Method for forecasting alloy composition of molten steel during LF refining process

A technology of refining process and alloy composition, applied in the field of metallurgy, can solve the problems affecting the refining rate of LF refining process, and achieve the effect of reducing refining time and refining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The matching software of the present invention is an intelligent forecasting algorithm of molten steel composition in the LF furnace refining process, and its forecasting steps are:

[0059] 1. Collect the test data of the molten steel composition and the quality data of the premelt at the end of the previous process before refining;

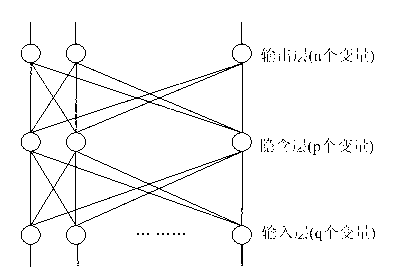

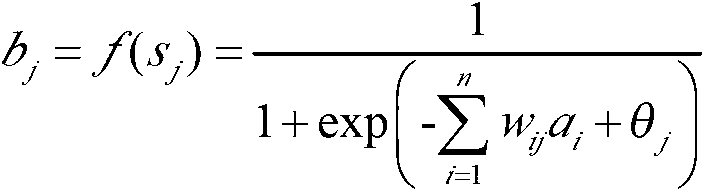

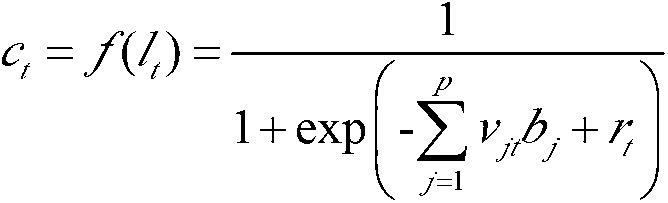

[0060] 2. In the refining process, a three-layer BP neural network is established and the logarithmic S-type transfer function is activated. The input layer is the composition value of each element of C, Si, Mn, P, S, molten steel temperature, molten steel weight, and alloy addition. The content of the main elements contained in the alloy and the yield of the element; the hidden layer is twice the number of variables in the input layer; the output layer is the predicted value of the composition including C, Si, Mn, P, and S elements.

[0061] 3. Carry out model training.

[0062] The weight threshold training of common steel types is carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com