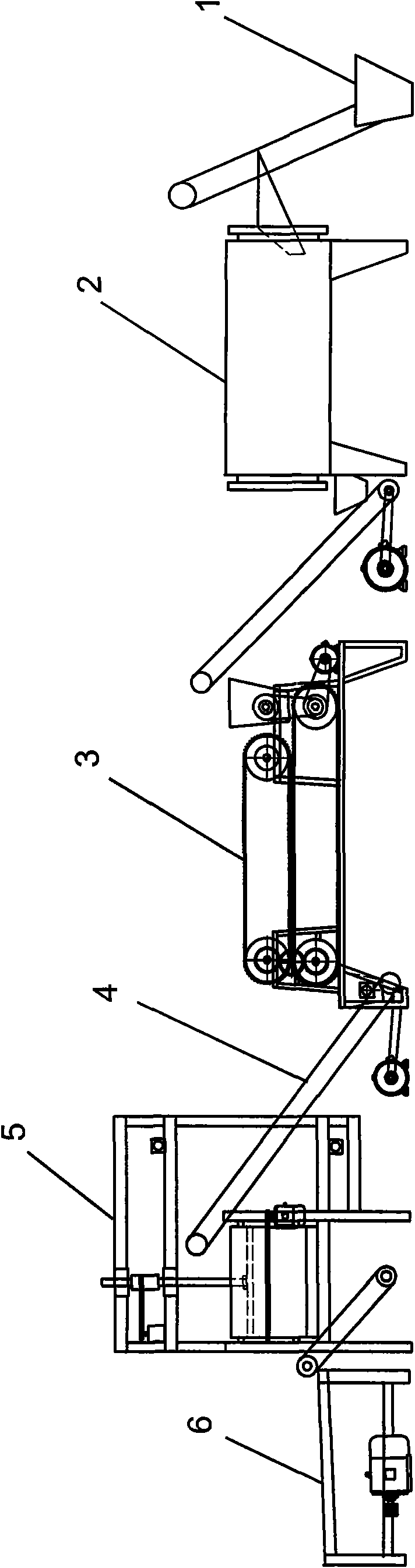

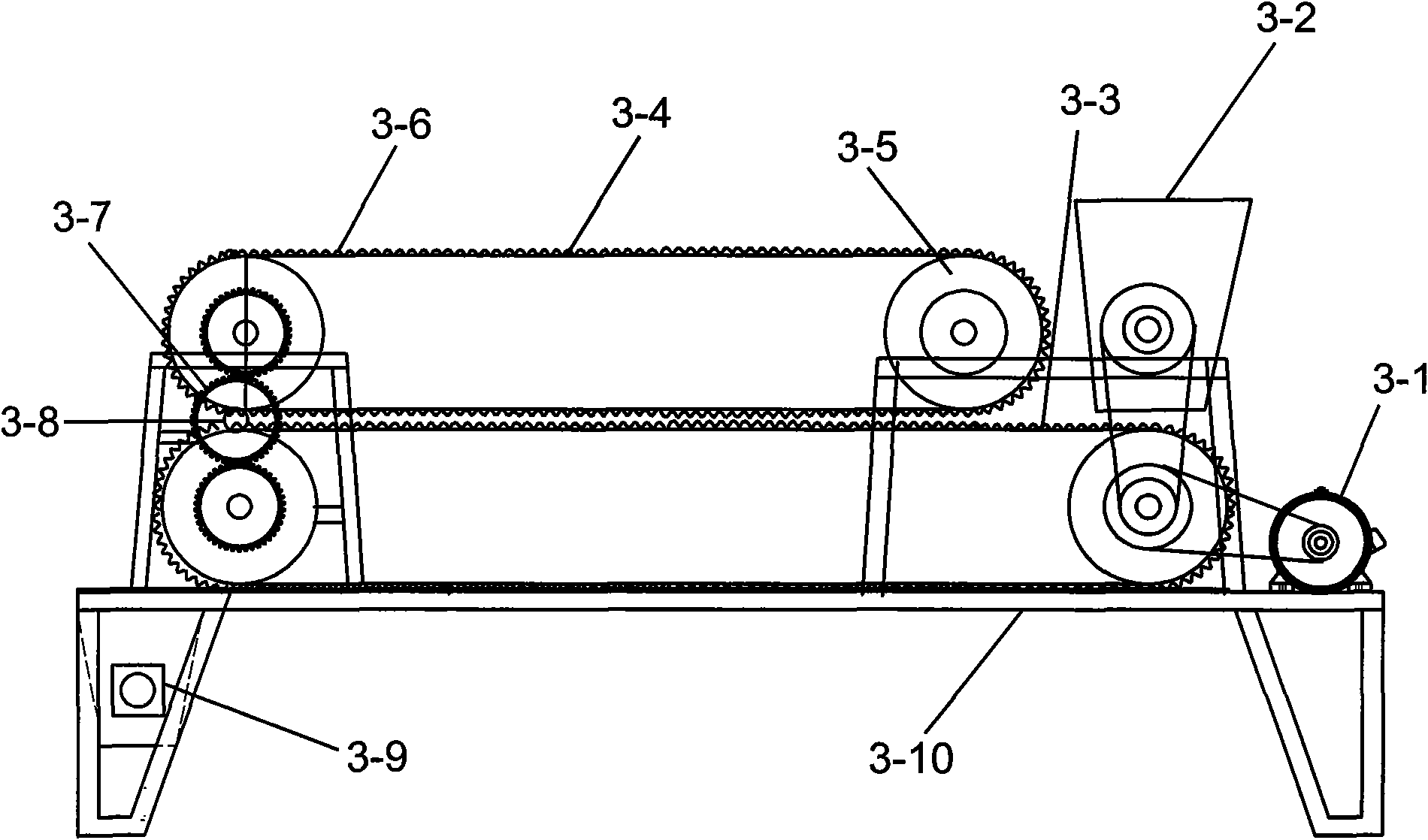

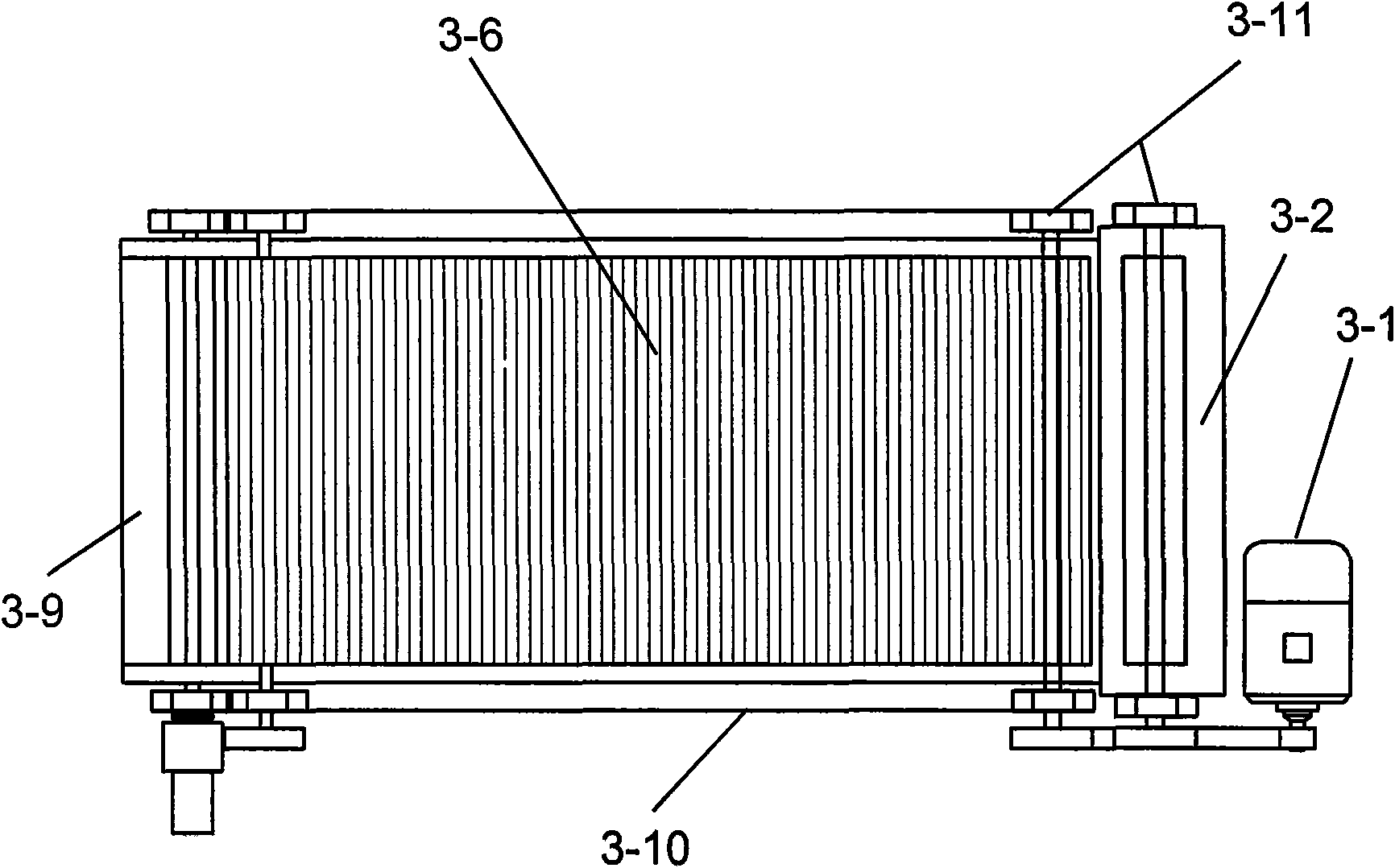

[0040] Such as figure 1 As shown, the unmanned tea making machine of the present invention includes the degreening machine 2, the rolling device A3, the rolling device B5 and the drying machine 6 connected sequentially through the transmission device, as well as the corresponding control system. Wherein kneading device A3 and kneading device B5, and the conveyer 4 that connects them forms the fine tea kneading machine.

[0041] see figure 1 , the tea leaves are transported from the hopper 1 to the de-greening machine 2, which is a drum-type de-greening machine. The leaf plate is about 50mm high, and it rotates about 360 degrees from the tea inlet to the tea outlet; the guide wheel and the transmission structure that drive the drum to rotate are welded on the furnace body of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com